Everidge PrepRite PVS27-6-1 Maintenance manual

1

Tabletop Vacuum Sealing Machine

Operation and Care and

Maintenance Manual

For

PVS27-6-1

PVS32-8-1

PVS32G-8-1

PVS42-12-1

PVS42G-12-2

PVS42GP-12-1

PVS52-25-1

PVS52-25-2

PVS52G-25-2

This appliance is for commercial use only

2

To avoid electrical shock, this appliance MUST be adequately grounded in accordance

with local electrical codes or, in the absence of local codes, with the current edition of

the national Electrical Code ANSI/ NFPA no. 70. In Canada, all electrical connections

are to be made in accordance with CSA C22.1, Canadian Electrical Code Part 1 or local

codes.

Warning!

This appliance is intended for use in commercial establishments where all operators are

familiar with the purpose, limitations, and associated hazards of this appliance.

Operating instructions and warnings must be read and understood by all operators and

users.

1. This appliance must be installed on a stable and level surface.

2. DO NOT install this appliance in any area where it may be affected by any adverse

conditions such as steam, grease, dripping water, high temperatures, etc.

3. DO NOT store or use any flammable liquids or allow flammable vapors in the vicinity

of this appliance or any other appliance.

4. This appliance must be kept free and clear of any combustible materials.

5. This appliance must be kept free and clear of any obstructions blocking access for

maintenance or service.

The sealing bar may reach high temperatures during and after the usage process.

It is recommended to watch out and avoid direct contact until the cooling process

is over.

This machine is designed to be only used indoors

3

These appliances are heavier than they look and should be moved with proper

equipment and personnel.

To reduce the risk of electric shock and injury to persons, unplug from the power

supply before servicing.

This appliance must service by qualified service personnel. Failure to properly

maintain and service to this appliance can and will cause injury or even death.

This appliance has parts that can cause pinching and injury, please ensure that fingers

are kept away from these areas and proper attire is worn.

4

CHAPTER 1

Operation and Care Manual

The operation and care manual is a document

issued by the manufacturing company and is an

integral part of the machine. This document is

adequately identified for easy tracing and/or

subsequent references.

All rights relating to the reproduction and

disclosure of the information contained in this

handbook and the documentation quoted and/or

attached are reserved. This handbook contains

the information necessary for the customer and

assigned personnel, to ensure the correct

installation, use and maintenance of the

appliance allowing it to be used safely.

Safety precautions and

Manufacturer’s liabilities.

Every operations related to the intended use of

this appliance and its overall life cycle has been

carefully and thoroughly analysed by the

manufacturing company during the design

phase, construction phase and the writing of the

operation and care manual.

It is nevertheless understood that experience,

proper training and “common sense” of the

personnel operating this appliance are of the

utmost importance. It is the responsibility of the

operator to observe all safety precautions as

outlined in this manual and to operate this

appliance accordingly.

The non-observance of the safety precautions or

specific warnings indicated in this manual, the

use of this appliance by unauthorized personnel,

violation of all safety standards regarding the

design, construction, and intended use of the

machine, will relieve the manufacturer from all

liability in the case of damage to personnel or

property.

The manufacturing company is therefore in no

way responsible for the non-observance on the

part of the user of the safety precautions listed

in this manual.

Regulatory references

The following manual CONFORMS TO

ANSI/UL Std. 963 –CERT. TO CAN/CSA

Std.C22.2 No. 68 –CONFORMS TO NSF 169

Disposal of this appliance after its

useful life.

Electric and electronic appliances contain

dangerous substances that may have potentially

harmful effects for people and the environment.

It is recommended to dispose of it properly, DO

NOT DISPOSE OF ELECTRICAL OR

ELECTRONIC EQUIPMENT WITH OTHER

MUNICIPAL WASTE.

CHAPTER 2

How to use the Operation and

Care Manual

This document is an integral part of the machine.

Preserve a copy of this operation manual for the

entire working life of the appliance even if

transferred or sold. Additional copies can be

obtained from the manufacturer.

To maintain the operation and care manual in

good condition:

1. Use the operation and care manual carefully

so as to not to damage its contents. In

particular, do not leave the operation and

care manual around after use and return it to

its proper place immediately after

consultation.

2. Do not remove, rip out or rewrite parts of the

operation and care manual. Any changes to

this manual are to be issued by the

manufacturer.

3. Keep the operation and care manual in a safe

place, away from environmental elements

which could damage it.

5

CHAPTER 3

WARRANTY

PrepRite Inc. warrants to the original

purchaser only that any original part that is

found to be defective in material or

workmanship will, at ThermalRite’s option,

subject to provisions hereinafter stated, be

replaced with anew or rebuilt part. For all

other original parts, twelve (12) months from

the date of shipment of appliance. The labor

warranty period is twelve (12) months from

the shipping date. PrepRite will bear

normal labor charges performed during

standard business hours, excluding

overtime, holiday rates or any additional

fees. To be valid, a warranty claim must be

filed during the applicable warranty period.

This warranty is not transferable.

1. All machine components normally

subject to wear and are considered

consumables are not included in the

warranty: Teflon sealing bars, rubber

gaskets , chamber opening pistons,

sealing gaskets ,air filters , oil filters ,

oil changes, pump blades.

2. If the vacuum pump of an appliance

is replaced under warranty because of

aspiration problems, the

manufacturer has the right to inspect

whether any foreign bodies have

been aspirated (liquids, solids,

sauces, etc.). If this is the case, the

repair (part and labor) will not be

covered, since the problem is not due

to manufacturing defects, but to

customer negligence during use.

3. Possible conditions causing electronic

controls to fail include incorrect

electrical supply, environmental

elements, storms, lightning, water

damage, could cause damages which

cannot be attributed to the

manufacturing company and to the

manufacture of the product itself.

