EvenGlo GA 301 Manual

__________________________________________________________________________________________________________________

Series GA301 1 LT071 Aug 2021

Installation, Operation and Service Instructions

INFRARED PATIO HEATER

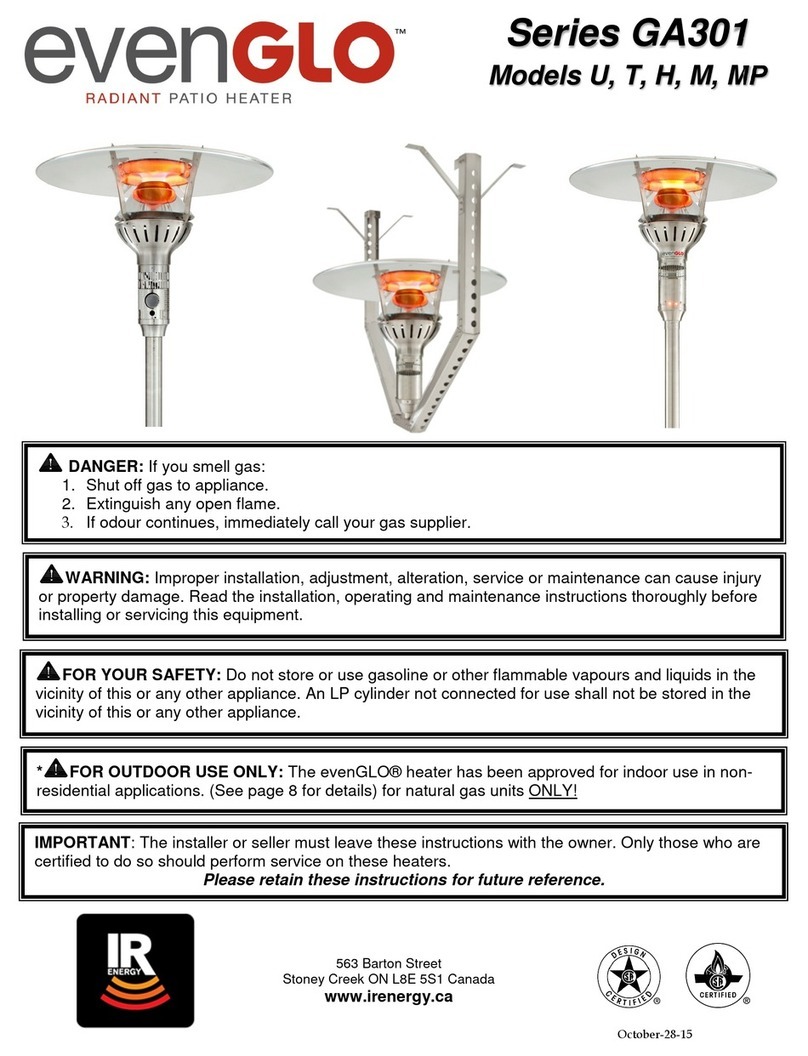

SERIES GA301

Models U, T, H (24 VAC)

Models M, MP (pilot)

DANGER

DANGER

If you smell gas:

1. Shut off gas to heater.

2. Extinguish any open flame.

If odor continues, keep away from the heater and

immediately call your gas supplier or fire department.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

heater.

A propane Cylinder not connected for use shall not be

stored in the vicinity of this or any other heater.

WARNING

WARNING

Improper installation, adjustment, alteration, service,

or maintenance can cause injury, death or property

damage. Read the installation, operation, and

maintenance instructions thoroughly before installing

or servicing this equipment.

FOR OUTDOOR USE ONLY

The evenGLO® heater has been approved for indoor

use in non-residential applications for natural gas

units ONLY!

IMPORTANT

CALIFORNIA PROPOSITION 65

Please retain these instructions for future reference.

The installer must leave these instructions with the

owner. Only those who are certified to do so should

perform service on these heaters.

This heater, its related accessories and by-product of

operation, contain chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm. For more information go to

www.P65Warnings.ca.gov.

DANGER CARBON MONOXIDE HAZARD

This heater can produce carbon monoxide which

has no odor.

Using it in an enclosed space can kill you.

Never use this heater in an enclosed space such as

a camper, tent or home.

Canada: 563 Barton St., Stoney Creek, Ontario L8E 5S1

www.irenergy.ca

__________________________________________________________________________________________________________________

Series GA301 2 LT071 Aug 2021

CAUTION - MAINTENANCE INSTRUCTION

1. Keep the heater area clear and free from combustible materials, gasoline and other flammable vapors

and liquids.

2. Do not obstruct the flow of combustion and ventilation air.

3. Visually check burner flames.

4. Clean the heater, including special surfaces, with recommended cleaning agents, if necessary.

Check the maintenance section in this manual for additional instructions.

CAUTION - INSTALLATION

This heater shall be used only in a well-ventilated space and shall not be used in a building, garage or any

other enclosed area.

The heater may be installed with shelter no more inclusive than:

1. With walls on all sides, but with no overhead cover.

2. Within a partial enclosure which includes an overhead cover and no more than two side walls. These

side walls may be parallel, as in a breezeway, or at right angles to each other.

3. Within a partial enclosure which includes an overhead cover and three side walls, as long as 30 percent

or more of the horizontal periphery of the enclosure is permanently open.

SAFETY REQUIREMENTS

•At all times, maintain clearance to combustible materials as further specified in this manual. Failure to do so

can result in serious fire hazard.

•Never operate heaters in atmosphere containing flammable vapours or combustible dusts.

•This heater is equipped with an electronic and automatic ignition device. Do not attempt to light the burner by

hand. Failure to comply can result in a serious fire and personal injury hazard.

