Step 2. Low-Speed Needle Adjustment, cont.

4. The fuel mixture may be too lean if the engine

stops at the lowest idle position or it stops when

the throttle is rapidly opened from the idle position.

Correct this by rotating the SetRight™adjustment

bar counterclockwise in small increments until the

engine transitions smoothly without hesitation upon

opening the throttle rapidly from idle.

SetRight Needle Valves

The design of the SetRight needle valve system is such

that, during normal operating conditions, the typical

user will find that the range of adjustment allowed by

the system is more than adequate for most situations.

As a matter of fact, we intended this to be used as a

tool to identify operating problems. If you find that the

range of adjustment allowed by the SetRight needle is

inadequate after your initial period of running, then a

problem in your engine system has occurred. This might

be a bad glow plug, dirty or old fuel, an air leak in the

fuel system somewhere or any number of other reasons.

Do not make any permanent adjustment range changes

to the SetRight needle system if it was once working

correctly for you and now does not. Investigate other

problems first.

However, occasionally due to atmospheric, altitude or fuel

conditions, you may find that the range of adjustment

built into the SetRight needle valve system is inadequate

for your needs. These conditions are rare and easy to fix.

High-Speed SetRight Needle Valve Correction

Should the high-speed SetRight needle valve

need to be adjusted outside of the factory-

established parameters, simply pull out the

detent spring on the high-speed needle

assembly and move the needle valve in the

desired direction so the SetRight pin passes

the spring detent. You now have re-established

a new range for your purposes.

Low-Speed SetRight Needle Valve Correction

Should the low-speed SetRight needle valve

need to be adjusted outside the factory-

established parameters, follow these steps:

A. Loosen the setscrew found on the ring of

the SetRight assembly to which the

adjustment bar is attached.

Low-Speed SetRight Needle Valve Correction, cont.

B. Rotate the needle valve itself (small

slot-headed screw inside the blue ring of

the SetRight assembly) clockwise to lean

the mixture or counterclockwise to richen

the mixture as desired.

C. Retighten the setscrew on the ring of

the SetRight assembly and you have

re-established a new range of motion.

Why would fuel go “bad”?

The largest portion of the fuel is methanol (alcohol).

Methanol is hygroscopic; it attracts moisture. This can

cause your fuel to be contaminated with water, which will

cause poor engine performance. Additionally, the UV rays

in sunlight will eventually break down the nitromethane if

the fuel jug is stored in sunlight for long periods of time.

How can you tell when your fuel has gone “bad”?

The first indications will generally be the inability to start

the engines at previously run needle-valve settings.

Another clue might be that the engine has very poor idle,

runs but bogs down tremendously during run up and/or

will not attain the same rpms that you are used to.

-

How do I keep my fuel fresh?

If you have the opportunity, look for someone at a flying

field on a sunny day who has a jug of fuel that is only

1/4 full. What you may notice is that there are droplets

attached to the top and sides of the container. This is

the moisture in the air that is condensing inside the jug

because of the greenhouse effect of the semi-translucent

plastic jug. The only way to overcome the greenhouse

effect is to store your fuel in a metal can.

-

You can also combat the effects of the moisture in the air

by squeezing all the extra air from your fuel container at

the end of the day or transferring your fuel into smaller

containers as the level of the fuel is reduced in your

gallon jug. Many pilots will invest in 1/2 gallon or quart-

size containers and only bring that amount of fuel to the

field on any given day. This allows their main supply of

fuel to stay at home in a controlled storage environment,

virtually insuring problem-free fuel.

76

Step 5. Attach the glow driver.

Step 6. Turn the engine over using an electric starter.

The engine should fire within seconds of applying

the starter.

Step 7. Allow the engine to idle for 30 seconds. Adjust the

throttle trim if necessary to achieve a constant

slow idle.

Step 8. With the glow driver still attached and a helper

securely holding the airplane, advance the

throttle smoothly to full throttle. The engine will

transition to full rpm.

Step 9. Reduce the throttle to idle and remove the

glow driver.

