EvenGlo GA201M2 Manual

__________________________________________________________________________________________________________________

Series GA201-M2 1 LT126 June 2021

Installation, Operation and Service Instructions

INFRARED OUTDOOR PATIO HEATER

SERIES GA201-M2

Canada: 563 Barton St., Stoney Creek, Ontario L8E 5S1

www.irenergy.ca

DANGER

If you smell gas:

1. Shut off gas to heater.

2. Extinguish any open flame.

3. If odor continues, keep away from the heater and immediately

call your gas supplier or fire department.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other heater.

A propane Cylinder not connected for use shall not be stored in the

vicinity of this or any other heater.

WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause injury, death or property damage. Read the installation,

operation and maintenance instructions thoroughly before installing or

servicing this equipment.

WARNING

FOR OUTDOOR USE ONLY

IMPORTANT

Please retain these instructions for future reference.

The installer must leave these instructions with the owner. Only those

who are certified to do so should perform service on these heaters.

WARNING

CALIFORNIA PROPOSITION 65

DANGER CARBON MONOXIDE HAZARD

This heater, its related accessories and

by-product of operation, contain

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm. For

more information go to

www.P65Warnings.ca.gov.

This heater can produce carbon

monoxide which has no odor.

Using it in an enclosed space can kill

you.

Never use this heater in an enclosed

space such as a camper, tent or home.

__________________________________________________________________________________________________________________

Series GA201-M2 2 LT126 June 2021

Contents

CONTENTS ..................................................................................................................................................................... 2

CAUTION AND GENERAL SAFETY ........................................................................................................................................ 3

INTRODUCTION.................................................................................................................................................................. 5

APPLICABLE REGULATIONS................................................................................................................................................. 5

LOCATION PLANNING......................................................................................................................................................... 6

GENERAL ....................................................................................................................................................................................... 6

SAFETY REQUIREMENTS.................................................................................................................................................................... 6

SPECIFICATIONS ................................................................................................................................................................. 7

EQUIPMENT DIMENSIONS ................................................................................................................................................................. 7

GAS AND POWER SPECIFICATIONS ...................................................................................................................................................... 7

LP-GAS CYLINDER COMPATIBILITY...................................................................................................................................................... 7

CLEARANCE TO COMBUSTIBLE MATERIALS ........................................................................................................................................... 8

INSTALLETION INSTRUCTIONS ............................................................................................................................................ 9

SHIPPING CRATE CONTENTS .............................................................................................................................................................. 9

HARDWARE KITS ........................................................................................................................................................................... 10

ASSEMBLY ................................................................................................................................................................................... 10

CONNECTING THE GAS SUPPLY......................................................................................................................................................... 14

POSITION /MOVE HEATER ............................................................................................................................................................. 15

SECURE THE HEATER (OPTIONAL) ..................................................................................................................................................... 16

TESTING / COMMISSIONNG ..............................................................................................................................................17

LEAK TEST METHOD ...................................................................................................................................................................... 17

ELECTRICAL WIRING AND BATTERY ...................................................................................................................................18

Wiring Diagram .................................................................................................................................................................... 18

Replacing the Battery ........................................................................................................................................................... 18

OPERATING INSTRUCTIONS...............................................................................................................................................19

LIGHTING..................................................................................................................................................................................... 19

ADJUSTING TEMPERATURE .............................................................................................................................................................. 19

SHUTDOWN ................................................................................................................................................................................. 19

MAINTENANCE & TROUBLESHOOTING

..........................................................................................................................20

MAINTENANCE ............................................................................................................................................................................. 20

CARE AND CLEANING ..................................................................................................................................................................... 21

TROUBLESHOOTING ....................................................................................................................................................................... 22

No Gas Supply at Burner ...................................................................................................................................................... 22

No Spark ............................................................................................................................................................................... 22

Flame Lights but Will Not Stay Lit ........................................................................................................................................ 22

REPLACEMENT PARTS .......................................................................................................................................................23

WARRANTY

....................................................................................................................................................................25

__________________________________________________________________________________________________________________

Series GA201-M2 3 LT126 June 2021

CAUTION AND GENERAL SAFETY

CAUTION - FIRE OR BURN INJURY HAZARD

WARNING

Do not install or place on a table or on an inclined surface, make sure the installation surface is level before

installing the heater.

