Evers LW-GTA User manual

Electric Gummed

Paper Tape Dispenser

LW-GTA

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

1. SAFETYNOTICE

2. DISPENSER COMPONENTS

3. KEYPAD OPERATION

4. ROLL SIDE PLATE INSTALLATION

5. LOADING THE TAPE

6. TAPE GUIDE PLATE INSTALLATION

7. BRUSH OPERATION

8. WATER BOTTLE

9. MAINTENANCE

Contents

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

Voltage Power Speed Weight Size

220/110V200W 1100mm/s 12kg 45x24x33cm

1. SAFETY NOTICE

Please use standard 50hz power supply only. Avoid placing

in direct sunlight and do not use outdoors. Disconnect the

power supply immediately if there is a fault. When cleaning

or repairing the equipment, please disconnect the power

supply and remove the plug.

Do not attempt to disassemble or repair the equipment

without authorisation.

PARAMETERS

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

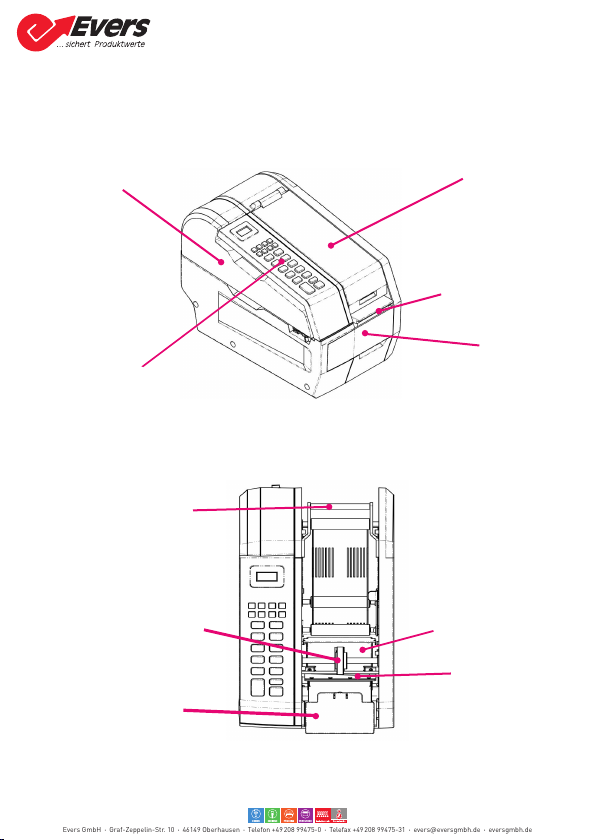

Rear guide roller

Heater assembly

Drive wheel

Cutter blade

Tape guide plate

2. DISPENSER COMPONENTS

Top cover

Keypad

Brush

Assembly

Water Tank

Water Bottle

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

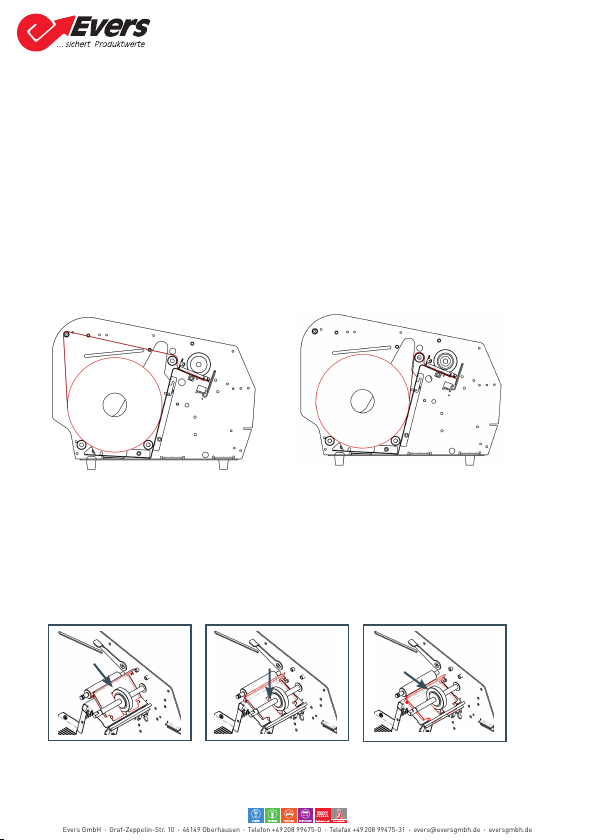

According to the tape width

used, install the first roll side

plate in the correct position.

See Figure 1, first insert the

upper part of the side plate

into the front slot.

See Figure 2, now insert the

lower end of the side plate

into the front slot.

See Figure 3, finally, insert

the bottom of the side plate

into the bottom slot.

Repeat with the opposite roll

side plate. The tape roll

should be central with some

space either side, not too

tight against the plates.

3.ROLL SIDE PLATE INSTALLATION

1

2

3

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

4.KEYPADOPERATION

