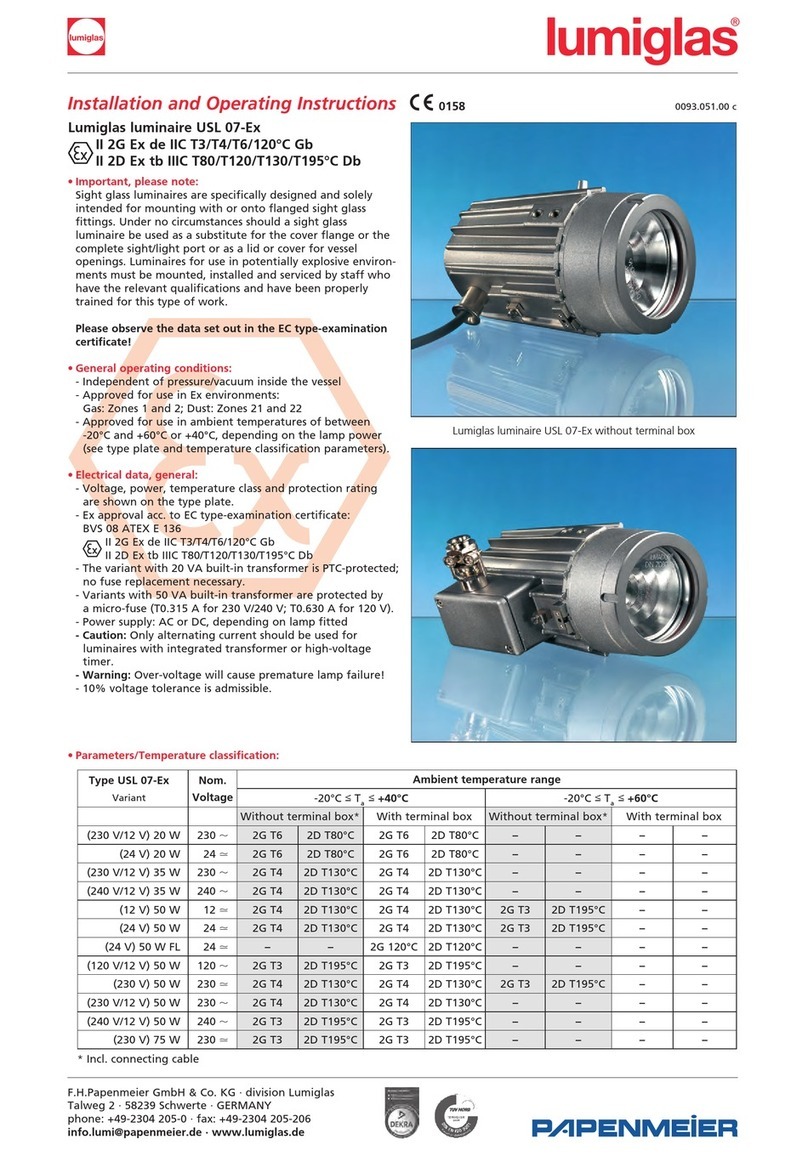

TABLE: DIAGNOSTIC STATUS INDICATIONS

STATUS DISPLAYFUNCTION ACTION

Battery in Float/Trickle Charge

Battery High Charging

In Test Mode

Insufficient Charge for User Test

Transfer System Failure Battery

Failure

Charger Failure

Lamp Failure

None

Wait for Green Status

Wait for Test to Complete

Wait for Full Charge

Factory Service

Check Connections/Replace Battery

Factory Service

Check Remote Connection/ Factory Service

Continuous Green

Continuous Red

Flashing Green

Alternate Red and Green

Red - One Blink ON / Pause

Red - Two Blinks ON / Pause

Red - Three Blinks ON / Pause

Red - Four Blinks ON / Pause

SECTION 4.0: DIAGNOSTICS

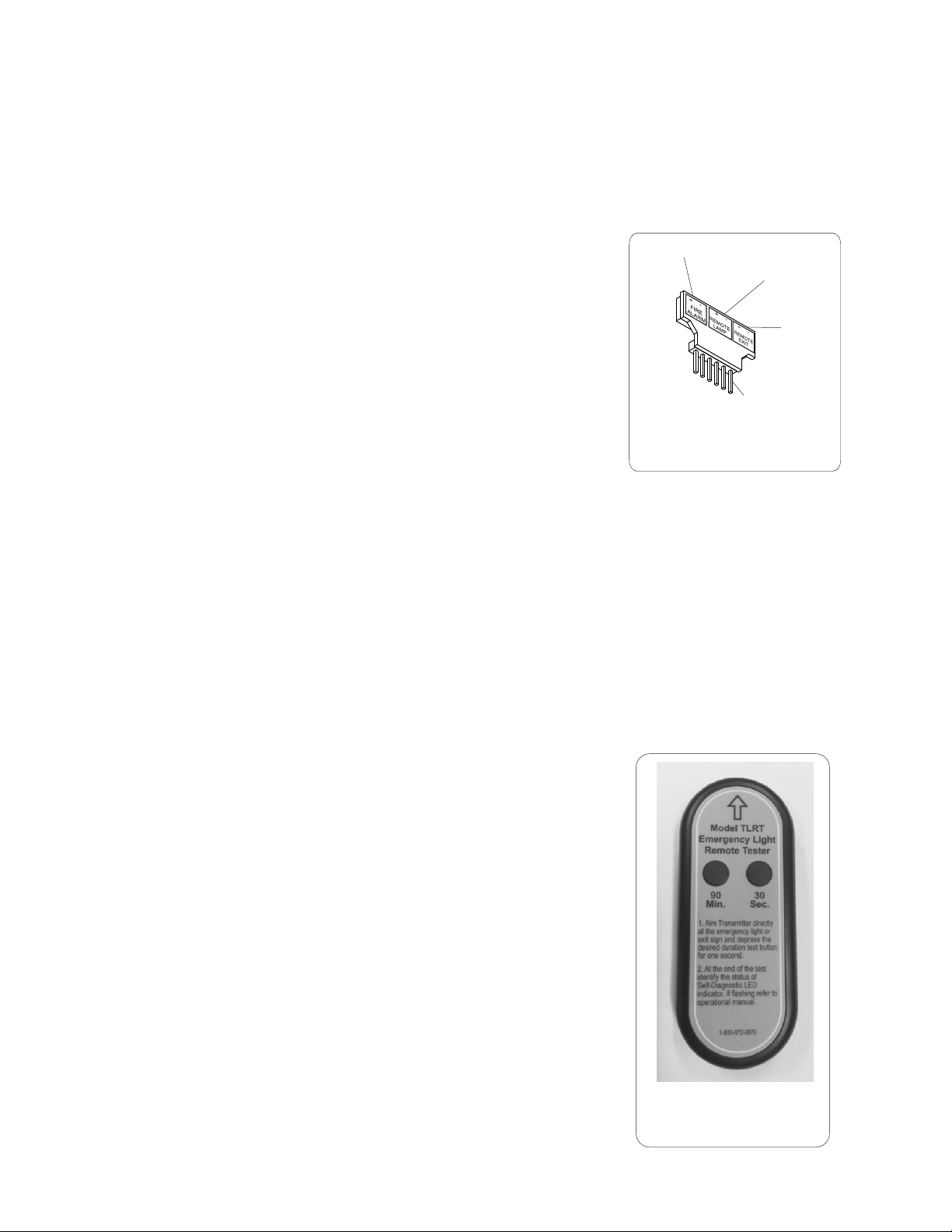

For units with Self-Testing/ Self Diagnostics option, refer to the section on next page for operating

instructions. Battery back-up units without Self-Testing/ Self Diagnostic option Include a battery

diagnostics system which indicates, via flashing of the indicator light, that the battery needs replacement. If

flashing occurs after a new installation, check that the battery plug is properly inserted into the circuit board

connector (For reference, see Figure 15).

SECTION 4.1: NON-SELF TEST/ DIAGNOSTIC MODELS

To test battery backup units, use test switch to simulate AC power outage. The indicator light will go out, and

the sign will remain lit, indicating transfer to emergency mode. It will remain lit on battery power until switch is

released. Release of switch will automatically restore AC/ Battery charge mode, with indicator light on.

Testing for longer periods is best accomplished by turning off AC circuit power. Signs should be tested in