•Assembly & Installation will require the efforts of Two individuals, it is not recommended for only One

Person to attempt complete assembly of the Heater.

•At all times maintain clearance to combustible materials as further specified in this manual. Failure to do so can

result in serious fire hazard.

•Never operate Heaters in atmosphere containing flammable vapours or combustible dusts.

•This Heater is equipped with an electronic ignition device. Do not attempt to light the burner by hand. Failure to

comply can result in a serious fire and personal injury hazard.

•Heater surfaces, other than the obvious flame and emitter surfaces, attain elevated temperatures during operation.

Do not touch the heater head during operation.

•Certain materials, when stored under this Heater are subjected to radiant heat can soften, distort or otherwise be

damaged; special care should be taken of plastic materials

•Children and adults should be alerted to the hazards of high surface temperatures and should stay away

to avoid burns or clothing ignition.

•Young children should be supervised when they are in the area of the heater. Playing or running around the

heater should be strictly forbidden.

•Clothing or other flammable materials should not be hung from the heater or placed on or near the heater.

•Any guard or other protective device removed for servicing the heater must be replaced prior to operating

the heater. Replacement pressure regulators and hose assemblies must be those specified by the manufacturer.

•Installation and repair should be done by a qualified / certified service person. The heater should be

inspected before use and at least annually by qualified service person. (Service person must be ‘Certified’

by the local / national regulating body).

•Frequent cleaning may be required. It is imperative that Burners and circulating air passageways of the heater be

kept clean of debris, dust and insects.

•Cleaning of the heater should only be done with non-combustible and non-corrosive cleaning agents. DO NOT

alter the heater in any way; this includes shortening the pole or removing the Base Body cover or Top Reflector.

•NEVER paint the Burner, Emitter, Shield Support Arms or the Reflector.

•The visible portion of the Hose Assembly must be visually inspected before each use. If there is evidence of

excessive abrasion or wear, or if the hose is damaged the hose assembly must be replaced prior to the heater

being put into operation.

__________________________________________________________________________________________________________________

Series GA201-M2 4 LT126 June 2021

•This heater shall be used only in a well-ventilated area/space and shall not be used in a building, garages or any

other enclosed area.

•Never go over connections looking for leaks with a lighted match, cigarette lighter, or any other flame.

•Perform the Leak Test before initial lighting and when connecting a new Propane-Gas Cylinder. A complete gas

tightness check must be performed at the installation on site due to possible miss handing in shipment or

excessive pressure being applied to the heater.

•Turn OFF Propane-Gas Cylinder when Heater is not in use.

•Once the Heater has been shut-down, there shall be a 5-minute complete shutoff period before the Heater

is re-lighted.

•Ensure the Propane-Gas Cylinder is turned OFF and disconnected prior to moving the Heater.

•Storage of a Heater indoors is permissible only if the Propane-Gas Cylinder is disconnected and removed from

the Heater.

•Use caution when moving the Heater, it may require two people to safely manoeuvre depending on the strength /

size of the person(s). Handle ONLY the Pole or Base Body when moving the Heater, handling other components

may result in damage and/or injury.

Propane-Gas Cylinder Caution and Safety

•Do not store a spare Propane gas cylinder under or near this heater.

•Never fill the Cylinder beyond 80 percent full.

•Keep Cylinders upright at all times, even during storage and transport.

•The pressure regulator and hose assembly supplied with the Heater must be used, or the replacement Hose

Assembly shall be that specified by the manufacturer.

•Propane-Gas Cylinders must be stored outdoors in a well-ventilated area out of the reach of children. A

disconnected cylinder must have dust caps tightly installed and must not be stored in a building, garage or any

other enclosed area. Ensure the storage area meets all local fire & safety requirements.

