Exhausto MCCW User manual

EXHAUSTO A/S

Odensevej 76

DK-5550 Langeskov

Tel. +45 65 66 12 34

Fax +45 65 66 11 10

exhausto@exhausto.dk

www.exhausto.dk

3006026-2018-11-22.fm Product Instruction

Cooling control with water coil

Styring af køling med vandflade

Kühlregelung mit Wasserregister

Styring av kjøling med vannbatteri

Styrning av kylning med vattenbatteri

Regeling van koeling met waterelement

Vesipatterilla jäähdyttämisen ohjaaminen

MCCW Module

3006026-2018-11-22.fm

2/88

1. GB - Product instruction

1.1 Description of MCCW (Modbus Coil Cold Water) ...........................................................................4

2. Fitting and connection

2.1 Positioning and fitting of the MCCW module ..................................................................................6

2.2 Positioning the temperature sensor (TE-SUPPLY).........................................................................6

2.3 Correct fitting of feed water temperature sensor ...........................................................................7

2.4 Cooling coil ........................................................................................................................................8

3. Electrical installation

3.1 Connection diagrams ......................................................................................................................10

3.2 Connection of Modbus devices......................................................................................................12

4. Commissioning

4.1 Commissioning ................................................................................................................................ 14

5. Troubleshooting

5.1 HMI panel error messages ..............................................................................................................15

1. DK - Produktvejledning

1.1 Beskrivelse af MCCW (Modbus Coil Cold Water) .........................................................................16

2. Montage og tilslutning

2.1 Placering og montage af MCCW-modulet .....................................................................................18

2.2 Placering af temperaturføler (TE-SUPPLY) ...................................................................................18

2.3 Korrekt montage af fremløbstemperaturføler ...............................................................................19

2.4 Køleflade...........................................................................................................................................20

3. El-installation

3.1 Tilslutningsdiagram for spændingsforsyning og styreboks .......................................................22

3.2 Tilslutning af modbus-enheder ......................................................................................................24

4. Idriftsættelse

4.1 Idriftsættelse ....................................................................................................................................26

5. Fejlsøgning

5.1 Fejlmeddelelser i HMI-panel............................................................................................................27

1. DE - Betriebsanleitung

1.1 Beschreibung von MCCW (Modbus Coil Cold Water) ..................................................................28

2. Montage und Anschluss

2.1 Anordnung und Montage des MCCW-Moduls...............................................................................30

2.2 Anordnung des Temperaturfühlers (TE-SUPPLY) ........................................................................30

2.3 Korrekte Montage des Temperaturfühlers für Vorlaufwasser .....................................................31

2.4 Kühlregister......................................................................................................................................32

3. El-Installation

3.1 Anschlussdiagramm für Spannungsversorgung und Steuergerät .............................................34

3.2 Anschluss von Modbus-Einheiten: ................................................................................................36

4. Inbetriebnahme

4.1 Inbetriebnahme ................................................................................................................................38

5. Fehlersuche

5.1 Fehlermeldungen im HMI-Panel .....................................................................................................39

1. NO - Produktveiledning

1.1 Beskrivelse av MCCW (Modbus Coil Cold Water) ........................................................................40

2. Montering og tilkobling

2.1 Plassering og montering av MCCW-modulen ...............................................................................42

2.2 Plassering av temperaturføler (TE-SUPPLY).................................................................................42

2.3 Korrekt montering av turvannstemperaturføler............................................................................43

2.4 Kjølebatteri .......................................................................................................................................44

3. Elektrisk installasjon

3.1 Koblingsskjema for matespenning og styreboks.........................................................................46

3.2 Tilkobling av Modbus-enheter ........................................................................................................48

4. Idriftsettelse

4.1 Idriftsettelse......................................................................................................................................50

5. Feilsøking

5.1 Feilmeldinger i HMI-panelet ............................................................................................................51

3006026-2018-11-22.fm

3/88

1. SE - Handbok

1.1 Beskrivning av MCCW (Modbus Coil Cold Water)........................................................................52

2. Montering og anslutning

2.1 Placering och montering av MCCW-modulen ...............................................................................54

2.2 Placering av temperaturgivare (TE-SUPPLY)................................................................................54

2.3 Korrekt montering av tilloppsvattentemperaturgivare.................................................................55

2.4 Kylbatteri ..........................................................................................................................................56

3. Installation

3.1 Kopplingsschema för spänningsförsörjning och styrbox...........................................................58

3.2 Anslutning av modbus-enheter:.....................................................................................................60

