ORIGINAL INSTRUCTIONS

- 1

CONTENTS

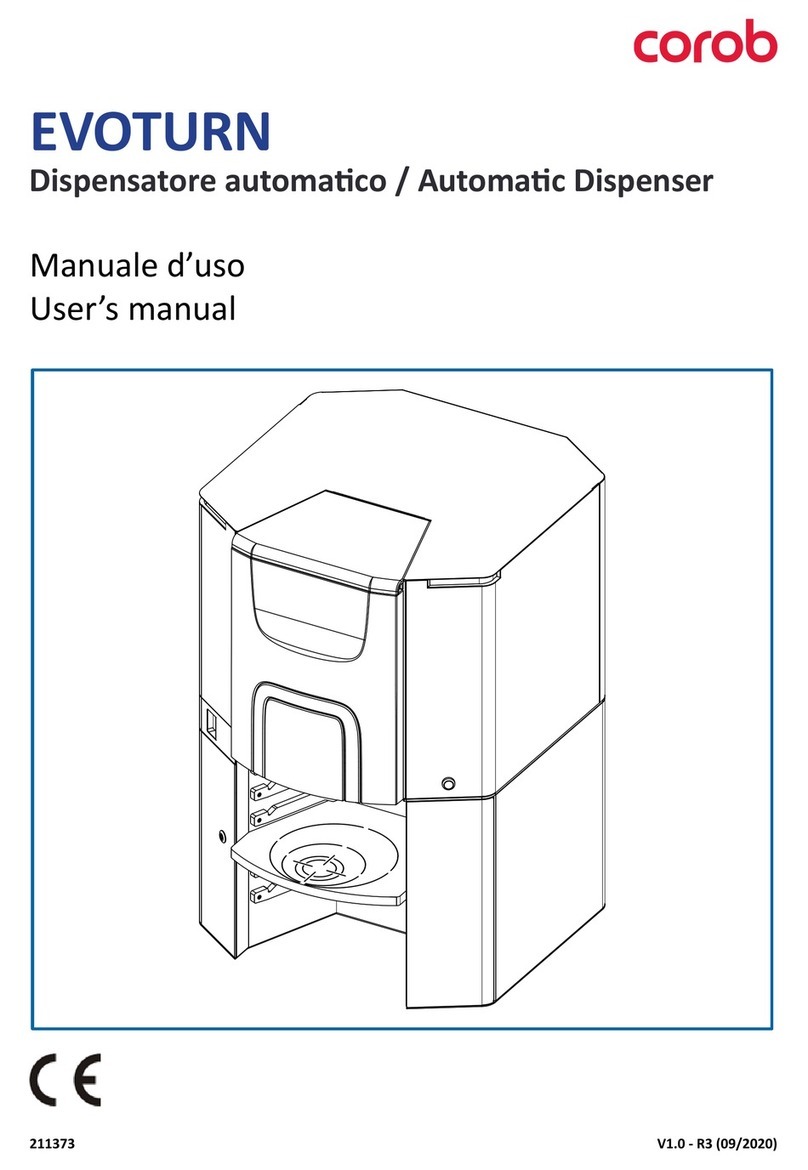

1 GENERAL INFORMATION.........................................................................................................3

1.1 Purpose and use of this manual.........................................................................................3

1.1.1 Conventionally used graphics .................................................................................3

1.2 Identifying information.....................................................................................................3

1.3 Intended and improper use ..............................................................................................4

1.4 Denitions ..................................................................................................................... 4

2 SAFETY ...................................................................................................................................5

2.1 General warnings ............................................................................................................ 5

2.2 Warnings on the use of colorants.......................................................................................6

2.3 Residual risks ................................................................................................................. 7

2.4 Safety devices ................................................................................................................ 8

3 FEATURES ...............................................................................................................................9