__________________________________________________________________________________________________________________

Series GA201-M2 5 LT126 June 2021

INTRODUCTION

IR Energy is a company in the infrared heating industry founded on the principles of product quality and customer

commitment.

Quality commitments are evidenced by superior design, a regard for design detail and an upgrade of materials

wherever justifiable.

Customer commitment is apparent through our ready responses to market demands and a never- ending training and

service support program for and through our distributor network.

IR Energy offers 25 years of experience in specialty infrared equipment design. Series GA201-M2 models are infrared

patio heaters that are easy to install and maintain, which were engineered with significant input from our customers.

They are designed to provide economical operation and trouble-free service for years to come.

Important

These instructions, the layout drawing, local codes and ordinances, and applicable standards such as apply to

gas piping and electrical wiring comprise the basic information needed to complete the installation and must be

thoroughly understood along with general building codes before proceeding.

Only personnel who have been trained and understand all applicable codes should undertake the installation. IR

Representatives are Factory Certified in the service and application of this equipment and can be called upon for

helpful suggestions about installation.

APPLICABLE REGULATIONS

•Installation must comply with local building codes or, in their absence, the latest edition of the applicable national

codes: USA - National Fuel Gas Code, ANSI Z 223.1 (NFPA 54), Canada - National Gas and Propane Installation

Code, CSA B149.1.

•Use and Storage of this heater must comply with local codes or, in their absence, the latest edition of the applicable

national codes: USA – Standard for Storage and Handling of Liquefied Petroleum Gases, Chapter 5 of

ANSI/NFPA 58, Canada - Propane Storage and Handling Code, CSA-B149.2.

•This heater, when installed, must be electrically grounded in accordance with local codes or, in their absence,

with the latest edition of the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA

C22.1.

•For use ONLY with 20# Propane-Gas Cylinders (with a maximum capacity of 8kg [20lb]) constructed and marked

in accordance with national codes: USA - U.S. Department of Transportation (“DOT” approved), Canada: Standard

for Cylinders, Spheres and Tubes for Transportation of Dangerous Goods and Commission, CSA-B339 (“TC”

approved).

Ensure Cylinders are:

•Provided with a permanent collar to protect the valve stem;

•Provided with a listed overfilling prevention device (OPD);

•Provided with a dust cap to cover the valve connection when not in use; (Only install the type of dust cap on the

cylinder valve that is provided with the cylinder valve, other types of cap plugs may result in leakage of propane);

and

•Provided with a cylinder connection device compatible with a QCC1 connection (Quick Connect Coupling).

__________________________________________________________________________________________________________________

Series GA201-M2 6 LT126 June 2021

LOCATION PLANNING

General

One Even-GLO heater, at high fire and in windless conditions, has a comfort radius of about twelve feet (24

ft. circle).

A series of heaters providing area heat should be placed about 14-20 feet apart.

Wind protection has an important influence on the body’s ability to retain radiant heat. Use natural or newly built wind

barriers where possible, such as existing buildings, shrubbery or tree lines and fences.

WARNING

This heater is NOT approved for any indoor Residential application.

If in doubt of your application consult with your local fire marshal or gas authority having jurisdiction.

A Residential Dwelling is a housekeeping unit used or intended to be used as a domicile by one or more

persons, containing cooking, eating, living, sleeping, and/or sanitary facilities. A Residential Dwelling

does not include an attached and detached garage, workshop or outdoors.

The Heater may be installed with shelter no more inclusive than:

1. With walls on all sides, but with no overhead cover.

2. Within a partial enclosure which includes an overhead cover and no more than two side walls. These side

walls may be parallel, as in a breezeway, or at right angles to each other.

3. Within a partial enclosure, which includes an overhead cover and three side walls, as long as 30 percent, or

more, of the horizontal periphery of the enclosure is permanently open.

A patio that has been almost entirely closed in with a roof and windbreak walls or a tent may be considered

an indoor location in some code authorities. Refer to the Natural Fuel Gas Code, ANSI Z.223.1 (NFPA 54) in

the US and CSA B149.1 and B149.2 Installation Codes in Canada.

