Evenlite TXP User manual

INSTRUCTIONS

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed including the following:

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS

2. Disconnect power before performing work on electrical equipment.

3. Do not use outdoors.

4. Do not let power cords touch hot surfaces and do not mount near gas or electric heaters.

5. Use caution when servicing batteries. Battery acid can cause burns to skin and eyes. If acid is spilled on skin or

eyes, flush with fresh water and contact a physician immediately.

6. Equipment should be mounted in locations and at heights where unauthorized personnel will not readily subject it to

tampering.

7. The use of accessory equipment not recommended by the manufacturer, may cause an unsafe condition, and

will void the unit’s warranty.

8. Do not use this equipment for other than its intended purpose.

9. Servicing of this equipment should be performed by qualified service personnel.

10. SAVE THESE INSTRUCTIONS!

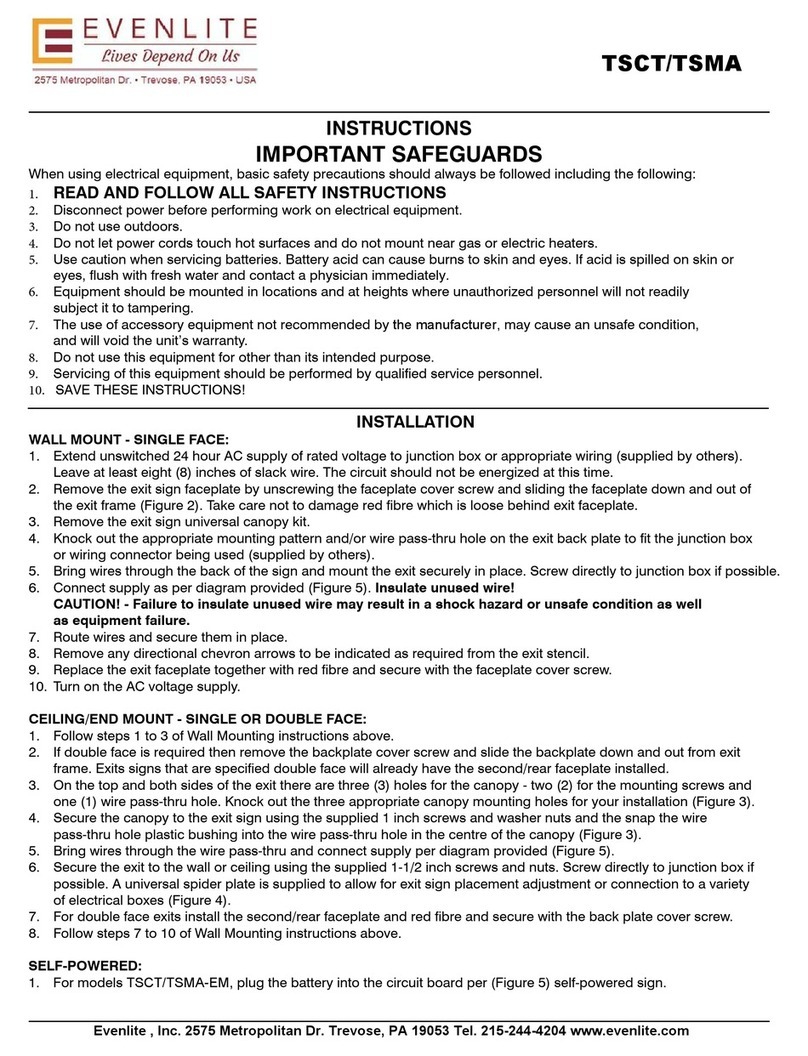

INSTALLATION

1. Extend unswitched 24 hour AC supply of rated voltage to a junction box or appropriate device wiring (supplied by

others) installed in accordance with all applicable codes and standards. Leave at least 8 inches of slack wire. This

circuit should NOT be energized/live at this time.

