1602020958 Rev C 10 July 20161602020958 Rev C 10 July 2016

1211

We are pleased to offer this warranty covering ASI products furnished for your project.

This warranty replaces any other warranties or product descriptions, whether expressed or

implied, written or oral.

It is understood that the products for this project have been selected and inspected by the

purchaser, and have been accepted without qualification by the purchaser as merchantable,

fit for the intended use, and satisfy the specifications.

EZ FILL™ SOAP DISPENSER PRODUCTS WILL BE FREE OF DEFECTS IN MATERIAL AND

WORKMANSHIP DURING NORMAL USE FOR (2) TWO YEARS FROM THE DATE OF INVOICE.

Should the product fail under this warranty, the sole remedy, at the seller’s option, will be

to repair the defective product, refund the purchase price, provide an equivalent new or

refurbished product or provide parts only.

ASI AND/OR SELLER DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES. This warranty excludes product damage due to incorrect installation, improper

maintenance, wear and tear, battery spoilage, product abuse, or product misuse, whether

performed by a contractor, service company, or the consumer.

ASI will not be responsible for labor costs associated with the removal, replacement, repair by

others, reinstallation, renovation or return of its products.

WARRANTYSPARE PARTS LIST

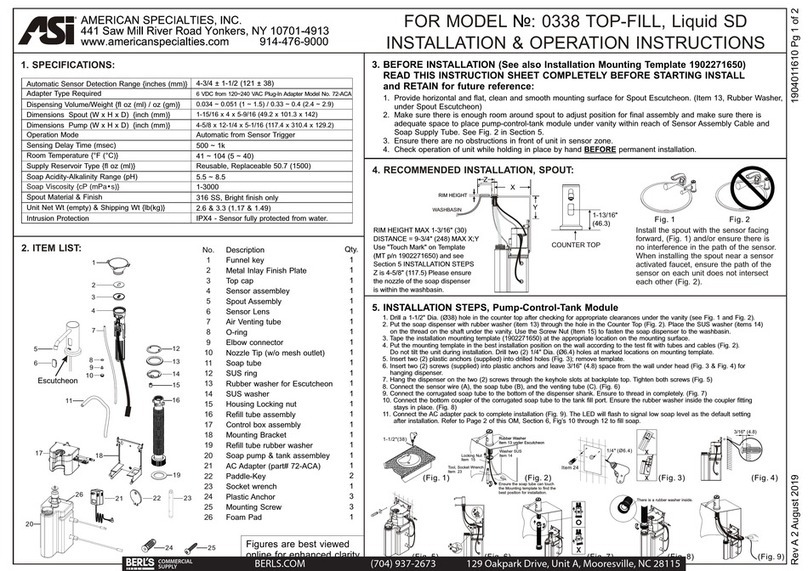

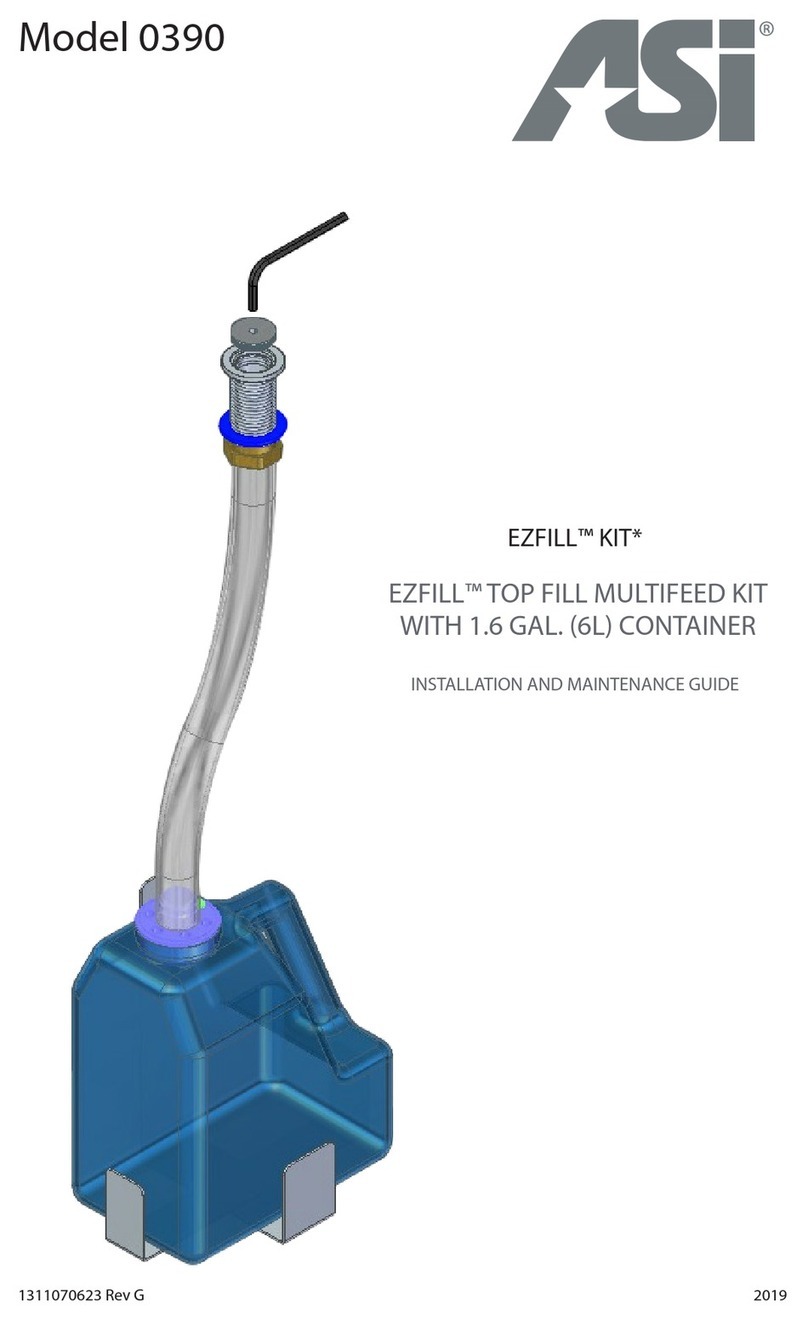

EZFILL™ AC Adapter 12V (US, UK, & EU) ......................................................................... 0390-ACA