Safety Requirements

1. Never locate the heater directly below electrical lines, gas lines or sprinkler systems.

NOTE: Sprinkler head heat fuse link performance may alter with age.

2. Do not locate heater too close to vinyl or plastic wall coverings. These materials may discolour or soften well

before they reach combustible limits.

3. The heater requires a minimum clearance from of combustible materials. See the Specifications / Details

4. Clearance to Combustible Materials information found in the Specifications / Details section.

5. Always allow room for removal of the Top Reflector and Burner head for maintenance purposes.

6. The heater aspirates (needs) air for combustion. Do not locate heater where there are severe draft conditions

or airflow restrictions to the Burner head of the heater.

__________________________________________________________________________________________________________________

Series GA201-M2 7 LT126 June 2021

SPECIFICATIONS

Equipment Dimensions

Figure 1: GA201-M2

Gas and Power Specifications

Maximum Fire Rate:

46,000 BTH/h

Gas Manifold Pressure

9.8” WC

Ignitor Electric Supply

One (1) “AA” Battery

Maximum Inlet Gas Supply Pressure:

250 psi

Weight without Propane Tank

140 lbs

Propane-Gas Cylinder Compatibility

To be used ONLY with 20lb Propane-Gas Cylinders with a maximum capacity of 8kg (20lb) which meet the criteria

described in the Installation Codes section of this manual.

The Cylinder and its connector fittings must be maintained in good condition.

High Altitude Installation

When installing this heater over 4500 ft. above sea level in Canada, the heater must be properly de-rated and installed

according to local codes. In the absence of local codes, the heater must be de-rated in accordance with the most

recent CSA -B149 code. In the United States for installations over 2000ft above sea level the heater must be installed

in accordance with the Current National Fuel Gas Code, ANSI Z223.1/NFPA 54(the heater shall be de-rated 4 percent

for each 1000 ft of elevation above sea level). High altitude conversion kits are available, contact manufacturer for

more details.

__________________________________________________________________________________________________________________

Series GA201-M2 8 LT126 June 2021

Clearance to Combustible Materials

The following clearance data is based on a maximum limit of 90°F (50°C) plus ambient temperature. Note with an

ambient temperature of 70°F the surface temperatures at the clearance distances listed below could reach 160°F.

Care should be taken with placement of plastic, or vinyl in the proximity of the heater as they tend to distort and soften

at these temperatures.

Combustible materials are considered to be wood, compressed paper, plant fibres, plastic, Plexiglas or other

materials capable of being ignited and burned. Such materials shall be considered combustible even through flame-

proofed, fire-retardant treated or plastered.

Additional clearance may be required for glass, painted surfaces and other materials which may be damaged by

radiant or convection heat.

NOTE: Some materials deteriorate or soften at sustained temperatures below 160°F.

Consult material manufacturer for recommendations

The Installer is responsible to ensure that building materials with a low heat tolerance which may degrade

at higher temperatures are protected to prevent degradation.

Figure 2: Clearance Dimensions

TOP

SIDE

BELOW

GA201-M2

18”

22”

33”

__________________________________________________________________________________________________________________

Series GA201-M2 9 LT126 June 2021

INSTALLATION INSTRUCTIONS

Shipping Crate Contents

Base with Case Cover, Pole, and Counterweight

QTY (1)

Heater Head with Gas Hose

QTY (1)

Wheels

QTY (1)

Top Reflector

QTY (1)

Regulator with Quick Disconnect

QTY (1)

__________________________________________________________________________________________________________________

Series GA201-M2 10 LT126 June 2021

Hardware Kits

Contents

Base Body:

•Bungee (EH044) – Used to Secure Supply Tank

•Wheel Kit (EH066) – Used to Mount Wheels

oWheel Assembly

o1/4”-20 x 1/2” S.S Button Socket (x2)

o1/4”-20 S.S Nuts (x2)

o1/4” S.S Lock Washer (x2)

•EH089 – Used to Secure Pole Assembly to Base Body

o3/8”-16 S.S Nylon Lock Nuts (x6)

o3/8” S.S Washers (x6)

o3/32” Allen Key

o1/8” Allen Key

Reflector:

•EH001 – Used to Secure Reflector to Support Arms

o1/4”-20 x 1/2” S.S Carriage Bolt (x4)

o1/4” S.S Washer (x4)

o1/4”-20 Acorn Nut (x4)

Note:

Hold Down Brackets to secure the heater to the ground are optional. If you require them for your installation,

please contact your Representative for more details.

