GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 7

SAFETY INFORMATION

LIGHTING SYSTEM SAFETY

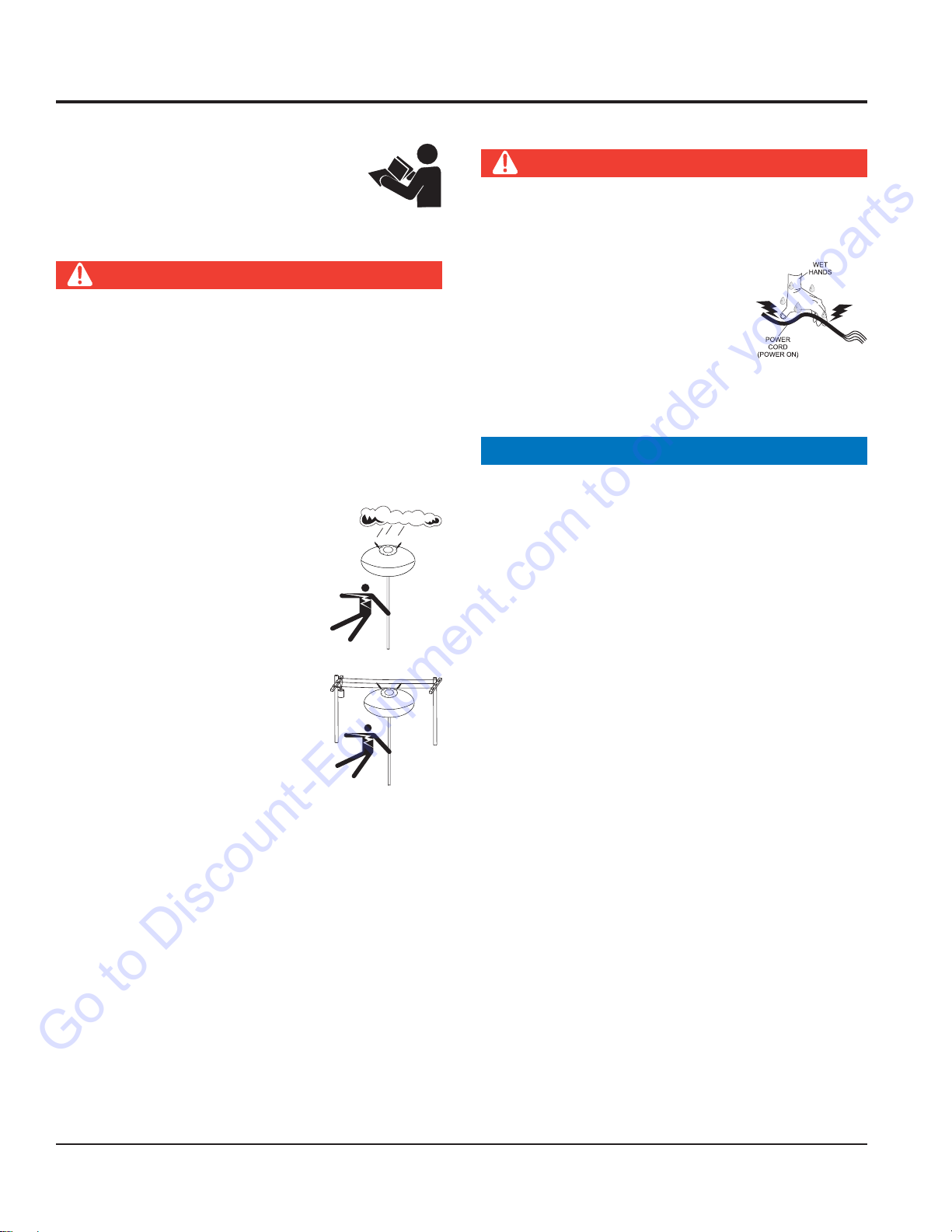

DANGER

NEVERuse lighting system in rain, snow or

areas of high humidity that could generate

electrical storms.

WARNING

NEVERdisconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of

these devices will void all warranties.

CAUTION

NEVERattempt service on a running machine.

NOTICE

To prevent the lighting system from overturning,NEVER

use in winds that exceed 22mph (10 m/s).

The lighting system should only be used in temperatures

between 23° to 104°F (-5° to 40° C). Failure to comply

with these operating parameters could cause the lamp

to malfunction and shorten the ballast life.

ALWAYSkeep the lighting system in proper running

condition.

Fix damage to lighting system and replace any broken

parts immediately.

ALWAYSstore equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

LAMP SAFETY

WARNING

NEVERattempt to replace lamp with the power on.

Always unplug the power cord from the generator or

power source when changing the lamp.

ALWAYSallow a sufficient amount of time for the lamp to cool

before changing. The possibility exists of severe burns.

CAUTION

NEVERuse force when installing the lamp.Excessive force

could cause the lamp to break, causing bodily harm.

NOTICE

NEVERleave any grease or oil residue on lamp surface

when replacing or removing lamp. This can create hot

spots, reducing the service life of the lamp.

ALWAYSmake sure lamp surface is clean and dry.