4. During the warranty period, for any

defect in workmanship and material,

all parts and labor will be covered. All

warranty claims must be submitted to

and conform by all statements and

policies of the OneSolutionSupport

service.

5. During the warranty period, we will

pay, not to exceed, one (1) hour

travel and fifty (50) miles travel. All

warranty service will be performed by

an authorized service center certified

by the manufacturer. All parts

replaced under warranty must be

returned to the manufacturer for

inspection before any warranty is

paid.

6. Any components considered defective

(pump, electronic control, etc.) and is

determined to be caused by misuse or

abuse during the warranty period

will not be considered under

warranty. The end user will be

responsible for any repairs or parts for

repairs.

7. Equipment modified in any manner

from original model, substitution of

parts other than factory authorized

parts, removal of any parts including

legs, or addition of any parts.

8. Any losses or damage resulting from

malfunction, including loss of product,

food product, revenue, or

consequential or incidental damages

of any kind.

9. Equipment damage caused by

accident, shipping, improper

installation or alteration.

10.This warranty is exclusive and is in

lieu of all other warranties, express or

implied, including the implied

warranties of merchantability and

fitness for a particular purpose. In no

event shall PrepRite be liable for

loss of use, loss of revenue or profit,

or loss of product, or for any indirect,

special, incidental, or consequential

damages. No person except an officer

of PrepRite Inc. is authorized to

modify this warranty or to incur on

behalf of PrepRite any other

obligation or liability in connection

with PrepRite equipment.

6

End User obligations

The end user must immediately inform the

manufacturer of any safety system defect and/or

any malfunction he or she is aware of.

It is strictly forbidden for the end user and/or any

third parties (excluding duly authorized service

personnel of the manufacturer) to make

modifications of any kind to the appliance, its

functions or to this technical publication. In case

of malfunctions or defects due to the non-

observance of the above, the manufacturing

company cannot be held responsible for the

consequences.

CHAPTER 4

GENERAL SAFETY PRECAUTIONS

1. Never touch the metal parts of the machine

with wet or damp hands;

2. Do not pull on the cord to disconnect the plug

from the current outlet.

3. Unqualified or untrained personnel are not

allowed to use the machine without

supervision.

4. Electrical safety of the machine is ensured by

a properly grounded electrical circuit, which

consists of a grounded cord and cord cap and

a correct electrical outlet.

5. The use of an extension cord is not allowed

and may result in injury or death.

6. In the event of damage to the cord, the end

user of the appliance must not attempt to

replace the part. This must be performed by

a qualified service personnel.

7. Always switch off and disconnect the

appliance from the power supply before

beginning any general cleaning or

maintenance operation.

8. Clean appliance coating, panels and controls

using soft and dry cloths, or cloths slightly

soaked in mild detergent solution.

CHAPTER 5

INSTALLATION

Carefully remove the appliance from the carton

or crate. Note: Do not discard the carton and

other packaging material until you have

inspected the unit for hidden damage and tested

it for proper operation.

Location

To ensure proper operation of this appliance and

its components, this appliance must be installed

on a stable and level surface, away from high

humidity items and excessive heat producing

equipment.

DO NOT store or use any flammable liquids

or allow flammable vapors in the vicinity of

this appliance or any other appliance.

DO NOT install this appliance in any area

where it may be affected by any adverse

conditions such as steam, grease, dripping

water, high temperatures, etc.

Disconnect the appliance from power

before performing any service or

maintenance operation which may require

parts.

Before connecting the vacuum packaging

machine, make sure that the voltage

listed on the UL data plate corresponds

with the voltage supplied to the

appliance.

