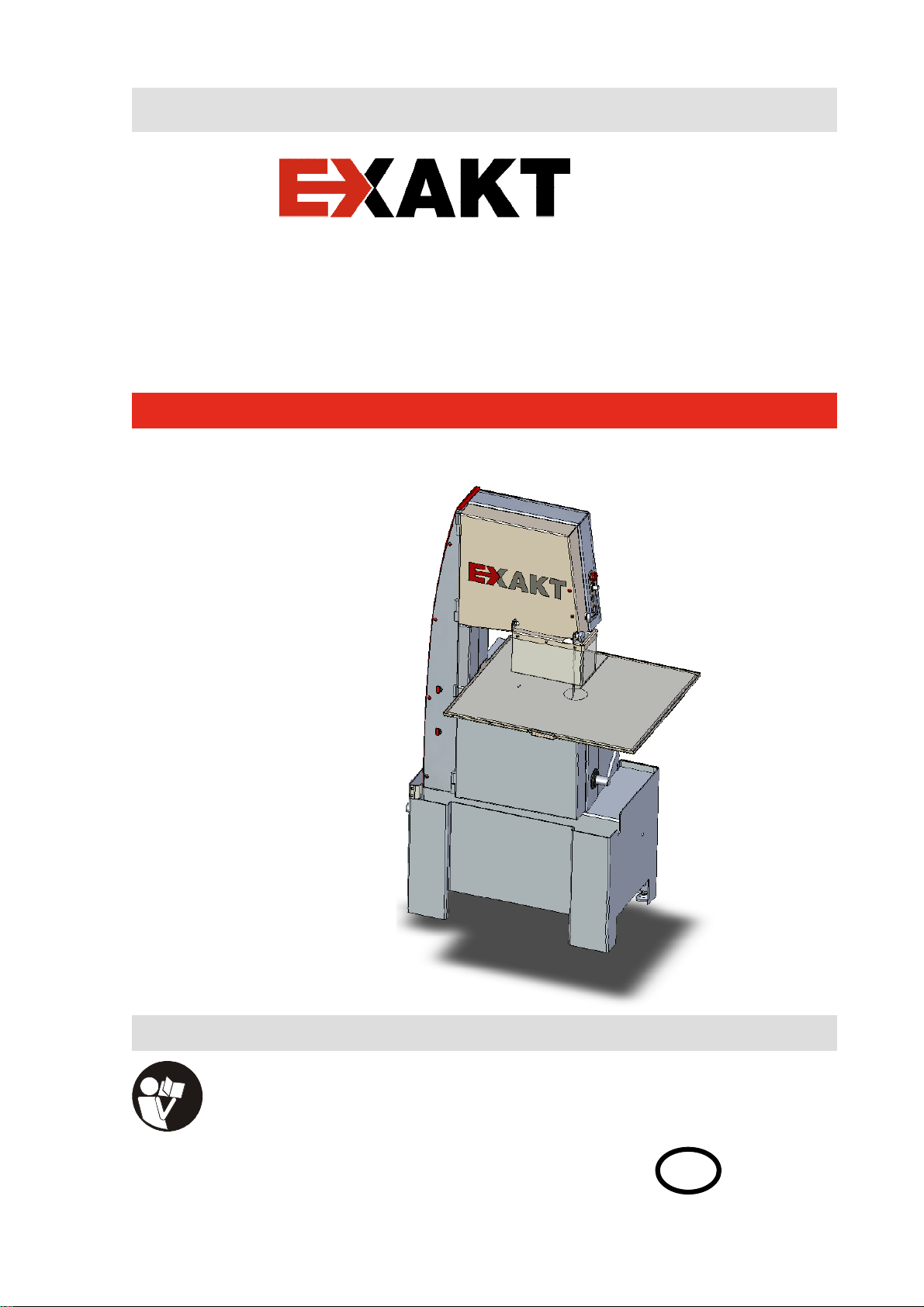

Exakt 312 User manual

Operating instructions

Diamond Pathology Saw

EXAKT 312

Edition 10_2010 - 38891EN-900-AB

It is imperative you read the operating instructions prior to placing the unit

in operation for the first time! Follow safety instructions!