4. Driftsättning

4.1 Driftsättning......................................................................................................................................62

5. Felsökning

5.1 Felmeddelanden i manöverpanelen ...............................................................................................63

1. NL - Handleiding

1.1 Beschrijving van de MCCW (Modbus Coil Cold Water)................................................................64

2. Montage en aansluiting

2.1 Plaatsing en montage van de MCCW module ...............................................................................66

2.2 Plaatsing van temperatuursensor (TE-SUPPLY) ..........................................................................66

2.3 Korrekt montage af fremløbstemperaturføler ...............................................................................67

2.4 Koelelement......................................................................................................................................68

3. Elektrische installatie

3.1 Ansluitschema voor voedingsspanning en aansluitkast.............................................................70

3.2 De modbus units aansluiten ...........................................................................................................72

4. Inbedrijfstelling

4.1 Inbedrijfstelling ................................................................................................................................74

5. Fouten opsporen

5.1 Foutmeldingen in het HMI paneel...................................................................................................75

1. FI - Tuote-esite

1.1 MCCW:n kuvaus (Modbus Coil Cold Water)..................................................................................76

2. Montage og tilslutning

2.1 MCCW-moduulin sijoitus ja asennus.............................................................................................78

2.2 Placering af temperaturføler (TE-SUPPLY) ...................................................................................78

2.3 Korrekt montage af fremløbstemperaturføler ...............................................................................79

2.4 Jäähdytyspatteri ..............................................................................................................................80

3. Asennus

3.1 Syöttöjännitteen ja ohjausrasian kytkentäkaavio.........................................................................82

3.2 Modbus-yksiköiden kytkentä..........................................................................................................84

4. Käyttöönotto

4.1 Käyttöönotto.....................................................................................................................................86

5. Vianetsintä

5.1 HMI-paneelin vikailmoitukset..........................................................................................................87

3006026-2018-11-22.fm

4/88

1.GB - Product instruction

Functional

description

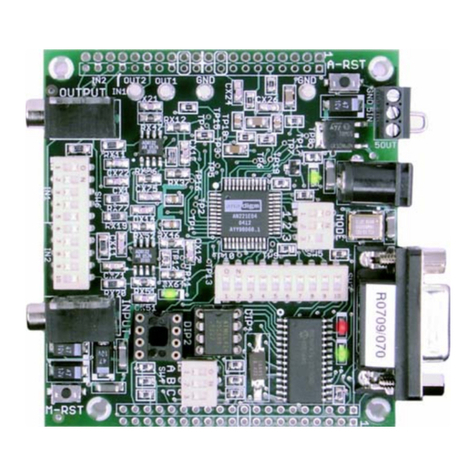

The MCCW module is able to control a water coil used for cooling. Together with the

EXact2 control system, the module is able to regulate the output from the water coil. If

necessary, a circulation pump can be started up.

NB The module is supplied as an MCOCW module.

It must be converted to an MCCW module by changing the following:

• Adding a jumper (supplied) to the module.

• Removing TE-RPT and TE-RPT-X sensors from the module.

See diagram in the section "Electrical installation" for further information.

The MCCW module can be used together with the following VEX/CX types:

• VEX100

• VEX200

• VEX320-370

• CX340-350

• VEX310T-VEX350T

Simplified

diagram

The MCCW module controls a 3-way motor valve connected to a water supply.

The water supply provides cold water.

.

Mixing loop Constant flow in the primary circuit (Supply) and in secondary circuit (Coil Cold Water)

1.1 Description of MCCW (Modbus Coil Cold Water)

3006026-2018-11-22.fm

5/88

Explanation of

simplified diagram

*) not EXHAUSTO delivery

Term Description input/output

TE-SUPPLY Measures air temperature after cooling coil. Temperature input

Capacity 0-10V Analogue outputs 0–10 V for setting of

0–100% cooling.

The MCCW module, via a temperature

regulator in EXact, sends an adjustable

0–10 V signal to the regulation valve (MVM).

Thus the setpoint for the supply air

temperature or room temperature is

maintained.

Analogue output

CP* Circulation pump 1x230V

MVM 3-way motor valve

Pump ON/OFF 230V supply to circulation pump Analogue output

TE-SPT Temperature sensor measures the feed

temperature to the cooling coil.

Temperature input

Coil Cold Water

(CCW)

Water coil (cooling)

Line regulating valve*

When there is no cooling requirement, valve adjustment must be

based on the required primary circuit water flow.