2

3

4

1

5

7

8

9

10

6

11

12

*

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

1 Temperature indicator

Temperature Control button

H0: No temperature H1-H5: 5 different temperature ranges

Summer setting: H1 Winter setting: H5

3Auto mode

Press “AUTO”, then press any number, machine will out feed one same

piece with preset length once the former one is taken away. Press”

AUTO” again to cancel the automatic mode. This model could be used

together with” COMBINED” mode.

7Define tape length 8Present tape length

9X2 Double length button

X2 button will double the selected tape length.

For example: In order to dispense 30CM tape, first press” X2” button, then

press the number “15” .

10 Length adjustment button

“+1” button adds 1cm to selected tape length;

”-1” button subtracts 1cm from selected length;

For example: In order to dispense 17CM tape, press” +1” button twice,

then pres the number button”15”

11 Manual feed button

Output tapes so long as this button is pressed, minimum length 13cm.

12Define length button

For example: In order to make the machine to remember and dispense

115CM all the time, first press”X2” -> ”+1” five times -> ”55”, then long

press”DEFINE” button until the display shows” Def: 115” -> finished.

Every time when you press” DEFINE” button, it will dispense 115CM.

Single piece/Combined pieces mode switch button

2

5

4

6

Combined pieces mode

For example: In order to dispenser different sizes:

15-35-55CM continously.

First, press” MODE” to change to “ COMB” mode;

Second, press” SET” -> ”15” -> ”35” -> ”55”- > ”END”,Third, press”

START”, machine will dispense 15CM, 35CM then 55CM. Press” MODE”

again to return back from” COMB” to “ FIXED” mode.

(*will indicate current number in group if comb mode is on)