Translation of original operating instructions (for the end user)

E

N

English

Edition 10_2010 - 38891EN-900-AB

2

EXAKT Advanced Technologies GmbH

Robert-Koch-Strasse 5

22851 Norderstedt

Germany

Tel: +49 (0)40 52 95 60-0 Fax: +49 (0)40 5 24 99 59

Imprint:

Operating instructions EXAKT 312

1st issue April 2010

© EXAKT Advanced Technologies GmbH, Norderstedt

Layout: WBS/TR06

Text layout: WBS/TR06

Illustrations: EXAKT Advanced Technologies GmbH, WBS/TR06

This documentation is copyrighted by EXAKT. Without prior written approval, the

documentation may not be copied or be used contrary to the legitimate interests of

EXAKT.

Subject to change without notice!

Edition 10_2010 - 38891EN-900-AB

3

Contact addresses

Manufacturer's address:

EXAKT Advanced Technologies GmbH

Robert-Koch-Strasse 5

22851 Norderstedt

Germany

Tel: +49 (0)40 52 95 60-0 Fax: +49 (0)40 5 24 99 59

Dealer's address and service address:

Note:

In case of enquires related to service and to order spare parts, please contact

the dealer from whom you purchased the unit.

Edition 10_2010 - 38891EN-900-AB

4

Table of contents

1

Safety............................................................................................................................ 7

1.1

General safety instructions.....................................................................................7

1.2

Safety devices........................................................................................................ 9

Emergency-stop pushbutton.............................................................................. 9

Nip guard........................................................................................................... 9

Acknowledge button ..........................................................................................9

Door lock.........................................................................................................10

Lockable main switch.......................................................................................10

2

About these instructions ........................................................................................... 11

2.1

Warning and danger symbols............................................................................... 11

2.2

Significance of signal words................................................................................. 11

2.3

Conventions.........................................................................................................12

3

Description of function .............................................................................................. 13

3.1

Correct use........................................................................................................... 13

3.2

Application............................................................................................................ 13

3.3

Special properties.................................................................................................13

3.4

Features............................................................................................................... 14

4

Description of the unit ............................................................................................... 15

4.1

Scope of delivery.................................................................................................. 15

4.2

Optional accessories............................................................................................ 16

4.3

An overview of the EXAKT 312 ............................................................................ 18

Front view........................................................................................................ 18

Right side view ................................................................................................19

Rear and left side view.....................................................................................20

Front view, doors removed............................................................................... 21

5

Installation .................................................................................................................. 22

5.1

Transport.............................................................................................................. 22

5.2

Installation location...............................................................................................22

5.3

Installing the EXAKT 312...................................................................................... 23

5.4

Assembly of the unit.............................................................................................23

Assembly of the work table, 1st part................................................................ 24

Fitting the top pulley.........................................................................................25

Fitting the cutting band ....................................................................................25

Centring the cutting band.................................................................................28

Fitting the doors............................................................................................... 29

Assembly of the work table, 2nd part...............................................................29

Mounting the splash guard............................................................................... 30

5.5

Connection to water and power supply.................................................................31

Edition 10_2010 - 38891EN-900-AB

5

Connecting the EXAKT 312 to the drainage system ........................................ 31

Connecting the EXAKT 312 to the water supply...............................................31

Connecting the EXAKT 312 to the power supply..............................................32

6

Placing in operation for the first time ....................................................................... 32

6.1

Undertaking a test run..........................................................................................33

6.2

Ending a test run..................................................................................................33

6.3

Checking the cutting band centring ......................................................................34

7

Routine operation....................................................................................................... 35

7.1

Preparing routine operation.................................................................................. 35

7.2

Undertaking routine operation..............................................................................36

Adjusting the height of the top cutting band guide............................................ 36

Adjusting the cutting band speed.....................................................................37

Cutting the sample...........................................................................................38

Ending the cutting process............................................................................... 38

7.3

Ending routine operation...................................................................................... 38

8

Cleaning...................................................................................................................... 39

8.1

General cleaning instructions............................................................................... 39

8.2

Cleaning in accordance with hygiene regulations.................................................39

8.3

Cleaning schedule................................................................................................ 40

8.4

Cleaning agents................................................................................................... 41

8.5

Cleaning and pre-disinfecting...............................................................................41

Cleaning the work table and external housing.................................................. 41

Pre-disinfecting the external and internal housing............................................ 41

Pre-disinfecting the work table.........................................................................41

8.6

Disinfecting...........................................................................................................42

Disinfecting the cutting band............................................................................ 42

Disinfecting the top pulley................................................................................ 43

Disinfecting the bottom pulley..........................................................................44

Disinfecting the cutting band guide.................................................................. 45

Disinfecting the internal and external housing.................................................. 46