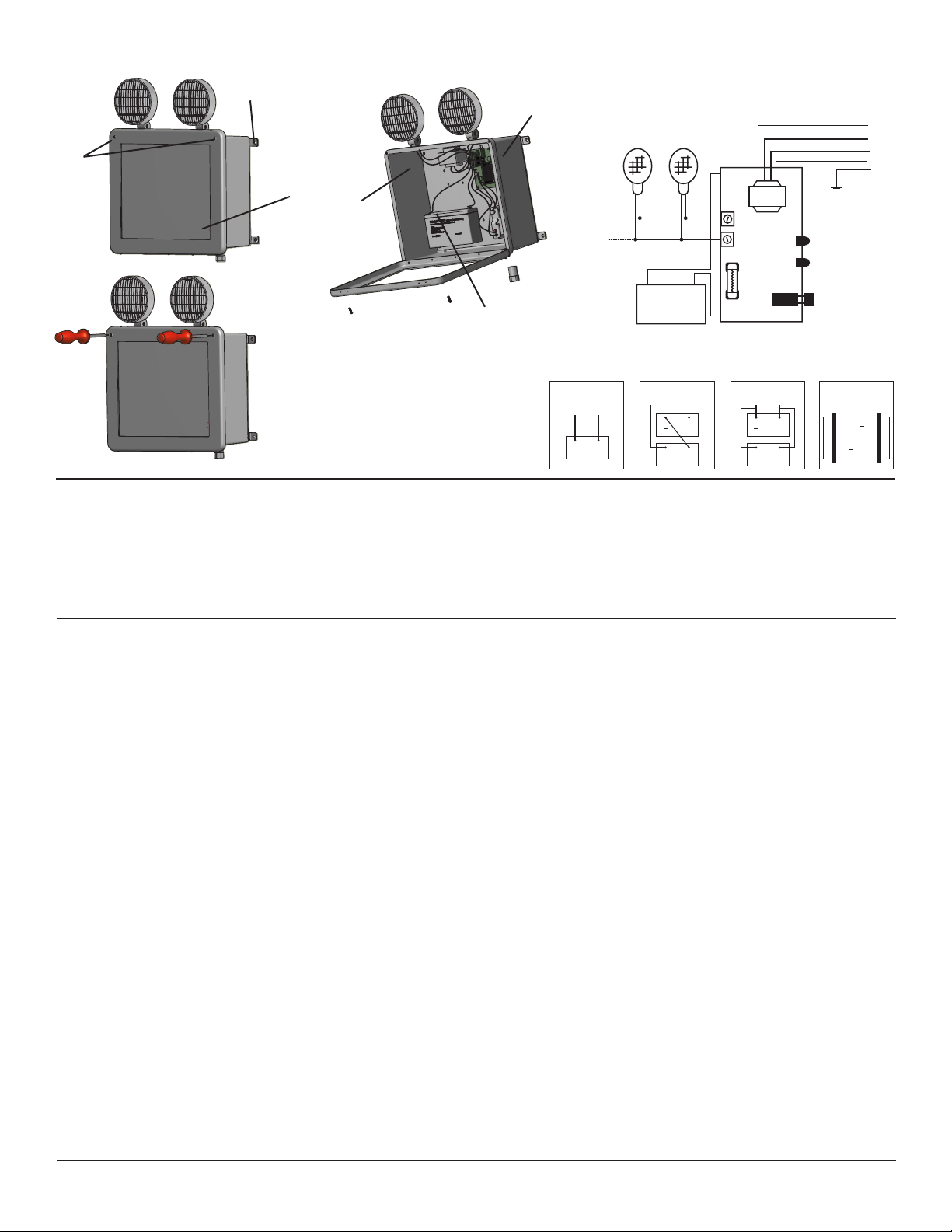

2. Drill 7/8” hole in area provided for AC supply and/or remote load and install bushing provided (Figure 3).

3. Mount the unit securely into place. Install four (4) mounting feet to the back of the cabinet. Fasten each foot with an

appropriately sized screw or mounting bolt (not supplied) through each hole and into the mounting surface/wall.

Each fastener must be securely in place to properly support the unit.

4. Open the unit by unscrewing the two (2) cover screws on the one side of the unit (Figure 1). The hinged door can

then be swung down.