7

Controls and inspections

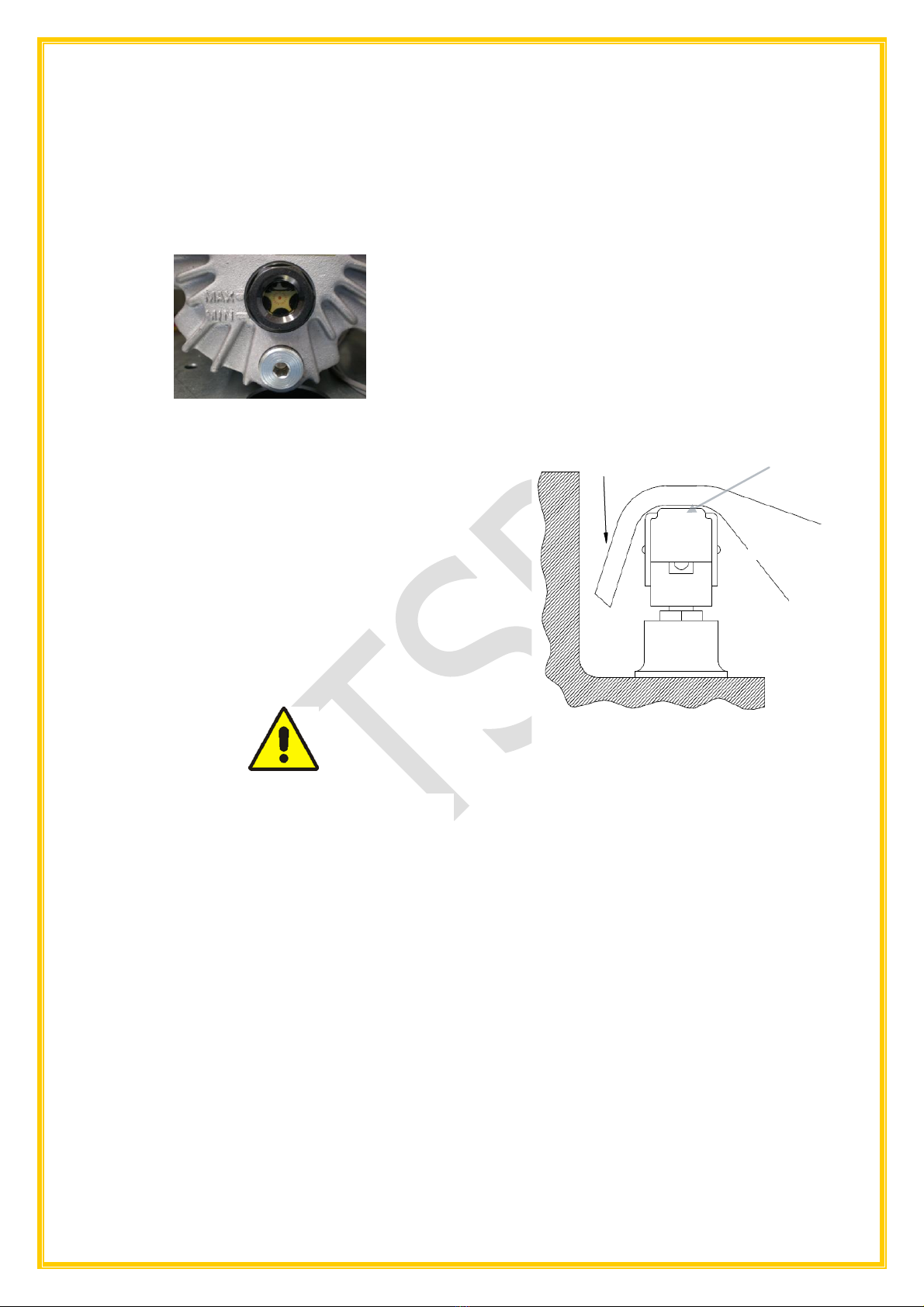

Before starting the appliance, check the oil level

through the sight glass located on the

motor/pump.

(Fig. 5.1). In order to access the pump, unscrew

the back panel of the appliance and remove it.

(Fig. 5.1.) Pump oil level indicators

After checking the oil level and ensuring it is level

with the maximum oil level indicator, reinstall the

back panel and secure it with the screws you

removed. Connect the plug to the proper outlet.

If it is not the correct outlet, the outlet must be

replaced with the correct one by a qualified

electrician, as well as ensuring the fuse or

breaker is the correct current capacity for the

draw of the appliance. Do not use adapters,

multiple outlets and/or extension cords.

Do not plug in multiple appliances on the same

outlet that may exceed current capacity of the

outlet.

This appliance must be grounded properly.

If the ground prong is broken, do not use

the appliance until it has been repaired or

serious injury or death may occur.

CHAPTER 6

USING THE VACUUM SEALER

Vacuum packaging

1. Plug in the grounded plug to the correct

outlet.

2. First turn on the main power switch on the

front of the appliance. Next press the

ON/OFF button on the control and the LCD

display should light up.

3. Set the vacuum time (or percentage)

required, the sealing time and the gas

injection time (if the appliance is equipped

with this option.).

4. Position the bag (or bags) with product in

the chamber, the polyethylene shelves can

be used inside the vacuum chamber to level

the product with the sealing bar and position

the bag opening flat on the sealing bar. The

polyethylene shelves can be removed

depending on necessity. (Fig. 6.1).

5. Lower the clear bell-lid and press firmly on it

until it remains closed, thus permitting the

sealing cycle to begin.

6. The different cycle phases are automatic and

after a pre-set amount of time the clear bell-

lid opens thus enabling the product to be

removed and subsequent cycles to begin.

(Fig. 6.1) Correct bag placement in chamber

Vacuum-packaging with inert gas

injection OPTIONAL (ref. table 1)

1. Set the sealing cycle with inert gas injection

on the control panel by pre-selecting the

relative time.

2. Connect the hose coming from the gas

cylinder to the hose connection positioned

on the side/rear of the vacuum sealing

appliance by means of the relevant clamp,

then set the gas cylinder gauge at a

pressure value of 1 ATA.

3. Position the bag containing the product

inside the vacuum chamber, fitting the gas

distribution nozzle inside the bag opening

(Fig. 6.2); make sure that there are no folds

obstructing the gas flow.

Open end of bag

Sealing bag

Cross Section of Chamber

Sealing

Bar

8

(Fig. 6.2) Positioning of the bag with gas

option active.

Vacuum packaging of liquid or

semiliquid products

By using the vacuum sealing appliance of the

correct size, it is possible to vacuum package

liquid or semi-liquid products (soups, sauces,

etc.) thus increasing their shelf life, while

keeping the freshness and taste unaltered.

When doing so, never fill bags up more than

50% of capacity, making sure that the bag

opening is higher than the sealing bar (thus

removing the internal shelves)

1. Vacuum cycles are set as described in the

chapter Vacuum packaging.

2. The SOFT-VACUUM option allows the

packaging of liquid products.

3. All the vacuum packages can be stored in a

freezer or cooler.

Cleaning the appliance

Before cleaning the appliance,

disconnect the power.

During normal usage of the appliance, no

particular cleaning operation of the chamber

machine is required. After the end of each

sealing operation, the chamber should be wiped

out with a damp cloth. Should it be needed (i.e.

bags inner product pours out of the bag), it is

recommended to use a damp cloth and mild

detergent, rinsing thoroughly.