8.7

Re-fitting removed components............................................................................ 46

9

Maintenance ............................................................................................................... 47

9.1

Maintenance after each use.................................................................................47

Cutting band.................................................................................................... 47

Cleaning a soiled cutting band using a whetstone............................................ 47

Removing the cutting band..............................................................................47

Fitting the cutting band ....................................................................................48

Band guide, top ............................................................................................... 50

Cutting band guide, work table.........................................................................50

Edition 10_2010 - 38891EN-900-AB

6

Cutting band flushing, bottom..........................................................................50

Drain pan.........................................................................................................50

9.2

Weekly maintenance............................................................................................ 50

Cooling water system ......................................................................................50

Flush water system..........................................................................................50

9.3

Maintenance every six months.............................................................................51

Cooling water hose..........................................................................................51

Replacing the cooling water hose.................................................................... 52

Checking the EXAKT 312 is level .................................................................... 52

Mains cable ..................................................................................................... 52

9.4

Annual maintenance.............................................................................................53

Replacing the yellow belt................................................................................. 53

Electrical system and safety circuit.................................................................. 53

9.5

Maintenance as required...................................................................................... 54

Replacing a fuse..............................................................................................54

10

Faultfinding and troubleshooting.............................................................................. 56

11

Disposal......................................................................................................................58

11.1

Disposing of packaging........................................................................................ 58

11.2

Disposing of unit................................................................................................... 58

12

Technical data............................................................................................................. 59

13

Spare parts and consumables................................................................................... 60

13.1

Spare parts list, EXAKT 312 diamond pathology saw........................................... 60

13.2

Consumables....................................................................................................... 61

13.3

Optional accessories............................................................................................ 61

14

Glossary......................................................................................................................62

15

Index............................................................................................................................ 63

16

Declaration of conformity.......................................................................................... 65

Safety

Edition 10_2010 - 38891EN-900-AB

7

1 Safety

1.1 General safety instructions

Every individual who is tasked with setting up, placing in operation,

operation, maintenance and care of the EXAKT 312 and the related

components must have read and understood these instructions, in

particular the Safety chapter.

If necessary instruction must be provided taking into account the specific

qualifications of the related individual.

It is imperative all safety instructions are followed for your safety.

Prior to placing the unit in operation, the operator must ensure all safety-

related conditions are met.

Note The applicable accident prevention regulations and generally applicable

health and safety regulations are to be followed.

Refrain from any action that:

•places the life and limb of the user or third parties at risk,

•causes degradation of the unit or other items,

•impairs the safety and the function of the unit or

•disregards the safety instructions stated.

The unit may only be maintained by individuals who are familiar with the

unit and informed about the hazards, and who have the necessary

qualifications.

Risk of electric shock!

Mains cable damage can result in serious injuries or death due to an

electric shock and cause damage to the unit.

uNever place the EXAKT 312 in operation with a damaged mains

cable.

uAlways check mains cable for damage.

uProtect mains cable against heat, aggressive liquids and sharp edges.

uLay mains cable so that it cannot be damaged.

uKeep mains cable away from water.

uUse a splash-proof mains socket.

Have a damaged mains cable replaced by a service engineer.

Danger –very powerful permanent magnets!

Mortal danger for individuals with heart pacemakers due to magnetic

fields.

uIndividuals with heart pacemakers must keep away from magnetic

fields.

Safety

Edition 10_2010 - 38891EN-900-AB

8

Danger –biological contamination!

Contaminated samples and contaminated water can cause infections.

uAlways wear the stipulated protective clothing and safety glasses for

work with the EXAKT 312.

uUse suitable disinfection methods in accordance with applicable

statutory provisions and guidelines, and the hygiene regulations.

uDispose of waste water, cleaning agents and used protective clothing

in accordance with applicable statutory provisions and the hygiene

regulations.

Risk of entanglement!

Hair and items of clothing can become entangled in the rotating cutting

band.

uWear tight-fitting clothing during all work.

uProtect long hair with headgear.

Warning –cuts!

Cuts may be caused on contact with the moving cutting band.

uDo not touch the cutting band in operation.

uEnsure you are standing firmly and the working area is clear.

Warning –risk of slipping!

Injuries due to slipping.

uKeep the floor around the EXAKT 312 as dry as possible.

uWear non-slip shoes.

Warning –very powerful permanent magnets!

Risk of injury due to crushing.

uOn opening and closing the doors, do not grasp the edge of the door.