•Certain materials, when stored under this heater are subjected to radiant heat can soften, distort or

otherwise be damaged, special care should be taken of plastic materials

•Heater surfaces, other than the obvious flame and emitter surfaces, attain elevated temperatures during

operation. Do not touch the heater head during operation. Everyone should be alerted to this hazard to avoid

burning.

•Children should be strictly supervised when in the area of this heating heater. Playing or running around the

structure should be strictly forbidden.

•Clothing or other flammable materials should not be hung on or near this heater.

•Any guard or other protective device removed for servicing the heater must be replaced prior to operating

the heater.

•Installation and repair should be done by a qualified service person. The heater should be inspected before

use and at least annually by a qualified service person.

SAFETY REQUIREMENTS

•Never locate the heater directly below electrical lines, gas lines or sprinkler systems.

•Do not locate heater too close to vinyl or plastic wall coverings. These materials may discolour or soften well

before they reach combustible limits.

•The heater requires a minimum clearance from combustible materials. See the Clearance to Combustible

Materials section for specific requirements.

•Always allow room for maintenance purposes.

•The heater aspirates air for combustion. Do not locate heater where there are severe draft conditions or airflow

restrictions to the burner.

__________________________________________________________________________________________________________________

Series GA301 3 LT071 Aug 2021

Contents

CONTENTS ..................................................................................................................................................................... 3

INTRODUCTION.................................................................................................................................................................. 4

I

NSTALLATION

C

O

DE

S..................................................................................................................................................................... 4

GENERAL SPECIFICATIONS.................................................................................................................................................. 5

DIMENSIONAL CHART ........................................................................................................................................................ 6

GA301-U, GA301-T, GA301-M .................................................................................................................................................... 6

GA301-H ..................................................................................................................................................................................... 7

GA301-MP .................................................................................................................................................................................. 8

COMPONENTS ................................................................................................................................................................... 9

GA301-U, GA301-T, GA301-M .................................................................................................................................................... 9

GA301-MP ................................................................................................................................................................................ 10

HARDWARE KITS ........................................................................................................................................................................... 11

CLEARANCE TO COMBUSTIBLE MATERIALS ........................................................................................................................13

LOCATION PLANNING........................................................................................................................................................ 14

OUTDOOR INSTALLATIONS .............................................................................................................................................................. 14

INDOOR INSTALLATIONS (NATURAL GAS MODELS ONLY) ....................................................................................................................... 15

INSTALLATION INSTRUCTIONS

........................................................................................................................................ 16

FLOOR MOUNT MODELS (GA301-U, GA301-T, GA301-M).............................................................................................................. 16

HANGING MODEL (GA301-H)........................................................................................................................................................ 20

PORTABLE MODEL (GA301-MP) .................................................................................................................................................... 25

GAS SUPPLY ...................................................................................................................................................................... 30

ELECTRICAL WIRING .......................................................................................................................................................... 31

INTERNAL WIRING GA301-U, GA301-T, GA301-H.......................................................................................................................... 31

INTERNAL WIRING GA301-M, GA301-MP ..................................................................................................................................... 31

EXTERNAL WIRING OPTIONS GA301-U, GA301-T, GA301-H ............................................................................................................ 32

STARTUP & SHUTDOWN INSTRUCTIONS

......................................................................................................................33

GA301-U, GA301-T, GA301-H ................................................................................................................................................... 33

GA301-M, GA301-MP............................................................................................................................................................... 33

MAINTENANCE & TROUBLESHOOTING

..........................................................................................................................34

MAINTENANCE ............................................................................................................................................................................. 34

CARE AND CLEANING ..................................................................................................................................................................... 35

TROUBLESHOOTING GA301-U, GA301-T, GA301-H........................................................................................................................ 36

TROUBLESHOOTING GA301-M, GA301-MP.................................................................................................................................... 36

REPLACEMENT PARTS ....................................................................................................................................................... 37

GA301-U, GA301-T, GA301-H REPLACEMENT PARTS ..................................................................................................................... 37

GA301-M &GA301-MP REPLACEMENT PARTS............................................................................................................................... 38

WARRANTY

.................................................................................................................................................................... 39

__________________________________________________________________________________________________________________

Series GA301 4 LT071 Aug 2021

INTRODUCTION

IR Energy is a company in the infrared heating industry founded on the principles of product quality and customer

commitment.

Quality commitments are evidenced by superior design, a regard for design detail and an upgrade of materials

wherever justifiable.

Customer commitment is apparent through our ready responses to market demands and a never- ending training

and service support program for and through our distributor network.

IR Energy offers 25 years of experience in specialty infrared equipment design. Series GA301 models are infrared

patio heaters that are easy to install and maintain, which were engineered with significant input from our customers.

They are designed to provide economical operation and trouble-free service for years to come.

Important

These instructions, the layout drawing, local codes and ordinances, and applicable standards such as apply to

gas piping and electrical wiring comprise the basic information needed to complete the installation and must be

thoroughly understood along with general building codes before proceeding.

Only personnel who have been trained and understand all applicable codes should undertake the installation. IR

Representatives are Factory Certified in the service and application of this equipment and can be called upon for

helpful suggestions about installation.

Installation C

o

de

s

Installations must comply with local building codes, or in their absence, the latest edition of the national regulations

and procedures as listed below.

General Installation

and Gas

Codes

Heaters must be installed only for use with the type of gas appearing on the rating plate, and the installation must

conform to the National Fuel Gas Code, ANSI Z223.1/NFPA 54 in the USA and CSA B149.1 and B149.2

Installation Codes in Canada.