Shut off valve*

3006026-2018-11-22.fm

6/88

2.Assembly and connection

Fitting the MCCW

module

The temperature

sensor is

positioned here

2.1 Positioning and fitting of the MCCW module

Step Action

1 Fit the module using the screw holes in each corner of the module's

mounting box

2 Position the module in the vicinity of:

- regulation valve and pipes

3 Position the temperature sensor in the supply air duct as shown below

(Example from VEX200).

2.2 Position of temperature sensor (TE-SUPPLY)

P

5'

7(6833/<

3006026-2018-11-22.fm

7/88

How to mount the temperature sensor correctly on the feed water pipe to the water coil:

2.3 Correct fitting of feed water temperature sensor

Step Action

1 Use heat paste to ensure good

contact between the pipe and the

sensor. Use strips to secure the

sensor in position.

2 Ensure there is sufficient

insulation around the sensor.

3006026-2018-11-22.fm

8/88

2.4.1 Connection of cooling coil

The dimensioning of valves, pipes, etc. and cooling coil connection must always be

carried out by authorised fitters in accordance with applicable regulations and

legislation.

Mixing loop See the simplified diagram.

Connecting an

insulated CCW

With an insulated CCW, the connection must be made with stopcocks and unions, in

order to allow easy release, extraction and cleaning of the coil.

NB

Do not connect the water coil like this!.

Connection without circulation pump risks frost damage!

Bleeding Following connection of water supply to the unit:

• Bleed the system thoroughly usin the upper bleed screw on the water coil.

Insufficient

bleeding Insufficient bleeding can result in still water forming in the system,

which may result in frost-induced leaks during the winter.

Fitting motor valve

The valve must not be fitted with the motor facing down.

Insulate supply

pipe and water coil The pipes and water coil must be insulated according to applicable

regulations.

Frost protection

The cooling coil can be protected against frost by mixing 25% ethylene

glycol. This provides frost protection down to -13°C.

2.4 Cooling coil

RD12900-03

3006026-2018-11-22.fm

9/88

2.4.2 MVM valve

Shielding Shield the valve motor from direct sunlight. Due to heat emission, the valve motor must

not be encapsulated (max. ambient temperature: 50°C).

Insulating the valveTo ensure normal operation at ambient temperatures below 0°C, it is very important that

the valve section is insulated according to current standards/procedures.

MVM-OD, valve for

outdoor fitting

IIf MVM-OD used, then shielding is part of the delivery - if the valve has a K vs value

below 6.3.

Regulating

properties

Optimal regulation is achieved when the differential pressure is between 5–20 kPa.

If the differential pressure is higher than 20 kPa, the installation of a pressure difference

regulator is recommended.

2.4.3 Cold water supply

The cold water supply must be constant.

2.4.4 Operation of circulating pump

The circulation pump is operated by the EXact control system, as described below:

1. When no cooling is required, the MVM valve operates at 0%.

2. The circulation pump runs for another 5 minutes and then stops.

3. EXact starts the 24-hour timer.

4. When the 24 hours have passed, the circulation pump runs for 5 minutes.

5. The exercise cycle is repeated once a day until a cooling requirement

occurs.

3006026-2018-11-22.fm

10/88

3.Electrical installation

Diagram The following diagram shows the connection of supply voltage (1 x 230 V) and the

cooling coil control box (MCCW).

3.1 Connection diagrams

3006026-2018-11-22.fm

11/88

Key to diagram

NB

Power Supply

Term Description Supplied by...

-A1 Voltage supply/modbus terminal in VEX EXHAUSTO

-A2 MCCW module EXHAUSTO

-F1 Distribution board fuse Costumer25

-T2 TE-SUPPLY Supply air temperature sensor EXHAUSTO

-T4 Temperature sensor, supply EXHAUSTO

-M1 MVM Motor valve EXHAUSTO

CP Cirkulation pump Costumer

-Q1 Distribution board group switch Costumer

-Q2 Isolation switch (disconnects all poles) Costumer

* Not supplied by EXHAUSTO Costumer

CN12

Terminals 1 and 3

It is possible to invert the control signal to MVM,

i.e. 0V→10V becomes 10V→0V. This is done by

fitting a jumper across terminals 1 and 3 of

CN12. The change will be registered the next

time the unit is powered up.

EXHAUSTO

**24VDC Strip connector for continuation of 24VDC EXHAUSTO

Term Description

CN5 The TE-RPT sensor between terminals 5 and 6 must be removed.