Attention –incorrect mains voltage!

If the mains voltage is incorrect, the EXAKT 312 may be damaged.

uOnly connect the EXAKT 312 to the mains voltage stated on the type

plate.

Attention –damage due to very powerful permanent magnets

Hazard due to magnetic fields for

– magnetic data carriers

– electronic equipment

uElectronic equipment and magnetic data carriers are to be kept away

from magnetic fields.

Attention –damage due to incorrect accessories and spare parts!

The usage of accessories and spare parts that have not been

recommended by EXAKT can impair the safety and function of the

EXAKT 312. Any warranty and/liability on the part of EXAKT for damage

Safety

Edition 10_2010 - 38891EN-900-AB

9

caused by accessories or spare parts that have not been recommended

is excluded.

uUse only accessories and genuine spare parts recommended by

EXAKT.

1.2 Safety devices

The safety devices on the EXAKT 312 comply with the statutory

requirements and are aimed at preventing injury or damage.

Emergency-stop pushbutton

The emergency-stop pushbutton is used to stop the cutting band motor

within approx. 4 seconds in case of danger.

Abb. 1 Emergency-stop pushbutton

In case of danger:

uPress the emergency-stop pushbutton 14.

uRectify malfunction.

uPull out the emergency-stop pushbutton 14 to unlock.

uPress the acknowledge button.

The interrupted circuit is closed again. However, the cutting band

does not

re-start automatically.

uTo start the cutting band, press the start button.

Nip guard

The nip guards protect against unintentional entanglement in the rotating

pulleys.

Acknowledge button

After any action that interrupts the safety circuit on the EXAKT312, the

14

Safety

Edition 10_2010 - 38891EN-900-AB

10

acknowledge button must be pressed prior to restarting the EXAKT 312.

Door lock

An electronically controlled safety circuit ensures the pulleys stop

automatically within 6 seconds on opening the doors.

Lockable main switch

By attaching a padlock the EXAKT 312 can be secured against

unauthorised usage.