This heater is approved for outdoor installation only. Even-GLO has been approved for indoor use in non-residential

applications for Natural Gas ONLY, see Ventilation section. Not for use in residential dwellings, refer to Rating

plate.

Gas Supply Lines

Gas supply pipe sizing must be in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 in the USA

and CSA B149.1 and B149.2 Installation Codes in Canada.

A 1/8” NPT plugged tap must be installed in the gas line connection immediately upstream of the burner farthest

from the gas supply meter to allow checking of system gas pressure.

Electrical

All heaters must be electrically grounded in accordance with the National Electric Code, ANSI/NFPA 70 in the USA,

and the Canadian Electric Code, CSA C22.1 in Canada, and must comply with all local requirements.

__________________________________________________________________________________________________________________

Series GA301 5 LT071 Aug 2021

GENERAL SPECIFICATIONS

GA301-U, GA301-T, GA301-H

Gas Supply

Inlet Pressure

Natural Gas

Propane

Minimum

6.5" W.C.

11.0” W.C.

Maximum

14.0” W.C.

14.0” W.C.

Manifold Pressure

Natural Gas

Propane

High Fire

5.5" W.C.

9.8” W.C.

Low Fire

4.0" W.C.

7.0” W.C.

Inlet Connection

Natural Gas

Propane

½” Male Quick Connect

3/8” Male Quick Connect

Electrical Supply

24 VAC, 0.8 A

Heater Specifications

Input

Natural Gas

Propane

High Rate

53,000 BTU/h

47,000 BTU/h

Low Rate

46,000 BTU/h

40,000 BTU/h

GA301-M, GA301-MP

Gas Supply

Inlet Pressure

Natural Gas

Propane

Minimum

6.5" W.C.

11.0” W.C.

Maximum

14.0” W.C.

14.0” W.C.

Manifold Pressure

Natural Gas

Propane

High Fire

5.5" W.C.

9.8” W.C.

Inlet Connection

Natural Gas

Propane

½” Male Quick Connect

3/8” Male Quick Connect

Heater Specifications

Input

Natural Gas

Propane

High Rate

53,000 BTU/h

46,000 BTU/h

High Altitude Installation

When installing this heater over 4500 ft. above sea level in Canada, the heater must be properly de-rated and installed

according to local codes. In the absence of local codes, the heater must be de-rated in accordance with the most

recent CSA -B149 code. In the United States for installations over 2000ft above sea level the heater must be installed

in accordance with the Current National Fuel Gas Code, ANSI Z223.1/NFPA 54 (the heater shall be de-rated 4

percent for each 1000 ft of elevation above sea level). High altitude conversion kits are available, contact

manufacturer for more details.