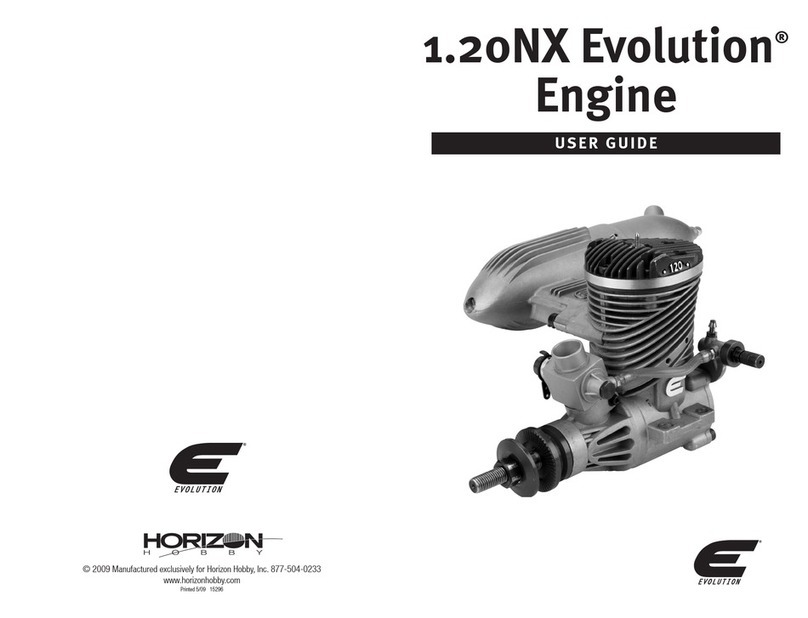

Needle Limiters

In some conditions: Due to high altitudes, extreme

temperatures, etc., it may be necessary to slightly adjust

the idle and high-speed needle valves. The

high- and low-speed needles have limiters that prevent

over adjustment.

If your engine starts from the above procedure, but won’t

reliably continue to run with the glow driver removed,

follow the steps above right.

Step 1. High-Speed Needle Adjustment

With the engine running, advance the throttle

to full throttle while a helper securely holds your

airplane. Carefully pinch and release the fuel line

to temporarily restrict the fuel flow.

Caution: Do not reach over the propeller while

the engine is running.

Correct: If the high-speed needle adjustment

is correct, the engine will increase rpm slightly

(about 300 rpm) and then die.

Too Rich: If the engine increases a lot (1,000

rpm or greater), the high-speed needle is too rich

and must be leaned or turned clockwise.

Too Lean: If the engine doesn’t increase rpm and

simply dies, the high-speed needle is lean and

must be richened or turned counterclockwise.

Step 2. Low-Speed Needle Adjustment

The low-speed or idle needle valve, included with

the SetRight™ assembly, is preadjusted at the

factory for best performance. It may be necessary

to fine-tune the low-speed adjustment using the

following procedure:

1. Start the engine and let it warm up, prior

to attempting any adjustments. Make sure

that the high-speed adjustment process is

complete before attempting to adjust the

low-speed needle valve.

2. Close the throttle slowly. You will adjust the

low-speed needle setting by rotating the

SetRight adjustment bar clockwise to lean

the engine and counterclockwise to richen the

engine.

Caution: Do not attempt to adjust the low-speed

needle valve while the engine is running.

3. The fuel mixture should be adjusted as

follows: The fuel mixture is too rich if, when

opening the throttle rapidly, the engine emits

smoke and "stutters" or "stumbles." Correct

this by rotating the SetRight adjustment bar

clockwise in small increments. Continue this

process until the engine transitions smoothly

from low rpm idle to high rpm without hesitation

upon opening the throttle rapidly.

The needle valves come preset from the factory. Extreme

conditions may require some minor adjustments. Note that

the needle adjustment range is limited, preventing adjust-

ment beyond the practical range.

Low-Speed Needle AdjustmentHigh-Speed Needle Adjustment