About these instructions

Edition 10_2010 - 38891EN-900-AB

11

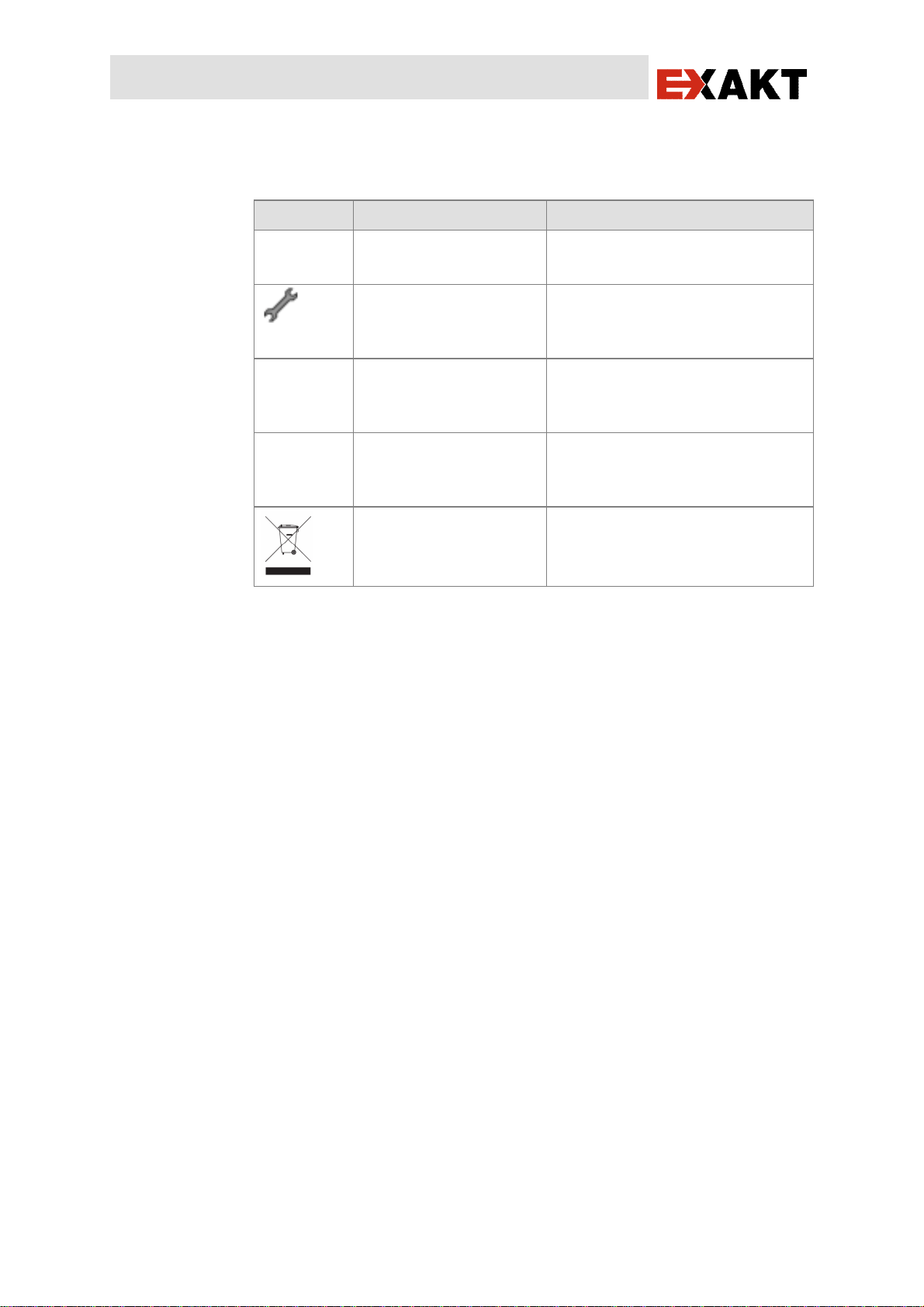

2 About these instructions

In these operating instructions graphic symbols help you to use all

functions correctly and optimally.

2.1 Warning and danger symbols

The symbols listed below warn of a possible risk of injury as well as

damage.

Symbol Term Significance

General safety notice Warns of risk of injury and

damage due to improper

operation.

Mains voltage Warns of injuries and damage

due to electric shock.

Biological

contamination Warns of harm to the health due

to biological contamination.

Hand injuries Warns of hand injuries, e.g.

crushing.

Powerful permanent

magnets Warns of damage due to very

powerful permanent magnets.

No entry for

individuals with heart

pacemakers

Forbids individuals with heart

pacemakers to enter the area

around the permanent magnets.

2.2 Significance of signal words

The sig

nal words listed here identify the severity of the possible source of

a hazard.

Signal word Significance

Danger! Disregard will result in very serious injuries or death.

Warning! Disregard can result in serious injuries and even

death.

Caution! Disregard can result in minor or moderate injuries.

Attention! Disregard can result in damage.

About these instructions

Edition 10_2010 - 38891EN-900-AB

12

2.3 Conventions

Symbol Significance

Note Important note This symbol identifies important

additional information.

Tool This symbol indicates that a

certain tool or consumable is

required.

•Bullet-point list Properties of the unit or

individual components are given

as a list of points.

uInstructions Instructions prompt you to do

something in the sequence

stated.

Disposal Information on the disposal of

packaging material, wearing

parts and faulty parts of the unit.

Description of function

Edition 10_2010 - 38891EN-900-AB

13

3 Description of function

The following subjects are described in this chapter:

•Correct use

•Application

•Special properties

•Features

3.1 Correct use

Permanently setup engine-powered band saws are used in medical

pathology for quickly cutting tissue samples and artificial implants for

histological studies.

The diamond pathology saw EXAKT 312 is designed as a cutting band

system for cutting fresh animal and human tissue, bones and implants as

per the safety instructions and in accordance with the relevant standards.

The EXAKT 312 is only of limited suitability for cutting implants made of

ductile substances (e.g. soft a

luminium, copper), as the chip clearance on

the cutting band can quickly become clogged on cutting such materials.

The EXAKT 312 is only intended to be used in medical pathology. In this

application only the original components supplied may be used. Any ot

her

usage beyond that stated is considered incorrect use. The manufacturer

is not liable for resulting damage. The risk is borne solely by the user.

3.2 Application

The EXAKT 312 has been developed for use in medical pathology. Users

are doctors, scientists and specialist medical personnel.