CN6 The jumper between terminals 4 and 6 must be added to change

from MCOCW to MCCW.

The TE-RPT-X sensor between terminals 2 and 3 must be

removed.

VEX size Maximum load of terminal in main board

VEX140 1,4A

VEX150-170 2A

VEX240 1,4A

VEX250-260-270-280 2A

VEX340-350-360 2A

VEX320C-330C-330H must be separately powered

VEX310T-350T 2A

3006026-2018-11-22.fm

12/88

Diagram Connection must be carried out according to the following diagram. Refer to the

Electrical Installation Guide for the relevant VEX. (supplied with the VEX unit) for further

details of how to connect standard components to the connection box.

3.2.1 Cable (type, max. length and termination)

Cable EXHAUSTO recommends the use of 4-core, twisted pair, shielded cable. To limit

voltage drop across the cable, 0.25 diameter conductor is recommended. For

correct connection of shielded cable to Modbus units, refer to the Electrical

Installation Guide for the relevant VEX.

Max. cable length The overall cable length of a complete installation may not exceed 200 m.

3.2 Connection of Modbus devices

MHCW/MHCE Module for controlling heating coil (water or electric)

MXCU/MCCW Module for control of coil with cold water supply.

MPT DUCT Pressure measurement in duct

XXXXX Can be different modules, e.g. MIO module or additional MPTDUCT

HMI Control panel

*Not supplied by EXHAUSTO

3006026-2018-11-22.fm

13/88

Modbus,

termination or

daisy chaining

The first and last devices on the bus must be terminated. The PCB contains a jumper

JP1, which can be used for termination.

If Then See diagram no.

MCCW is the first or last device on

the bus

it must be terminated by use of jumper

JP1 (jumper nearest terminal 1 on

CN7).

1

MCCW is not the first and last

device on the bus

it must be daisy-chained to the next

device = default setting

2

1.

2.

3006026-2018-11-22.fm

14/88

4.Commissioning

HMI panel Refer to the VEX unit HMI panel for menu items displayed during commissioning of the

MCCW module.

See the following section for further information about the individual menu items or in

the Exact Control System Basic Instructions for the relevant VEX.

4.1.1 Detection of MCCW

Menu 3.4

Accessories

• Select CCW under cooling unit in menu 3.4.

NB Cold recovery must be active when operating with MCCW (menu 3.1.6)

4.1.2 Operating readings, MCCW

Menu 2.4 Temp.

reg. units

The menu will show, e.g.,

• output of cooling unit (A) and whether cooling is active = value > 0%

4.1 Commissioning

Ice-detect. >

De-icing method >

Heating coil >

Cooling unit >

Filter detect. >

PIR >

TS >

CO2 >

RH >

3.4 Accessories

Pressure

0

IHCW

CCW

Press.

None

None

CO2B

None

Dining solution > No

3 Settings

Unit >

General >

Configuration >

Accessories >

BMS >

Web server >

Backup/restore >

2 Operating readings

Air temperature >

Airflows >

MC parameters >

Temp. reg. units >

Pressure >

Heating coil >

CH cooling unit

CCW

CU cooling unit

MXCU

MXHP

Timers >

CO2/RH sensors >

2.4 Temp. reg. units

Heat recovery

Heating coil

Heat pump unit

Cooling unit

Cooling recovery

0.0

0.0

0.0

0.0

0.0

%

%

%

%

%

A

3006026-2018-11-22.fm

15/88

Menu 2.8 Cooling

coil (CCW)

The menu shows:

• Supply temperature for CCW cooling coil

• Pump - if the circulation pump in the heating cycle is in operation

4.1.3 Forced start, MCCW (CCW)

Conditions for use To use the forced start menu, the unit must be set to OFF in the user menu (Ventilation).

Menu 8.3.3

Cooling unit

If there are no current errors for the cooling coil("Error on unit" shown as "No"),

forced start may be activated:

• Set output for CCW. The pump starts up at an output greater than 0%.

NB When Menu 8.3 "Forced start" is exited, forced start is reset and normal operation can

be resumed. When a submenu is exited, the values in the submenu are reset.

5.Troubleshooting

NB An error will be displayed on the HMI panel in the event of a fault or irregular operation.

To resolve the problem, refer to EXact Basic instructions for the relevant VEX.

