Exhausto EBC 12 Installation instructions

3001435 05.12 Installation & Operating Manual

USA

CAN

EBC 12

Modulating Fan Control

VENTING DESIGN SOLUTIONS

ENERVEX Inc.

1685 Bluegrass Lakes Pkwy.

Alpharetta, GA 30004

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

www.enervex.com

Job Name:

Installer:

Installation Date:

Product Information

Mechanical Installation

Electrical Installation

Start Up and Conguration

Maintenance and Troubleshooting

.............................. Chapters 1+2

......................... Chapter 3

............................. Chapter 4

.................. Chapter 5

...... Chapter 6

READ AND SAVE THESE INSTRUCTIONS!

VOLKO SUPPLY

800-685-8263

VENTING DESIGN SOLUTIONS

2

3001435 05.12

How to use this manual

This installation manual does not contain any system design

documentation. System design documentation is available from any

authorized EXHAUSTO representative.

Accessories, fans and variable frequency drives are not covered by

this manual. Please refer to these component’s individual manuals.

1. Product Information

1.1 Function ...............................................................................................3

1.2 Shipping ...............................................................................................3

1.3 Warranty...............................................................................................3

2. Specications

2.1 Dimensions & Capacities......................................................................4

3. Mechanical Installation

3.1 Location................................................................................................5

3.2 Mounting of Control .............................................................................5

3.3 Mounting of Transducer .......................................................................6

3.4 Mounting of Stack Probe......................................................................6

3.5 Connecting Transducer to Stack Probe ...............................................6

4. Electrical Installation

4.1 General ................................................................................................7

4.2 Continuous Chimney Fan Operation (120V only) ................................8

4.3 Intermittent Chimney Fan Operation ....................................................9

4.4 Connection of a Variable Frequency Drive......................................... 11

4.5 Integrated PDS with External PDS Backup........................................12

5. StartupandConguration

5.1 General ..............................................................................................13

5.2 Setting Operating Pressure................................................................14

6. MaintenanceandTroubleshooting

...........................................................................................................15

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Caution: Indicates an imminent hazardous situation

which, if not avoided, may result in personal injury or

property damage.

SymbolLegend:

The following terms are used throughout this manual to bring attention

to the presence of potential hazards or to important information

concerning the product.

Danger: Indicates an imminent hazardous situation

which, if not avoided, will result in death, serious injury or

substantial property damage.

1. Use this unit in the manner intended by the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed on the front of the manual.

2. Before servicing or cleaning the unit, switch off at service panel

and lock service panel to prevent power from being switched on

accidentally.

3. Installationworkandelectricalwiringmustbedonebyaqualied

person(s) in accordance with applicable codes and standards.

4. Follow the appliance manufacturer’s guidelines and safety

standards such as those published by the National Fire Protection

Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the

local code authorities.

5. This unit must be grounded.

3

VENTING DESIGN SOLUTIONS

3001435 05.12

1. Product Information

1.1 Function

Use The EXHAUSTO EBC 12 is a Modulating Fan Control used with single appliances to monitor

and maintain a constant draft or pressure in a chimney or duct. This is achieved by modulating the speed

of a chimney fan or ventilator. The EBC 12 can be used with EXHAUSTO Models RSV, BESF and BESB.

It can control the fan speed directly or via a Variable Frequency Drive (VFD).

The EBC 12 is typically used to control the draft in systems requiring a single boiler or water heater.

Function The control monitors the draft in a chimney system via connection to a pressure sensor (XTP2)

attached to the chimney, and maintains it by modulating the fan speed. The control has an integrated safety

system that assures the heating appliance is shut down in case of fan failure or control failure.

The use of the EBC 12 is not restricted to any type of fuel or type of heating appliance. When the

appliance thermostat closes and calls for heat, the control will send maximum voltage to the chimney fan or

VFD.Whenthenecessarydraftisachieved,thecontrolwillallowboilerringandregulatethevoltage

to the fan or VFD, so the required draft is maintained (the value can be viewed in the display). In

caseofinsufcientdraft,thecontrolwillassuretheburnerwillbeshutdownafter12seconds.When

theappliancehassatisedthethermostatandshutsdown,thecontrolwillturnoffthefan.