__________________________________________________________________________________________________________________

Series GA301 6 LT071 Aug 2021

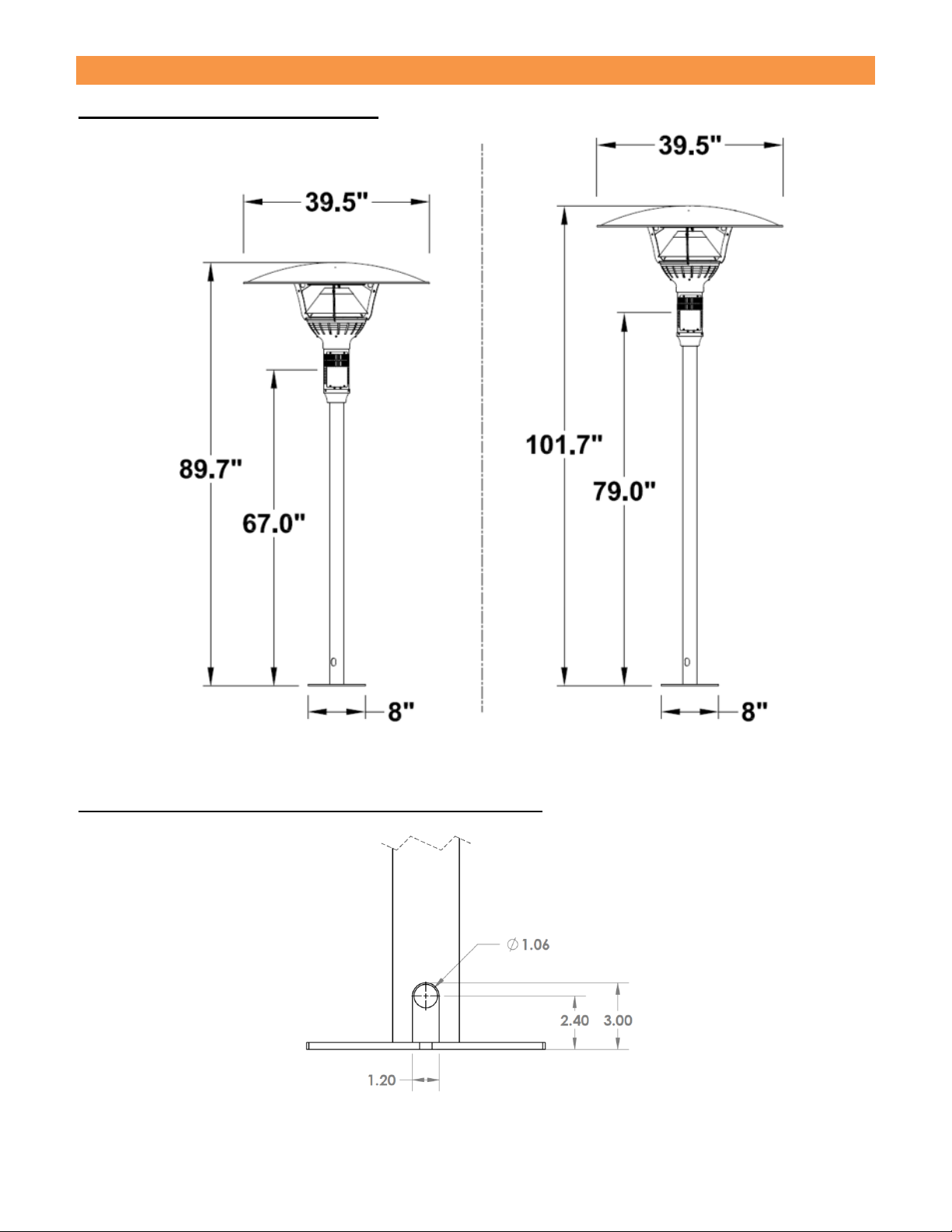

DIMENSIONAL CHART

GA301-U, GA301-T, GA301-M

Figure 1: GA301-U, GA301-M Figure 2: GA301-T

Pole Hole Configuration GA301-U, GA30-T, GA301-M

Figure 3: Pole Hole Configuration (Mounted Heaters)

__________________________________________________________________________________________________________________

Series GA301 7 LT071 Aug 2021

GA301-H

Figure 4: GA301-H Top Dimensions

Figure 5: GA301-H Side Dimensions

__________________________________________________________________________________________________________________

Series GA301 8 LT071 Aug 2021

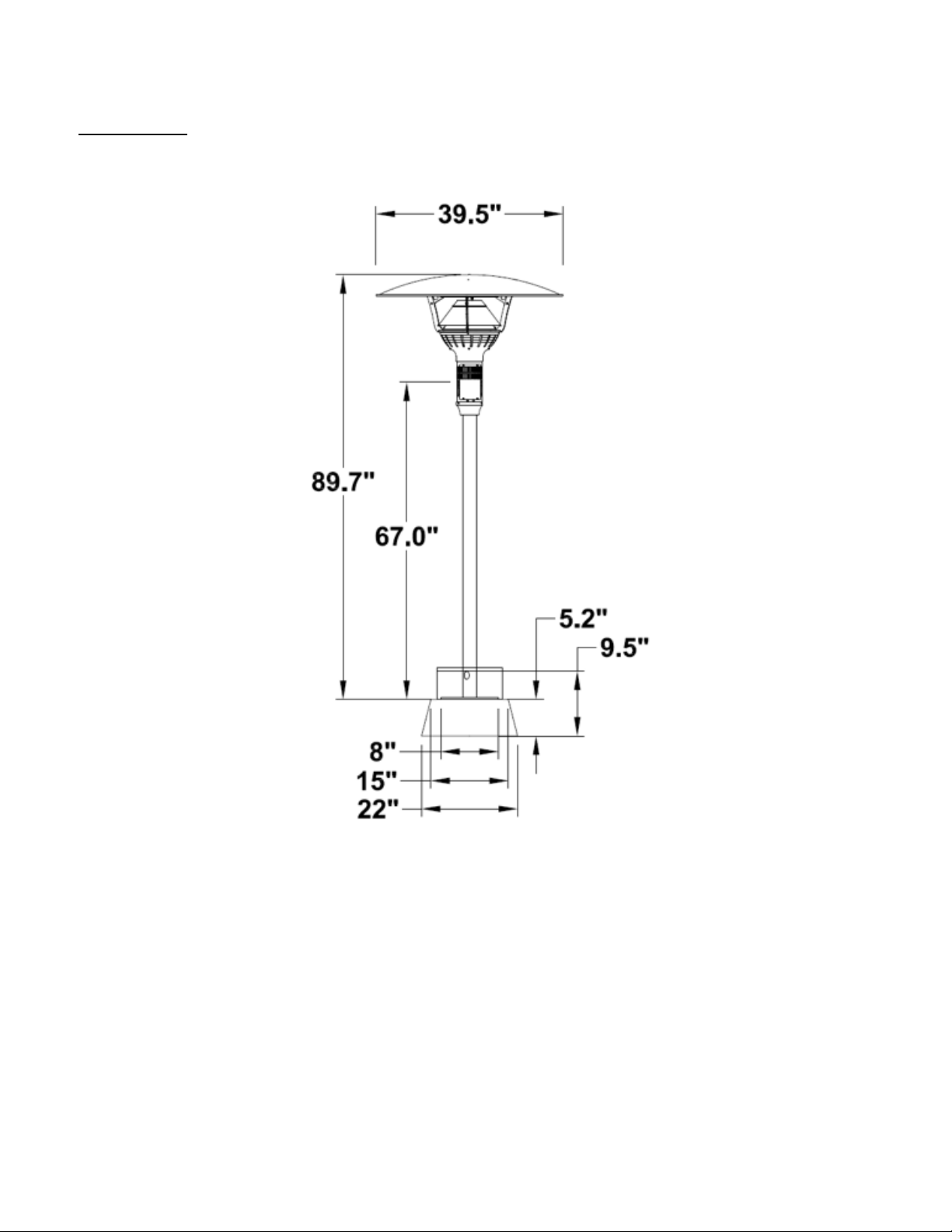

GA301-MP

Figure 6: GA301-MP

__________________________________________________________________________________________________________________

Series GA301 9 LT071 Aug 2021

COMPONENTS

GA301-U, GA301-T, GA301-M

GA301-H

Heater Heat

with Gas

Hose

QTY (1)

Top

Reflector

QTY (1)

Fixed

Mounting

Pole

QTY (1)

Heater Base

QTY (1)

__________________________________________________________________________________________________________________

Series GA301 10 LT071 Aug 2021

GA301-MP

Heater

Head with

Gas Hose

QTY (1)

