Everflo EDS90 User manual

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

ISSUE 3 MAY 2015

01 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

PAGE CONTENT

2 Introduction

3 Storage, Handling & Supply Requirements

3 Component Table

4 Sitting the unit

5 General Installation

7-8 Discharge Arrangement

9 Technical Specications: Slimline - Direct & Indirect

10 Technical Specications: Direct & Indirect

11 Technical Specications: Solar Direct

12 Technical Specications: Solar Indirect

13 Solar Coil Installation

4 Solar High Limit

15 S-Plan Wiring Schematics

16 Y-Plan Wiring Schematics

17 - 18 Pre-Plumbed Wiring Schematics

19 Pre-Plumbed Installation

20 Technical Specications: Pre-Plumbed

21 System Fit Installation

22 Technical Specications: System Fit

23 Commissioning & Servicing

24 Fault Finding & User Instructions

25 - 27 Guarantee - Terms & Conditions

28 Technical Specication

29 - 30 Specication & Performance

31 Benchmark

32 Commissioning Check Sheet

33 Service Record

INTRODUCTION

The EVERFLO STAINLESS UV Unvented cylinder is made from

Duplex Stainless Steel for excellent corrosion resistance.

EVERFLO STAINLESS UV has a strong rust-proofed steel case

and is highly insulated with environmentally friendly foam.

EVERFLO STAINLESS UV is supplied complete with all the

necessary safety and control devices needed to connect

to the cold water mains. All are pre-adjusted. High quality

controls have been selected to combine high ow rate

performance with minimum pressure drop to make EVERFLO

STAINLESS UV perform well in all areas, even those with poor

water pressure.

EVERFLO STAINLESS UV is KIWA approved to show

compliance with Building Regulations G3+L.

Benchmark places responsibilities on both manufacturers and installers. The

purpose is to ensure that customers are provided with the correct equipment

for their needs, that it is installed, commissioned and serviced in accordance

with the manufacturer’s instructions by competent persons and that it meets

the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations

and should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing

work in accordance with the Benchmark Code of Practice which is available

from the Heating and Hotwater Industry Council who manage and promote

the Scheme. Visit www.centralheating.co.uk for more information.

IMPORTANT NOTE TO

THE INSTALLER

Read these instructions before commencing installation.

Unvented cylinders are a controlled service as dened in the

latest edition of the building regulations and should only be

tted by a competent person.

The relevant regulations are: England and Wales – Building

Regulation G3, Scotland – Technical Standard P3, N Ireland –

Building Regulation Part F

After installation the Benchmark check list must be

completed and left, with these instructions, with the

householder for future reference.

IMPORTANT NOTE TO THE INSTALLER

Read these instructions before commencing installation. Unvented cylinders are a controlled service

as dened in the latest edition of the building regulations and should only be tted by a competent

person.

The relevant regulations are: England and Wales – Building Regulation G3, Scotland – Technical Standard

P3, N Ireland – Building Regulation Part F

After installation the Benchmark check list must be completed and left, with these instructions, with

the householder for future reference.

02

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

STORAGE PRIOR TO INSTALLATION

EVERFLO STAINLESS UV should be stored in its original packaging

in an upright position in an area free from excessive damp.

Regulations G3+L.

HANDLING PRODUCT

The EVERFLO STAINLESS UV should be carried upright where

possible. Assessments of risks for carrying the cylinder should

be conducted. Use more than 1 person for carrying where

appropriate. Always follow latest guide lines for lifting techniques,

to avoid injury and damage to the product.

WATER SUPPLY

EVERFLO STAINLESS UV operates at 3 bar (controlled by the inlet

control set) and is capable of delivering over 50 litres per minute.

The high quality inlet control set has been designed to make the

most of the ow rates available, however the performance of any

unvented system is only as good as the mains water supply. The

maximum possible water demand should be assessed, taking

into consideration that both hot and cold services are supplied

simultaneously from the mains.

The water supply should be checked to ensure it can meet these

requirements. If necessary, consult the local water company

regarding the likely pressure and ow rate availability.

If measuring the water pressure, note that a high static (no ow)

mains pressure is no guarantee of good ow availability. In a

domestic installation 1.5 bar and 25 l/min. should be regarded as

the minimum. The maximum mains pressure that the inlet control

set can accept is 12 bar.

Consideration should be given to upgrading existing ½” (15mm)

cold mains pipework to a larger size if the recommended

minimum pressure/ow rate is not being achieved.

ELECTRIC SUPPLY

The EVERFLO STAINLESS UV requires 240 Volt electrical supply for

the standard Incoloy immersion elements. The electrical supply

to each immersion heater must be fused at 13A via a double

pole isolating switch to BS 3456. The cable must be at least

2.5mm2 heat resistant (85°C HOFR) sheathed ex complying to BS

6141:1981 Table 8.

UNPACKING THE UNIT

EVERFLO STAINLESS UV comes complete with the ttings required

to complete the installation. Please see over for component

content list.