The control can be used in one of two ways:

•Interlocked with the appliance to pre-purge the chimney prior to boiler start-up and post-purge

the chimney for 3 minutes after boiler shut down.

or

•Settorunthefancontinuously.

Other Functions The control has an integrated safety function. It can be operated with either a manual reset function

(reset button) or an automatic reset function. All terminal connections are monitored by LED’s for easy

service and troubleshooting.

Listings EXHAUSTO’s EBC 12 is ETL listed to the Standard for Industrial Control Equipment, UL Standard 508,

17th Ed. and CSA C22.2 No. 14-95 as well as UL378, Standard for Draft Equipment. It is also tested and

listed as a part of an ETL listed CASV System (ETL Report 045099A) and an ETL listed MDVS System

(ETL Report J99*18091-004)

1.2Shipping

Standardpackinglist

The EBC 12 contains the following:

•EBC12controlunit

•Pressuretransducer(XTP2)

•Siliconetubing

•Stackprobe

•Jumpers

If other components are shipped, these will appear as separate items on the shipment packing list.

1.3 Warranty

Complete warranty conditions are available from ENERVEX, Inc.

VENTING DESIGN SOLUTIONS

4

3001435 05.12

2.1 Dimensions & Capacities

Symbols:

Fig. 1-A Fuse holder

Fig. 1-B Alarm-red LED

Fig. 1-C Reset button

Fig. 1-D Set point button

Fig. 1-E Potentiometer for draft setting

Fig. 1-F Display

Fig. 1-G LEDs (yellow) showing

increasing/decreasing speed

Fig. 1-H Dipswitch block

Fig. 1-I LEDs (green) showing ON/OFF

status

I

A

D

C

E

FBGH

RD10103

+24V

+24V

COM-0

COM

+24V-+

0-10V-

+0-10V

__

>

Fig.1

In. WC / Pa

Setpoint Reset Alarm

EBC 12 Control

Power supply V 1x120VAC

Amperage A 6.3

Operating temperature °F/°C -4 to 122 / -20 to 50

Range of operation inWC/Pa 0-0.6 / 0-150

Tolerance inWC/Pa 0.01 / 3 +/-10%

Control signal mA max. 10

Control relay Max. 120 VAC/8A

Output VAC 10-120

VDC 0-10

Dimensions A in/mm 6.9 / 175

B in/mm 8.1 / 205

C in/mm 4.0 / 102

Weight lbs/kg 3.0 / 1.5

EMC standard Emission EN50 081-1

Immunity EN50 082-2

XTP2 Sensor

Power supply VDC 12-36

Amperage mA <20

Output VDC 0-10

Operating temperature °F/°C 0 to 160 / -18 to 71

Accuracy +/- 0.08%

Dimensions D in/mm 3.70 / 94

E in/mm 5.12 / 130

F in/mm 6.18 / 157

G in/mm 3.13 / 80

Weight lbs/kg .6 / .3

Chimney Probe

Dimensions H in/mm 4.25 / 108

I in/mm 3.50 / 89

2.Specications

5

VENTING DESIGN SOLUTIONS

3001435 05.12

3. Mechanical Installation

3.1 Location

The control and the transducer must be installed inside, preferably in the boiler room. The control does not need to

be installed in an enclosure. Fig. 2 shows how the components are connected.

Thetransducercannotbemountedinsideanairtightenclosure.Itusestheboilerroom

pressure/atmospheric pressure as reference pressure.

3.2MountingofControl

The control can be mounted directly on a wall or similar. Remove the clear cover. The mounting holes are located

under the plastic screws that hold the cover in place (Fig. 3).

The distance between the control and the transducer should not exceed three hundred (300) feet.