accordance with National Electric Code and NFPA 101 Life Safety Code Requirements which specify monthly

testing for 30 seconds and yearly testing for 90 minutes. Note that the batteries will take some time to reach

full charge after a prolonged test, and that the unit cannot provide full duration operation should a real power

outage occur before the batteries have had an opportunity to reach full charge. It is recommended that long

duration tests be limited to once yearly, and be conducted when the area will be unoccupied afterwards.

SECTION 4.2: SELF TESTING/ SELF DIAGNOSTIC MODELS

The unit meets the requirement of NFPA 101 for Periodic Testing of Emergency Lighting Equipment. It provides

visual indication of unit malfunctions including: Battery Fault, Charger Fault, Transfer Fault, Lamp Fault

SELF TEST

The unit will perform a self-test and diagnostic function at least once every 28 days. The self test will

disable the charger and turn on the LEDs for 30 seconds to check the lamp load, battery and transfer

function. The test will be performed only if the battery is fully charged. If not, the test will automatically

reschedule. The charger function is monitored while AC is applied.

USER TEST

A user-test may be performed at any time the status display is continuous green. On initial power-up, it

could take up to 72 hours for the status display to reach continuous green. With a fully charged battery,

pressing the test switch momentarily will initiate a 30 second test. Pressing the test switch continuously for

4 seconds and releasing it will initiate a 90 minute test.

Either Test can be cancelled by pressing the test switch again for 1 second.

After installation is complete, reapply power and notify the authority

having jurisdiction.

Z410139 Rev FPage 10