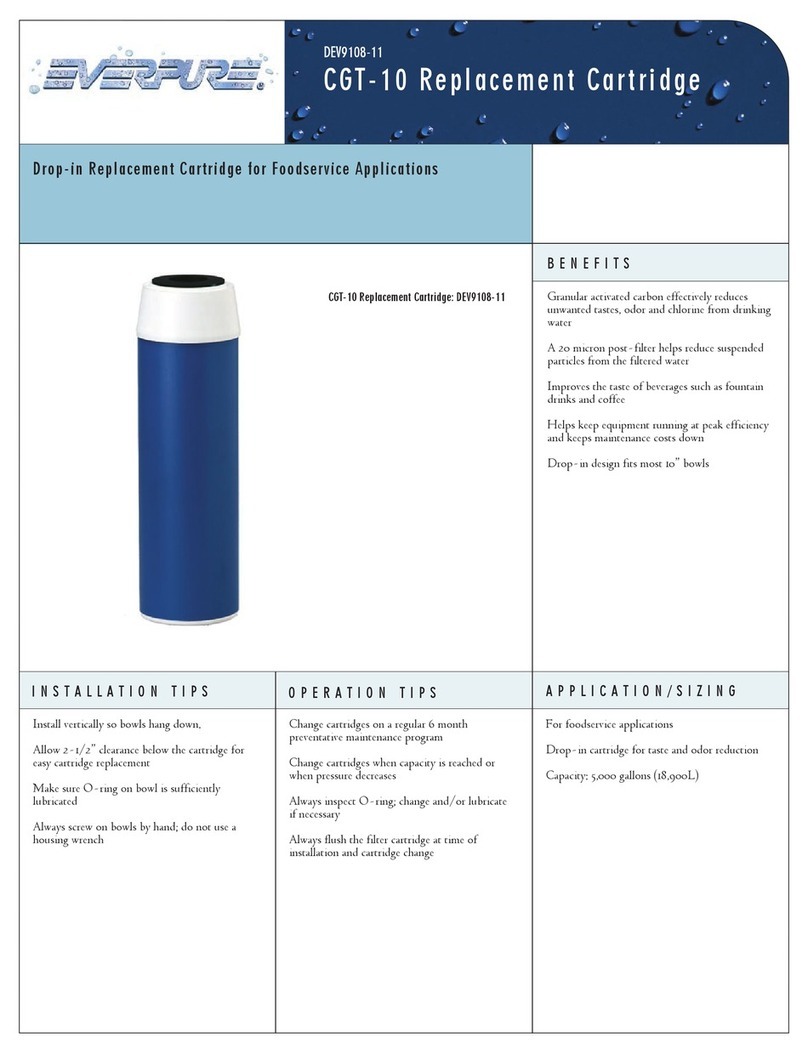

High ow rate inlet control set

TS201-533

Temperature and pressure relief valve

TS202

Acetal tundish 15 x 22 mm

TS3

Incoloy long life

3 kW immersion heater

TS9 - DIRECT TS10 - INDIRECT

Two port valve

TS5

Dual thermostat

US201

High Limit thermostat

TS28

Installation &

Maintenance Instructions

Expansion Vessel

• 60, 90, 120 & 150 ltr units - 12 ltr vessel TS212

• 180, 210 & 250 ltr units - 18 ltr vessel TS219

• 300 ltr units - 25 ltr vessel

TS224

03 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

COMPONENT CONTENT TABLE

Inlet Control set ••••••••••

Temp & Pressure relief valve • • • • • • • • • •

Tundish ••••••••••

Expansion vessel • • • • • • • • • •

Immersion Heater (Direct) • • •

Immersion Heater (Indirect) • • • • • • •

Two Port Valve • • • • • • •

Dual Thermostat • • • • • • •

Single High Limit Stat • • • • • •

Sensor pocket retaining bungs • • • •

Robo-Kit • • • •

TP9000 • • • •

TP5000 • •

Installation & Maintenance

Instructions ••••••••••

Slimline Direct Models (Electric)

Slimline Indirect Models

Direct Models

Indirect Models

Solar Direct Models

Solar Indiect Models

Indirect pre-plumbed

models - 1 zone heating

Indirect pre-plumbed

models - 2 zone heating

Solar indirect pre-plumbed models - 1

zone heating

Solar indirect pre-plumbed models - 2

zone heating

Direct Models (Electric)

Direct Solar Models (Electric + Coil)

Indirect Models (Single Coil)

Indirect Solar Models (Twin Coil)

04

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

SITTING THE UNIT

EVERFLO STAINLESS UV can supply outlets above it or at some

distance from it. Site the unit to minimise “dead leg” distances,

especially to the point of most frequent use.

Outlets above the EVERFLO STAINLESS UV will reduce the outlet

pressure available by 0.1 bar for every 1m of height dierence. The

unit should be protected from frost. Particular care is needed if

sitting in a garage or outbuilding. All exposed pipework should be

insulated. EVERFLO STAINLESS UV must be installed VERTICALLY

on a at base capable of supporting the weight of the cylinder

when full. See technical specication section (page 27-28) for

weights. The minimum recommended cupboard size is 650mm

square.

NOTES:

The pressure reducing

valve, non-return valve and

expansion relief valve are

combined together in the

inlet control set.

On 60 – 180 litre sizes there

is no dedicated secondary

return boss and the

secondary return circuit

should be tee’d into the cold

feed pipe just above the

drain elbow.

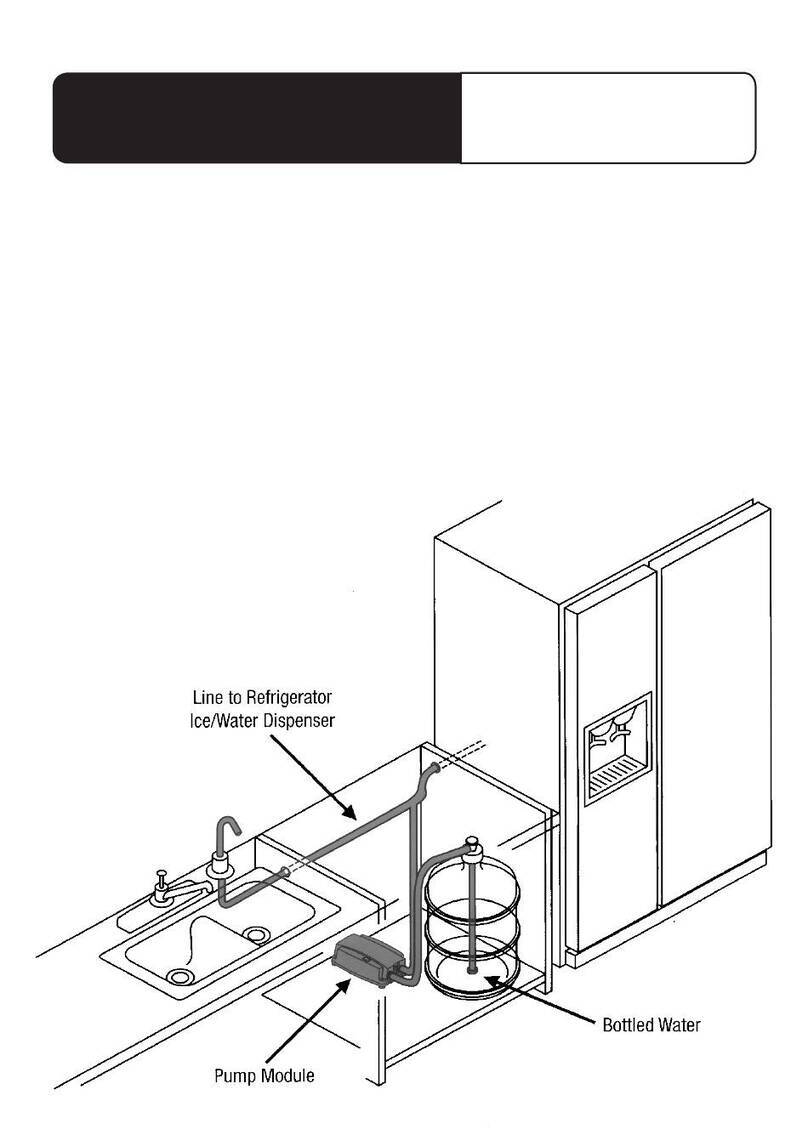

SCHEMATIC DIAGRAM

Access for maintenance of the valves should be considered.

Consideration should be given to position of discharge pipes

(tundish), drain valves - shall be positioned away from electrical

components.

The immersion heaters are 375mm long and care should be taken

to ensure that they can be withdrawn for servicing if required.

The discharge pipework from the safety valves should fall

continuously and terminate safely.

