1

SOFTENER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA TF: 705.733.8900 WWW.EXCALIBURWATER.COM

TABLE OF CONTENTS

1) Installation ............................................................................................................................................ 3

1.1) Pre-installation instructions.......................................................................................................... 3

1.2) General Installation and Service Warnings................................................................................... 3

1.3) Site Requirements......................................................................................................................... 3

1.4) Loading Instructions...................................................................................................................... 4

1.5) Installation Drawing ...................................................................................................................... 5

1.6) Piping and Instrumentation Drawing............................................................................................ 6

1.7) Installation Instructions ................................................................................................................ 7

1.8) Plumbing ....................................................................................................................................... 7

1.9) Brine Line Connection................................................................................................................... 7

1.10) Overflow Line Connection......................................................................................................... 8

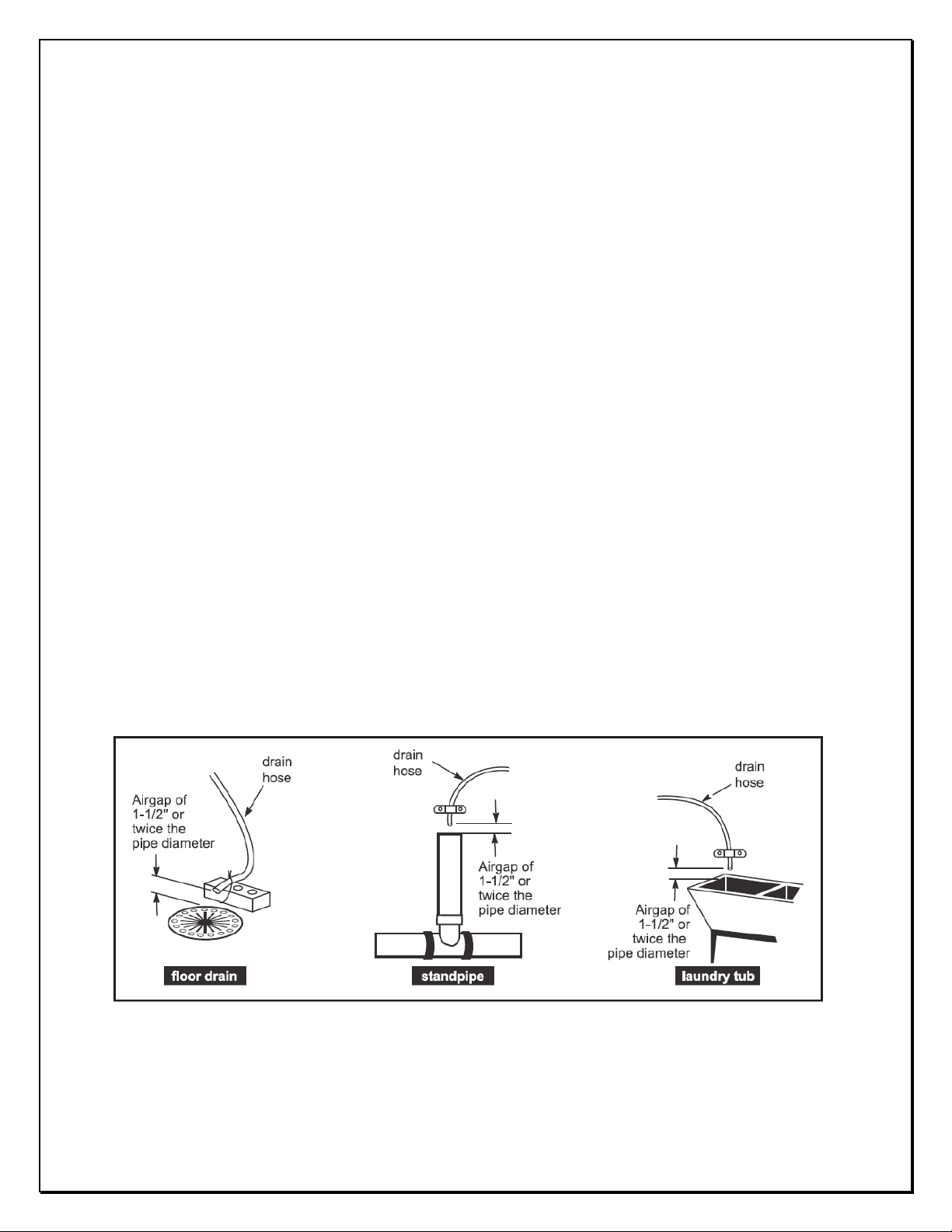

1.11) Drain Line .................................................................................................................................. 8

1.12) System Drawing ........................................................................................................................ 9

1.13) Bypass Valve............................................................................................................................10

1.14) Wiring......................................................................................................................................12

1.15) ALT A Control Valve Wiring .....................................................................................................13

2) Programming and Start Up ................................................................................................................. 14

2.1) Regeneration and Error Screens .................................................................................................14

2.2) Button Operation........................................................................................................................14

2.3) User Displays............................................................................................................................... 16

2.4) Setting Time of Day.....................................................................................................................16

2.5) Startup Instructions ....................................................................................................................17

2.6) Configuration Settings ................................................................................................................18

2.7) Installer Display Settings .............................................................................................................19

2.8) OEM Softener System Setup....................................................................................................... 20

2.9) Specifications ..............................................................................................................................24

2.10) Programming Summary ..........................................................................................................25

2.11) Flow Controls and Injectors .................................................................................................... 25

3) Control Valve....................................................................................................................................... 26

3.1) Control Valve Function and Cycles ofOperation..........................................................................26

3.2) Flow Diagrams............................................................................................................................. 27

3.3) Components of Control Valve..................................................................................................... 30