Gas Distribution

Nozzle

Sealing Bag

Cross Section Of Chamber

Sealing

Bar

9

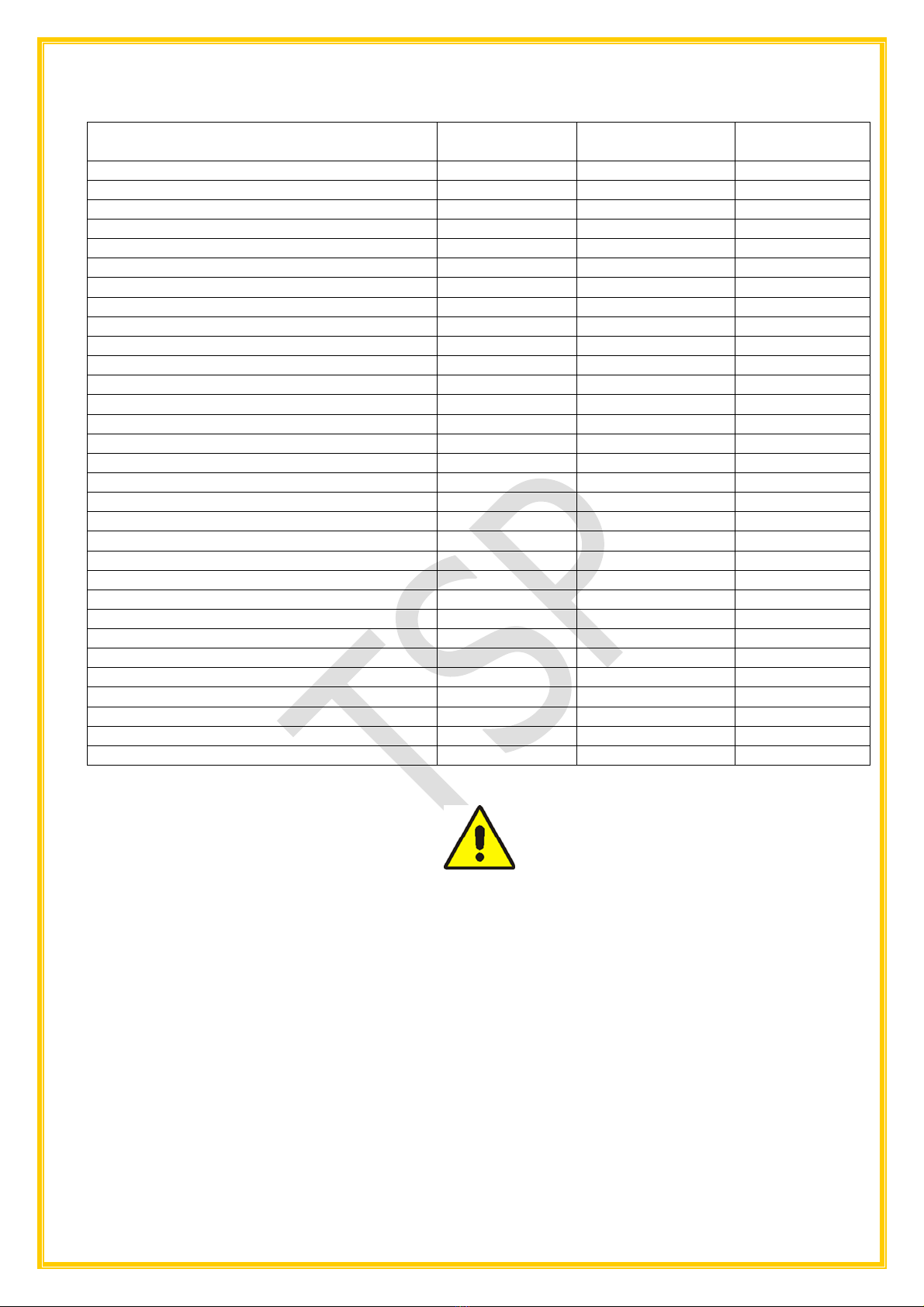

Table 1. EXAMPLES OF PACKAGING WITH INERT GAS INJECTION OPTION

PRODUCT

OXYGEN

% (O2)

CARBON DIOXYDE

% (CO2)

NITROGEN %

(N2)

Sliced salami

-

20

80

Roast meat

80

20

-

Biscuits and oven products

-

100

100

Coffee

-

100

100

Fresh meat

70/80

30/20

-/-

Dehydrated meat and spices

-

-

100

Minced meat

-

-

100

Chocolate

-

100

-

Fresh cheese / Mozzarella

-/-

20/-

80/100

Mature cheese / Cream / Butter /Margarine

-

-

100

Fresh salad / parsley

-

50

50

Yogurt / Puff pastry

-

100

-

Powdered milk

-

30

70

Baking powder

-

100

100

Apples

2

1

97

Sliced bacon

-

35

65

Sandwich loaf / Bread

-

100

-

French toast / Toasted bread

-

80

20

Pasta

-

-

100

Fresh pasta / tortellini / Lasagne

-

70/100

30

Potatoes / French fries / Snacks

-

0

100

Anchovies, sardines…

-

60

40

Fish

30

40

30

Pizza

-

30

70

Poultry

-

75

25

Tomatoes

4

4

92

Pre-cooked food

-

80

20

Sausages

-

20

80

Escalopes

70

20

10

Fruit juices

-

-

100

Wine / Oil

-

-

100

For the packaging of food with the inert gas injection option, make sure to use food

certified gases, not industrial gases.

10

CHAPTER 7

OPERATION

7.1 Control and LCD Display

Description.

To start a sealing cycle, push the main power

switch on (1). Next push the ON/OFF on the

display board (3). Next push the SET button (4)

to enter the program mode, vacuum, seal or gas

option, by using the +or –(5) to select which

mode you wish to use, push SET (4) to select

the program and +or –(5) to increase or

decrease the programs parameters. The cycle

starts when the clear chamber bell-lid is closed,

which will then activate the vacuum pump. VAC

will appear on the display together with the

countdown (in seconds) of vacuum time down to

0 (zero). Should the gas option be activated,

GAS will appear during the cycle, as it will be

injected inside the chamber. Next, sealing will

start as the SEAL appears on the display. At the

end of this process, the cooling of the sealing bar

starts, indicated by the COOLING on the

display. Finally, OPENING will appear on the

display and the clear chamber bell-lid will open

automatically.

NOTE: Should there be a need to interrupt the

cycle for any reason, press the ON/OFF button

(3) for 3 seconds. The appliance will

automatically allow air to enter the chamber and

allow the lid open.