5. Make proper wiring connections between the AC supply and the unit’s transformer per diagram provided (Figure 4).

Insulate unused wire! Connect ground to supplied green ground wire in accordance with local codes. Reassemble

all wire connections and connectors. CAUTION! - Failure to insulate unused wire may result in a shock hazard

or unsafe condition as well as equipment failure. All wires must be dressed and routed to ensure they will not

come in contact with the circuit board.

6. Connect the wire lead(s) from the positive circuit board terminal (+) to the positive terminal connector on the battery

(Figure 3). For large units the batteries may be shipped separate from the cabinet. Install the batteries into the cabinet

and make the appropriate inter-battery connections (Figure 5).

7. Close cover and secure cover screws.

8. Turn on AC line voltage supply.

9. Position lamps/heads to provide best lighting distribution by loosening head set screws to adjust angle and swivel

Manually rotate or twist head to desired position then tighten set screws to lock position.

Tufflite Unit (TXP)

CAUTION

WARNING! Before servicing parts, ensure area is known to be non-hazardous

This equipment is furnished with a sophisticated low voltage battery dropout circuit to protect the battery from over-discharge

after it’s useful output has been used. Allow 24 hours recharge time after installation or power failure for full load testing.

OPERATION

1. To test, pass a magnet over test marking to initiate the test (Figure 1). Charge indicator will go out and the DC lamps

will come on.

2. A bright charge indicator indicates a high charge rate. After the battery has reached full charge, the indicator light will

go out. Under normal operation the high charge indicator will turn off and on intermittently while the unit is in standby

mode (regular/mains AC present) since the charge rate will vary in order to maintain an optimal battery charge.

TROUBLESHOOTING

IMPORTANT NOTE: If the Time Delay optional feature is installated, emergency lamps will remain lit for up to

10 minutes following the resumption of regular/mains AC power to the unit.

EMERGENCY LAMPS DO NOT COME ON AT ALL LED “AC ON” indicator is out before test...

Pilot Light is out before test...

1. Check AC supply - be sure unit has 24 hour AC supply (unswitched).

2. AC supply is OK, and indicator light is out, replace PC Board Assembly.

Pilot Light is on before test

3. Either the output is shorted or overloaded, or the battery is not connected.

4. Battery is severely discharged. Allow 24 hours for recharge and then retest. NOTE: This could be the result of a

switched AC supply to the unit (which has been turned off at some point), a battery with a shorted cell, an old

battery or a battery which has been discharged due to a long power outage and is not yet fully recharged.

EMERGENCY LAMPS COME ON DIM WHEN TEST SWITCH IS ACTIVATED

1 . Battery discharged - permit unit to charge for 24 hours and then retest. If lamps are still dim, check charger for

proper function. If charger functions correctly, replace battery.

EMERGENCY LAMPS COME ON WHEN BATTERY IS FIRST CONNECTED

1 . Battery may be connected in reverse polarity. Check connections. Connect Positive lead to Positive battery terminal

and Negative lead to Negative battery terminal. The lamps should then turn off and the charge indicator should light

when AC power is applied.

EMERGENCY LAMPS COME ON DIM WHEN AC POWER IS ON -

1 . Check supply voltage and AC connections. This emergency light is provided with brownout protection. The AC

supply must be at least 80% of nominal (96V on a 120V line) for equipment to function normally. At lower voltages the

emergency lamps will begin to glow dimly until the source voltage drops below the full “turn-on” point. NOTE: This

condition may also be caused by incorrectly connecting a 120 Volt supply line to the wrong voltage transformer lead.

SAVE THESE INSTRUCTIONS

Figure 1

MAINTENANCE

1. The manufacturer strongly recommended compliance with all Code requirements.

2. The lamps listed herein when used according to the instructions with this unit are in accordance with the requirements of

CSA Standard C22.2, No. 141 – Unit Equipment for Emergency Lighting.

3. Clean lenses on a regular basis.

NOTE: The servicing of any parts should be performed by qualified service personnel only. The use of replacement

parts not furnished by the manufacturer may cause equipment failure and will void the warranty.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

This document is the property of and contains information proprietary to Beghelli Canada, Inc. It is submittedin confidence and is to be used solely for the

purpose for which it was furnished and returned upon request. This document and such information is not to be reproduced, transmitted, disclosed, or used

otherwise in whole or in part without prior authorization of Beghelli Canda, Inc. The recepient's acceptance of this document shall be considered an

agreement to the foregoing.