IMMERSION

HEATER

COLD

MAIN

ISOLATING

VALVE

PRESSURE

REDUCING

VALVE

NON

RETURN

VALVE

EXPANSION

RELIEF

VALVE

TUNDISH

TEMPERATURE

& PRESSURE

RELIEF VALVE

BALANCED

COLD

CONNECTION

COLD

INLET VIA

DRAIN

NON

RETURN

VALVE

BRONZE

PUMP

SECONDARY RETURN CIRCUIT

( 210, 250 & 300 L SIZES )

DUAL

STAT

2 PORT

VALVE

BOILER

FLOW

BOILER

RETURN

HOT OUTLET

EXPANSION

VESSEL

WITH WALL

BRACKET

05 EVERFLO UNVENTED HOT WATER CYLINDERS

GENERAL INSTALLATION

COLD MAINS PIPEWORK

Run the cold main through the building to the place where the

EVERFLO STAINLESS UV is to be installed. Take care not to run the

cold pipe near hot water or heating pipework so that the heat

pick-up is minimized. Identify the cold water supply pipe and t

an isolating valve (not supplied).

A 22mm BS1010 stopcock can typically be used but a 22mm

quarter turn full bore valve would be better as it does not

restrict the ow as much. Do not use “screwdriver slot” or similar

valves. Make the connection to the cold feed of the cylinder

and incorporate a drain valve. Position the drain valve no higher

than the cold inlet to ensure sucient draining of cylinder when

required. Position the inlet control just ABOVE the Temperature &

Pressure Relief Valve (TPRV) mounted on the side of the cylinder.

This ensures that the cylinder does not have to be drained down

in order to service the inlet control set. Ensure that the arrow

points in the direction of the water ow. Select a suitable position

for the expansion vessel. Mount it to the wall using the bracket

attached to the vessel. Use suitable ttings capable of supporting

full vessel weight (and with appropriate consideration to wall

material). Ensure the pre-charge in the vessel is set at 3 Bar.

Connect the expansion vessel to the cold feed pipework between

the inlet control set and the cold inlet on the cylinder. Ensure that

the top of the vessel is accessible for servicing.

CONNECTING TO THE CYLINDER

All of the pipework connections on the cylinder are 22mm

compression and supplied complete with gland nuts and olives, in

the Accessory Kit box. Only connect 22mm Table X copper tube to

these connections.

Cut the tube with a pipe cutter and ensure no sharp edges or

burrs protrude. Slide both gland nut and olive onto the tube and

push tube fully home into the connection, ensuring the tube

end fully bottoms on the connection recess. Smear the outer

wall of the olive with plumbing paste and tighten gland nut

in the prescribed manner. Upon lling/commissioning, ensure

all connections are completely watertight. Note: No control or

isolation valve should be tted between the expansion relief valve

and the storage cylinder. The relief valve connections should not

be used for any other purpose.

(expansion vessel not to scale)

Turn to

test

Cold

Mains In

Balanced Cold

Connection

Outlet to Cylinder

Expansion

Relief to

Tundish

Expansion

Relief

Connection

06

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

BALANCED COLD CONNECTION

If there are to be showers, bidets or monobloc taps in the

installation then a balanced cold supply is necessary. There is a

22mm balanced connection on the inlet set.

HOT WATER PIPEWORK

Run the rst part of the hot water distribution pipework in 22mm.

This can be reduced to 15mm and 10mm as appropriate for the

type of tap etc. Your aim should be to reduce the volume of the

hot draw-o pipework to a practical minimum so that the time

taken for the hot water is as quick as possible. Where monobloc

mixing taps and showers are used, these should be installed to

comply with the Water Supply (Water Fittings) Regulations 1999.

If these devices are supplied with un-balanced supplies there

should be single check valves installed at both inlets, to stop over

pressurising of either supply.

PRIMARY COIL CONNECTIONS FOR INDIRECT UNITS

For Solar input models refer to pages 13-14 before making any

connections.

Connect the primary connections (Indirect only) using the

compression connections provided. The primary circuit must

be positively pumped. Gravity circulation is not suitable. Either

primary connection may be used as the primary ow, reheat times

are not eected. The primary circuit can be open vented or sealed,

with up to a maximum pressure of 3.5 bar. If you seal the primary

circuit an additional expansion vessel and safety valve is required.

The boiler may be Gas, Electric or Oil but must be under eective

thermostatic control. Uncontrolled heat sources such as some

AGA’s, back boilers, solid fuel stoves, etc. are NOT SUITABLE. Please

contact our Technical department for guidance. Connect the two

port zone valve ( indirect only ) into the primary ow pipework.

The direction of ow arrow should be towards the primary ow

connection.

SECONDARY CIRCULATION

EVERFLO STAINLESS UV can be used with secondary circulation.

An appropriate WRAS approved bronze circulator should be

used in conjunction with a non-return valve to prevent backow.

On large secondary circulation systems it may be necessary

to incorporate an extra expansion vessel into the circuit to

accommodate the increased system water volume. Secondary

circulation should be avoided on Direct electrically heated units

being used on o-peak electricity taris.

A secondary return boss is tted as standard on 210, 250 & 300 ltr

units. On smaller sizes, tee into the cold feed pipe above the drain.

IMMERSION HEATERS

Only immersion heaters with a thermal cut-out may be used. To

help ensure this, the immersion heaters have a special 1¾” thread.

They are rated at 3kW at 240V and are of a low noise Incoloy

construction.

They have both a thermostat and a high limit cutout. Please order

the correct replacement via ourselves; tting non-approved

immersions may aect your guarantee. When tting, ensure the

‘O’ ring is positioned correctly on the head of the immersion

heater and lubricate before tting. Fit it by hand until almost

home then tighten gently as the ‘O’ rings will seal easily. The

electrical supply to each immersion heater must be fused at 13A

via a double pole isolating switch to BS 3456. The cable must be

2.5mm2heat resistant (85°C HOFR) sheathed ex complying to BS

6141:1981 Table 8. Do not operate the immersion heater/s until the

unit is full of water. Do not operate the immersion heater/s if any

sterilisation liquid is in the cylinder as this will cause premature

failure.

ELECTRICAL CONNECTIONS

Complete the wiring – use the appropriate wiring diagrams on

page 15 - 18.

