Exhausto VEX200 series User manual

Other manuals for VEX200 series

5

This manual suits for next models

2

Table of contents

Other Exhausto Control Unit manuals

Exhausto

Exhausto MCCW User manual

Exhausto

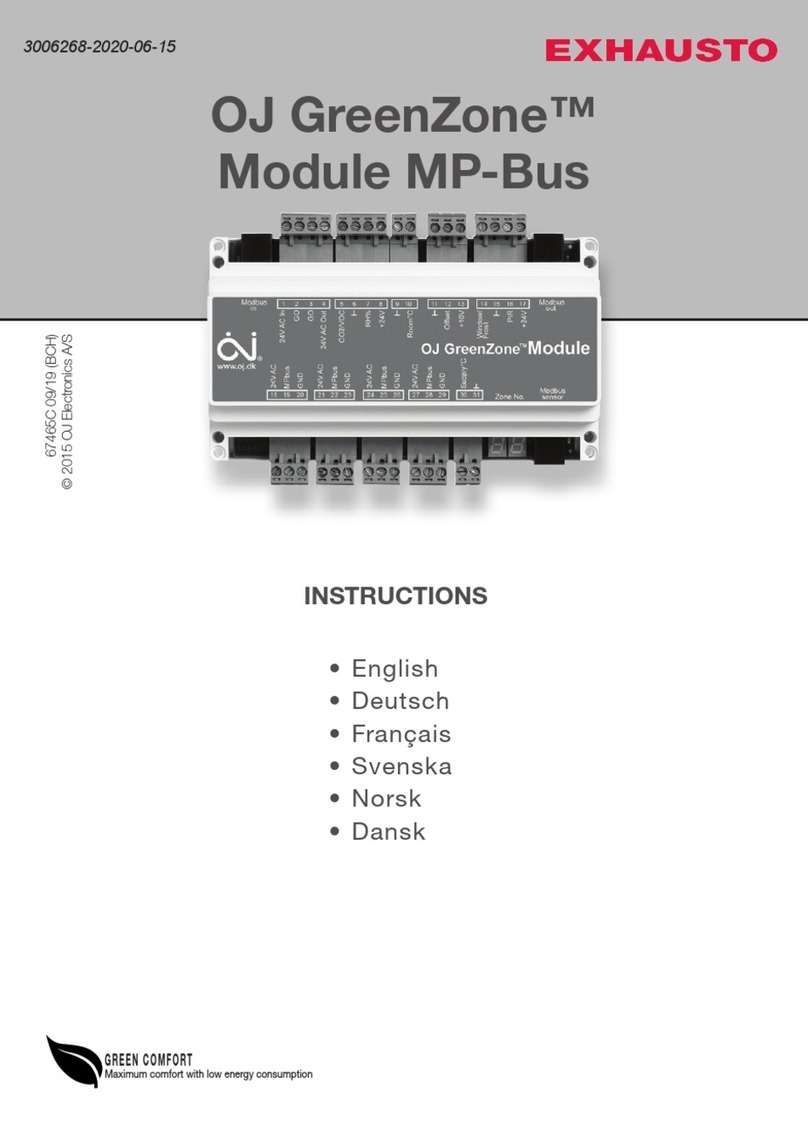

Exhausto OJ GreenZone Module M User manual

Exhausto

Exhausto EBC 10-P Installation instructions

Exhausto

Exhausto OJ GreenZone Module A User manual

Exhausto

Exhausto EBC12 Series User manual

Exhausto

Exhausto VEX260 User manual

Exhausto

Exhausto OJ GreenZone User manual

Popular Control Unit manuals by other brands

bolid

bolid S2000-AR8 installation manual

LIFE home integration

LIFE home integration GENIUS GE 224 Instructions and indications for installation, use and maintenance