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS = INCHES

ANGLES + 1/2

TOLERANCES:

.X = .020

.XX = .010

.XXX = .005

.XXXX = .003

3900 14th AVE.

Markham Ontario, L3R 4R3

Tel. # 905 948-9500 Fax # 905 948 8673

email: sales@beghellicanada.com

Web: http://www.beghelli.com

MATERIAL

FINISH

DRAWN BY DATE

SIZE SCALE

REV

SHEET

PART NAME

DWG NO

REF NO

DO NOT SCALE

ROBUSTO BATTERY UNIT INSTRUCTION

SHEET

2/21/2012

PART #

L D

Figure 2

Mounting Feet

(four in total)

Cover

Screws

Figure 3 Figure 4

TEST

CHARGE

AC ON

WHITE - Neutral / Common

GREEN - Ground

BATTERY

NEG

-

POS

+

BATTERY+

BATTERY -

LAMP +

LAMP -

CHARGER PC BOARD

ASSEMBLY

LAMPS

TRIPLE INPUT VERSION

RED - 347V Line / Hot

FUSE

CHARGER BOARD

BLACK - 120V Line / Hot

ORANGE - 277V Line / Hot

Figure 5

1 Battery Unit

(+)( )

Black Red

2 Battery Unit

(connected in series)

(+)( )

Black

Red

(+)( )

2 Battery Unit

(connected in parallel)

(+)( )

Black Red

(+)( )

2x 12V. 32Ah

(+)

( ) (+)

( )

1

1

2

2

3

3

4

4

A A

B B

C C

D D

This document is the property of and contains information proprietary to Beghelli Canada, Inc. It is submittedin confidence and is to be used solely for the

purpose for which it was furnished and returned upon request. This document and such information is not to be reproduced, transmitted, disclosed, or used

otherwise in whole or in part without prior authorization of Beghelli Canda, Inc. The recepient's acceptance of this document shall be considered an

agreement to the foregoing.

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS = INCHES

ANGLES + 1/2

TOLERANCES:

.X = .020

.XX = .010

.XXX = .005

.XXXX = .003

3900 14th AVE.

Markham Ontario, L3R 4R3

Tel. # 905 948-9500 Fax # 905 948 8673

email: sales@beghellicanada.com

Web: http://www.beghelli.com

MATERIAL

FINISH

DRAWN BY DATE

SIZE SCALE

REV

SHEET

PART NAME

DWG NO

REF NO

DO NOT SCALE

ROBUSTO BATTERY UNIT INSTRUCTION

SHEET

2/21/2012

PART #

L D

1

1

2

2

3

3

4

4

A A

B B

C C

D D

This document is the property of and contains information proprietary to Beghelli Canada, Inc. It is submittedin confidence and is to be used solely for the

purpose for which it was furnished and returned upon request. This document and such information is not to be reproduced, transmitted, disclosed, or used

otherwise in whole or in part without prior authorization of Beghelli Canda, Inc. The recepient's acceptance of this document shall be considered an

agreement to the foregoing.

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS = INCHES

ANGLES + 1/2

TOLERANCES:

.X = .020

.XX = .010

.XXX = .005

.XXXX = .003

3900 14th AVE.

Markham Ontario, L3R 4R3

Tel. # 905 948-9500 Fax # 905 948 8673

email: sales@beghellicanada.com

Web: http://www.beghelli.com

MATERIAL

FINISH

DRAWN BY DATE

SIZE SCALE

REV

SHEET

PART NAME

DWG NO

REF NO

DO NOT SCALE

ROBUSTO BATTERY UNIT INSTRUCTION

SHEET

2/21/2012

PART #

L D

Uncoil battery wire

and connect end to

battery terminal

Magnetic

Test

drill hole for

AC supply or

remote load

drill hole for

AC supply or

remote load

unscrew and swing

open hinged cover

Table of contents

Other Evenlite Lighting Equipment manuals