07 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

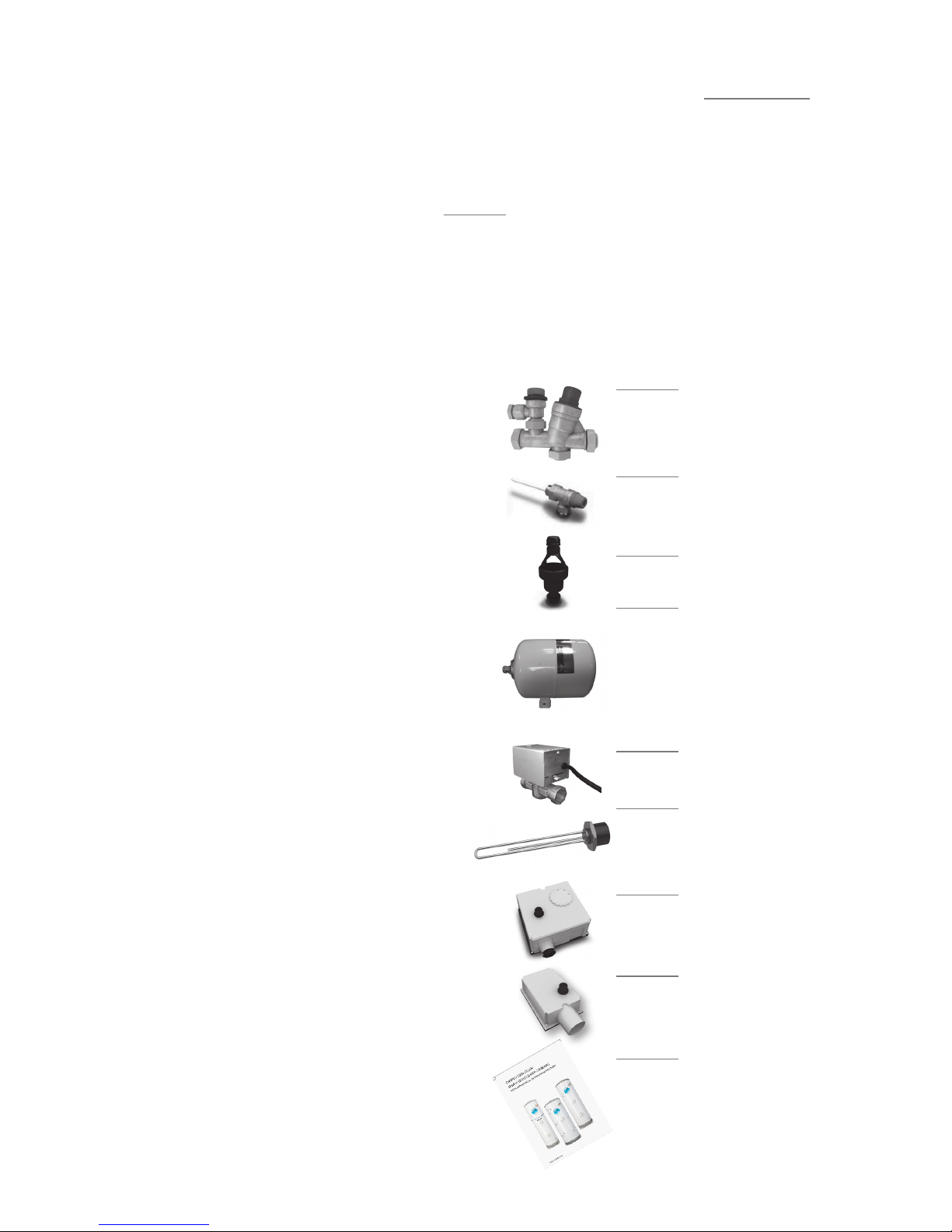

DISCHARGE ARRANGEMENT

Position the inlet control group so that the discharge from both

safety valves can be joined together via a 15mm end feed Tee (see

diagram above). Connect the Tundish and route the discharge

pipe. The discharge pipework must be routed in accordance with

Part G3 of schedule 1 of the Building Regulations. The information

that follows is not exhaustive and if you are in doubt you should

seek advice. The two safety valves will only discharge water under

fault conditions. When operating normally water will not be

discharged. The tundish should be vertical, located in the same

space as the unvented hot water storage system and be tted

as close as possible to, and lower than, the safety device, with

no more than 600mm of pipe between the valve outlet and the

tundish. The tundish should be positioned away from electrical

devices.

Any Discharge should be visible at the tundish. The tundish should

be located such that any discharge is visible. In addition, where

discharges from safety devices may not be apparent, e.g. people

with impaired vision or mobility, consideration should be given to

the installation of a suitable safety device to warn when discharge

takes place, e.g. electronically operated.

Diagram of a typical discharge pipe arrangement (extract from

Building Regulation G3)

Note: The discharge will consist

of scalding water and steam.

Asphalt, roong felt and

non-metallic rainwater goods

may be damaged by such

discharges.

Note: D2 pipe from tundish is

now allowed to be installed in

soil stacks within premises. This

activity is not recommended

by Kingspan as discharge

from T&P may continue for

long periods of time. It is the

installer’s responsibility to

ensure the discharge pipework

can support the discharge for

prolonged periods.

If used follow guidance on

mechanical seal without water

trap given in G3 Building

Regulations.

As discharge can be in

excess of 90oC discharge into

plastic pipework is also not

recommended.

08

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

The discharge pipe (D2) from the tundish should:

A) Have a vertical section of pipe at least 300mm long, below the

tundish before any elbows or bends in the pipework.

B) Be installed with a continuous fall of at least 1 in 200 thereafter.

The discharge pipe (D2) from the tundish should be of metal or

other material that have been demonstrated to be capable of

withstanding temperatures of the water discharged.

The discharge pipe (D2) should be at least one pipe size larger

than the nominal outlet size of the safety device unless its total

equivalent hydraulic resistance exceeds that of a straight pipe

9m long i.e. discharge pipes between 9m and 18m equivalent

resistance length should be at least two sizes larger than the

nominal outlet size of the safety device, between 18 and 27m at

least 3 sizes larger, and so on. Bends must be taken into account

in calculating the ow resistance. Refer to diagram 1, Table 1 and

the worked example. An alternative approach for sizing discharge

pipes would be to follow BS6700 Specication for design

installation, testing and maintenance of services supplying water

for domestic use within buildings and their curtilages.

The discharge pipe (D2) should terminate in a safe place where

there is no risk to persons in the vicinity of the discharge.

Examples of acceptable discharge arrangements are:

a. To a trapped gully with the end of the pipe below the xed

grating and above the water seal.

b. Downward discharges at a low level; i.e. up to 100mm above

external surfaces such as car parks, hard standings, grassed

areas etc. are acceptable providing that where children play or

otherwise come into contact with discharges, a wire cage or

similar guard is positioned to prevent contact whilst maintaining

visibility.

c. Discharges at a high level; e.g. in to metal hopper and metal

down pipe with the end of the discharge pipe clearly visible or

onto a roof capable of withstanding high temperature discharges

of water and 3m from any plastic guttering systems that would

collect such discharges.

d. Device to warn when discharge takes place.

WORKED EXAMPLE

The example below is for G1/2 temperature relief valve with a

discharge pipe (D2) having 4 No. elbows and length of 7m from

the tundish to the point of discharge.

From Table 1:

Maximum resistance allowed for a straight length of 22mm

copper discharge pipe (D2) from a G1/2 temperature relief valve is:

9.0m. Subtract the resistance for 4 No. 22mm elbows at 0.8m each

= 3.2m. Therefore the maximum permitted length equates to:

5.8m. 5.8m is less than the actual length of 7m therefore calculate

the next largest size. Maximum resistance allowed for a straight

length of 28mm pipe (D2) from a G1/2 temperature relief valve

equates to: 14m. As the actual length is 7m, a 28mm (D2) copper

pipe will be satisfactory.

TABLE 1

Sizing of copper discharge pipe ‘D2’ for a temperature

relief valve with a G1/2 outlet size (as supplied).