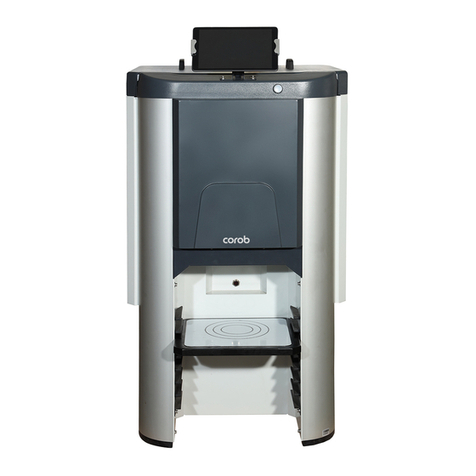

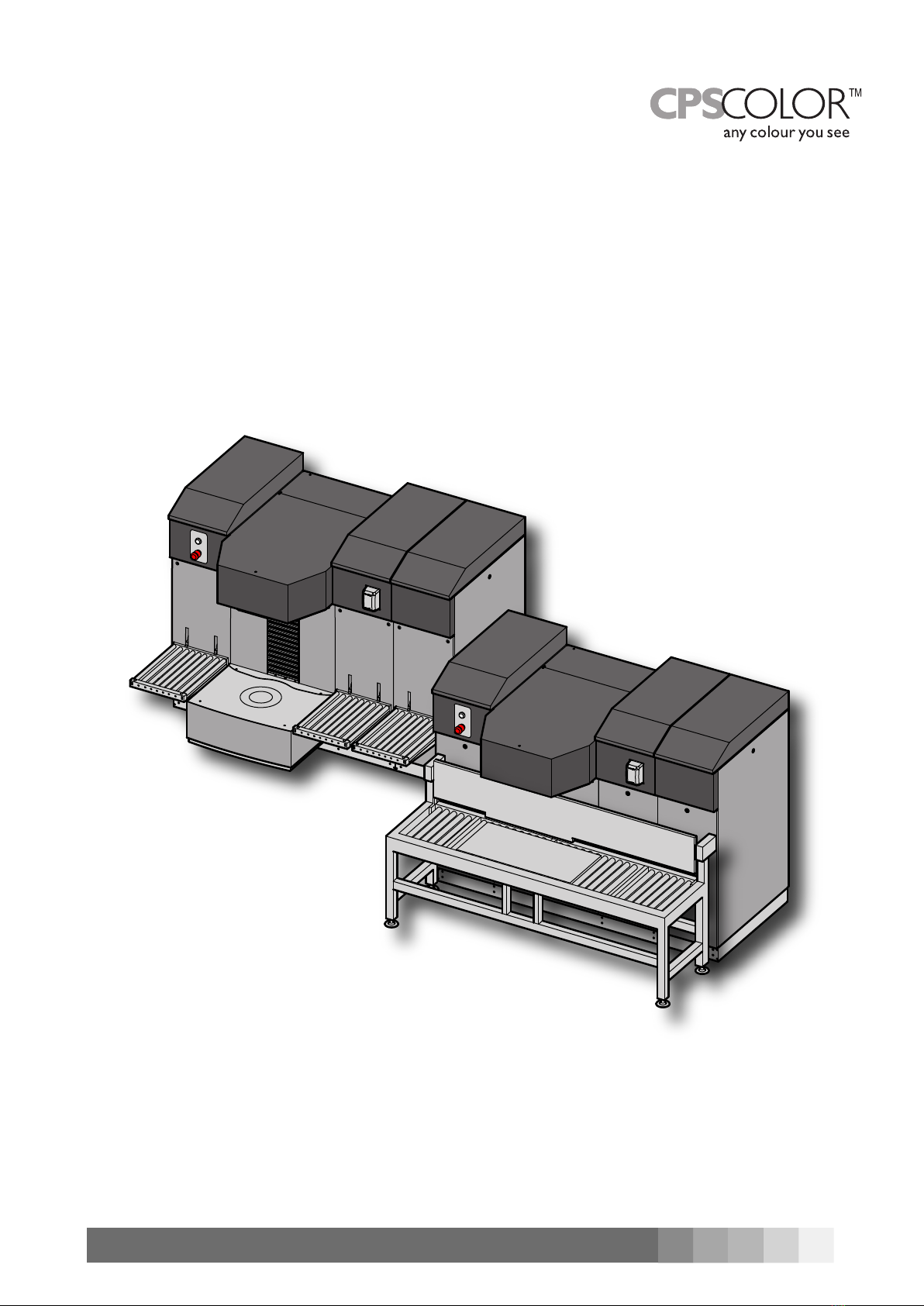

3.1 Description of the machine ...............................................................................................9

3.2 Description of units ....................................................................................................... 10