Heater Head Assembly

Base Body, Base Cover,

Pole & Counterweight

Reflector

EH001

__________________________________________________________________________________________________________________

Series GA201-M2 11 LT126 June 2021

Assembly

1. Disassemble shipped parts and separate the hardware packages. Start with the heater base unit and the

heater head assembly as shown in Figure 3.

2. Remove the screws from the burner head assembly (4 screws). Insert the gas supply hose into the pole

neck. The hose will slide down the pole until the head assembly sits in the pole neck.

Figure 3: Heater Base and Heater Head Assemblies

3. Rotate the head assembly so the EvenGlo label on the heater head lines up with the EvenGlo label on the

Main Base.

Figure 4: Location of Front Control Knob

4. Use the screws that were removed in Step 1 to secure the burner assembly to the pole neck assembly (4

screws).

__________________________________________________________________________________________________________________

Series GA201-M2 12 LT126 June 2021

5. Please refer to the illustrations below for clarity in this step:

a. Lift the pole assembly with the head attached, upwards. The housing top cover will come with it as

there is packing underneath to hold the top cover in place while you lift the pole up.

b. Rotate the pole so that the mounting flanges almost line up with the cut-out on the base plates.

Once the top mounting flange is above the surface, rotate the pole so the holes line up with the

threaded bolts.

c. Lower the pole assembly onto the bolts so that they come through the holes on the mounting

flange. Make sure the front of the heater is facing the Even-GLO faceplate on the front of the base.

Note: Housing cover is not shown below for ease of illustration.

Figure 5: Pole and Housing Assembly

6. Take the contents out of hardware bag EH089. Slip the washers on the threaded bolts (6 washers). Secure

the pole assembly by threading the lock nuts (6 lock nuts) onto the threaded bolts and tighten with a

wrench or socket.

7. Remove the 4 screws in the Heater Base housing and use them to attach the housing top cover. Carefully

take off the packaging holding the housing top cover up the pole. Slide the top cover down the pole,

covering the pole mounting flange and hardware. Use the 3/32” allen key to tighten, located in hardware

bag EH089.

8. Locate the Wheel Kit. Open the packaging and take the wheel assembly and the hardware provided out.

Locate the two mounting holes on the Main Base. Line up the wheel assembly as shown in Figure 6 below.

Insert both bolts into the matching set of mounting holes. Tip the heater slightly to be able to thread on the

nylon nuts provided underneath the main base. Tighten the nuts until the wheel assembly is secure.

__________________________________________________________________________________________________________________

Series GA201-M2 13 LT126 June 2021

Figure 6: Attach Wheel Assembly to Main Base

9. Locate the reflector and hardware bag EH001. Install the Top Reflector on to the Shield Support Arms of the

heater using the carriage bolts (4) with nuts provided. Insert the bolts up through the shield support arms

and then through the top reflector. Secure each bolt on top of the reflector.

Note: Make sure to remove (or peel off) the plastic covering on the reflector before assembly.

Figure 7: Attach Top Reflector to Shield Support Arms

10. Your patio heater is now assembled and ready to connect to your Propane Gas Supply Cylinder.

WARNING

This Heater is equipped with a tilt / tip switch for your safety. This heater will shut the gas valve if it is tipped

or tilted.

This Heater will not operate at an inclined position. Ensure the heater is in the upright position and should

never be positioned on an incline.