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

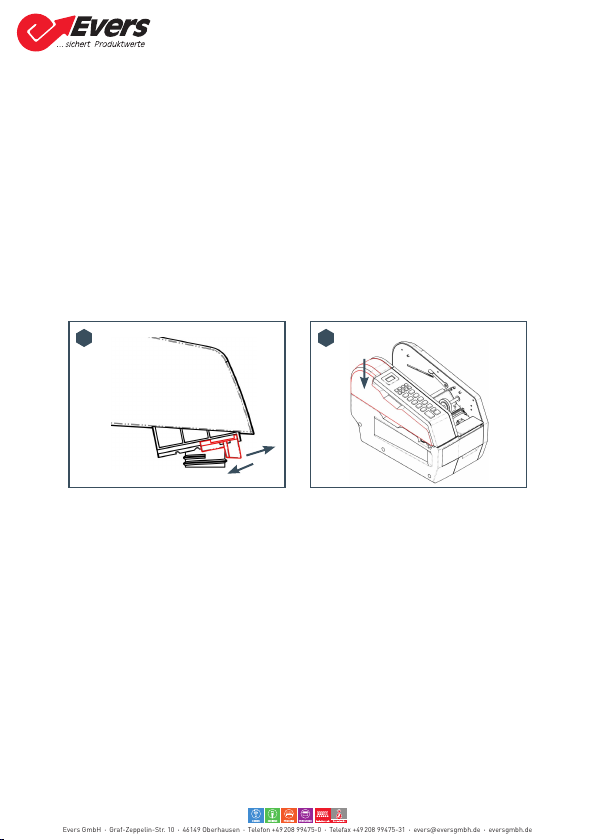

5. LOADING THE TAPE

Use scissors to cut the end of the tape so that it has a clean,

square end to allow it to feed under the drive wheel.

Remove the upper tape guide plate. Now see Figure 1, pass

the tape over the rear guide roller and forward toward the

drive wheel. Push down on the drive wheel lifter, while

passing the tape under the drive wheel, pushing it forward

until it meets the cutter blade. Release the drive wheel lifter.

6. TAPEGUIDE PLATE INSTALLATION

Check that the upper tape guide plate is the correct way up.

Install the upper tape guide plate as shown below.

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

7. BRUSH OPERATION

As shown in Figure 1, first take out the water tank, then

take out the water trough with its brush.

As shown in Figure 2, water the top surface of the brush

until the brush is completely soaked.

As shown in Figure 3, put the water trough in position,

and then put back the water tank.

As shown in Figure 4, gently press down the part

highlighted in red with your hand to make it contact fully

with the brush.

12

3 4

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

8. WATER BOTTLE

Fill the bottle with water and place in position.

The water level in the water tank can be adjusted using

the cam shown in Figure 1.

Normally, the water level is adjusted to the highest level.

Caution: Pay attention to the amount of water

remaining in the water bottle when using the dispenser.

Make sure the brush stays wet.

12

9. MAINTENANCE

REGULAR MAINTENANCE IS ESSENTIAL

Weekly: clean the whole machine using a lint free damp

cloth. Pay special attention to the path the tape follows.

If any pieces of tape remain stuck, carefully dampen

them and remove them without scratching the metal

surface. Dry the tape path with paper towel.

Monthly: rinse the water trough, brush and bottle with a

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

mild detergent, then rinse well with clean water. If in a

hard water area, rinse the brush with mild detergent

more frequently to prevent scale build up.

The first time you use the dispenser, the sticky side of

the tape may have too little moisture. Please dispense

several pieces of tape until the tape is moistened.

1

10.Common problems and maintenance:

1. Cover opening alarm:

When pressing NUMBER button, START button, DEFINE

button etc if the machineʼs lid is not closed, opening alarm

will be triggered: The screen displays ERR and with 2 alarm

sounds.

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

3. Tape use up alarm:

During automatic mode, if the tapes runs out, this will

trigger tape use up alram: 4 alarm sounds.

123

2. Tape residue alarm:

When pressing NUMBER button, START button, FEFINE

button etc, if there still has unremoved tapes in machine ‘s

ejection channel, this will trigger paper remaining alarm: 4

alarm sounds.

4. How to deal with paper jam

(1) Remove the tape guide plate

(2) Lift the shear blade by manual handle

3) Remove the remaining tapes under tape guide plate

(4) Lift the heating cover and remove the remaining tape.

(5) Restore position of the tape guide plate, manual handle

and heating cover.

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49208 99475-0 Telefax +49208 99475-31 evers@eversgmbh.de eversgmbh.de

Table of contents

Popular Dispenser manuals by other brands

Cornelius

Cornelius QUEST ELITE 2 FLAVOR installation manual

Cornelius

Cornelius Jetspray JT20 owner's manual

ASI

ASI EZFILL 0394 Series Installation and maintenance guide

Secura

Secura ASD-500 quick start guide

Keurig

Keurig B150P Setup guide

Georgia Pacific

Georgia Pacific PRO enMotion 59466A reference guide