Evers WATER WONDER Mini User manual

Popular Water Filtration System manuals by other brands

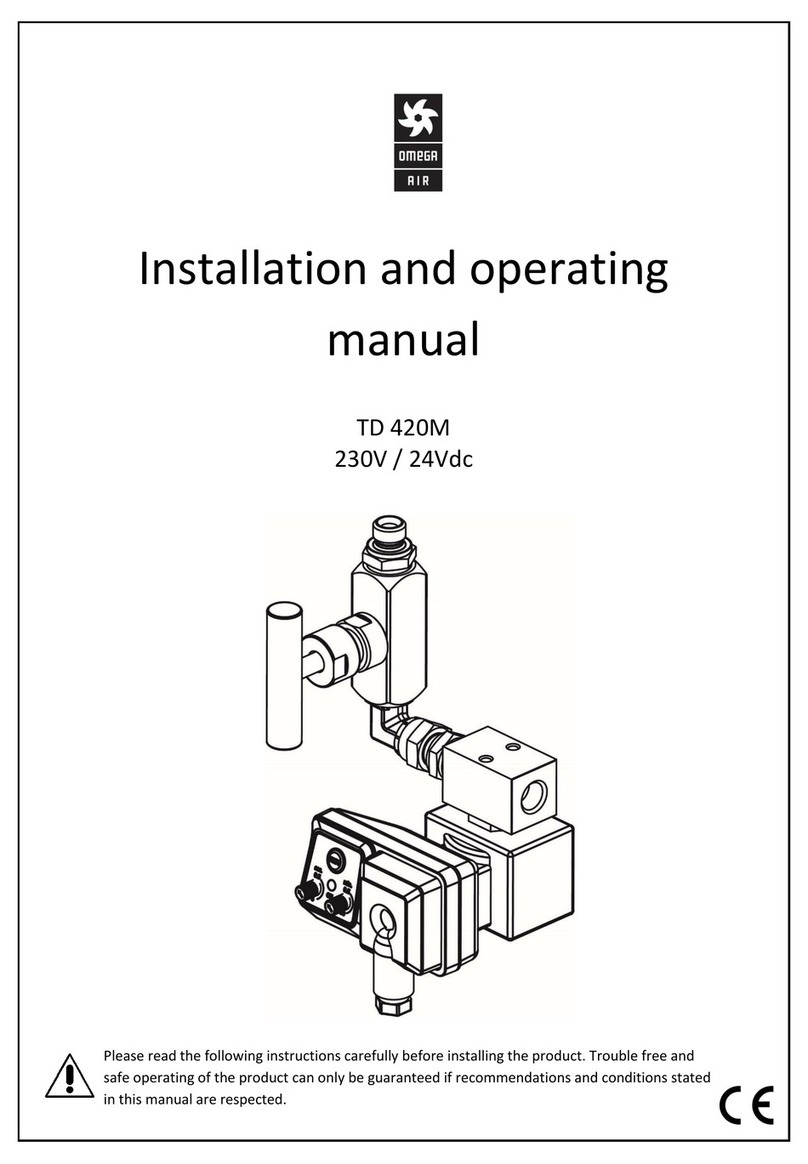

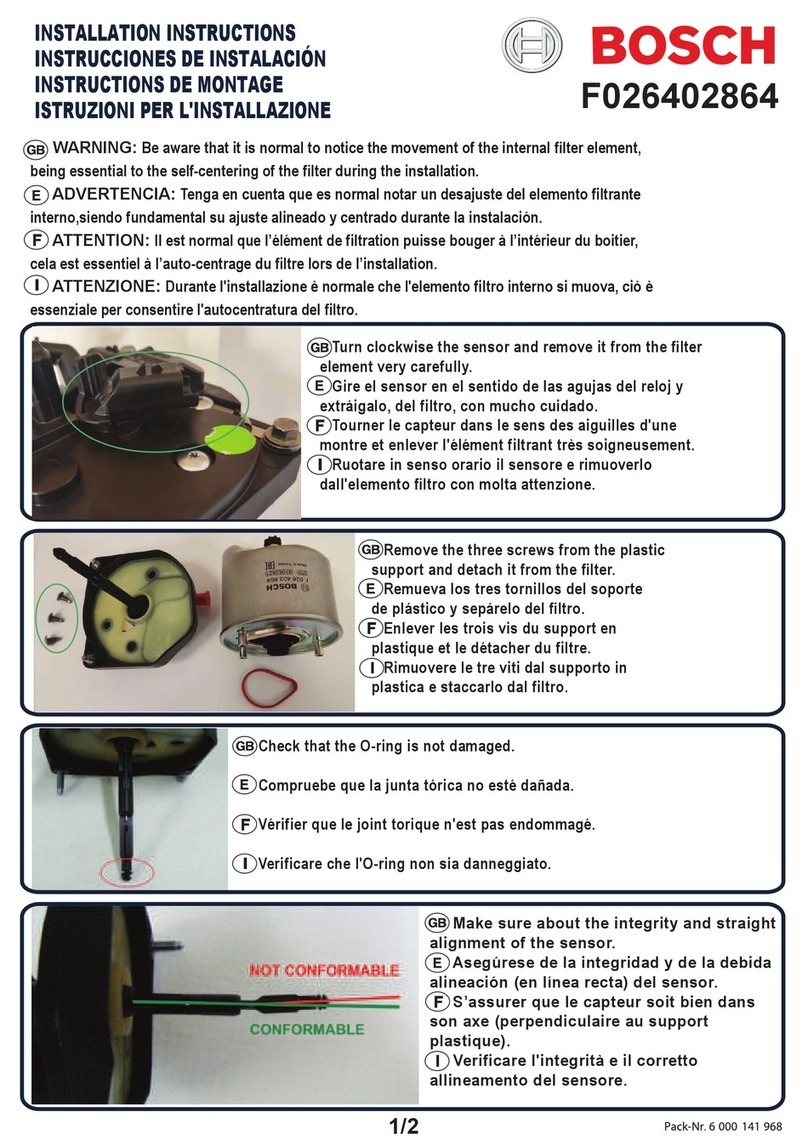

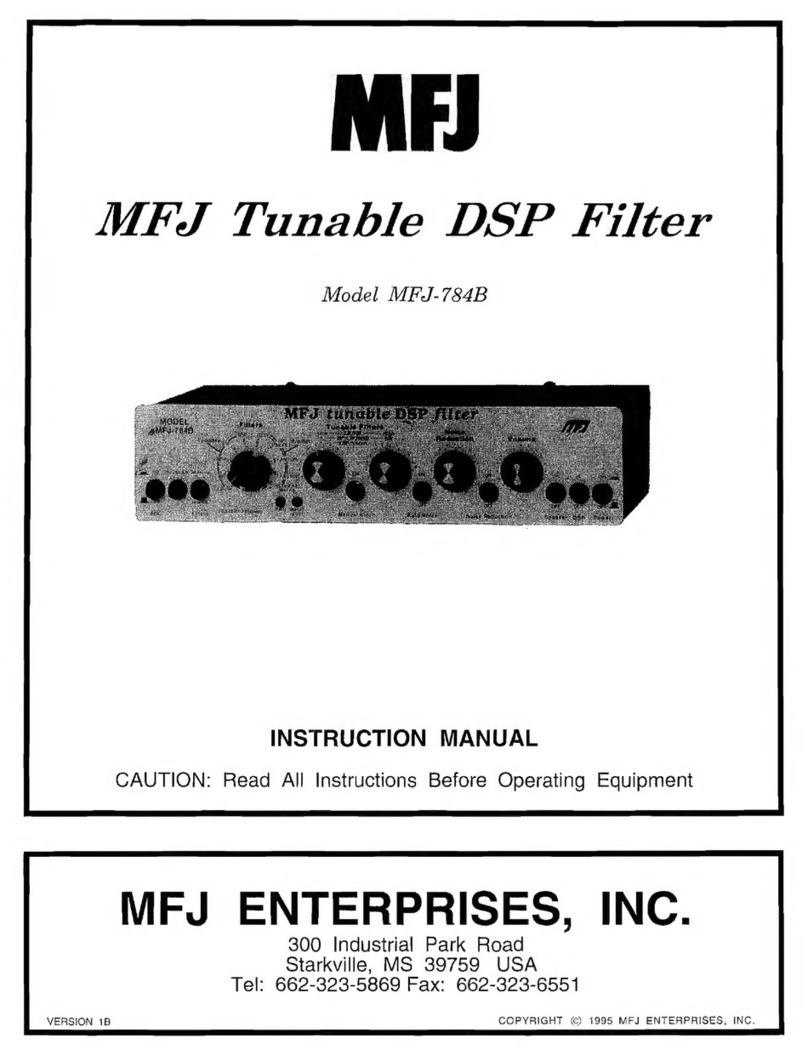

MFJ

MFJ MFJ-784B instruction manual

Unilever

Unilever pureit Copper + Eco MINERAL RO+UV+MF instruction manual

