3

deCking installation

FASTENERS

Theuseofstainlesssteelfastenersis

stronglyrecommended.Approvedcoated

fastenersmayalsobeused,buttheir

performancemaynotbeasgoodasstainless

steel.Plain,galvanizedsurfacefastenersare

notrecommended.

Fastenersrecommendedforusewith

EverNewPTdeckingincludestainlesssteel

compositefasteners.CertainTeeddoes

notendorseorrepresentspecicthird

partyproducts.Otherfastenersspecically

designedforwoodcompositedecking

shouldbetestedinaninconspicuousarea

rst,astheymayresultinanunacceptable

appearance.Ifhiddenfastenersaredesired,

PhantomHiddenDeckFastenersavailable

fromCertainTeedaredesignedtotthe

EverNewPTgrooveddeckboardforquick

andeasyinstallation,whileprovidinga

smooth,unmarredlook.

Theuseoftraditionalatorbuglehead

deckscrewsisnotrecommendedfor

EverNewPTdeckingandwilllikelyresultin

mushrooming.Otherfastenersnotspecically

designedforwoodcompositedeckingare

notrecommended.Hiddenfastenersystems

otherthanPhantomHiddenFastenersare

notrecommended,andtheirusewillvoidthe

productwarranty.

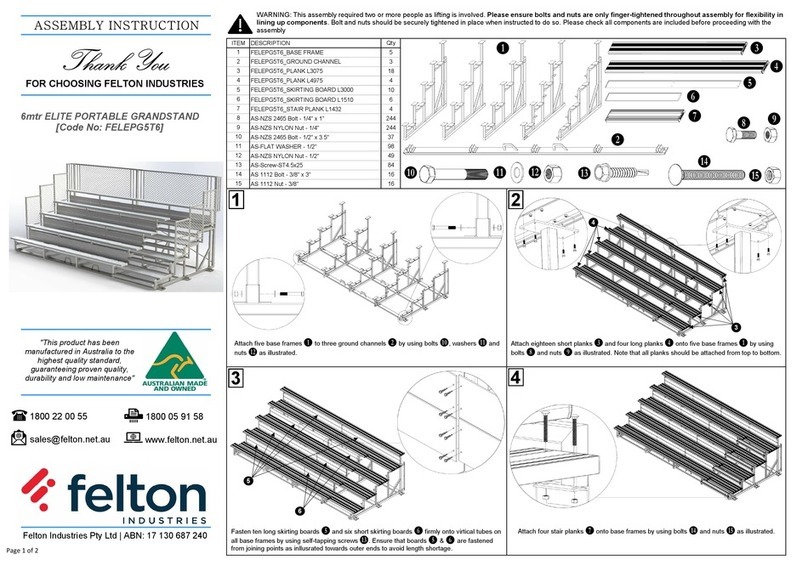

Requirements

Donotfastenwithin1-1/2"oftheendofa

boardor1"fromthesideoftheboard.Itis

necessarytopre-drillendofboardscrewholesto

preventimmediateoreventualendsplitting

(FigureF).Pre-drillingallholes,whichwilladdtime

totheproject,isnotnecessary,butitwillresultin

better-lookingnishedprojects.Pre-drillingwill

greatlyreducethechanceofanymushrooming.

DONOTover-tightenfasteners.Overtighteningwill

inducecrackingat

boardends.

Surfacefasteners

shouldalwaysbe

driveninata90

degreeangletothe

deckingsurface.Toe

nailing/screwingis

notrecommended

(FigureG).

Instead,the

placementofan

additionaljoist,

whenneeded,is

recommendedto

allowperpendicular

installationofsurface

fasteners(FigureH).

Pre-drillingisrequired

incoldtemperatures.

Clean,perfectly

straightlinesof

fastenerslookbetterthanwobblylines.Usewhite

chalk,straightboardsorstringlinesastemplates

forstraightlines.DONOTUSECOLOREDCHALK.

Coloredchalkisdesignedtobepermanentandwill

stainthedeckingsurface.Thereisnoknown

waytoremovecoloredchalkfromdecking.

EverNewPTdeckingmaybefacefastened.

Annualthread,ringshankandspiralshank

nails,ofsufcientlength,haveexcellent

holdingpowerandproducegoodresults.