Fixed Mounting Pole

with Detachable Pole

Neck

QTY (1)

Top

Reflector

QTY (1)

Supply Hose

with Quick

Disconnect

QTY (1)

Bottom Base

with Top Cover

and Wheel Kit

QTY (1)

½” QD Socket

Regulator with

Mounting Plate and

Nipple

QTY (1)

__________________________________________________________________________________________________________________

Series GA301 11 LT071 Aug 2021

Hardware Kits

Model GA301-U, GA301-T:

•EH001: Top Reflector to Support Arms

oEH027: 1/4”-20 x 1/2” S.S Carriage Bolt (x4),

oCH143: 1/4” S.S Flat Washer (x4),

oEH028 1/4”-20 S.S Acorn Nut (x4)

•EH021: Pole Package

oEG011: 3/8” x 3/8” FPT x FJIC Swivel Adapter (x1)

oEG013: 3/8” x 90° Bulkhead Elbow (x1)

oEG073: Washer S/S (x1)

Model GA301-H:

•EH001: Top Reflector to Support Arms

oEH027: 1/4”-20 x 1/2” S.S Carriage Bolt (x4),

oCH143: 1/4” S.S Flat Washer (x4),

oEH028 1/4”-20 S.S Acorn Nut (x4)

•EH022: Hanging Package

oCH115: 5/16” – 8 S/S Nut (x17)

oCH116: 5/16” S/S Lock Washer (x17)

oCH140: 8 – 32 S/S Nut (x4)

oCH148: 5/16” – 18 x ¾” S/S Button Socket Bolt (x48)

oCH157: #8 – 32 x 3/8” S/S Screw (x4)

oEG012: 3/8” x 3/8” MJIC x MPT 90° Elbow (x1)

oEH013: #8-18x1/2" S/S Screw (x21)

oES121: Middle Mounting Support S/S (x2)

oES122: Gusset Plate S/S (x8)

oES123: Reflector Stabilizer Bracket S/S (x2)

__________________________________________________________________________________________________________________

Series GA301 12 LT071 Aug 2021

Model GA301-M:

•EH001: Top Reflector to Support Arms

oEH027: 1/4”-20 x 1/2” S.S Carriage Bolt (x4),

oCH143: 1/4” S.S Flat Washer (x4),

oEH028 1/4”-20 S.S Acorn Nut (x4)

•EH085: Heater Head to Pole Neck

oEH041: #10 – 24 S/S Button Socket Cap Screw (x4)

oEH063: 1/8” Allen Key (x1)

•EH087: Pole Neck to Pole

oEH070: 5/16” – 18 x ½” 18 – 8 S/S Button Socket Cap Screw (x)

oEH081: 5/16” S/S Internal Lock Washer (x4)

oEH072: 5/16” – 18 Brass Nylon Insert Lock Nut (x4)

oEH088: 5/16” Allen Key (x1)

Model GA301-MP:

•EH001: Top Reflector to Support Arms

oEH027: 1/4”-20 x 1/2” S.S Carriage Bolt (x4),

oCH143: 1/4” S.S Flat Washer (x4),

oEH028 1/4”-20 S.S Acorn Nut (x4)

•EH084: Housing Top Cover to Base Housing

oEH042: 8 – 32 x 3/8” 18 – 8 S/S Button Socket Cap Screw (x4)

oEH062: 3/32” Allen Key (x1)

•EH085: Heater Head to Pole Neck

oEH041: #10 – 24 S/S Button Socket Cap Screw (x4)

oEH063: 1/8” Allen Key (x1)

•EH086: Pole Flange to Bottom Base

oEH057: 3/8” – 16 S/S Nylon Insert Screw Lock Nut (x4)

oEH056: 8/8” S/S Flat Washer (x4)

•EH087: Pole Neck to Pole

oEH070: 5/16” – 18 x ½” 18 – 8 S/S Button Socket Cap Screw (x)

oEH081: 5/16” S/S Internal Lock Washer (x4)

oEH072: 5/16” – 18 Brass Nylon Insert Lock Nut (x4)

oEH088: 5/16” Allen Key (x1)

Hose Kits (Model GA301-MP):

•EG065: 12’ Hose Kit

oEG052: NG Regulator (x1)

oEG059: ½” Brass Socket (x1)

oEG061: ½” Brass Close Nipple (x1)

oES216: Regulator Mounting Bracket (x1)

oCH122: 8-32 x 3/8” S/S Screw (x2)

oEG062: ½:” x 12’ Supply Hose (x1)

•EG066:15’ Hose Kit

oEG052: NG Regulator (x1)

oEG059: ½” Brass Socket (x1)

oEG061: ½” Brass Close Nipple (x1)

oES216: Regulator Mounting Bracket (x1)

oCH122: 8-32 x 3/8” S/S Screw (x2)

oEG058: ½” x 15’ Supply Hose (x1)

__________________________________________________________________________________________________________________

Series GA301 13 LT071 Aug 2021

CLEARANCE TO COMBUSTIBLE MATERIALS

The following clearance data is based on a maximum limit of 90°F (50°C) plus ambient temperature. Note with an

ambient temperature of 70°F the surface temperatures at the clearance distances listed below could reach 160°F.

Care should be taken with placement of plastic or vinyl in the proximity of the heater as they tend to distort and soften

at these temperatures.

Combustible materials are considered to be wood, compressed paper, plant fibres, plastic, Plexiglas or other

materials capable of being ignited and burned. Such materials shall be considered combustible even through flame-

proofed, fire-retardant treated or plastered.