__________________________________________________________________________________________________________________

Series GA201-M2 14 LT126 June 2021

Connecting the Gas Supply

WARNING

For use ONLY with 20# Propane-Gas Cylinders (with a maximum capacity of 8kg [20lb] ) constructed and

marked in accordance with national codes: U.S. Department of Transportation (“DOT” approved) in the USA,

and Standard for Cylinders, Spheres and Tubes for Transportation of Dangerous Goods and Commission,

CAN/CSA-B339 (“TC” approved) in Canada.

1. Lift the Main Housing Cover up by the handles until the bottom lip is clear of the 2 spring latches as shown

below:

Figure 8: Lift Main Housing Cover

2. Secure the Propane-Gas cylinder to the Base using the Bungee cord. Hook one side of the Bungee cord to the

mounting holes on either the right side or the left side, as shown in Figure 9. Make sure the Propane-Gas

cylinder is in the upright position. Feed bungee through the handle of the Propane cylinder, then hook the

bungee on the other set of securing holes.

Figure 9: Secure Propane Cylinder with Mounting Holes and Bungee Cord

__________________________________________________________________________________________________________________

Series GA201-M2 15 LT126 June 2021

3. Locate the regulator assembly. Look over the assembly to make sure no damage has occurred during shipping

or handling. Attach the regulator assembly to the male quick connect on the fuel supply hose as shown in

Figure 10.

Figure 10: Connect Regulator Assembly to Fuel Supply Hose

4. Secure the Gas Hose Regulator onto the Propane-Gas cylinder valve by turning the Regulator clockwise until

tight. Push the 2 spring latches that are holding the main housing cover in place inwards, one hand holding the

bottom lip of the main housing cover and the other one pushing the latches one at a time. Be careful of the

bottom edge of the main housing as it is sharp.

Figure 11: Secure Gas Regulator to Propane Cylinder

CAUTION

Before using the patio heater:

•Perform a leak test to make sure the regulator connection does not have leaks.

•Move heater to desired location.

•

Secure the Base Body to the floor (optional).

Position / Move Heater

1. Ensure the Propane-gas Cylinder is turned OFF, secured and disconnected from the Gas Hose prior to

moving the Heater.

2. Ensure the wheels are properly connected to the base body (refer to installation step 8).

__________________________________________________________________________________________________________________

Series GA201-M2 16 LT126 June 2021

3. Move the Heater by handling ONLY the Pole or the Base Body. It may take two people to manoeuvre the

Heater safely depending on the size / strength of the person(s).

4. Tip the Heater backwards at an angle to / overtop of the wheels until the Base no longer touches the ground.

Wheel / Roll the heater to the desired location and return base to the ground. Ensure the heater is on level

ground and stable in new location.

5. If the heater is going to be operated at the new location, the “Testing / Commissioning” procedure must be

completed.

Secure the Heater (Optional)

1. Ensure that the Hold Down Brackets are properly installed as described in Installation Step 8.

2. The type of Foundation Fastener required depends on the type of Floor / Ground that the Heater is located

on. Prepare the Floor / Ground as detailed in Table A at all three bracket locations. (Ensure that alignment

with the connecting hole(s) of the Base Bracket is maintained)

Table A: Methods for Securing Heater to Floor / Ground

Floor / Ground Type Foundation Fastener

Type & Size

Mounting Method

Summary

Floor / Ground

Preparation

Concrete Concrete Anchor

Ø5/16" x 2 1/2"

Place Anchors into pilot

holes aligned with Base

Brackets -

tap / hammer lightly,

screw fastener into anchor

Drill 3 - Pilot Holes

Pilot hole drill size:

Concrete = 9/16"

Wood Deck Wood Screw

#10 x 1 1/2"

Secure using Wood

Screws in pilot holes

aligned with Base

Brackets

Drill 3 - Pilot Holes

Pilot hole drill size:

Hardwood = 7/64"

Softwood = 3/32"

__________________________________________________________________________________________________________________

Series GA201-M2 17 LT126 June 2021

TESTING / COMMISSIONING

Leak Test Method

WARNING

Never go over connections looking for leaks with a lighted match, cigarette lighter, or any other flame.

