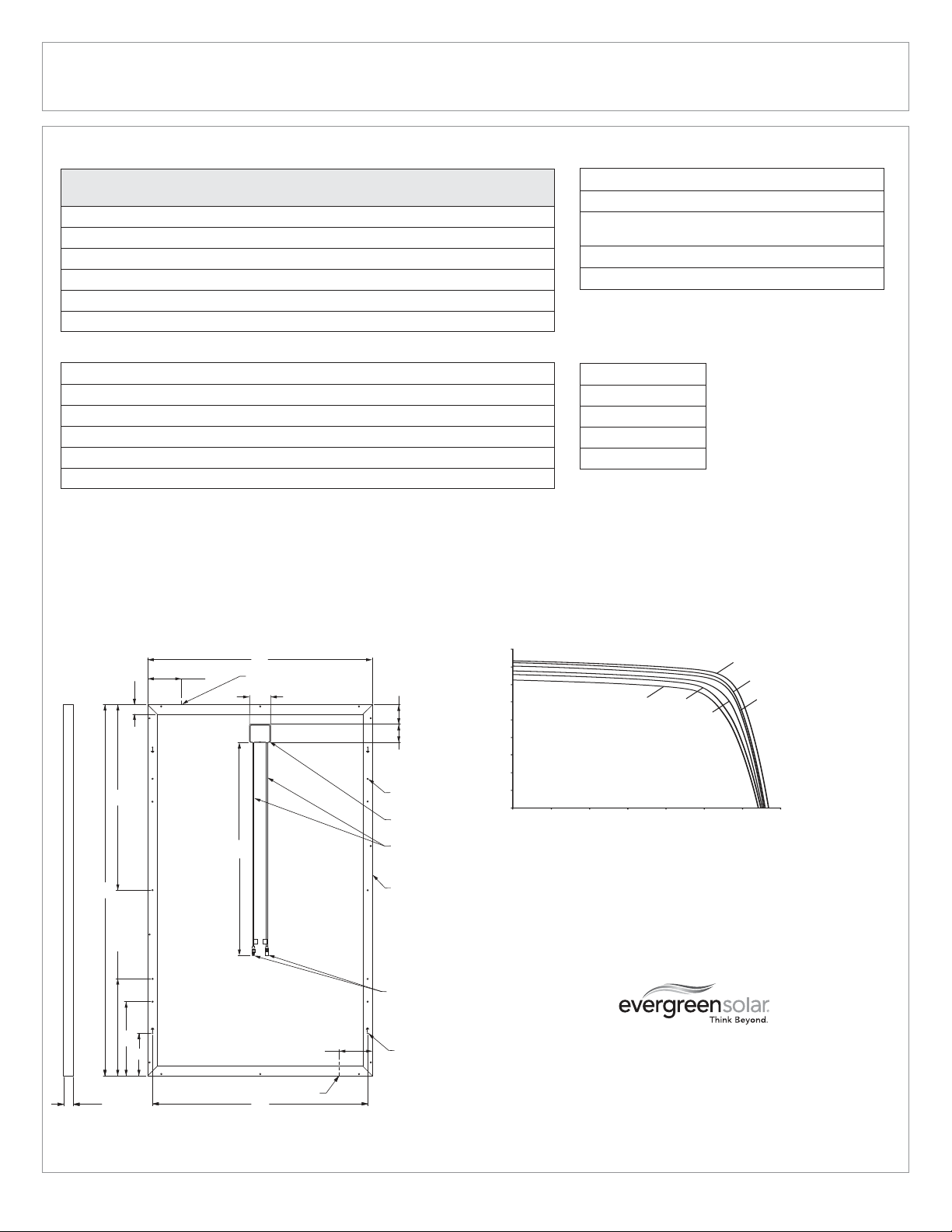

evergreensolar ES Series Setup guide

This manual suits for next models

6

Other evergreensolar Solar Panel manuals

evergreensolar

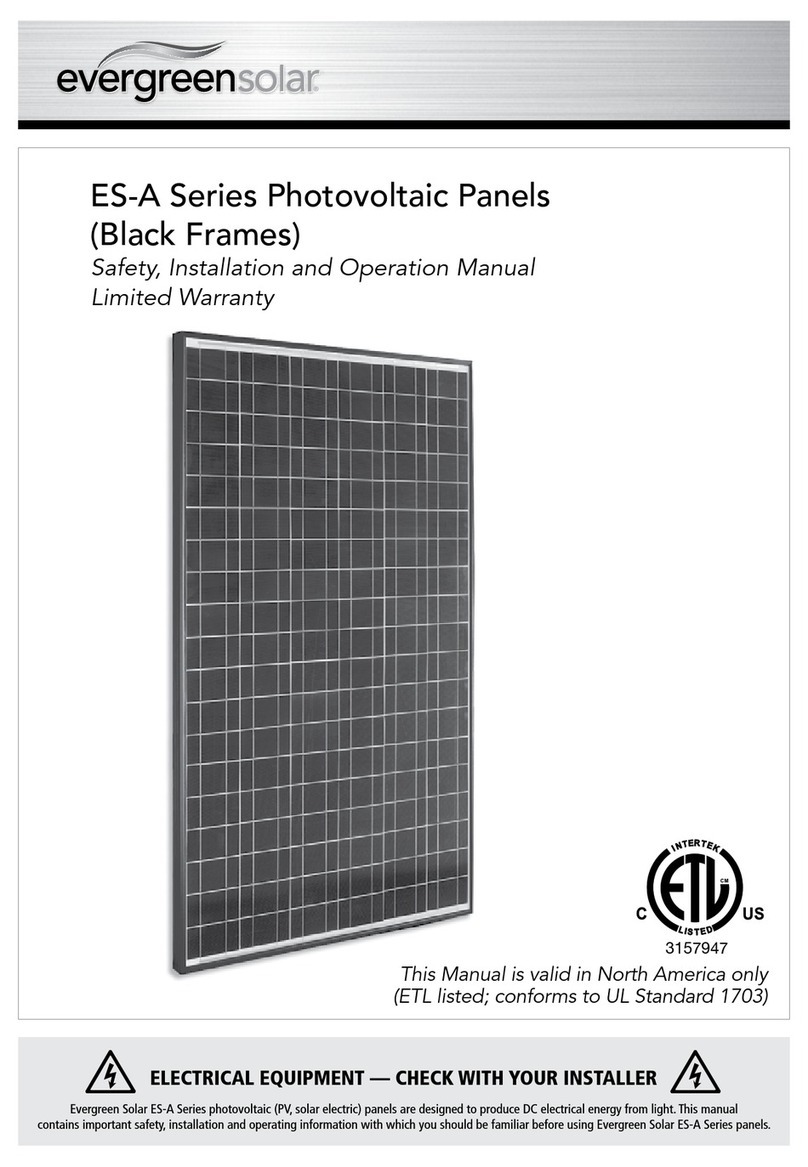

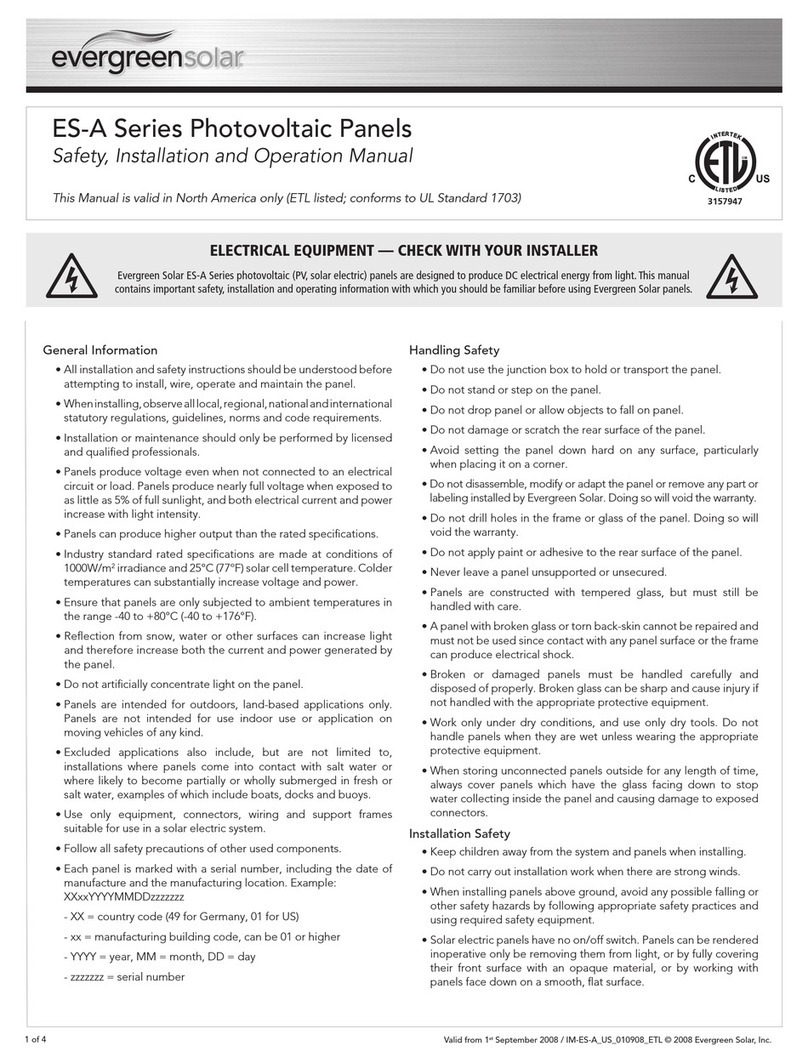

evergreensolar ES-A Series Setup guide

evergreensolar

evergreensolar ES-A Series Setup guide

evergreensolar

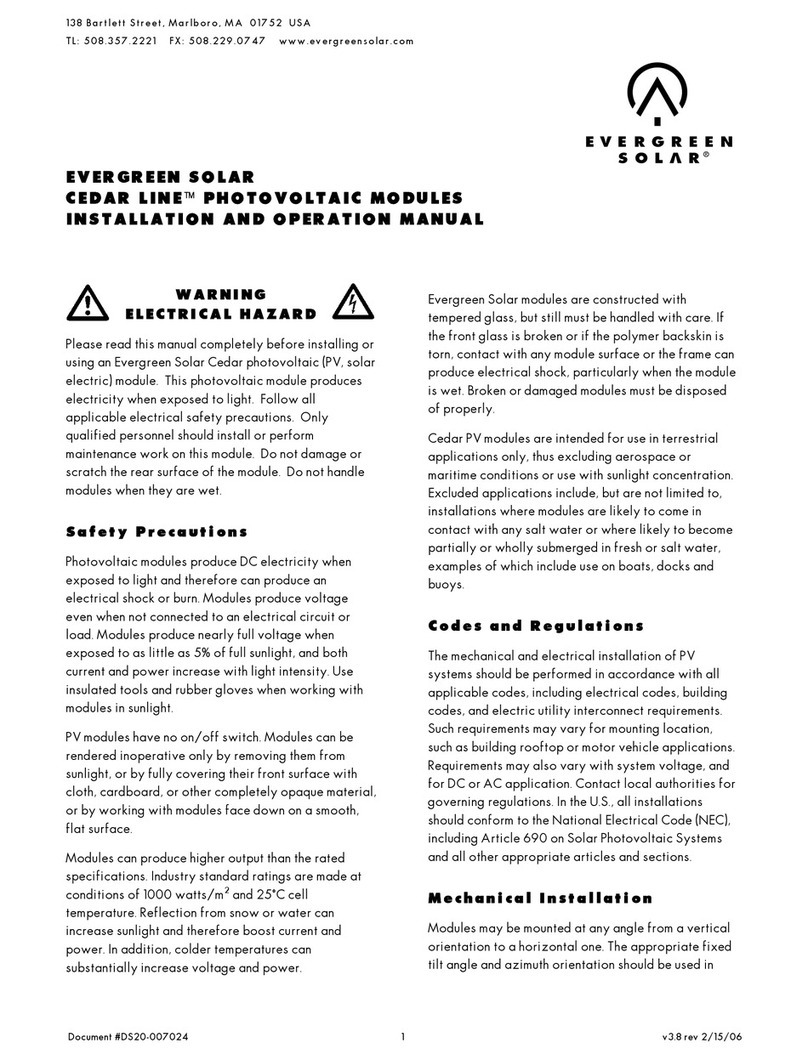

evergreensolar Cedar Line User manual

evergreensolar

evergreensolar SPRUCE LINE ES-170-RL User manual

evergreensolar

evergreensolar ES-A Series Setup guide

evergreensolar

evergreensolar ES-A Series Installation instructions manual

evergreensolar

evergreensolar ES-C-70-fa5 Setup guide

evergreensolar

evergreensolar ES-C-70-fa5 Setup guide

evergreensolar

evergreensolar ES-A-190 Setup guide

Popular Solar Panel manuals by other brands

PV-ezRack

PV-ezRack SolarRoof Pro 2.0 Code-Compliant Planning and Installation Guide

General Solar Systems

General Solar Systems GK5-AL manual

Nature Power

Nature Power 56801 instruction manual

Phaesun

Phaesun Sun Peak SPR Series Safety and installation manual

GAF

GAF DecoTech RI 2000 installation instructions

Goodwe

Goodwe GALAXY Series installation manual

Mission Solar Energy

Mission Solar Energy PERC Series Installation and user manual

Novalynx

Novalynx 320 Series user manual

Ghost Controls

Ghost Controls AX30 instructions

Euro-Line Solar

Euro-Line Solar ApolloFLEX Mono instructions

Vaillant

Vaillant auroTHERM exclusive VTK SERIES installation manual

rollease acmeda

rollease acmeda AUTOMATE Series instructions