Fig.3

Fig.2

EBC 12

XTP2 Sensor

Max. 6 feetMax. 300 feet

Fig.2a

VENTING DESIGN SOLUTIONS

6

3001435 05.12

3.3MountingofTransducer

Attention must be paid to the location of the transducer. The transducer can be mounted in any orientation but prefer

ably with the pressure ports facing down.

The transducer should be mounted within six (6) feet of the stack probe.

3.4MountingofStackProbe

The probe (Fig. 2a on page 5) is inserted into the chimney or vent at the point where the draft should be kept constant.

This could be at the appliance outlet, in the vent or similar.

ReferringtoFig.2,makesurethetipofthetubeisushwiththeinnerwallofthestack.Insertingittoofarmayaffect

the reading and thereby the operation.

3.5ConnectingTransducertoStackProbe

The transducer is connected to the stack probe via a silicone tube. Make sure that the tube is connected to the proper

transducer port as shown in Fig. 5.

Fig.4

Fig.5

+

-

Front

7

VENTING DESIGN SOLUTIONS

3001435 05.12

+24V

+24V

COM-0

COM

+24V-+

0-10V-

+0-10V

__

>

Terminal Use

1 Power Supply-L1

2 Power Supply-N

3 Power Supply-Ground

4-5 Voltage Input from Appliance thermostat

Optocoupler (-) (10-120VAC/CDC

6-7 Voltage Input from Appliance thermostat

Optocoupler (+) (10-120VAC/DC)

8 24VDC power supply to dry set of

contacts (appliance thermostat)

9 0VDC power supply to dry set of

contacts (appliance thermostat)

14 Burner relay contact-Common

(max. 120 VAC, 8 Amps.)

15 Burner relay contact-Normally Open

(max. 120VAC, 8 Amps.)

16 PDS-C (Common) Proven Draft Switch

Terminal Use

17 PDS-NC (Normally Closed) Proven

Draft Switch

18 PDS-NO(NormallyOpen)Proven

Draft Switch

19 Chimney Fan-L1

20 Chimney Fan-N (regulating)

21 Chimney Fan-Ground

22 XTP-0VDC Power Supply

(transducer)

23 XTP-24VDC Power Supply

(transducer)

24 XTP-0-10VDC Return Signal

(transducer)

25 Control signal 0VDC

26 Control signal 0-10VDC

Fig.6

4. Electrical Installation

4.1 General

Danger:Turnoffelectricalpowerbeforeservicing.Contactwithliveelectriccomponentscan

cause shock or death.

EBC12isdesignedfor1x120VACpowersupplyonly.Fanoutputisregulatingontheneutralside

and cannot be connected to other circuits.

The control can be used in two ways:

• Connectedsothefanrunscontinuouslyindependentofapplianceoperation(seeparagraph4.2).

• Interlockedwithanappliancesotheapplianceoperationindirectlycontrolsthefanoperation(see

paragraph 4.3).

In both cases the control will still monitor and maintain a constant draft.

There are two types of safety systems available:

• IntegratedProvenDraftSwitch(standard).

• IntegratedProvenDraftSwitchwithExternalProvenDraftSwitch(accessory)backup(seeparagraph

4.4).

TheterminalsareconnectedasshownonFig.6:

VENTING DESIGN SOLUTIONS

8

3001435 05.12

EBC 12 Control Board

COMVout Vin

4.2 Continuous Chimney Fan Operation

Fig. 7 shows how to connect a chimney fan to the EBC 12 if continuous operation is needed:

• Connectthepowersupplytoterminals1,2and3.

• Jumpterminals5and9.

• Jumpterminals6and8.

• Connectiontotheappliance(s):

- Connect the start signal from the burner to terminals 14 and 15.

• Toconnectthechimneyfan:

- If using a 1x120V chimney fan, connect it to terminals 19, 20 and 21. Refer to the fan’s Installation

Manual.

- If using a 3-phase fan and VFD, connect the VFD to terminals 25 and 26 as shown in Fig. 10 and 11.

DO NOT connect the fan directly to the MEC 18 control.