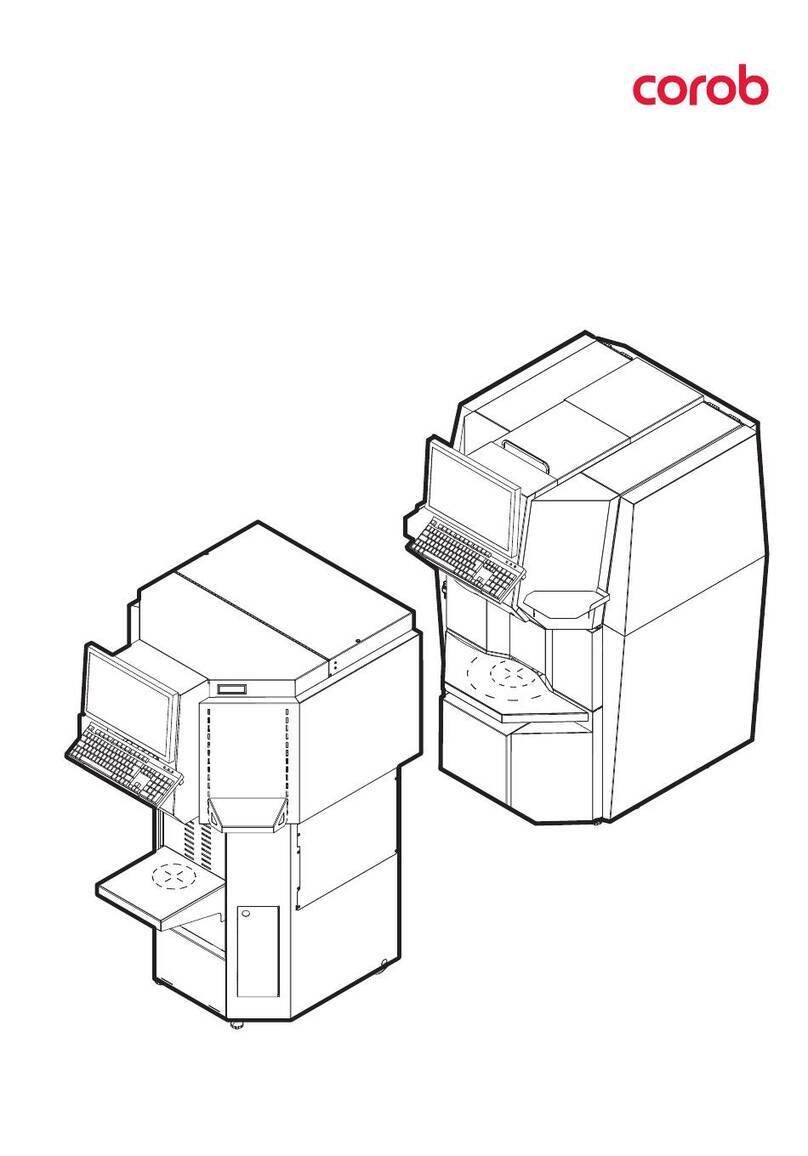

3.3 Standard and optional congurations ............................................................................... 12

3.4 Usable cans.................................................................................................................. 12

4 SHIPPING, HANDLING AND UNPACKING............................................................................... 13

4.1 General warnings .......................................................................................................... 13

4.2 Environment conditions of the installation site .................................................................. 13

4.3 Unpacking and placement .............................................................................................. 14

4.3.1 Adjusting the support feet ................................................................................... 16

4.3.2 Standard material supplied .................................................................................. 16

4.4 Installation................................................................................................................... 16

4.5 Packing and handling..................................................................................................... 16

5 START-UP .............................................................................................................................17

5.1 General warnings .......................................................................................................... 17

5.2 Control devices and connections...................................................................................... 18

5.3 Electrical connection and start-up.................................................................................... 19

5.3.1 Grounding instructions ........................................................................................ 19

5.3.2 Extension cords ................................................................................................. 20

5.4 Machine conditions ........................................................................................................ 21

5.5 Initialization ................................................................................................................. 21

5.6 Use of the off-line button ............................................................................................... 21

5.7 Emergency stop ............................................................................................................ 22

5.8 Shut-down ................................................................................................................... 22

6 USING THE DISPENSER......................................................................................................... 23

6.1 General warnings .......................................................................................................... 23

6.2 At the beginning of the working day................................................................................. 23

6.3 Running the machine ..................................................................................................... 23

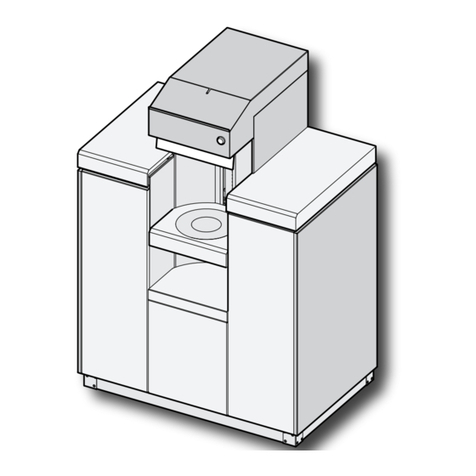

6.3.1 Loading the can - Roll Conveyor ........................................................................... 24

6.3.2 Loading the can - Pull Out Shelf ........................................................................... 24

6.3.3 Loading the can - Automatic Shelf ........................................................................ 25

6.3.4 Use of the Bung Hole Locator ............................................................................... 25

6.3.5 Dispensing ........................................................................................................ 26

6.4 Automatic timed processes ............................................................................................. 26

6.5 Relling the canisters..................................................................................................... 27

6.6 Troubleshooting ............................................................................................................ 29

7 ORDINARY MAINTENANCE ....................................................................................................31

7.1 General warnings .......................................................................................................... 31

7.2 Maintenance table ......................................................................................................... 31

CONTENTS