Size of

discharge

pipework

Maximum length of

straight pipe

(no bends or elbows)

Deduct the gure below

from the maximum length

for each bend or elbow in the

discharge pipe

22mm Up to 9m 0.8m

28mm Up to 18m 1m

35mm Up to 27m 1.4m

09 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

EVERFLO STAINLESS UV

SLIMLINE DIRECT

EVERFLO STAINLESS UV

SLIMLINE INDIRECT

25.0˚

40.0˚

45.0˚

35.0˚

15.0˚

40.0˚

45.0˚

15.0˚

B

A

120.00

“ F PTRV BOSS

1

2

D A B C G

F D A B C G

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

“ F PTRV BOSS

1

2

22mm COLD FEED WITH

DRY STAT POCKET

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

120.00

SECOND IMMERSION HEATER

(not always tted. See table)

30.0˚

50.0˚ 50.0˚

10.0˚

25.0˚

40.0˚

45.0˚

35.0˚

15.0˚

40.0˚

45.0˚

15.0˚

B

A

120.00

“ F PTRV BOSS

1

2

D A B C G F D A B C G

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

“ F PTRV BOSS

1

2

22mm COLD FEED WITH

DRY STAT POCKET

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

120.00

SECOND IMMERSION HEATER

(not always tted. See table)

30.0˚

50.0˚

50.0˚

10.0˚

25.0˚

40.0˚

45.0˚

35.0˚

15.0˚

40.0˚

45.0˚

15.0˚

B

A

120.00

“ F PTRV BOSS

1

2

D A B C G F D A B C G

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

“ F PTRV BOSS

1

2

22mm COLD FEED WITH

DRY STAT POCKET

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

120.00

SECOND IMMERSION HEATER

(not always tted. See table)

30.0˚

50.0˚

50.0˚

10.0˚

CODE HEIGHT DIAMETER A B C D G

EDS60 673 478 175 210 N/F N/F 483

EDS90 1048 478 175 210 610 N/F 858

EDS120 1236 478 175 210 710 N/F 1046

EDS150 1424 478 175 210 810 N/F 1234

EDS180 1674 478 175 210 910 N/F 1484

EDS210 1987 478 175 210 1100 1500 1797

25.0˚

40.0˚

45.0˚

35.0˚

15.0˚

40.0˚

45.0˚

15.0˚

B

A

120.00

“ F PTRV BOSS

1

2

D A B C G

F D A B C G

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

“ F PTRV BOSS

1

2

22mm COLD FEED WITH

DRY STAT POCKET

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

120.00

SECOND IMMERSION HEATER

(not always tted. See table)

30.0˚

50.0˚ 50.0˚

10.0˚

CODE HEIGHT DIAMETER A B C D F G

ENS60 673 478 340 380 440 395 N/F 483

ENS90 1048 478 340 380 440 395 N/F 858

ENS120 1236 478 340 380 440 395 N/F 1046

ENS150 1424 478 380 420 520 520 N/F 1234

ENS180 1674 478 380 420 520 610 N/F 1484

ENS210 1987 478 380 420 520 710 1500 1797

TECHNICAL SPECIFICATIONS

10

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

EVERFLO STAINLESS UV DIRECT

EVERFLO STAINLESS UV INDIRECT

25.0˚

40.0˚

45.0˚

35.0˚

15.0˚

40.0˚

45.0˚

15.0˚

B

A

120.00

“ F PTRV BOSS

1

2

D A B C G F D A B C G

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

22mm HOT

DRAW - OFF

22mm SECONDARY

RETURN (not always tted.

See table)

“ F PTRV BOSS

1

2

22mm COLD FEED WITH

DRY STAT POCKET

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

120.00

SECOND IMMERSION HEATER

(not always tted. See table)

30.0˚

50.0˚

50.0˚

10.0˚

15.0 0

25.0 0

30.0 0

45.0 0

160mm

195mm

FD

22mm HOT

DRAW - OFF

“ F PTRV BOSS

22mm SECONDARY

RETURN (not always tted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

1

2

SECOND IMMERSION

HEATER (not always tted.

See table)

CODE HEIGHT DIAMETER D F

ED90 718 550 N/F N/F

ED120 906 550 N/F 510

ED150 1093 550 N/F 610

ED180 1281 550 N/F 710

ED210 1469 550 1000 810

ED250 1719 550 1250 950

ED300 2032 550 1500 1100

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

22mm SECONDARY

RETURN (not always tted.

See table)

22mm HOT

DRAW - OFF

“ F PTRV BOSS

1

2

DRY STAT

POCKET

SECOND IMMERSION HEATER

(not always tted. See table)

F E D C B A

40.0 0

45.0 0

15.0 0

25.0 0

35.0 0

50.0 0

10.0 0

CODE HEIGHT DIAMETER A B C D E F

EN90 718 550 290 330 390 345 N/F N/F

EN120 906 550 290 330 390 345 N/F N/F

EN150 1093 550 330 370 465 385 N/F N/F

EN180 1281 550 330 370 465 385 N/F N/F

EN210 1469 550 365 405 465 465 N/F 1150

EN250 1719 550 365 405 465 560 950 1400

EN300 2032 550 365 405 465 660 1100 1600

All Dimensions are in mm and

are of the cased unit.

N/F = not tted.

TECHNICAL SPECIFICATIONS

11 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

TECHNICAL SPECIFICATIONS

EVERFLO STAINLESS UV

SOLAR DIRECT

AB GCDEF

22mm HOT DRAW-OFF

22mm COLD FEED

WITH DIP PIPE

TO DEFLECTOR

IN BOTTOM

OF CYLINDER

“

F PTRV BOSS

1

2

DRY STAT

POCKET

25.0015.00

40.0045.00

35.00

22mm SECONDARY

RETURN (not always fitted.

See table)

AB GCDEF

22mm HOT DRAW-OFF

22mm COLD FEED

WITH DIP PIPE

TO DEFLECTOR

IN BOTTOM

OF CYLINDER

“

F PTRV BOSS

1

2

DRY STAT

POCKET

25.0015.00

40.0045.00

35.00

22mm SECONDARY

RETURN (not always fitted.

See table)

CODE HEIGHT DIAMETER A B C D E F G

ESD150 1093 550 290 345 390 610 N/F 892 390

ESD180 1281 550 290 345 445 710 N/F 1080 390

ESD210 1469 550 365 420 500 810 1150 1268 465

ESD250 1719 550 365 420 670 1045 1400 1519 465

ESD300 2032 550 365 420 670 1100 1600 1831 465

12

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

TECHNICAL SPECIFICATIONS

EVERFLO STAINLESS UV

SOLAR INDIRECT

All Dimensions are in mm and

are of the cased unit.

N/F = not tted.

25.0 015.0 0

40.0 045.0 0

35.0 0

DRY STAT

POCKET

DRY STAT

POCKET

22mm COLD

FEED WITH DIP PIPE

TO DEFLECTOR IN

BOTTOM OF CYLINDER

22mm SECONDARY RETURN

(not always tted. See table)

½” F PTRV BOSS

22mm HOT DRAW-OFF

EF D C B A G H

50.0 00

45.0

CODE HEIGHT DIAMETER A B C D E F G H

ET150 1093 550 290 345 642 697 N/F 892 390 693

ET180 1281 550 290 345 674 729 N/F 1080 390 725

ET210 1469 550 365 420 779 834 1150 1268 465 830

ET250 1719 550 365 420 950 1005 1400 1518 465 1000

ET300 2032 550 365 420 979 1034 1600 1832 465 1030

13 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

EVERFLO SOLAR

UNVENTED

DIRECT SINGLE COIL CYLINDER

Detail for the installation of a Solar Unvented Direct cylinder.