Additional clearance may be required for glass, painted surfaces and other materials which may be damaged by

radiant or convection heat.

NOTE: Some materials deteriorate or soften at sustained temperatures below 160°F.

Consult material manufacturer for recommendations

The Installer is responsible to ensure that building materials with a low heat tolerance which may degrade

at higher temperatures are protected to prevent degradation.

Figure 7: Clearance Dimensions

TOP

SIDE

BELOW

ALL MODELS

18”

22”

33”

__________________________________________________________________________________________________________________

Series GA301 14 LT071 Aug 2021

LOCATION PLANNING

WARNING

This heater is NOT approved for any indoor Residential application.

If in doubt of your application consult with your local fire marshal or gas authority having jurisdiction.

A Residential Dwelling is a housekeeping unit used or intended to be used as a

domicile by one or more

persons, containing cooking, eating, living, sleeping, and/or sanitary facilities. A Residential Dwelling

does not include an attached and detached garage, workshop or outdoors.

Safety Requirements

1. Never locate the heater directly below electrical lines, gas lines or sprinkler systems.

NOTE: Sprinkler head heat fuse link performance may alter with age.

2. Do not locate heater too close to vinyl or plastic wall coverings. These materials may discolour or soften well

before they reach combustible limits.

3. The heater requires a minimum clearance from of combustible materials. See the Specifications / Details

4. Clearance to Combustible Materials information found in the Specifications / Details section.

5. Always allow room for removal of the Top Reflector and Burner head for maintenance purposes.

6. The heater aspirates (needs) air for combustion. Do not locate heater where there are severe draft conditions

or airflow restrictions to the Burner head of the heater.

Layout Considerations

One Even-GLO heater, at high fire and in windless conditions, has a comfort radius of about twelve feet (24

ft. circle).

A series of heaters providing area heat should be placed about 14-20 feet apart.

Wind protection has an important influence on the body’s ability to retain radiant heat. Use natural or newly built wind

barriers where possible, such as existing buildings, shrubbery or tree lines and fences.

Outdoor Installations

The Heater may be installed with shelter no more inclusive than:

1. With walls on all sides, but with no overhead cover.

2. Within a partial enclosure which includes an overhead cover and no more than two side walls. These side

walls may be parallel, as in a breezeway, or at right angles to each other.

3. Within a partial enclosure, which includes an overhead cover and three side walls, as long as 30 percent, or

more, of the horizontal periphery of the enclosure is permanently open.

A patio that has been almost entirely closed in with a roof and windbreak walls or a tent may be considered

an indoor location in some code authorities. Refer to the Natural Fuel Gas Code, ANSI Z.223.1 (NFPA 54) in

the US and CSA B149.1 and B149.2 Installation Codes in Canada.

__________________________________________________________________________________________________________________

Series GA301 15 LT071 Aug 2021

Indoor Installations (Natural Gas models only)

The Even-GLO heater has been approved for indoor use in non-residential applications (Natural Gas Models

ONLY).

Venting of the flue gases is accomplished by means of an interlocked fan. Refer to the Natural Fuel Gas Code,

ANSI Z.223.1 (NFPA 54) in the US and CSA B149.1 and B149.2 Installation Codes in Canada.

Requirements for combustion air supply and dilution air vary by jurisdiction, building type and specific installation

details. See local codes for guidance.

In general, where heaters are installed without direct outside combustion air, fresh air ventilation must be provided

to building space (3 cfm per 1000 BTU/Hr in Canada, 4 cfm per 1000 BTU/Hr in the USA). Verify applicable local

codes in the USA as requirements change by jurisdiction.

__________________________________________________________________________________________________________________

Series GA301 16 LT071 Aug 2021

Installation Instructions

Floor Mount Models (GA301-U, GA301-T, GA301-M)

Mounting Plate Hole Pattern

(Full size)