Gunnailsmaybeusedbut,dependingon

thegun,thetemperatureofthedeckingand

otherfactorssuchasheadtype,headsizeand

shanknailgeometry,gunsmaynotproduce

optimalresults.Testrst.Stainlesssteel

fastenersarerecommended.

Screwshavesuperiorholdingpower.

Conventionalbuglehead

deckingscrewsproduce

solidconnectionsbut

haveatendencyto

causemushrooming.The

mushroomsmaybeleftas

is,attenedorremoved(pat

downwitharubbermallet)as

desired.

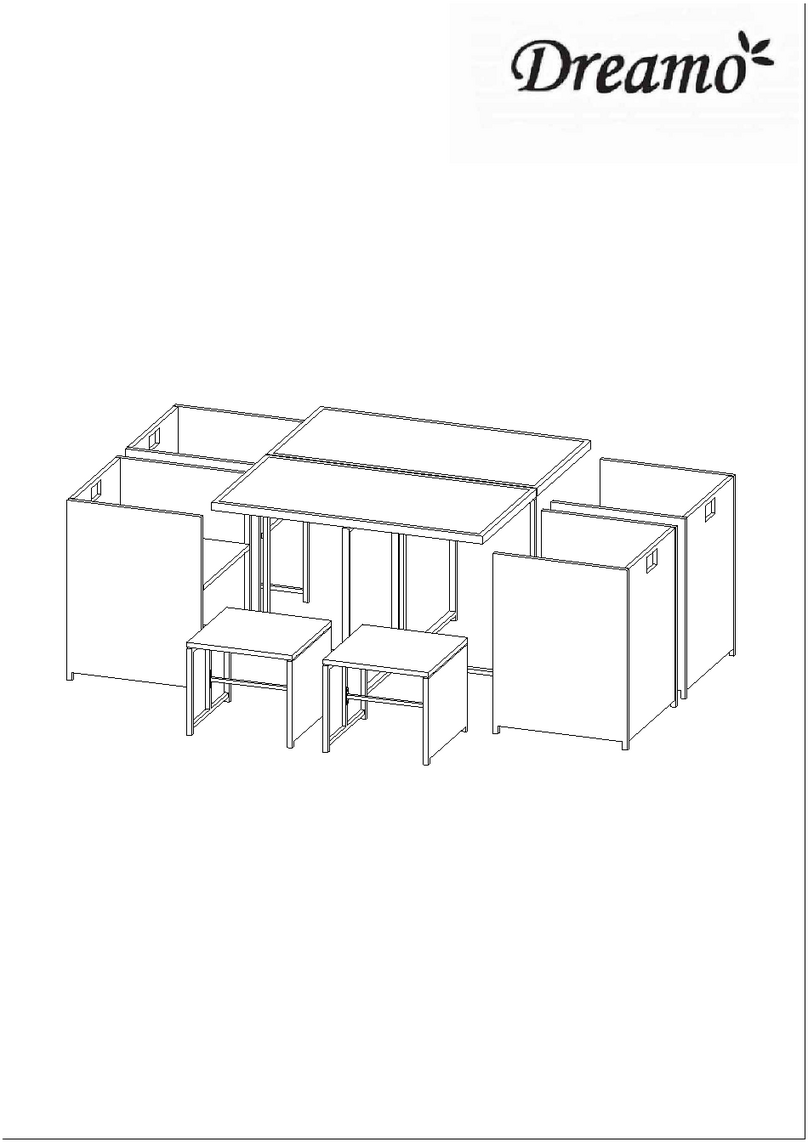

Foracleanerlook,stainless

steelscrewswithsmallcasingornish

styleheadscanproducenearlyinvisible

results.Achievingthislookispossible

withscrewsdesignedspecicallyfor

compositedecks.Availablecommercially,

inhomecentersandhardwarestores,

thesescrewsareengineeredspecicallyto

workwithcompositedeckingandprevent

mushrooming,resultingin

better-lookingnishedprojects(FigureI).