GENERAL

When installing this product it is essential the overall installation

meets all current legislation including, in particular, the high limit

isolation requirements of Building Regulation G3. This document

is designed to assist in achieving that aim.

WATER

The potable water connection and tundish discharge connection

are to be connected in exactly the manner described in Pages 5 to

8 of this manual.

IMMERSION HEATERS

The standard issue immersion heaters are designed for domestic

usage where the lower heater is connected to a low rate o-peak

tari and the upper heater used for occasional top-up purposes.

Heaters of this nature are not designed to be permanently live.

Connect in accordance with instructions on page 6.

SOLAR CONNECTIONS

The ow and return from the solar heat source are to be

connected to the indirect coil. Either primary coil connection may

be utilised as the ow or return. The solar primary circuit must

have its own dedicated circulating pump, thermal and safety

controls which must be installed as per the solar manufacturers

instructions. The solar control system used must be of the solar

dierential control type and should be connected to the solar

sensor.

The solar sensor, supplied as part of the solar controls should be

inserts into Pocket B (page 11) and is held in-situ with the black

sensor pocket retaining bung provided.

It is necessary to connect the solar pump via the over-temperature

high limit cut-out (provided) to ensure the heat input to the solar

coil is interupted if the cylinder over heats. Some method to

prevent thermosyphoning must also be employed. Non-return

check valves in the primary ow and return pipework would be

acceptable.

If solar controls do not oer appropriate isolation a 2 port zone

valve (not supplied) can be used with the pump and high limit stat

as shown on pages 13 and 14.

INDIRECT TWIN COIL CYLINDER

UPPER COIL

The upper coil is connected to the fossil fuel boiler as per the

instructions for the EVERFLO STAINLESS UV Unvented Indirect

single coil model with the dual stat control and high limit

thermostat inserted into pocket D (diagram page 12). The wiring

requirements are as depicted on page 14.

LOWER COIL: SOLAR INSTALLATION

The ow and return from the solar heat source are to be

connected to the indirect coil. Either primary coil connection may

be utilised as the ow or return. The solar primary circuit must

have its own dedicated circulating pump, thermal and safety

controls which must be installed as per the solar manufacturers

instructions. The solar control system used must be of the solar

dierential control type and should be connected to the solar

sensor.

The solar sensor, supplied as part of the solar controls should

be inserts into Pocket B and is held in-situ with the black sensor

pocket retaining bung provided.

It is necessary to connect the solar pump via the over-temperature

high limit cut-out (provided) to ensure the heat input to the solar

coil is interrupted if the cylinder overheats. Some method to

prevent thermosyphoning must also be employed. Non-return

check valves in the primary ow and return pipework would be

acceptable. If solar controls do not oer appropriate isolation a

2 port zone valve (not supplied) can be used with the pump and

high limit stat as shown on page 14.

NOTE: If it is intended to t a cylinder with a solar coil to be used at

a later date, the 2 coils should be connected in series to make use

of the solar coil, using the dual stat in Pocket D

The Domestic Heating Compliance Guide document L1A and

L1B provides excellent advice in sizing both cylinder designated

solar areas and heat exchangers to the surface area of the solar

collectors. Using this guide Range are able to oer sizing advice

for specication.

NB: The total detail of compliance guide document should be

consulted prior to specifying product or commencing design.

14

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

SOLAR HIGH LIMIT CONTROL

These schematic wiring

diagrams depict an IMIT high

limit control stat and the

connections are numbered

accordingly. Where an

alternative is supplied , such as

the solar dierential controller,

connect as per manufacturer’s

instructions.