EZFILL™ AC Adapter 12V (AU) ........................................................................................ 0390-ACA-3

EZFILL™ Anti-Rotation Kit...................................................................................................... 0390-ARK

EZFILL™ Battery Pack (Batteries not included) .................................................................. 0390-BP

EZFILL™ Battery Pack (0390-BP) Extension Cable/1M Male

to Female Connectors ............................................................................................................ 0390-EBC

EZFILL™ Soap Pump .................................................................................................................... 0390-P

EZFILL™ 180° Quick Connector ............................................................................................ 0390-QC

Mounting Bracket for EZFILL™ Soap Pump & 1 Liter Container ............................ 0391-PBR

EZFILL™ 1 Liter Container Only ............................................................................................ 0391-SB

EZFILL™ Air Compresor........................................................................................................... 0393-C

EZFILL™ Filter for Air Compressor ........................................................................................ 0393-F

EZFILL™ 90° Quick Connector and

¼” Dia. [Ø6 mm] Plastic Pipe 24” [610 mm] long ...................................................... 0393-QC

EZFILL™ Remote for Foam Dispensers ........................................................................... 0393-R

DO NOT use steel wool or cleansing agents containing alcohol, acid, abrasives, or the like.

Use of any cleaning or maintenance products containing these substances could damage

the surface of the soap dispenser. For surface cleaning use ONLY soap and water, then

wipe dry with a clean cloth or towel. When cleaning bathroom tiles or counters, protect

the soap dispenser from any splattering of harsh cleansers.

Care and cleaning of chrome and special finishes- see also PCM document.

MAINTENANCE

Filter cleaning instructions:

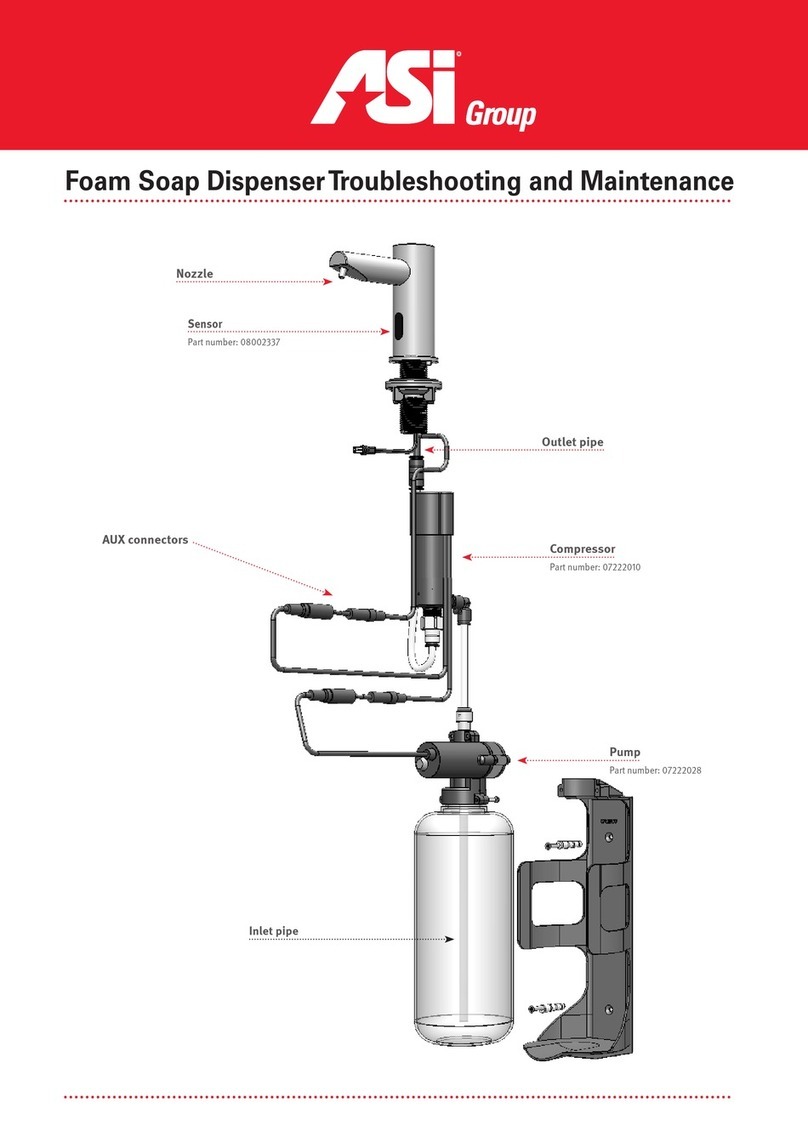

The foam soap dispenser’s compressor is provided with a filter. It is recommended to

clean the filter every six (6) months.

A decrease in soap supply may indicate that the the filter is clogged and requires cleaning.

Cleaning instructions:

1. Disconnect the compressor from the soap dispenser body

2. Unscrew the nut at the bottom of the foam compressor and pull out the filter.

3. Wash the filter under running water.

4. Reassemble the parts.

MAKE SURE THE SOAP CONTAINER IS CLEAN BEFORE FILLING IT WITH SOAP.

DIRTY SOAP MAY CAUSE CLOGGING.