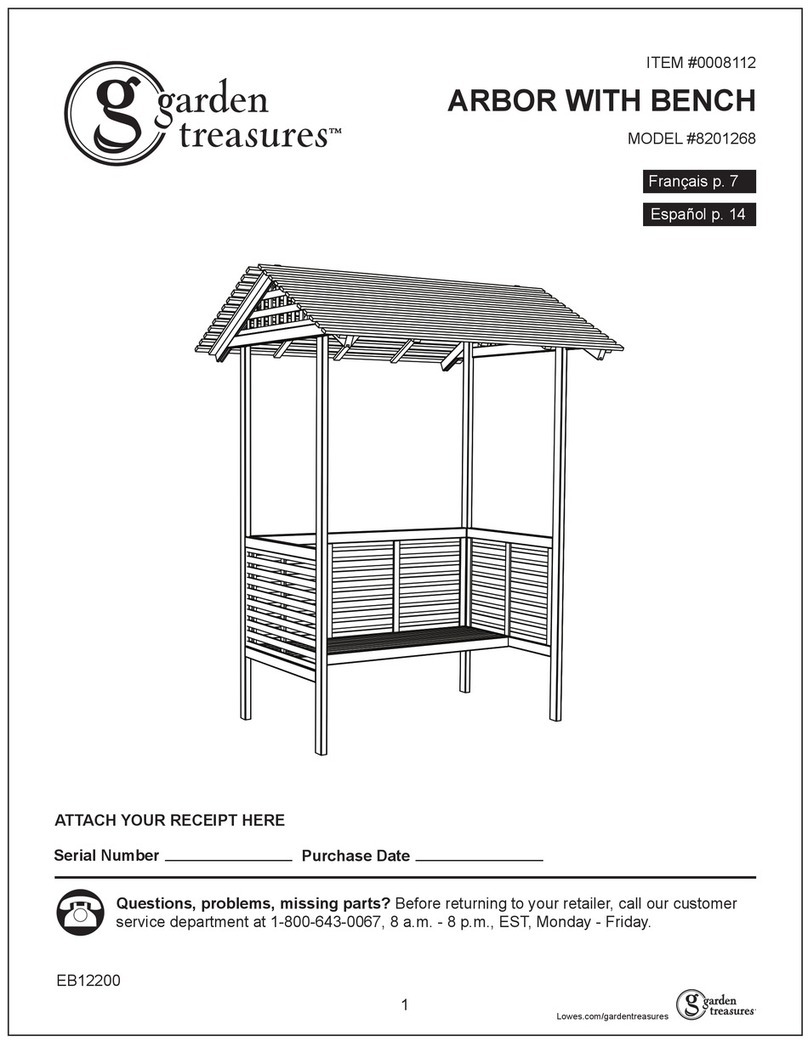

Figure I

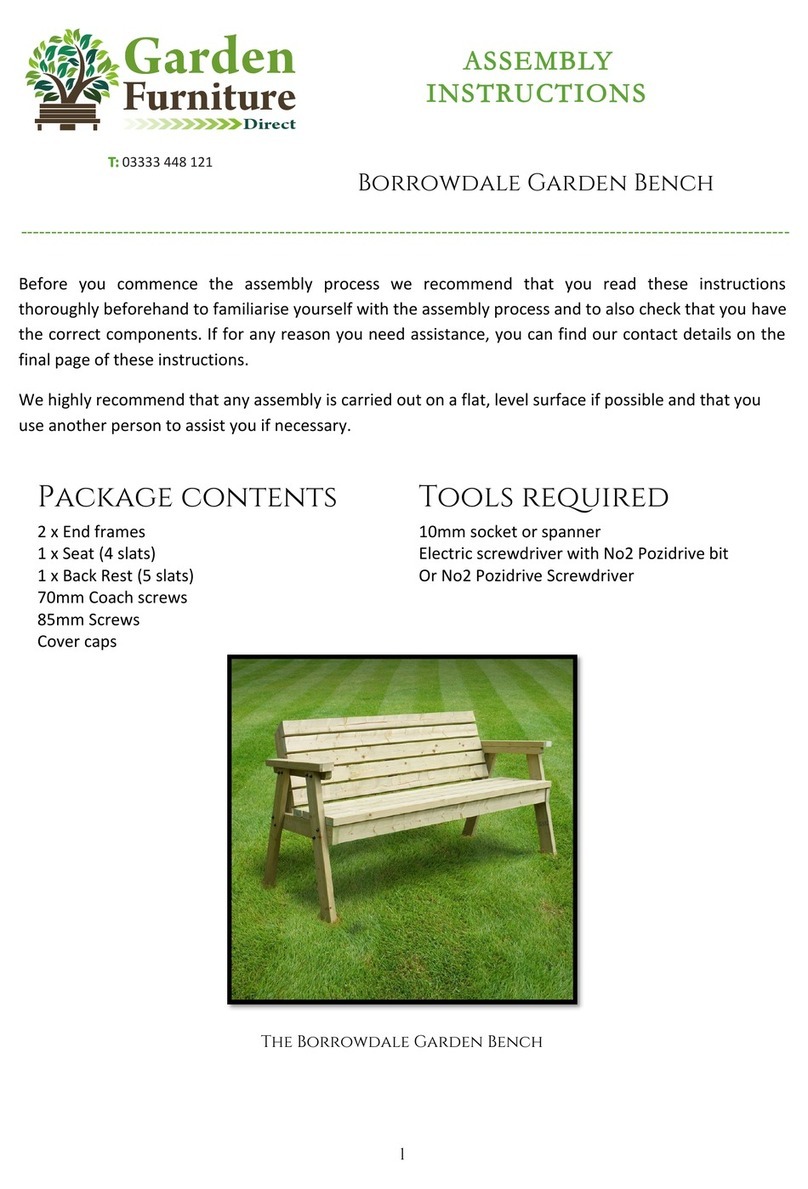

HIDDEN DECK FASTENERS

Caution: Contains parts with sharp edges.

Use proper care.

Installation of First Deck Board

Positiontherstdeckboardonthe

supportjoists.Leavea1/4"gapfrom

anypermanentstructure.

Pre-drilltherstdeckboardwitha1/8"drill

alongtheoutsideedgeoftheboardatevery

supportjoist.Topreventcrackingoftheboard,

theholesattheendoftheboardshouldbea

minimumof1-1/2"fromtheend.Theholes

alongthegroovededgeoftheboardshouldbea

minimumof1"fromtheedge.

Securetherstdeckboardbyfasteningwith

aminimum#10x2-1/4"longstainlesssteel

deckscrewineachpre-drilledhole.

DONOTOVER-TIGHTENTHESCREWSORUSE

OPTIONALENDCLIPFASTENERS.

Optional End Clip Fastener

PlaceEndClipa

minimumof1/4"

fromwallwitha

singlescrewinto

joist.Repeatat

eachjoistlocationnomorethan16"oncenter.

Installation of Deck Boards

Slidefastenerintosidechannelofdecking

boardateverysupportjoist.

Installscrewsprovidedthroughdestination

holeintoeachsupportjoist.