• ConnecttheXTP2transducertoterminals22,23and24.

Fig.7

9

VENTING DESIGN SOLUTIONS

3001435 05.12

Sample Wiring Diagram - Burner Interlock

Connection to 120V Fan - Internittent Operation

EBC 12 Control Board

COMVout Vin

4.3IntermittentChimneyFanOperation(120V)

The control can be interlocked with an appliance in two ways:

It can be interlocked directly with an appliance control, or with a dry set of contacts.

Interlock with Burner

Figure 8 shows how an appliance control signal (10-120V AC/DC) is connected to the EBC 12:

• Connectthepowersupplytoterminals1,2and3.

• Connectiontotheappliance:

- Connect the boiler start signal to terminal 4.

- Jump terminals 5 and 14.

- The start signal to the burner is now activated by terminal 15.

- Connect Neutral to terminal 6.

• Toconnectthechimneyfan:

- If using a 1x120V chimney fan, connect it to terminals 19, 20 and 21. Refer to the fan’s Installation

Manual.

- If using a 3-phase fan and VFD, connect the VFD to terminals 25 and 26 as shown in Fig. 10 and 11.

DO NOT connect the fan directly to the MEC 18 control.

• TheXTP2transducerisconnectedtoterminals22,23and24.

Fig.8

VENTING DESIGN SOLUTIONS

10

3001435 05.12

Sample Wiring Diagram - Dry Contact Relay

Connection to 120V Fan

EBC 12 Control Board

COMVout Vin

Interlock with dry set of contacts

Figure 9 shows how a dry set of contacts is connected to the EBC 12:

• Connectthepowersupplytoterminals1,2and3.

• Connectiontotheappliance:

- Connect the dry set of contacts to terminals 6 and 8.

- Jump terminals 4 and 9.

- Connect the start signal to the burner to terminals 14 and 15.

• Toconnectthechimneyfan:

- If using a 1x120V chimney fan, connect it to terminals 19, 20 and 21. Refer to the fan’s Installation

Manual.

- If using a 3-phase fan and VFD, connect the VFD to terminals 25 and 26 as shown in Fig. 10 and 11.

DO NOT connect the fan directly to the MEC 18 control.

• ConnecttheXTP2transducertoterminals22,23and24.

Fig.9

11

VENTING DESIGN SOLUTIONS

3001435 05.12

4.4 Connection to a Variable Frequency Drive

To connect the 3-phase fan and variable frequency drive (VFD), connect the VFD to terminals 25 and 26 of the EBC 12.

DO NOT connect the fan directly to the control.

Wire the ABB ACS320 series variable frequency drive according to Fig. 10.

Wire the VLT Micro Drive variable frequency drive according to Fig. 11.

POWER SUPPLY

200-240/3/60

OR

400-480/3/60

#26 #25

TO EBC 12

CONTROL

TO EXHAUST FAN

TO EBC 12

CONTROL

29

Fig.10

Fig.11

VENTING DESIGN SOLUTIONS

12

3001435 05.12

EBC 12 Control Board

4.5IntegratedProvenDraftSwitchwithExternalProvenDraftSwitchBackup

Fig. 12 shows how to connect a external Proven Draft Switch (PDS) to the EBC 12. The external PDS is a

backup to the integrated PDS and bothmustbesatisedbysufcientdrafttoreleasetheappliance:

• Removethefactoryinstalledjumperoverterminals16and18.

• Connecttheswitchtoterminals16,17and18asshownonFig.11.

Fig.12

13

VENTING DESIGN SOLUTIONS

3001435 05.12

5.StartupandConguration

5.1 General

Prior to start up please review the paragraph below titled Dipswitch settings.

Dipswitchsettings

Prior to starting the system, check to see if the dipswitch settings are as required:

•Defaultfactorysetting:AllOFF

• Ifthefactorysettingmustbechanged,theblackcoverplatemustberemovedtogainaccesstothe

dipswitches (see Fig 12-A):

1. Remove the potentiometer dial.

2. Removethe(4)atheadscrewsandliftthetopplateofftheboard.

3. Change the dipswitch settings.

Fig.12

*) Always OFF if the Proven Draft Switch (PDS) is not connected.