During the normal vacuum cycle, press the

button PUMP GASTRO (6) for 3 seconds to

start heating the sealing bar for manual sealing.

7.1.1 Control and LCD Display 110V

1. Main Power Switch O-I

2. LCD display

3. ON/OFF: to switch on the Control and LCD

display.

4. SET: to enter the program mode (vacuum,

sealing and gas).

5. + or -: to select the desired program and to

increase or decrease the programs

parameters.

6. PUMP GASTRO: to activate the functions of

vacuum in GN trays, pump cleaning and

manual sealing.

7. Vacuum gauge

8. Printer (OPTIONAL)

9. Indicator Lite: indicates power supplied to

the printer and that the printer paper needs

replacing.

10. Button to scroll the printer paper.

7.1.2 Control and LCD Display

Descriptions (double sealing bar)

1. Main Power Switch

2. LCD Display

3. ON/OFF: to switch on the control and LCD

display.

4. Set: to enter the program mode (vacuum,

sealing and gas).

5. + or -: to select the desired program and to

increase or decrease the programs

parameters.

6. PUMP GASTRO: to activate the functions of

vacuum in GN trays, pump cleaning and

manual sealing.

7. Vacuum Gauge.

8. Printer (OPTONAL)).

9. Indicator Lite: indicates power supplied to

the printer and that the printer paper needs

replacing.

10. Button to scroll the printer paper

11. Sealing bar selector knob ( 1 or 2 bars)

11

7.1.3 User setting menu

To enter the user setting mode, first turn on the

main power switch and then push and hold both

the ON/OFF button and the SET button for 5

seconds. The display will show the following;

1. Language Setting (Lang)

Use +or –buttons to choose the desired

language: English, Italian, Spanish, German

and French.

Press the SET button to confirm the

selection and move to the next option.

2. Vacuum Mode Setting (Vac Type)

It is possible to select the percentage of

vacuum desired within the chamber or

length of time. By using the + or –buttons

to make the selection.

0: time in seconds

1: vacuum percentage

Press the SET button to confirm the

selection and move to the next option.

3. Display Setting (Display)

It is possible to set the display mode

(PRINTER OPTION). By using the +or –

buttons to make the selection.

0: fixed: hour/date

1: intermittent: hour/date

Press the SET button to confirm the

selection and move to the next option.

4. Time/Date Setting

It is possible to set time and date by using

the buttons + or –. Press the SET button,

to move the cursor to the next segment.

Time is set in 24h format and date is

DD/MM/YY i.e. 07th September 2016

appears as 07/09/16.

Press the SET button to confirm the

selection and move to the next option.

5. User Name Setting

It is possible to insert the user name by

following method:

Press + or –buttons to choose

characters, then press SET to move to the

next segment. By pressing the SET button,

it is possible to pass over the empty

positions and then confirm the set

parameters to close this menu. Afterward

the user’s name will appear.

7.1.4_Program setting

Switch the machine on by pressing the button

ON/OFF. The following will appear in the

screen:

The number 1indicates which program is being

used. By pushing the + or –buttons it is possible

to change to another program (20 programs).

1. Vacuum time setting

By pressing the SET button for 5 seconds in

each program, the following will appear:

By using the + or –buttons it is possible to

increase or decrease the seconds (between

0 and 50) of vacuum.

By pressing the SET button it will confirm

the selection and move to the next option.

2. Vacuum Percentage Setting

(VACUUM MODE OPTION)

By pressing the SET button for 5 seconds in

each program, the following will appear:

By using the + or –buttons it is possible to

increase or decrease the percentage (between 0

and 99) of vacuum.

By pressing the SET button it will confirm the

selection and move to the next option.

3. Intermittent Pump Setting

(Liquids and Creams)

SOFT VACUUM OPTION)

This option allows the pump to run

intermittently when vacuuming liquids and

creamy products.

By pressing the + or –buttons it is possible to

set the type of vacuum the pump will deliver.

When this cycle is selected, the cycle will

consist of 4 seconds of vacuum and 7 second

--- Program 1

Vacuum 30

Vacuum 99%

Vacuum Type 1

12

pause, until the time set has elapsed. When set

to 0, the pump will run continuously for the

time set.

Vacuum Type 0: standard vacuum.

Vacuum Type 1: soft vacuum with

intermittent pump activated.

By pressing the SET button it will confirm

the selection and move to the next option.

2. Sealing Time Setting

By pressing the SET button, the following

will appear:

By using the + or –buttons it is possible to

increase or decrease the time of sealing

(tenths of seconds, between 0 and 4

seconds).

By pressing the SET button it will confirm

the selection and move to the next option.

3. Gas flush setting

(GAS OPTION)

By pressing the SET button, the following

will appear:

By using the + or –buttons it is possible to

increase or decrease the time of gas

injection (tenths of seconds, between 0 and

9.9 seconds).

By pressing the button SET it will confirm

the selection and move to the next option.

Do not set time of gas flush longer than

vacuum time, otherwise the lid open

prematurely.

Make sure that the gas pressure

entering the chamber is not higher

than 14 -21 PSI or (1 –1.5 bars)

4. Printer Label Settings

(PRINTER OPTION)

By pressing the SET button, the following

will appear:

By using the buttons + or –it is possible to

set the first number, indicating the number

of product labels to be printed (between 1

and 9). NOTE: Setting this number to 0, will

cause the printer to not print any labels.

By pressing the SET button the cursor will

move to the second number, indicating the

number of days the product can be held

(between 1 and 183). By pressing the SET

button it will confirm the selection and move

to the next option.

5. Product Name and Ingredients

Setting.

By pressing the SET button, there will be an

empty line on the display:

By using the +or -buttons, it is possible

to insert a text of up to 16 lines with 16

characters each allowing the printing on

the labels (i.e. food name, ingredients…).

If there are no further options, the display

will show the number of the program

modified. This means that all parameters

are properly set.