Locatenextslottedboardagainstthe

fastenertabs.

Slightlylifttheouteredgeoftheboard

andslideoverfastenertabs.

Besurefastenersarefullysecuredinto

eachboardtoensureevenspacing.

Repeatstepsuntildeckiscomplete.

Installation of Final Deck Board

Positionthenaldeckboardontothelast

setoffasteners.Ensuringaconsistentgap

betweenboards,pre-drillthenaldeckboard

witha1/8"drillalongtheoutsideedgeof

theboardateverysupportjoist.Theholesat

theendoftheboardshouldbeaminimum

of1-1/2"fromtheend.Theholesalong

thegroovededgeoftheboardshouldbea

minimumof1"fromtheedge.

Securethenaldeckboardbyfastening

a#10x2-1/4"longstainlesssteeldeck

screwineachpre-drilledhole.DONOT

OVER-TIGHTENTHESCREWS.Installthe

Fiberon-approvedHiddenFastenersupto

50%fasterwiththeBallisticNailScrewDriver.

Step 3

Step 2

Step 1

90º

Joist

Joist

Deck Deck

1-1/2”

22.5º cut

1”

Joist

Deck Deck

Figure G

90º

Joist

Joist

Deck Deck

1-1/2”

22.5º cut

1”

Figure H

1“

Added Joist

Deck

Board #1

Deck

Board #2

1-1/2”Setback

Figure F