__________________________________________________________________________________________________________________

Series GA301 17 LT071 Aug 2021

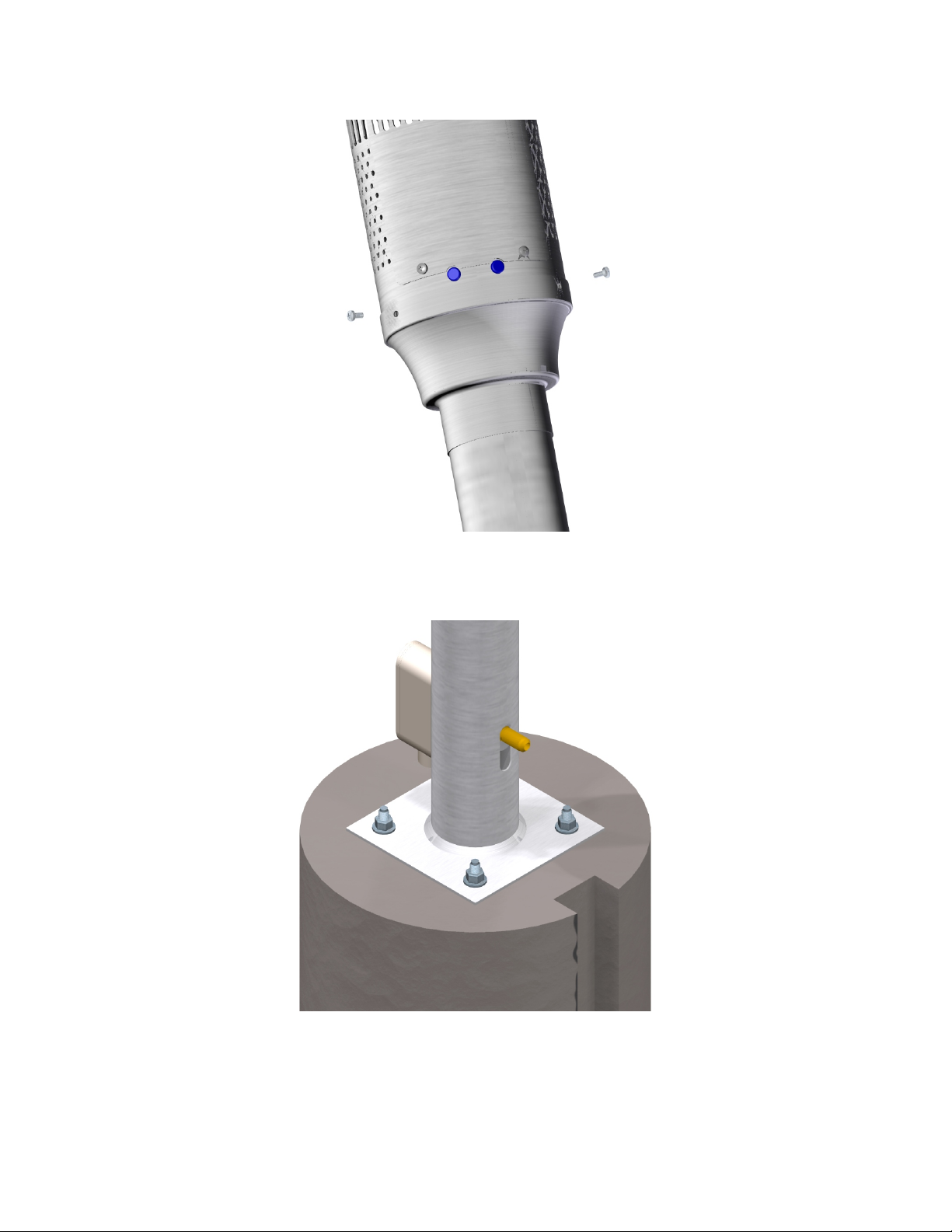

1. Mount pole base onto a concrete floor or cast concrete with a minimum below grade depth of 12” and

having a 12” diameter. If forming concrete, cast in place appropriate passage for gas and control wires.

Use minimum 3/8” x 5” 90° lag bolts or equivalent to mount heater base to the concrete base. The pole

base could also be mounted on wood decks with 3/8” bolts and lock washers on the underside of the deck.

Periodically check for tightness when mounted to a wood deck.

Figure 8: Pole Base Placement

2. Arrange the burner head such that the wires and gas hose are arranged as illustrated. Feed a pull wire

through the pole to assist in pulling the three power wires into the pole and through the junction box. Firmly

tape the pull wire to the power wires. Lower the assembly into place while pulling the wires. Two people

may be necessary for this operation.