7.2 MANUAL SEALING

While running a normal processing cycle, push

and hold the PUMP GASTRO for 3 seconds you

can start the sealing process before the end of

the cycle.

Sealing 2.0

2.0

Gas 0.0

Stamp 3/ 1

13

CHAPTER 8

MAINTENANCE AND SERVICE

Pump heating

If the ambient temperature is below 60 degrees

F, it is advisable to pre-heat the pump in the

morning in order to liquefy the oil before it

circulates throughout the machine.

When the chamber lid is open press and hold the

PUMP GASTRO button for 3 seconds and let the

pump work for about 15 to 20 seconds, and after

that, press PUMP GASTRO button to stop the

pump.

Do not allow the pump to run continuously

for more than 30 seconds or damage will

occur, as the pump is not designed for

continuous operation.

Pump Cleaning Cycle Warning

When the appliance has run 10,000 cycles, the

display will show a warning as follows;

This shows that it's necessary to do the pump

service.

Scheduled pump cleaning cycle

Every 10,000 cycles the pump oil requires

cleaning. To start the pump cleaning cycle, push

the PUMP GASTRO button and at the same time,

lower the clear chamber bell-lid. The display will

show the following:

During this cycle, which lasts approximately 10

minutes, the pump will work intermittently.

NOTE: To end the cleaning cycle at any time,

push the ON/OFF button for 5 seconds. Once the

cleaning cycle is complete, the screen will revert

back to showing the number of programs in use.

The pump maintenance is not strictly

linked to the 10,000 cycles, but more

dependent on the product used (i.e. flour,

breading, liquids, the oil check must be

done monthly). Also, for heavy usage of

the appliance, pump cleaning must be

done every 6 months.

Internal components

Access to the appliances internal components

must be performed by a qualified service

technician, authorized by the manufacturer. In

the case of unauthorized service, doing so will

be at he/she own risk and the manufacturer

cannot be held liable for possible damage or

injury.

To reach any electrical components, it is

neccesary to remove the appliances

casing which are held in place by screws.

Before any service is performed, please

disconnect the appliance from power and

check with an appropriate meter to verify

it is safe to service.

Inner chamber maintenance and

cleaning

Because food product is being sealed, it is

important that the inner chamber be cleaned

after every use.

1. Wipe off the sealing bar(s), (Fig 8.1) with a

damp cloth and mild detergent daily,

making sure to rinse well.

(Fig 8.1) Sealing bar within the chamber

OIL

Pump Cleaning

14

2. Wipe off the silicone sealing bar gasket on

the bell-lid (Fig 8.2) every day with a damp

cloth and mild detergent.

(Fig 8.2) Silicone Sealing Bar Gasket on the

bell-lid

3. Replacement of the Silicon Sealing Bar

Gasket on the Bell-Lid (Fig 8.2).

Inspect the silicone sealing bar gasket for

wear. If it is worn, it will cause the clear

chamber bell-lid to pop open on its own,

affecting the vacuum sealing of the product

and it must be replaced. To replace it, pull it

from the gasket retainer and make sure the

retainer is clean of debris. Install the new one

by pressing in place. Close lid and test for a

seal.

4. Replacement of the Clear Chamber

Bell-Lid Gasket.

5. Replacement of Teflon Sealing Bar

The sealing bar needs to be replaced by a

qualified service technician.

Image 8.3. Sealing bar teflon

The silicone gaskets and the Teflon

sealing bar should be replaced every 200

working hours, for maximum efficiency.

The check of pump, filters and electro

valves must be done every 2000 working

hours by authorized personnel only

(Fig 8.3) Clear Chamber Bell-Lid Gasket

Remove the gasket by carefully pulling out the

gasket from the clear chamber bell-lid groove.

Ensure the gasket groove is clean and free of

debris and press a new one in place. Close lid

and test for a seal.

15

CHAPTER 9

PROBLEMS SOLVING

AFTER SWITCHING ON THE MAIN

POWER SWITCH, THE SWITCH DOES

NOT LIGHT UP

1. Check outlet and make sure there is

power.

2. Check breaker or fuse to make sure it

is not blown.

3. Check to make sure the appliance is

plugged in.

4. Check appliance in another known

good outlet.

5. Call service.

AFTER SWITCHING ON THE MAIN

POWER SWITCH, THE CONTROL WILL

NOT POWER UP.

1. Make sure the main power switch lights

up.

2. If main power switch lights up but the

control will not power up, call service.

THE MAIN SWITCH AND CONTROL

POWER UP, BUT APPLIANCE WILL NOT

START WHEN THE SEALING BAG IS

PLACED IN THE CHAMBER.

1. Make sure there is a program selected.

2. Make sure the clear chamber bell-lid is

firmly pushed closed.

3. The micro-switch is either defective or

out of adjustment and you need to call

service.

THE MACHINE STOPS UNEXPECTEDLY

WHILE IT IS RUNNING

1. Make sure you have power, the main

power switch is on and the control is lit

up.

2. Make sure the clear chamber bell-lid is

still pressed down.

3. Call service.

THE MACHINE WORKS PROPERLY BUT

THE BAG IS NOT SEALED OR IS NOT

SEALED CORRECTLY AT LID OPENING

1. Unplug appliance from power

2. Lift the Teflon sealing bar up to ensure the

2 cables are firmly attached.

3. Verify that the distance between the

Teflon sealing bar and the silicone sealing

bar gasket is at least .125 inches (4-

5mm).

4. Verify that the Teflon sealing bar is dry

and there are no creases in the surface.

5. Verify that sealing bar gasket is not worn

or damaged.

6. Verify that the sealing time is long enough

for a proper seal.

7. Verify that you have the correct bags.

THE MACHINE DOES NOT ATTAIN THE

OPTIMUM VACUUM

1. With the control on and a program selected,

close the clear chamber bell-lid to start a

cycle. Allow the pump to produce a vacuum

of at least 70/cm HG. If the pump will not

achieved that vacuum, then there is an

issue with the pump, blocked, worn,

damaged.