Dipswitch Name OFF ON

1 MANUAL

RESET

Automatic reset

at power failure or

insufcientdraft.

Manual reset at

power failure or

insufcientdraft.

2 POST

PURGE

No post-purge. 3 minutes of post

purge.

3*) PDS CHECK No monitoring to see

if the PDS was in NC

position prior to start.

The PDS must be in

NC prior to start.

VENTING DESIGN SOLUTIONS

14

3001435 05.12

Fig.14

EXHAUSTO

CHIMNEY DRAFT TECHNOLOGY

EBC 12

+24V

+24V

COM-0

COM

+24V-+

0-10V-

+0-10V

__

>

Fig.13

5.2SettingOperatingPressure

The pressure setting of the EBC 12 must be adjusted to assure proper draft for the heating system. The display (Fig.

13-C) has two functions. It can show what the draft set-point is, and it can show what the actual draft is.

The default mode shows the actual draft. To change the mode, the set-point button must be pressed

continuously.

To adjust the draft set-point follow this procedure:

Temporary adjustment of the draft:

1. Press the set-point button continuously with a pen or screwdriver (Fig. 13-A). The pressure setting will

now show on the display. Use the potentiometer (Fig. 13-B) to set the required draft in WC/Pa on the

display (Fig. 13-C). Release the set-point button; the actual draft will now show up on the display.

2. Start the heating system and wait until the thermostat (Fig. 14-A) closes and the draft has stabilized

(none of the yellow diodes are lit).

Final adjustment of the draft:

3. Check the draft at the appliance outlets and make any necessary adjustment by following the procedure

described under step 1 above.

4. Check that the safety system disconnects the appliance (Fig. 14-B). An error can be simulated by

disconnecting the tube (-) to the transducer (XTP).

5. Checkthestartfunctionafterthenaldraftsettingadjustmentshavebeenmade.

15

VENTING DESIGN SOLUTIONS

3001435 05.12

6.MaintenanceandTroubleshooting

Some appliances require a certain startup procedure after a shutdown. Follow this procedure prior

topressingtheRESETbutton(Fig.15-C).

Fig.15

Observation Problem Solution

NolightintheSUPPLYdiode(Fig15-A) Blown fuse or interrupted power supply 1) Check the fuse (Fig. 15-B) and the fan power.

2) Check the power supply.

Constantlightin“IncreasingSpeed”diode

(Fig15-E)

System fault 1) Check that the probe is connected to the “-” port on the

XTP2 transducer.

2) Check that the probe is not clogged.

CAUTION: Do not blow into the XTP2 transducer.

3) Check that the fan is running.

4) Set-point is too high for the fan capacity. Check/reduce

setting.

5) Check the entire system’s adjustment, including any

balancingbafesinstalled.

6) Check breaching and common vent for leakages.

7) Check the power supply to the XTP2.

Constantlightin“DecreasingSpeed”diode

(Fig15-D)

System fault 1) The natural chimney draft prevents the system from

reaching the set-point. Check the adjustment. If necessary,

installabalancingbafeorotherresistanceinthechimney.

2) The probe may be in a bad location. Move it to another

position closer to the appliance.

ConstantlightinALARMdiode(Fig.15-H), but

no light in FAN diode (Fig. 15-G) (Can only occur

when MANUAL RESET is ON (Fig. 15-F)

Power outage Press the RESET button (Fig. 15-C) for (1) second — see

warning.

ConstantlightinAlarmdiode

and light in fan diode (Fig. 15-H)

Insufcientdraft 1) Press the RESET button (Fig. 15-C) — see warning.

2) Check that the service disconnect switch is working

properly.

3) Check the connectors, chimney and fan for blocking

restrictions.

FlashingALARMdiode(Fig.15-H)

Can only occur when PDS CHECK is ON (Fig.