Hayward

Hayward HCF Series Installation and operation manual

Sartorius

Sartorius arium mini plus operating instructions

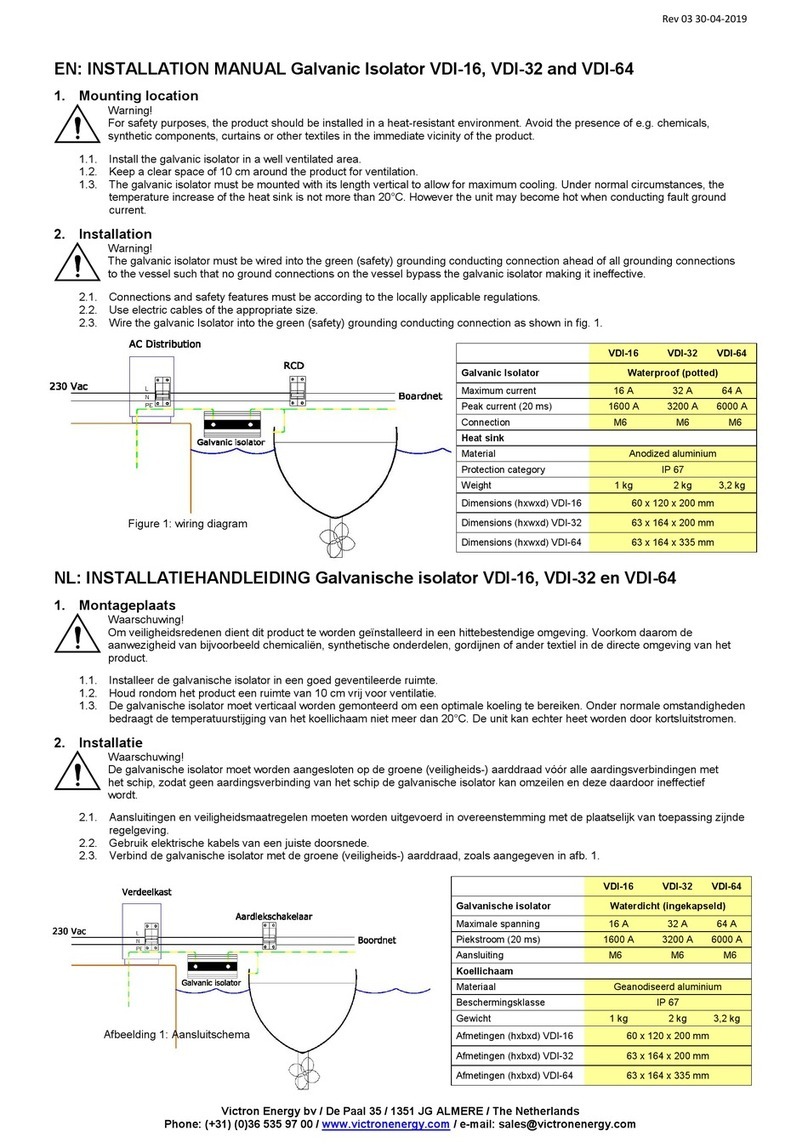

Victron energy

Victron energy VDI-16 installation manual

Loctite

Loctite LAS 250 operating manual

HYDAC International

HYDAC International NFD Spare parts list

Axeon Water Technologies

Axeon Water Technologies L1-Series user manual

MAUNAWAI

MAUNAWAI Wai Assembly and operating instructions

AquaCo

AquaCo SYS-925-3 Installation

Oase

Oase BioTec ScreenMatic2 18000 operating instructions

Kessel

Kessel LW 400 installation instructions