ALWAYSreplace with MQ recommended type lamp. See

parts section of this manual.

If applicable,ALWAYS make sure the lamp guard is

installed correctly. NEVER deform the lamp guard.

NEVERunplug the lamp’s AC power cable during

operation.

ALWAYShave a trained technician to install and

remove lamp or replace any damaged fixture wiring.

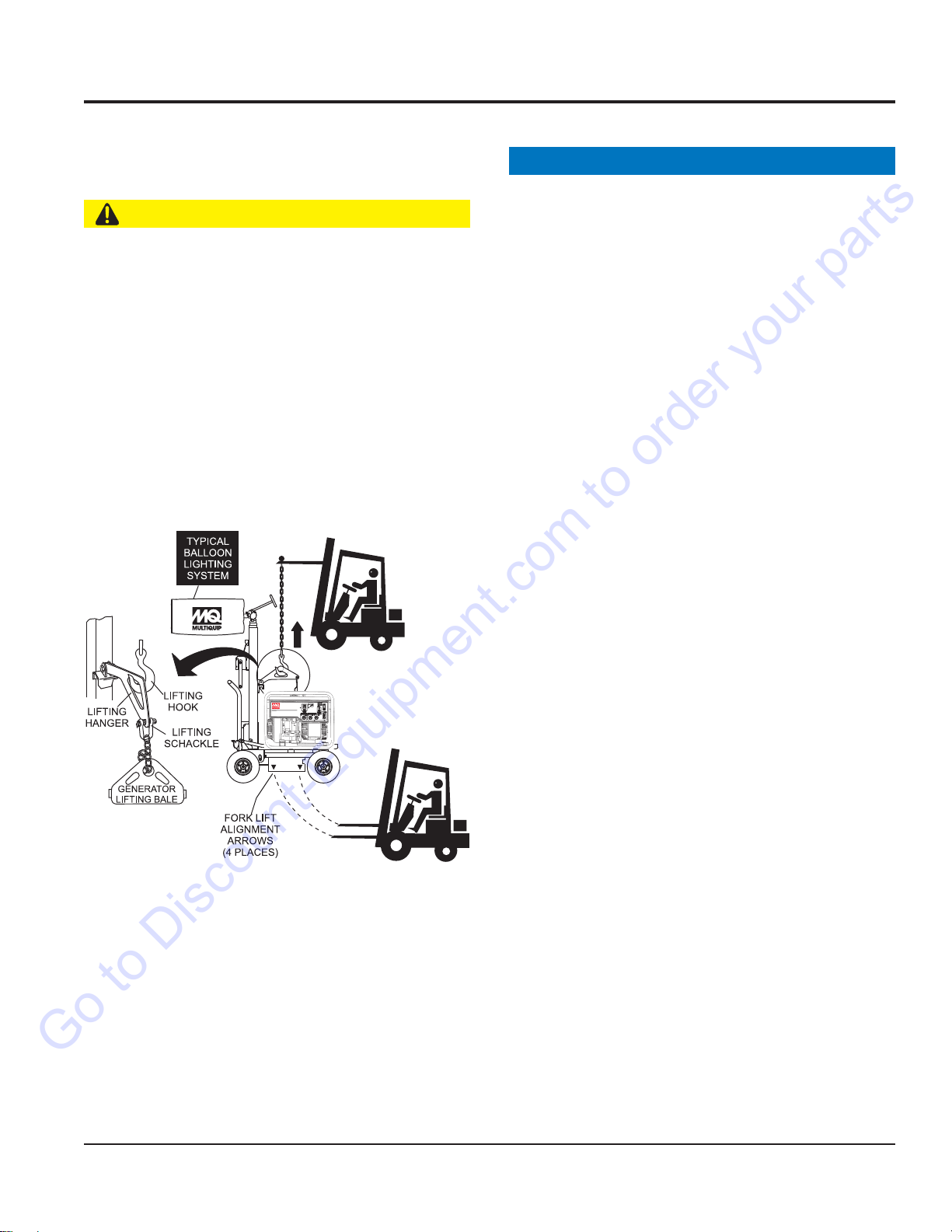

BALLOON SAFETY

WARNING

To prevent serious burns,NEVER touch

or unzip the balloon envelope when the

lamp is on.

CAUTION

ALWAYSkeep the balloon away from sharp objects and

excessive amounts of heat.

NOTICE

To prevent balloon deformation,NEVER use lighting

system in strong winds.

DO NOTplace the balloon inside its protective cover

until the lamp has had a sufficient amount of time to cool

down. This will prevent the balloon’s nylon cover from

being burned (touching the lamp surface).

ALWAYSplace the balloon inside its protective cover

after each use. This will prolong the life of the balloon

material, keeping it protected from harsh environmental

elements.

Replace balloon immediately if damaged. A damaged

balloon will not inflate properly, and may become more

damaged by touching the hot lamp surface.

DO NOTuse excessive force when zipping and unzipping

the balloon. Be gentle with the zipper mechanism. If the

zipper is broken, the balloon will become unusable.

Go to Discount-Equipment.com to order your parts