Puls

Puls DIMENSION YR40.245 manual

Emerson

Emerson ASCO 290 Series Installation and maintenance instructions

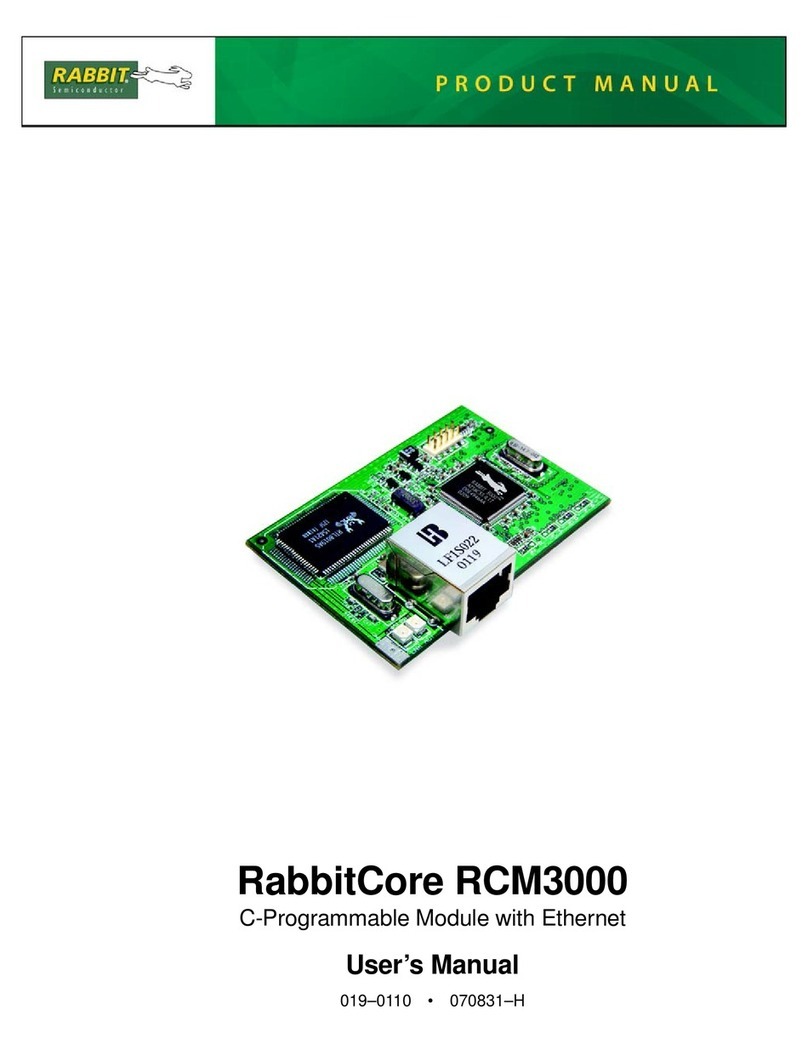

Rabbit

Rabbit RabbitCore RCM3000 user manual

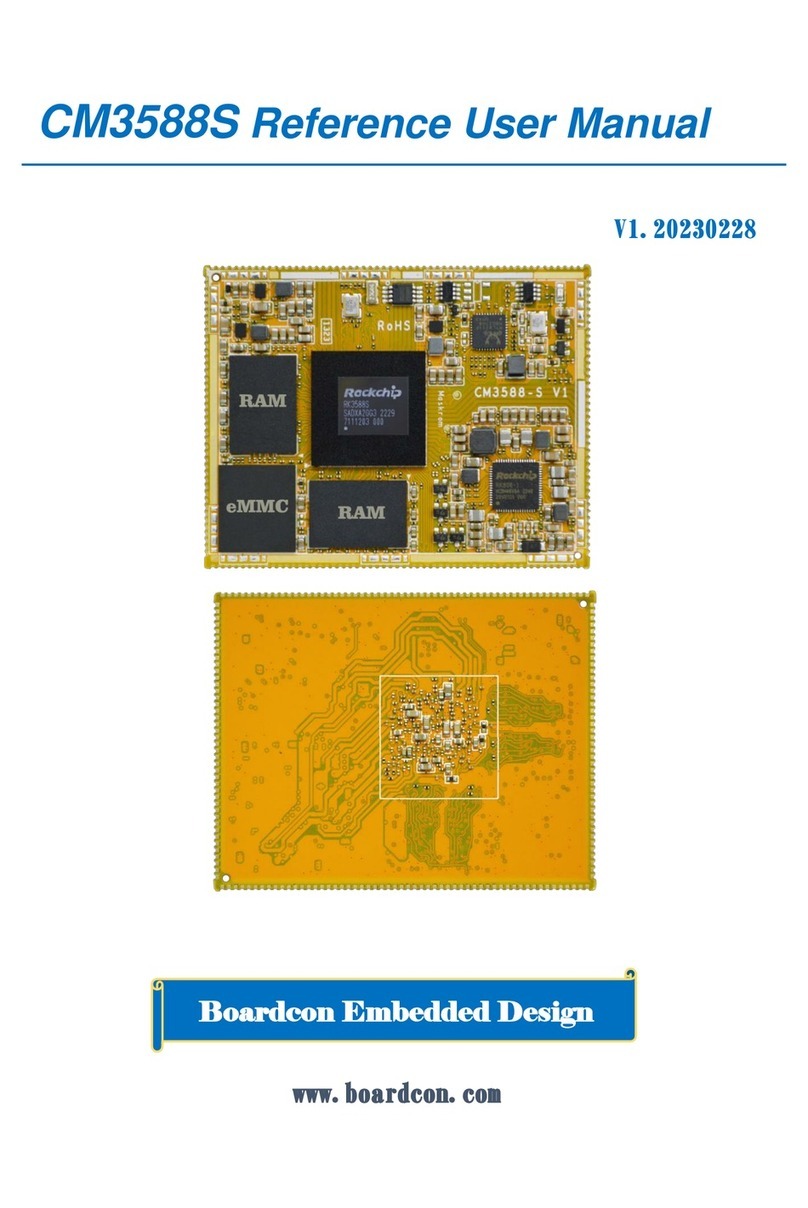

Boardcon Embedded Design

Boardcon Embedded Design CM3588S Reference User Manual