Perform the leak test before initial lighting and when connecting a new Propane-Gas Cylinder. A complete gas

tightness check must be performed at the installation on site due to possible mishandling in shipment or excessive

pressure being applied to the heater

1. Make up a dish of soap and water solution of one-part liquid detergent and one-part water.

2. Spread the soap and water solution over the hose connections with a spray bottle, a small paintbrush or rag.

3. With the heater shut OFF, turn the cylinder valve ON. Check the connections at the Propane-Gas cylinder.

4. Take off the Housing Service Cover (see Figure 12). Check the gas line attachment points to the valve.

5. Any leaks will result in bubbles forming in the solution. If a leak is detected, shut OFF the cylinder valve.

6. Repair any leak by tightening leaking parts (Replacement Gas Hose Assembly shall be as specified by the

manufacturer).

7. Repeat steps 1, 2, and 3 until no leaks are detected at all hose connection locations as shown in Figure 12.

If you cannot stop the leaks, shut OFF the supply valve on the Propane-gas Cylinder and disconnect the cylinder

from the heater. Please the heater OUT OF SERVICE and consult a certified service person.

Figure 12: Leak Check Points

After passing the Leak Test your patio heater is now ready for use.

CAUTION

Heater will produce smoke the first time it is lit. This is normal.

DO NOT light the heater in an enclosed area.

Make sure all protective plastic has been removed from all surfaces before lighting.

__________________________________________________________________________________________________________________

Series GA201-M2 18 LT126 June 2021

ELECTRICAL WIRING AND BATTERY

Wiring Diagram

Figure 13: GA201-M2 Wiring Diagram

Replacing the Battery

1. Remove the Housing Service Cover to access the Ignitor Module Knob.

2. Turn the ignitor module knob counter-clockwise to unscrew it.

3. Pull out the battery while taking note of the polarity orientation (+ / -).

4. Replace battery and screw knob back into place.

5. Test spark by going to the front of the heater and pressing Ignition Knob in the Pilot position.

6. Replace the Housing Service Cover.

Figure 14: Replacing the Battery

__________________________________________________________________________________________________________________

Series GA201-M2 19 LT126 June 2021

OPERATING INSTRUCTIONS

Lighting

1. Open the propane cylinder valve.

2. Push and turn the ignition knob counter-clockwise from the OFF position to the PILOT position (lightening

symbol). To start the gas flow and sparking, push the knob inwards. Keep pressing until the pilot is lit and

stays lit (for approximately 30-45 seconds to heat up the thermocouple) and then release the pressure

from the knob. If you have warmed up the thermocouple enough, when you release the pressure from the

ignition knob, the main burner will automatically light. If it does not, try igniting the pilot again, but waiting a longer

interval before releasing the knob.

Note: When using the heater with a fresh fuel supply, pilot may take some time to light because the light

needs to purge all the air out of the line first.

Figure 15: Location of Ignition Knob and Temperature Control Knob

CAUTION

Heater will produce smoke the first time it is lit. This is normal.

DO NOT light the heater in an enclosed area.

Adjusting Temperature

Adjust the heat output by rotating the Temperature Control Knob counter-clockwise to increase the output, clockwise

to lower the output.

Shutdown

1. Turn the ignition knob clockwise into the OFF position to turn off the gas flow and extinguish the burner flame.

2. Turn propane cylinder valve clockwise to OFF position when heater is not in use.

WARNING

Improper Lighting, Shutting Down can cause injury, death, or property damage. Read the Lighting and

Shutting Down instructions thoroughly before operating or servicing this equipment.

__________________________________________________________________________________________________________________

Series GA201-M2 20 LT126 June 2021

Maintenance & Troubleshooting

Maintenance

CAUTION

•Always follow all Caution and General Safety rules before / during use.

•Before performing ANY service to the heater, shut off the gas supply, disconnect the

regulator from the Propane-Gas Cylinder and remove the battery from the ignitor module.

•If any maintenance issues are found place the heater OUT OF SERVICE until it has been

repaired by a certified service person. Use only manufacturer recommended replacement

parts.

Daily Inspections:

1. Keep the heater area clean and free from combustible materials, gasoline and other flammable vapors and

liquids.