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

B

LG O

B

R

G

Y

ZONE VALVE

L

N

PUMP

E

3

2

E C 1 2

HIGH LIMIT CONTROL

Maints supply

double pole

fused spur

230/220 3amp L

N

E

E C 1 2

HIGH LIMIT CONTROL

Maints supply

double pole

fused spur

230/220 3amp L

N

E

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

B

LG O

B

R

G

Y

ZONE VALVE

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

B

LG O

B

R

G

Y

ZONE VALVE

L

N

PUMP

E

3

2

E C 1 2

HIGH LIMIT CONTROL

Maints supply

double pole

fused spur

230/220 3amp L

N

E

E C 1 2

HIGH LIMIT CONTROL

Maints supply

double pole

fused spur

230/220 3amp L

N

E

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

B

LG O

B

R

G

Y

ZONE VALVE

TYPICAL SCHEMATIC WIRING DIAGRAMS

15 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

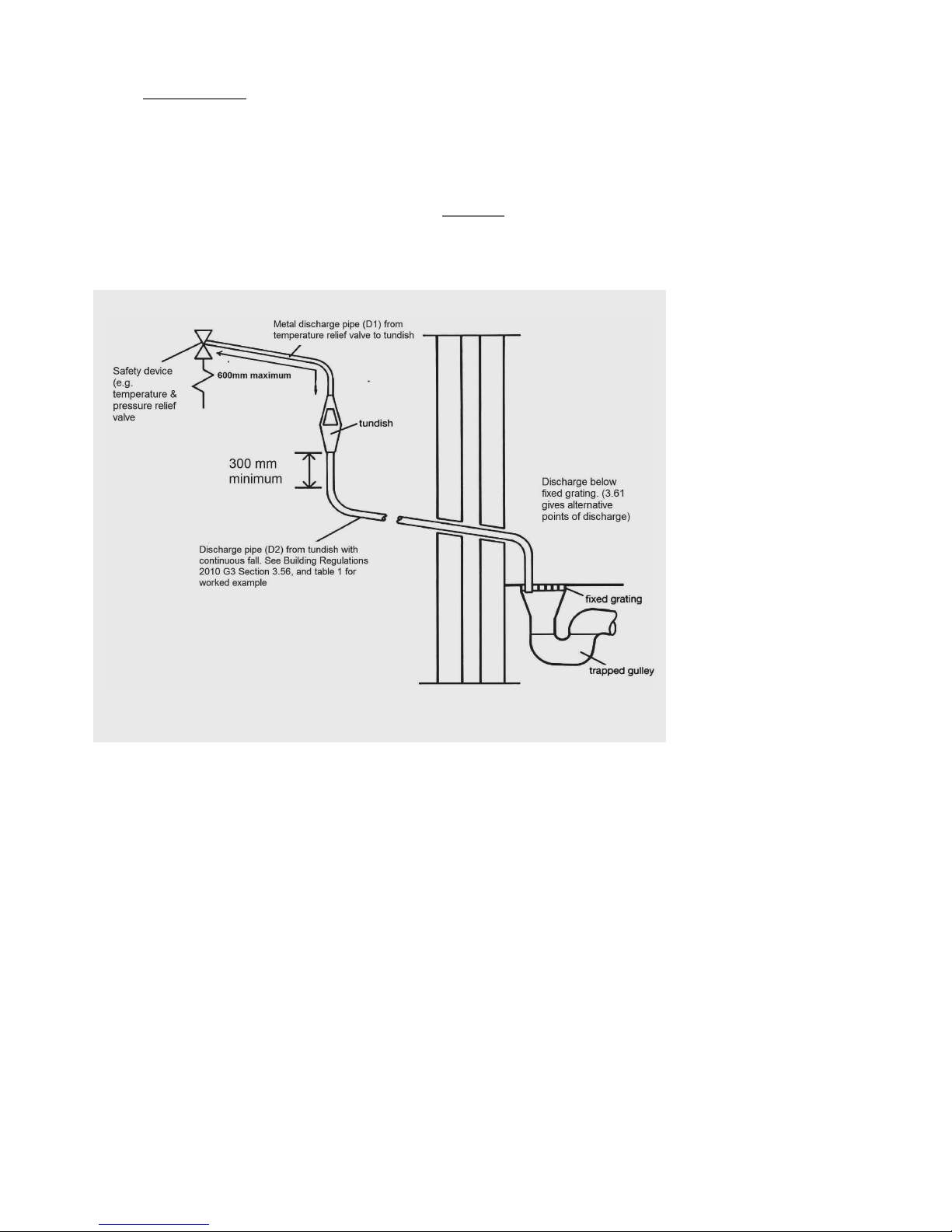

TYPICAL SCHEMATIC WIRING DIAGRAMS

The diagrams shown relate to the components listed. Other

components and other manufacturers’ components may vary in

their wiring requirements, particularly thermostats. Always refer

to manufacturers’ instructions which may override the detail in

order to function correctly.

VARIANT DUAL THERMOSTAT WIRING

WIRING DIAGRAM 2 x TWO PORT ZONE VALVES (S-PLAN)

WIRING DIAGRAM 2 PORT ZONE VALVE (S-PLAN)

VARIANT DUAL THERMOSTAT WIRING

2 PORT (HTG)

Br G BI O G

Y

123 3

2

1

DUAL STAT 2 PORT (DHW)

C2 C 21Br G Bl O G

Y

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

WIRING CENTRE

3

L

N

2

L N

1 2 3 4 L N E 4 5 6 1 2 3 4

2

5A SUPPLY

ROOM STAT PROGRAMMER BOILER

PUMP

16

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

TYPICAL SCHEMATIC WIRING DIAGRAMS

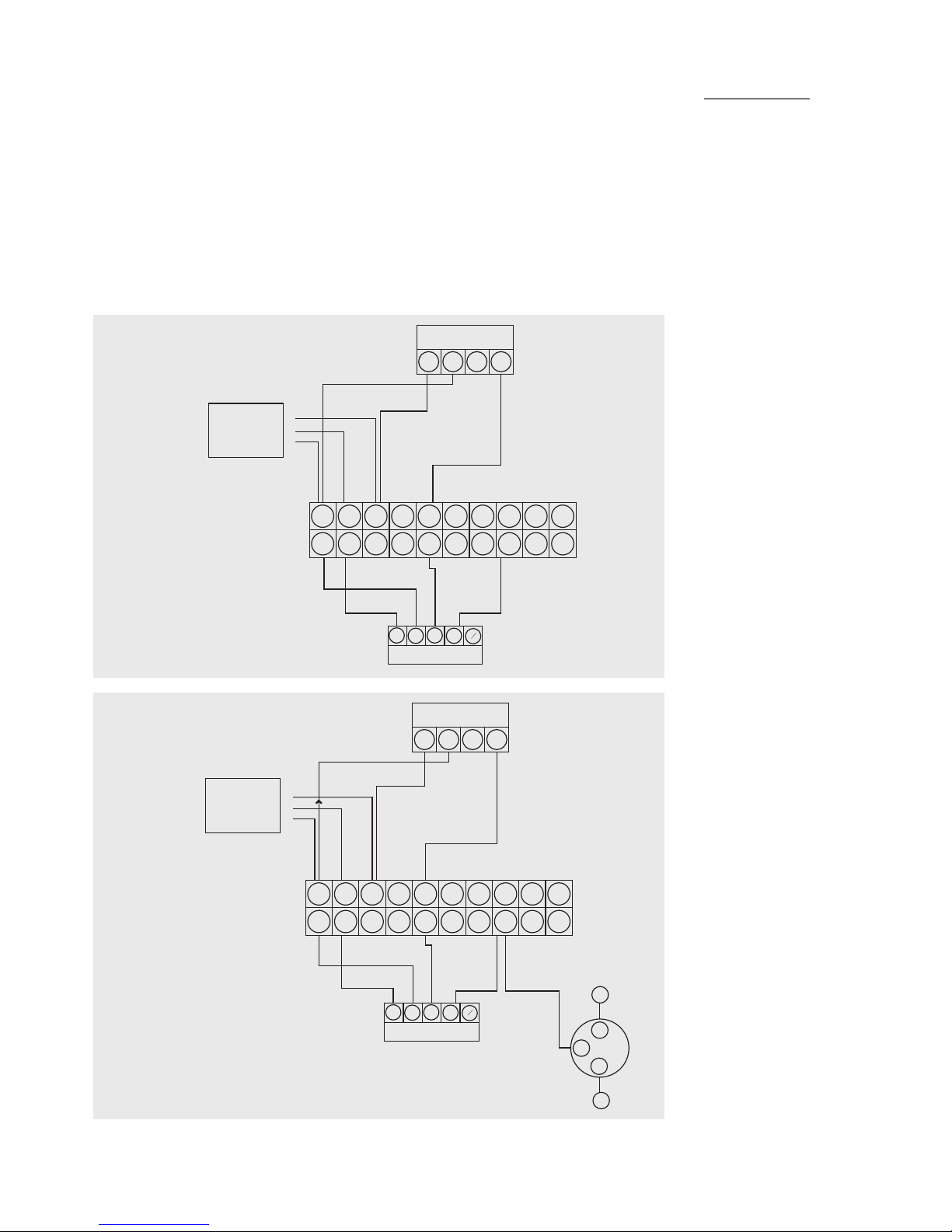

WIRING DIAGRAM THREE PORT MID POSITION VALVE (Y-PLAN) +

TWO PORT VALVE

VARIANT DUAL THERMOSTAT WIRING

WIRING DIAGRAM 3 PORT MID POSITION (Y-PLAN) +2 PORT VALVE

WIRING DIAGRAM 3 PORT MID POSITION (Y-PLAN) + 2 PORT VALVE

VARIANT DUAL THERMOSTAT WIRING

3 PORT (HTG)

WG BI O G

Y

723 3

2

1

DUAL STAT 2 PORT (DHW)

C2 C 21Br G Bl O G

Y

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

WIRING CENTRE

3

L

N

2

L N

1 2 3 4 L N E 4 5 6 1 2 3 4

2

5A SUPPLY

ROOM STAT PROGRAMMER BOILER

PUMP

17 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

SINGLE ZONE HEATING

TWIN ZONE HEATING

Connect power supply as per instruction manual. TP9000 terminals 5 & 6 can be used for remote sensor connection.

