Operation Manual / Power2 / 1 Introduction

1 Introduction / 1.5 Storage of new low-pressure and high-pressure

stages

© Copyright 2017 ABB. All rights reserved. HZTL4004_EN Revision D June 2017

1.5 Storage of new low-pressure and high-pressure

stages

Storage of new low-pressure and high-pressure stages and cartridge groups for up to

6 months

New low-pressure and high-pressure stages and cartridge groups from ABB Turbo Systems

can be stored in their closed packages for 6 months from the date of delivery without addi-

tional mothballing measures (indicated by VCI label on package).

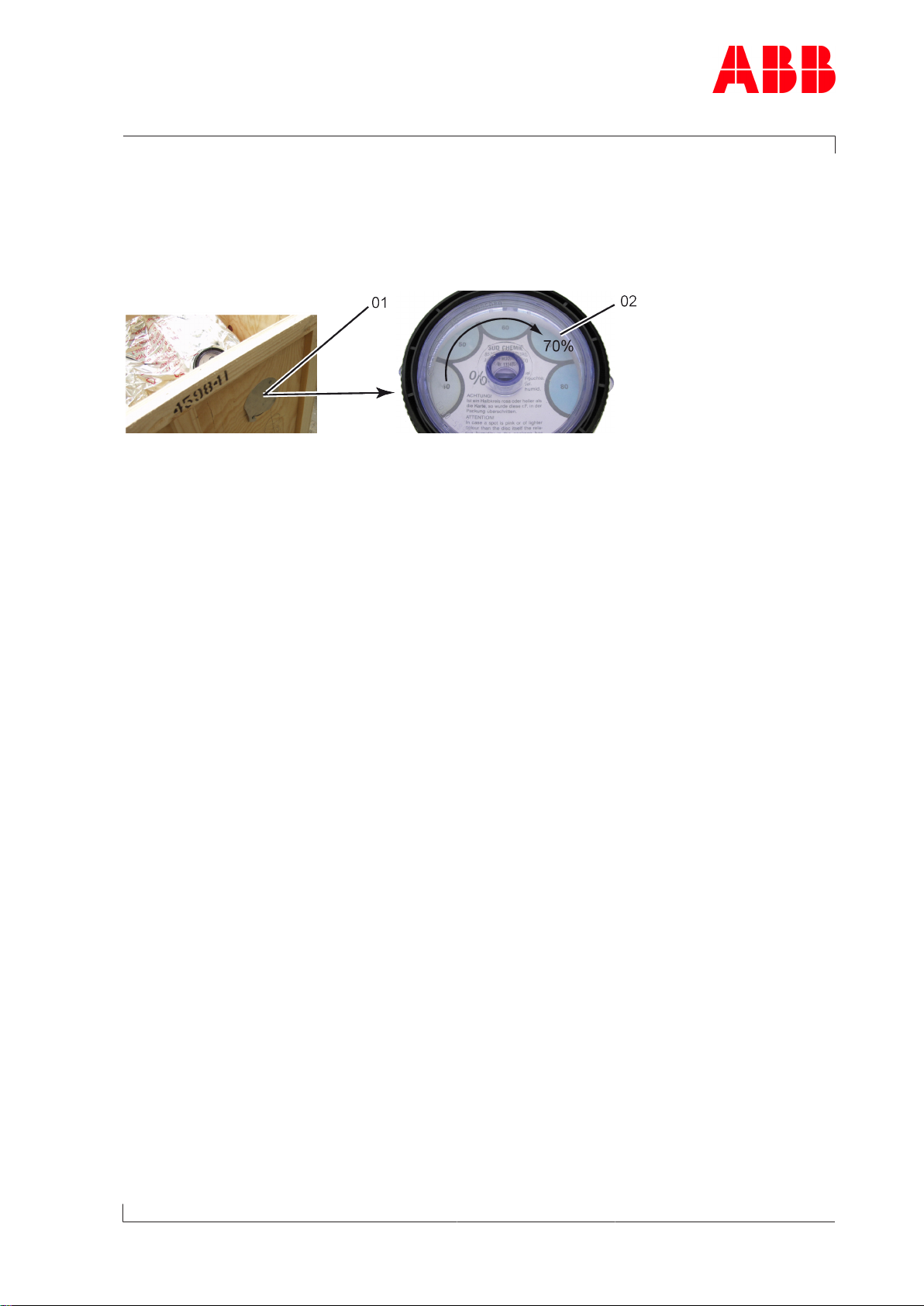

Fig.2: Volatile Corrosion Inhibitor (VCI)

Only dry rooms with 40...70 % atmospheric humidity, in which no water condensation can

form, are suitable as storage locations.

Storage of new low-pressure and high-pressure stages and cartridge groups for more

than 6 months (VCI)

WARNING

Health protection when handling VCI

VCI products are not hazardous in terms of the Ordinance on Hazardous

Substances. Nevertheless, the following points must be observed when

handling VCI:

uEnsure proper space ventilation.

uDo not eat, drink or store food at the workplace while working with VCI.

uWear safety gloves.

uClean hands and face after working with VCI.

uFor more information, see www.branopac.com.

Every 6 months, the following mothballing measures are required:

uOpen package.

uRemove VCI corrosion protection emitter from package and replace with a new VCI corro-

sion protection emitter of the same kind. New VCI corrosion protection emitters can be

obtained from www.branopac.com.

uOld VCI corrosion protection emitters must be disposed of in an environmentally compat-

ible, professional way and in compliance with locally applicable regulations.

uClose package. The more tightly the package is sealed, the longer the protection dura-

tion.

Page 6 / 8