Figure 9: Wire and Hose Assembly

__________________________________________________________________________________________________________________

Series GA301 18 LT071 Aug 2021

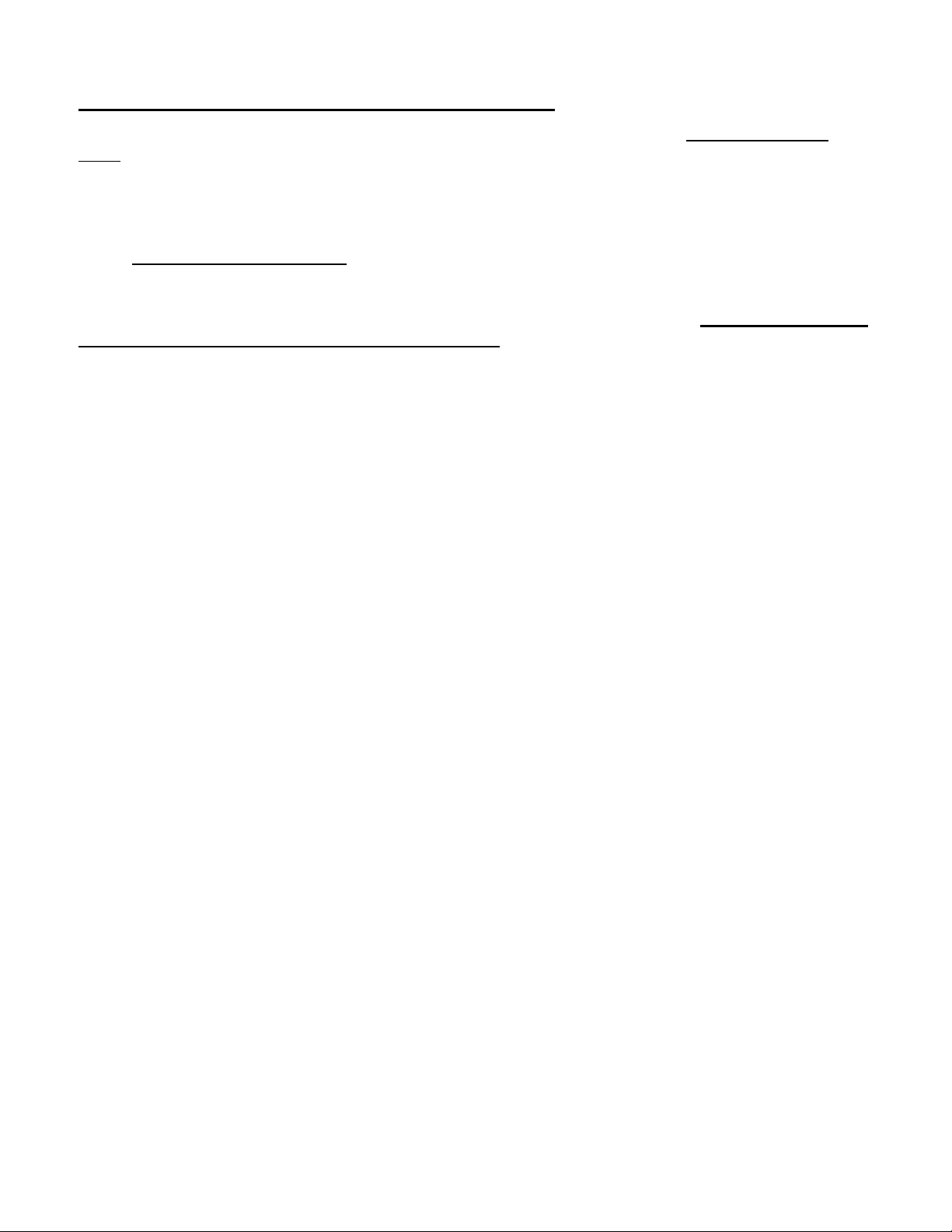

3. Secure burner head to pole with four #10 screws provided.

Figure 10: Burner Head Installation

4. Push the gas connection into the slot by slightly pushing on the gas line through the electrical box. The gas

fitting should be positioned as illustrated below.

Figure 11: Gas Connection Position

__________________________________________________________________________________________________________________

Series GA301 19 LT071 Aug 2021

5. Place gas connection cover onto the fitting and install the nut to fasten the cover assuring the nut is

properly seated. See below.

Figure 12: Gas Connection

6. Install reflector using the four carriage bolts, nuts and washers provided.

Figure 13: Reflector Installation

Figure 4

__________________________________________________________________________________________________________________

Series GA301 20 LT071 Aug 2021

Hanging Model (GA301-H)

1. Disconnect gas hose from reducing coupling. Connect flared elbow to reducing couple and align elbow to

point at a right angle to the heater door opening.

Figure 14: Gas Hose Connections

2. After inserting the heater assembly into the frame base, connect the swivel fitting on the opposite end of

the gas hose to the flared elbow. See Figure 15. Note: All gas connections must be done according to

local and national codes. Also, all new connections must be leak tested.

Figure 15: Insert Heater Assembly into Frame Base

3. Assemble 4 gusset plates to the base as illustrated. Use 5/16” carriage bolts with washers and nuts.

Figure 16: Gusset Plate Assembly

This manual suits for next models

5

Table of contents

Other EvenGlo Patio Heater manuals

Popular Patio Heater manuals by other brands

empasa

empasa Classic light user manual

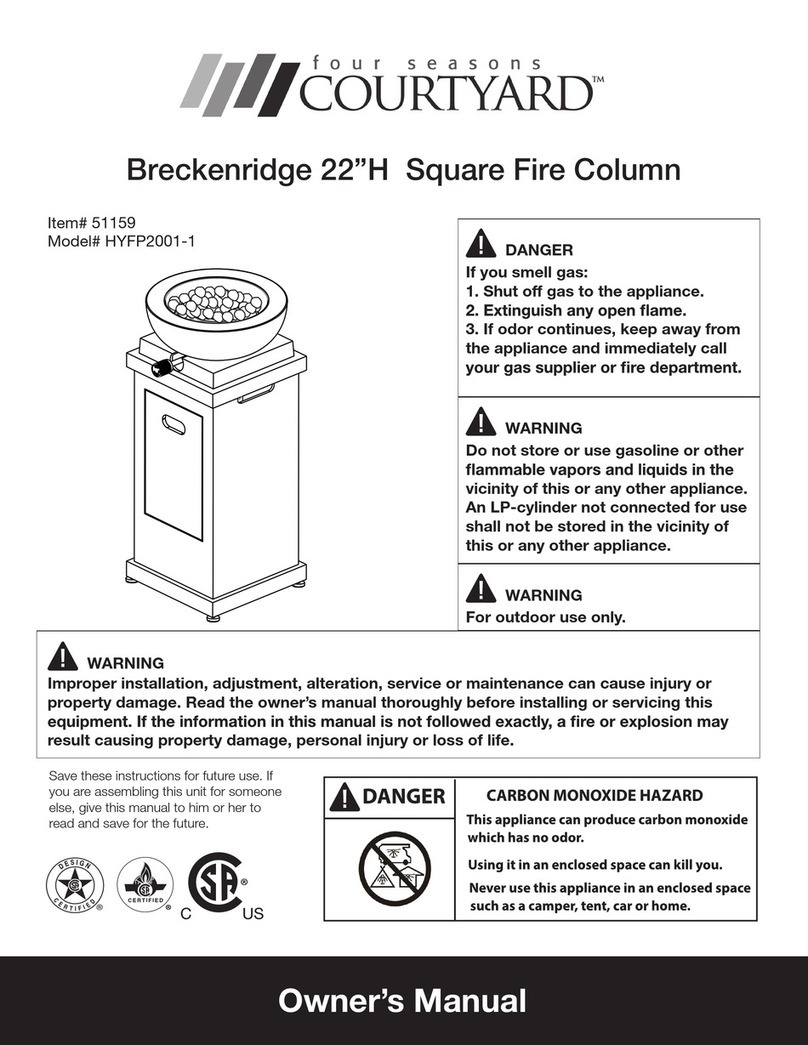

Four Seasons Courtyard

Four Seasons Courtyard HYFP2001-1 owner's manual

Pinnacle AGRI

Pinnacle AGRI FIRESTORM Phoenix Instruction leaflet

Martin

Martin 132/PH01G User installation and operation guide

Blumfeldt

Blumfeldt 10028637 manual

Heatmaxx

Heatmaxx SRPH98 instruction manual