Connect power supply as per instruction manual. TP9000 terminals 5 & 6 can be used for remote sensor connection.

TYPICAL SCHEMATIC WIRING DIAGRAMS

PLUMBED CYLINDER

18

EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

CONNECTED TO BOILER WITH PUMP OVER-RUN FACILITY

E N L 1 2 3

TP5000

E N L 3 4 5

TP9000

0W Y G/Y

Green Plug

B1 G/Y

Br

L N E SLB LP

Boilder with over run

BL BR GR OR

Red Plug - Heating 1

BL BR GR OR

Yellow Plug - Heating 2

B1 Br Gr Or

Blue Plug - Water

Wiring Diagram for Twin Zone Heating and Hot Water

TP9000 + TP5000 to system using boilder to control pump

1 2 3 4 5 6 7 8 9 10 11 12

Pump

INSTRUCTION FOR CONNECTION TO A BOILER WITH PUMP OVER

RUN FACILITY SUCH AS IDEAL LOGIC HEAT

1.Disconnect brown pre-wire pump ex from position 10

2.Reconnect brown pre-wire pump ex to position 12

3.Connect 5 core cable between boiler and wiring control centre

to following positions

WIRING CENTRE BOILER

TERMINAL 1 PERMANENT LIVE L

TERMINAL 3 PERMANENT NEUTRAL N

TERMINAL 5 PERMANENT EARTH E

TERMINAL 10 SWITCHED LIVE TO BOILER SL B

TERMINAL 12 SWITCH LIVE TO PUMP L P

19 EVERFLO STAINLESS UV

UNVENTED HOT WATER CYLINDERS

PRE-PLUMBED

CYLINDER INSTALLATION

COLD MAINS PIPEWORK

Run the cold main through the building to the place where the

EVERFLO STAINLESS UV PRE-PLUMB unit is to be installed. Take

care not to run the cold pipe near hot water or heating pipework

so that the heat pick-up is minimized. Identify the cold water

supply pipe and t an isolating valve (not supplied). A 22mm

BS1010 stopcock can typically be used but a 22mm quarter turn

full bore valve would be better as it does not restrict the ow as

much. Do not use “screwdriver slot” or similar valves. Make the

connection to the inlet control set (Position 2). Ensure that the

arrow points in the direction of the water ow. Select a suitable

position for the expansion vessel. Mount it to the wall using the

bracket provided. Connect the expansion vessel to the cold feed

pipework between the inlet control set and the cold inlet. Ensure

that the top of the vessel is accessible for servicing.

CONNECTING TO THE CYLINDER

All of the pipework connections on the cylinder are 22mm

compression and supplied complete with gland nuts and olives, in

the Accessory Kit box. Only connect 22mm Table X copper tube to

these connections. Cut the tube with a pipe cutter and ensure no

sharp edges or burrs protrude. Slide both gland nut and olive onto

the tube and push tube fully home into the connection, ensuring

the tube end fully bottoms on the connection recess. Smear the

outer wall of the olive with plumbing paste and tighten gland nut

in the prescribed manner. Upon lling/commissioning, ensure all

connections are completely watertight.

BALANCED COLD CONNECTION

If there are to be showers, bidets or monobloc taps in the

installation then a balanced cold supply is necessary. There is a

22mm balanced connection on the inlet set.

HOT WATER PIPEWORK

Connect to HWDO (Position 1 on diagram). Run the rst part of the

hot water distribution pipework in 22mm. This can be reduced to

15mm and 10mm as appropriate for the type of tap etc. Your aim

should be to reduce the volume of the hot draw-o pipework to

a practical minimum so that the time taken for the hot water is as

quick as possible. Where monobloc mixing taps and showers are

used, these should be installed to comply with the Water Supply

(Water Fittings) Regulations 1999. If these devices are supplied

with un-balanced supplies there should be single check valves

installed at both inlets, to stop over pressurising of either supply.

CONNECTIONS FOR INDIRECT UNITS

Connect to the boiler ow and return (Positions 19 & 14) lines.

An additional expansion vessel and safety valve is supplied. The

boiler may be Gas, Electric or Oil but must be under eective

thermostatic control. Uncontrolled heat sources such as some

AGA’s, back boilers, solid fuel stoves, etc. are NOT SUITABLE.

Please contact our Technical department for guidance. Connect

to (Position 9 & 13) for the radiator circuits. Twin zone heating unit

are supplied with 2 port zone valves in positions 9a and 9b.

CONNECTIONS FOR SOLAR COILS

Connect to the solar coil as detailed on page 13 ensure the solar

pump is connected via the over temperature cut out as described

on page 13.

SECONDARY CIRCULATION

EVERFLO cylinder can be used with secondary circulation. An

appropriate WRAS approved bronze circulator should be used in

conjunction with a non-return valve to prevent backow. On large

secondary circulation systems it may be necessary to incorporate

an extra expansion vessel into the circuit to accommodate the

increased system water volume. A secondary return boss is tted

as standard on 210, 250 & 300 ltr units (Position 17). On smaller

sizes, tee into the cold feed pipe above the drain.

IMMERSION HEATERS

Only immersion heaters with a thermal cutout may be used. To

help ensure this, the immersion heaters have a special 1¾” thread.

They are rated at 3 kW at 240 V and are of a low noise Incoloy

construction. They have both a thermostat and a high limit cutout.

Please order the correct replacement via ourselves; tting non-

approved immersions may aect your guarantee. When tting,

ensure the ‘O’ ring is positioned correctly on the head of the

immersion heater and lubricate before tting. Fit it by hand until

almost home then tighten gently as the ‘O’ rings will seal easily.

The electrical supply to each immersion heater must be fused at

13A via a double pole isolating switch to BS 3456. The cable must

be 2.5mm2 heat resistant (85°C HOFR) sheathed ex complying

to BS 6141:1981 Table 8. Do not operate the immersion heater/s

until the unit is full of water. Do not operate the immersion

heater/s if any sterilisation liquid is in the cylinder as this will cause

premature failure.

ELECTRICAL CONNECTIONS

Complete the wiring – use the appropriate wiring diagrams on

pages 17 & 18.

COMMISSIONING

Carry out commissioning as per instructions on page 21 and in line

with boiler manufacturer’s instructions for the heating and the

primary circuit. Primary pipework must be lled, bled and tested

in accordance with the boiler manufacturer’s instructions, to avoid

damage to the circulation pump.

This manual suits for next models

5

Table of contents

Popular Water Dispenser manuals by other brands

Vivreau

Vivreau V3-201 owner's manual

gledhill

gledhill PulsaCoil PCS 120 Design, installation & servicing instructions

Judo

Judo i-soft Installation and operating instructions

Smith Water

Smith Water 700 Owner's manual and installation guide

Whirlpool

Whirlpool W10295370 installation instructions

SMC Networks

SMC Networks HAW7 Operation manual