2 Operating readings

Air temperature >

Airflows >

MC parameters >

Temp. reg. units >

Pressure >

Heating coil >

CH cooling unit

CCW >

CU cooling unit

MXCU

MXHP

Timers >

CO2/RH sensors >

2.8 CCW

Supply

Pump

25.0

Off

°C

8.3.3 Cooling unit

CCW

Error on unit

0%

No

8 Service

Filter >

VDI 6022 >

Forced start >

Calibration of MPT >

Light > Off

8.3 Forced start

Fans >

Heating coil >

Cooling unit >

Dampers and relays >

EXEB relays >

5.1 HMI panel error messages

3006026-2018-11-22.fm

16/88

1.DK - Produktvejledning

Funktions-

beskrivelse

MCCW-modulet kan styre en vandflade, som kan bruges til at køle. Sammen med

EXact2 styringen kan modulet regulere ydelsen på vandfladen. En cirkulationspumpe

kan startes ved behov.

Bemærk Modulet er leveret som MCOCW-modul. Det skal ombygges til et MCCW modul ved at

ændre følgende:

• Tilføje en lus (medleveret) i modulet.

• Fjerne TE-RPT og TE-RPT-X følere i modulet.

Se diagram i afsnittet “El-installation” for yderligere information.

MCCW-modulet kan benyttes sammen med følgende VEX/CX-typer:

• VEX100

• VEX200

• VEX320-370

• CX340-350

• VEX310T-VEX350T

Principskitse MCCW-modulet styrer en 3-vejs motorventil, som er tilsluttet en vandforsyning.

Vandforsyningen leverer koldt vand.

.

Blandesløjfe Der er konstant flow i primærkreds (forsyning) og i sekundærkreds (Coil Cold Water).

1.1 Beskrivelse af MCCW (Modbus Coil Cold Water)

3006026-2018-11-22.fm

17/88

Forklaring til

principskitse

*) ikke EXHAUSTO leverance.

Betegnelse Forklaring input/output

TE-SUPPLY Måler lufttemperatur efter kølefladen. Temperatur input

Capacity 0-10V Analog udgang 0-10V, for indstilling af

0-100% køl.

MCCW-modulet afgiver via temperatur-

regulator i EXact, et indstilleligt 0-10V signal

til regulerings-ventilen. (MVM)

Således kan setpunktet for tilluft- eller

rumtemperatur holdes.

Analog output

CP* Cirkulationspumpe 1x230V

MVM 3-vejs motorventil

Pump ON/OFF 230V forsyning til cirkulationspumpe Analog output

TE-SPT Temperaturføler måler

fremløbstemperaturen til kølefladen.

Temp. input

Coil Cold Water

(CCW)

Vandflade (køling)

Strengreguleringsventil*

Ventilen skal indstilles på basis af den vandmængde som ønskes

i primærkredsen, når der ikke er kølebehov.

Kontraventil*

3006026-2018-11-22.fm

18/88

2.Montage og tilslutning

Sådan fastgøres

MCCW-modulet

Her placeres

temperaturføleren

TE-SUPPLY

2.1 Placering og montage af MCCW-modulet

Trin Handling

1 Fastgør modulet ved hjælp af skruehullerne i hjørnerne af modulets

montageboks.

2 Placer modulet i nærheden af:

- reguleringsventil og rørføring

3 Placer temperaturføleren i tilluftkanalen som anvist herunder.

(Eksempel fra VEX200 er vist)

2.2 Placering af temperaturføler (TE-SUPPLY)

P

5'

7(6833/<

3006026-2018-11-22.fm

19/88

Sådan monteres temperaturføleren korrekt på fremløbsrøret til vandfladen:

2.3 Korrekt montage af fremløbstemperaturføler

Trin Handling

1 Benyt varmeledende pasta for at

opnå en god kontakt mellem rø-

ret og føleren.

Fastgør føleren med strips.

2 Sørg for tilstrækkelig isolering

omkring føleren.

3006026-2018-11-22.fm

20/88

2.4.1 Tilslutning af køleflade

Dimensionering af ventiler og rør mv. samt tilslutning af fladen skal altid udføres af

autoriseret personale iht. gældende love og regler.

Blandesløjfe Her henvises til pricipskitse.

Tilslutning af

isoleret CCW

For isoleret CCW skal tilslutningen ske med stophaner og unioner, sådan at fladen let

kan løsnes, trækkes ud og rengøres.

Bemærk

Sådan må fladen ikke tilsluttes.

Tilslutning uden cirkulationspumpe medfører risiko for frostsprængning.

Udluftning Efter tilslutning af vand på aggregatet:

• Udluft systemet grundigt via den øverste udluftningsskrue på vandfladen.