2. Watch the needle on the gauge and ensure

it stays at that vacuum. If it starts dropping

there is a leak.

3. Check the clear chamber bell-lid silicone

seal and if damaged, replace it.

4. Check the bad to make sure it is flat on the

sealing bar and there are no wrinkles.

5. Verify that the distance between the

Teflon sealing bar and the silicone sealing

bar gasket is at least .125 inches (4-5mm).

6. Verify that you have the correct amount of

vacuum time or percentage for the product

you are sealing.

7. Verify that you have the correct pressure if

using the Gas Flush.

DO NOT LIFT THE LID ON OR RAISE A

LITTLE

1. Verify the proper operation of the clear

chamber bell-lid pistons.

2. Call service.

16

CHAPTER 10

NAME PLATE AND TECHNICAL

DETAILS

CONFIGURATION AND

CONSUMPTION

Image 8.5. Name plate example

17

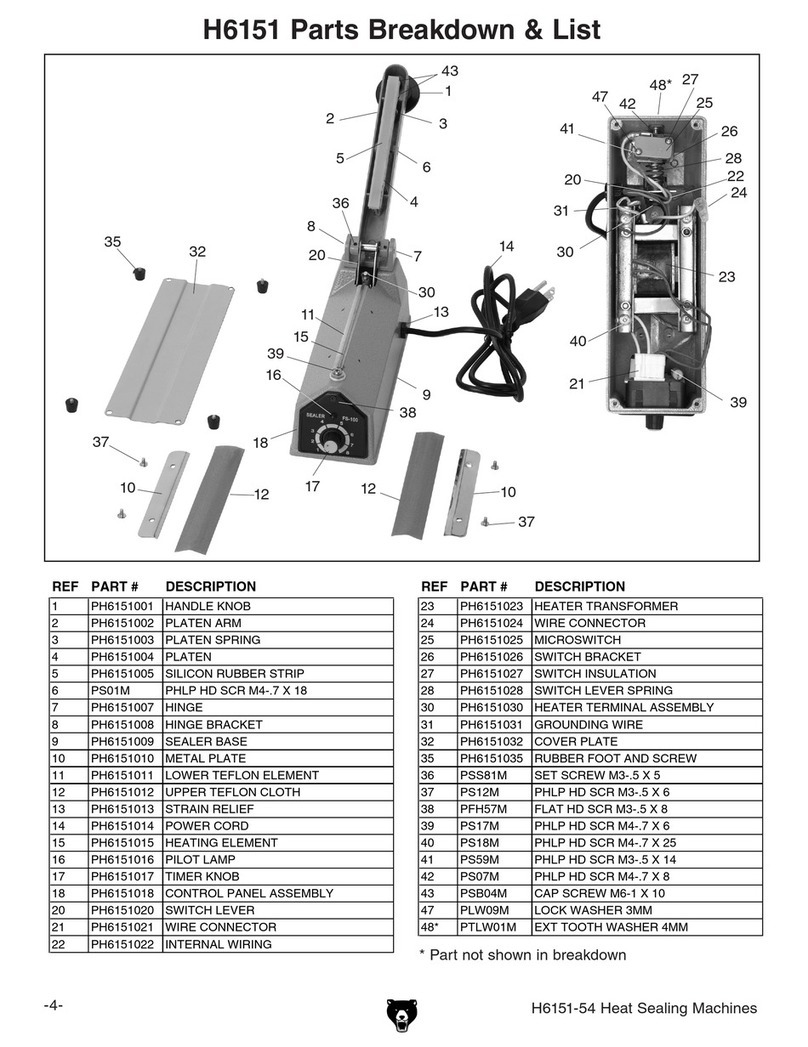

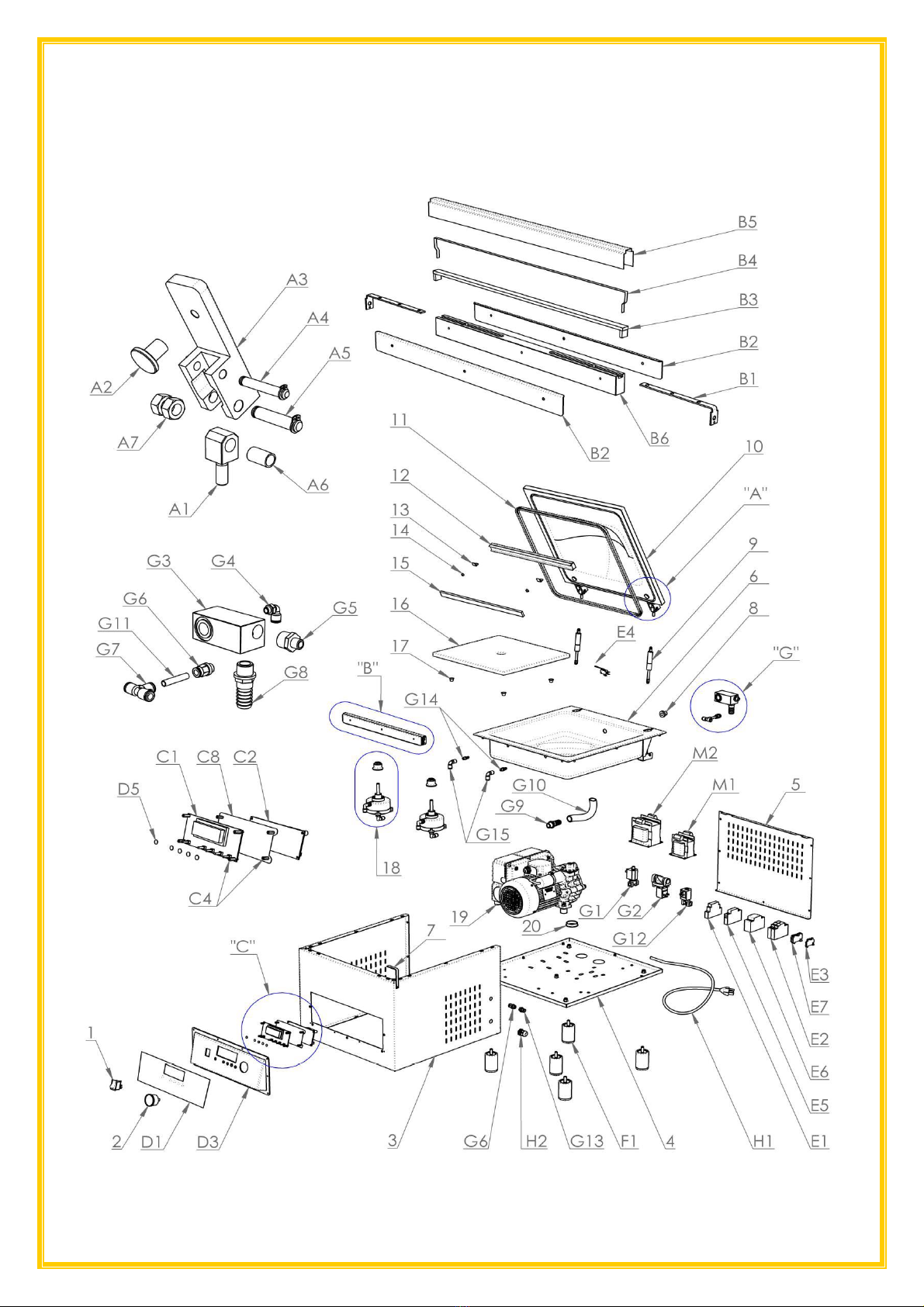

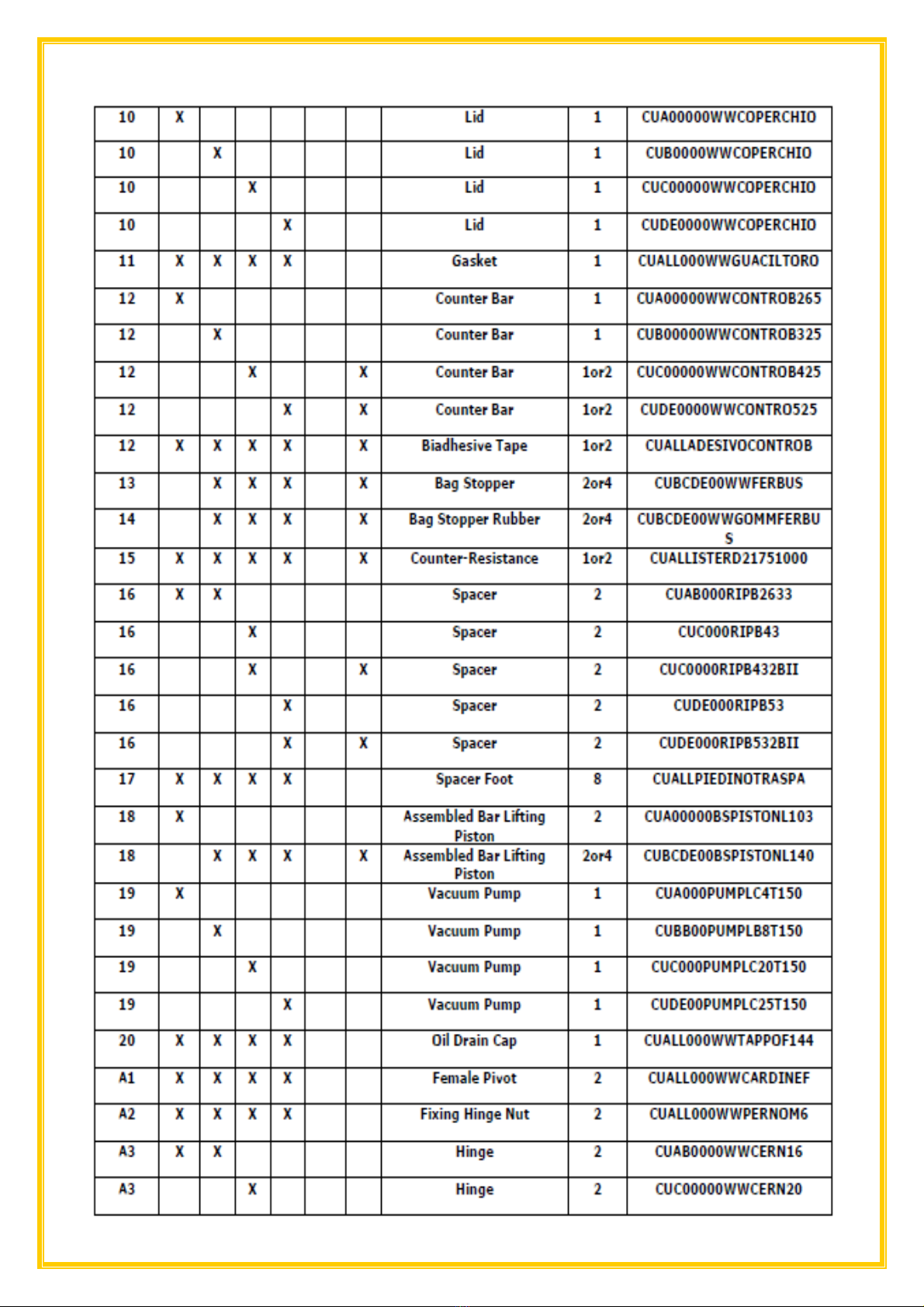

CHAPTER 11

18

EXPLODED VIEWS AND PART

19

LISTS.

20

This manual suits for next models

8

Table of contents