2. The visible portion of the Gas Hose must be visually inspected before each use. If there is evidence of excessive

abrasion or wear, or if the hose is damaged the hose assembly must be replaced prior to the heater being put

into operation.

3. Keep the ventilation opening(s) of the cylinder enclosure free and clear from debris and cobwebs.

4. Visually check the Burner flame pattern during use. A “Proper Flame” should resemble image on Figure 16.

5. If at any time flames extend beyond the emitter surface (see image in Figure 17 “Improper Flame”) or black soot

is found on the inside of the reflector TURN OFF the heater immediately and place OUT OF SERVICE until

repairs are made.

6. Clean the heater if necessary with non-combustible and non-corrosive cleaning agents. Ensure control

compartment (ignition module), burners & circulating air passageways are kept clean of dust, insects, cobwebs

and other debris

Figure 16: Proper Flame Pattern Figure 17: Improper Flame Pattern

Annual Inspections:

1. Inspect and Leak Test entire Gas Hose Assembly for damage, excessive abrasion, wear and leaks:

a. Ensure burner is cool to touch and supported while disassembling.

b. Disassemble the Burner from the Pole by removing the three (3) screws in the Pole Neck.

c. Remove the Gas Hose Assembly from the Pole to inspect and Leak Test the entire hose and all

connections. Repair / replace as required.

2. Check condition of the Burner, especially the integrity of the flame screen.

3. Inspect condition of spark and sense electrode. Check for cracks in ceramic insulators or excessive corrosion.

4. Inspect condition of high-tension lead to spark rod.

Other manuals for GA201M2

1

Table of contents

Other EvenGlo Patio Heater manuals

Popular Patio Heater manuals by other brands

Suntec Wellness

Suntec Wellness Klimatronic Heat Patio Halogen 1500 LED instruction manual

RADtec

RADtec H1501A instruction manual

Sencor

Sencor SHH 760BK user manual

Oreck

Oreck HEATWISE HW1000P user guide

VONROC

VONROC ALICUDI PH515AC Original instructions

Outdoor Leisure

Outdoor Leisure TD113 owner's manual

Hortus

Hortus ZHQ1580-RM-S instructions

Renson

Renson Heat & Sound-Beam manual

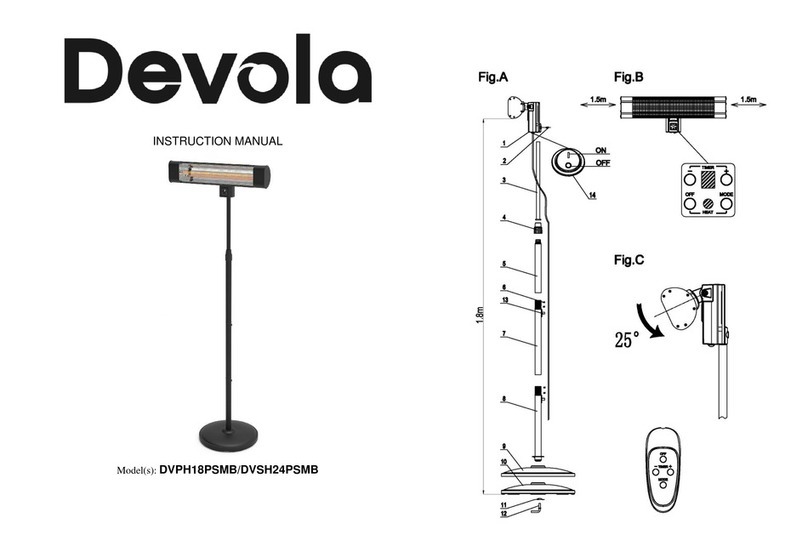

DEVOLA

DEVOLA Platinum DVPH18PSMB instruction manual

CROWN VERITY

CROWN VERITY Terrace and Patio Heater User installation and operation guide

Italkero

Italkero INFRA Spider User manual and assembly instructions

Outdoor Leisure

Outdoor Leisure TD120 owner's manual