Manglende

udluftning Ved manglende udluftning er der risiko for stillestående vand i systemet,

hvilket kan medføre frostsprængninger i kolde perioder.

Montage af

motorventil Ventilen må ikke monteres med motoren nedad.

Isoler fremløbsrør

og vandflade Rør og vandflade skal isoleres i henhold til gældende krav.

Frostsikring

Kølefladen kan frostsikres ved at iblande kølevandet 25% ethylen-glycol.

Herved opnås frostsikring ned til -13°C.

2.4 Køleflade

RD12900-03

Table of contents

Languages:

Other Exhausto Control Unit manuals

Exhausto

Exhausto VEX260 User manual

Exhausto

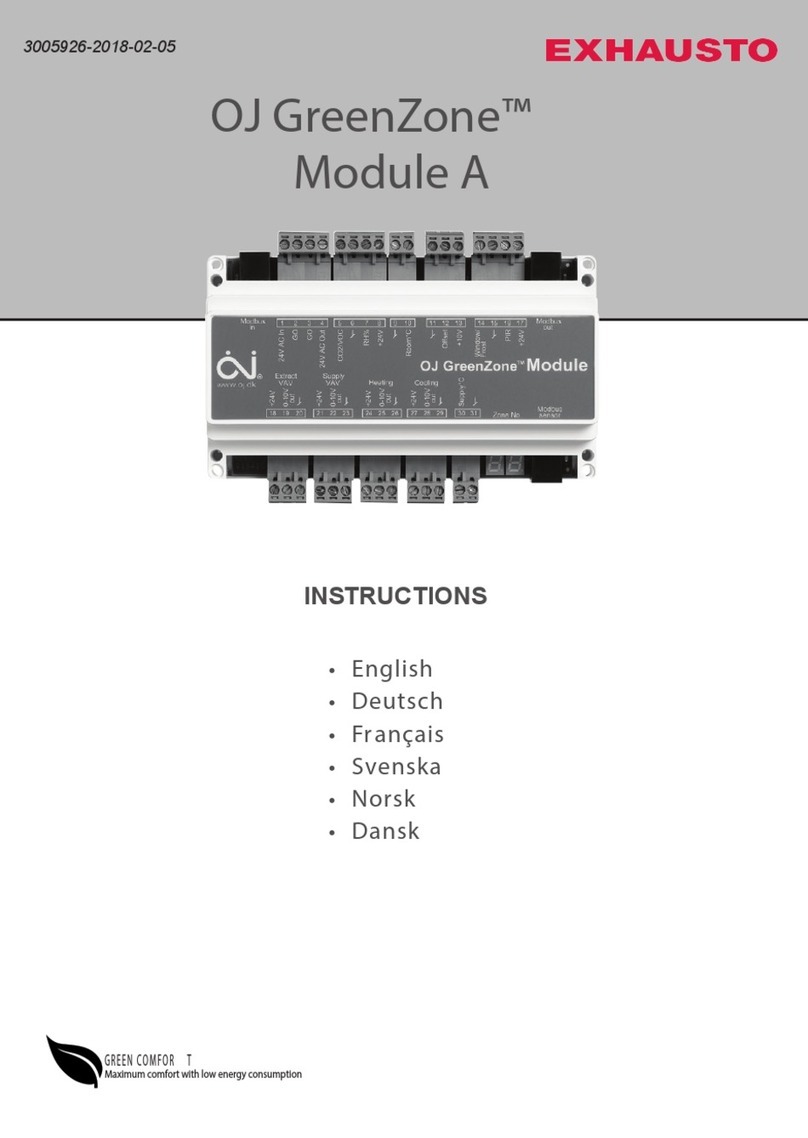

Exhausto OJ GreenZone Module A User manual

Exhausto

Exhausto EBC12 Series User manual

Exhausto

Exhausto OJ GreenZone Module M User manual

Exhausto

Exhausto EBC 10-P Installation instructions

Exhausto

Exhausto VEX200 series User manual

Exhausto

Exhausto OJ GreenZone User manual

Popular Control Unit manuals by other brands

Crestron

Crestron C2N-FT-TPS4 Operations & installation guide

Landis+Gyr

Landis+Gyr WZU-M Series Installation and operating guide

Komfovent

Komfovent ping installation manual

Eaton

Eaton Vickers CM2 Series Overhaul manual

Anadigm

Anadigm Servenger PAM-5002R Series quick start guide

Ksenia

Ksenia lares 4.0 - 40 wls Installation and use manual