3.3 Special properties

Currently, band saws with toothed saw bands, as are used in the meat

processing industry, are used in pathology. They involve a high risk of

injury. The EXAKT 312 stands out compared to these band saws due to:

•a lower risk of injury in case of unintentional contact with the cutting

band

•high cut quality, even on bones with implants

•a lower risk of infection due to water flushing/cooling of the cut

•easy cleaning and disinfection

Description of function

Edition 10_2010 - 38891EN-900-AB

14

3.4 Features

The EXAKT 312 is equipped with the following parts as standard:

•Integrated, adjustable water flushing/cooling

•Height-adjustable cutting band guide

•Cutting band speed control

•Splash guard

•Safety devices:

– Emergency-stop pushbutton

– Nip guard

– Acknowledge button

– Door lock

– Lockable main switch

Description of the unit

Edition 10_2010 - 38891EN-900-AB

15

4 Description of the unit

The following subjects are described in this chapter:

•Scope of delivery

•Optional accessories

•An overview of the EXAKT 312

4.1 Scope of delivery

The scope of delivery of the EXAKT 312 diamo

nd pathology saw includes

the following components:

•Saw base unit

•Cutting band (as required)

•Work plate (plastic)

•Work table tray with support

•Run-off plate

•Cutting band guide, work table

•Door, top

•Door, bottom

•Pulley, top, with yellow belt (pulley, bottom, is pre-assembled)

•Water supply hose incl. clips

•Water drain hose incl. clips

•Splash guard (1 x)

•Double open-end spanner AF 14/17

•Screwdriver size 4

•Hexagon key set

•Spirit level

•Operating instructions

Description of the unit

Edition 10_2010 - 38891EN-900-AB

16

4.2 Optional accessories

To make the work easier, the following accessories can be ordered for

the EXAKT 312 (for order numbers see section 13.3 Optional

accessories):

Accessory Description

Rip fence

For straight and parallel cuts on tissue

samples a rip fence can be installed on the

work table.

Line laser

To align the cutting plane on the sample

with the aid of the laser projection of the

saw blade plane.

Cleaning gun

For intermediate cleaning and rinsing of the

work plate after use, we recommend a

cleaning gun. The cleaning gun is

connected to the water supply connection.

When not in use it is placed in a holder on

the base.

Castor set

A castor set eases the transport of the saw

base unit to the installation location. The

castors can be locked once the unit is

setup.

Description of the unit

Edition 10_2010 - 38891EN-900-AB

17

Table illumination

A LED-ledge gives permanent illumination

of the work table. Optimum illumination of

the sample during cutting with low energy

consuption (approx. 5W)

Large splash

guard

Better cover of the sample especially for

large samples or when working with high

cooling flush. Very good protection against

spraying water by a large plexiglass plate

additionally with flexible plastic foils. Retrofit

at each machine can easilly done by the

operator.

Additional diamond

cutting band for cutting

implants

On cutting implants the cutting band will

wear very quickly. It is recommended to use

separate cutting bands for cutting implants

and for cutting fresh samples.

Whetstone

With some samples the cutting band will

clog very quickly. The cutting band can be

cleaned quickly and conveniently using the

whetstone.

Description of the unit

Edition 10_2010 - 38891EN-900-AB

18

4.3 An overview of the EXAKT 312

Front view

Abb. 2 Front side of unit

1 Splash guard 8 Door, bottom

2 Door, top

3 Cutting band 10 Drain pan to drain off the

waste water

4 Work plate (plastic) 11 Drain nozzle for the water

drain hose

5 Cutting band guide, work

table 12 Flush water control to

control the amount of flush

water

6 Work table tray to drain off the

waste water 13 Cooling water control to

control the cooling water

flow rate

7 Run-off plate, connected under

the work table tray

2

11

8

3

4

5

6

7

10

12

13

1

Description of the unit

Edition 10_2010 - 38891EN-900-AB

19

Right side view

Abb. 3 Right side of unit

14 Emergency-stop pushbutton to stop the cutting band within

approx. 4 seconds

15 Cutting band speed control

16 Start button to start the cutting band

17 Stop button to stop the cutting band after 6 seconds

18 Tensioning lever for tensioning and relieving the tension on the

cutting band

19 Clamping bolt for the top cutting band guide

19a

Clamping bolt for the splash guard

18

17

14

16

15

19

19a

Description of the unit

Edition 10_2010 - 38891EN-900-AB

20

Rear and left side view

Abb. 4 Rear and left sideof unit

20 Adjusting lever (outer) to adjust the pulley for cutting band

centring

21 Acknowledge button to restart the unit after interruption

22 Main switch to switch on and off the mains voltage

23 Water connection for cooling and flushing

24 Locking lever (inner) to lock the pulley setting

24

22

20

21

23

Table of contents

Other Exakt Saw manuals