15-F)

Error in safety system (PDS) 1) Check that a PDS is installed.

2) Check the setting of the safety system (the natural draft

can prevent close/alternatively the PDS CHECK dipswitch can

be moved to its OFF position.

3) Check the connection to the PDS and the PDS itself.

TheEBC12doesnotregulateandthefanis

runningatfullspeed

The neutral connection is shared with other

devices.

1) Check the amp-draw on terminal Nreg. If it is “0”, the

neutral connection to the fan is being shared.

ENERVEX Inc.

1685 Bluegrass Lakes Pkwy.

Alpharetta, GA 30004

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

www.enervex.com

VENTING DESIGN SOLUTIONS

3001435 05.12

Table of contents

Other Exhausto Controllers manuals

Popular Controllers manuals by other brands

Lamtec

Lamtec FA1 operating instructions

Henny Penny

Henny Penny 10013404 Replacement instructions

Samson

Samson 43-2 Mounting and operating instructions

Milnor

Milnor E-P Plus Reference

Ingersoll-Rand

Ingersoll-Rand ST700 Series Installation and maintenance information

Ingersoll-Rand

Ingersoll-Rand ST900 Series Installation and maintenance information

Digital Equipment

Digital Equipment 21143 Reference manual

Nice

Nice UST1K-1.1kW Instructions and information for installation and use

Industrial Shields

Industrial Shields ARDBOX Series user guide

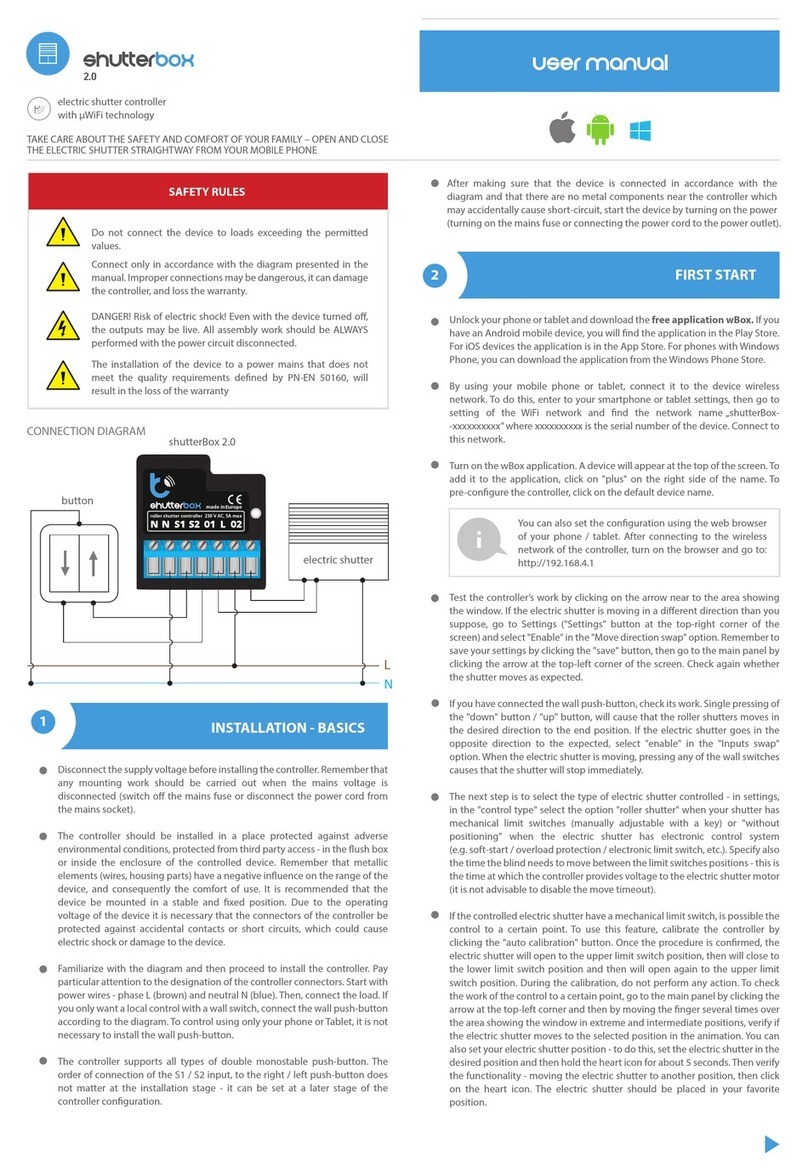

BleBox

BleBox shutterBox 2.0 user manual

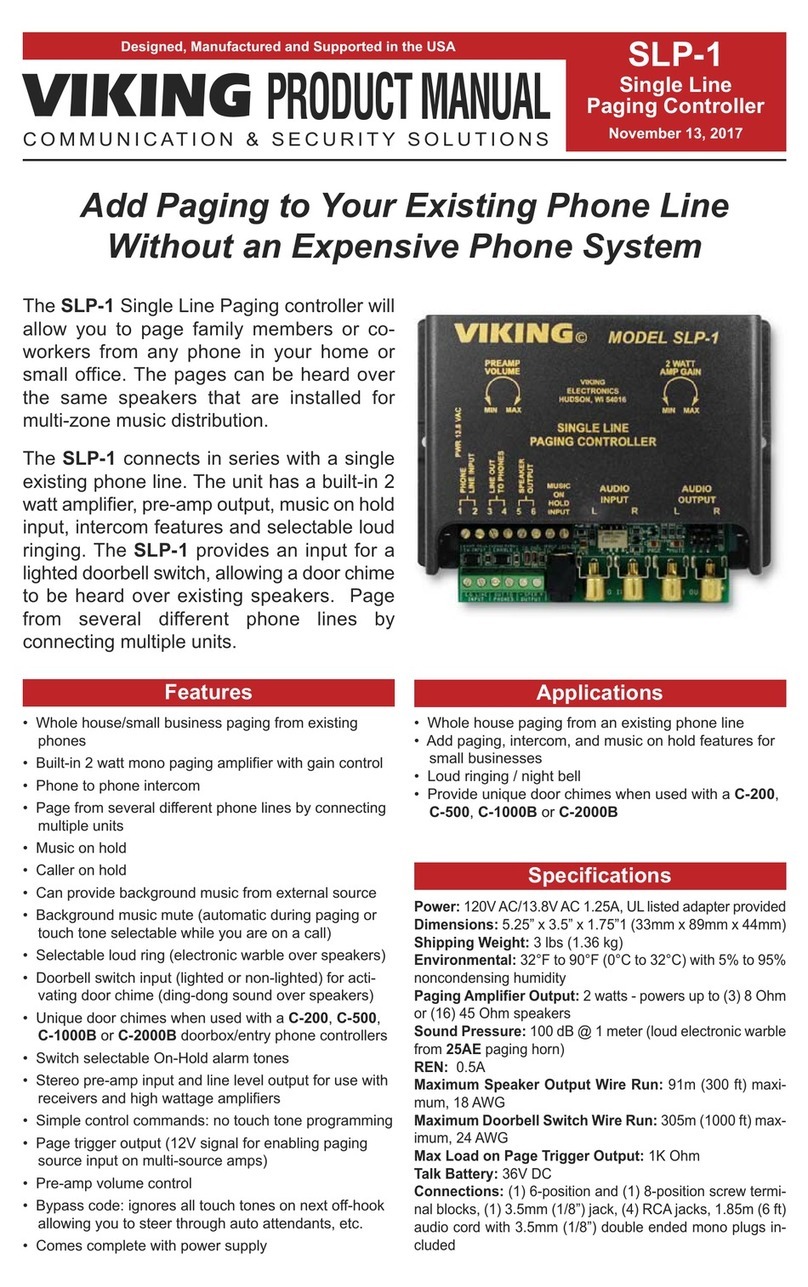

Viking Electronics

Viking Electronics SLP-1 Installation and application manual

RNA

RNA ESK 2002 operating instructions