Rhein-Nadel Automation GmbH 2

VT-BA-ESK2002_EN-2020 / 06.05.2020 SJ

Table of Contents

1. About this document ..............................................................................................................4

2. Safety directives.....................................................................................................................4

2.1. Design of safety directives..................................................................................................4

2.2. Fundamental safety directives ............................................................................................4

2.3. Personnel............................................................................................................................4

2.4. Intended use.......................................................................................................................5

2.5. Residual hazards................................................................................................................5

2.5.1. Device ..........................................................................................................................5

2.5.2. Protection of the drive system......................................................................................5

2.5.3. Degree of protection - Protection of persons and equipment .......................................5

3. Product information................................................................................................................6

3.1. Characteristic features........................................................................................................6

3.2. CE conformity .....................................................................................................................6

3.3. Technical data.....................................................................................................................7

3.4. Accessories ........................................................................................................................7

4. Note on start-up .....................................................................................................................8

4.1. Modes of operation.............................................................................................................8

4.2. Automatic mode change.....................................................................................................9

4.3. Sensor inputs and sensor linkages.....................................................................................9

4.4. Sensor connection............................................................................................................10

4.5. Status outputs and relays .................................................................................................11

5. Operation .............................................................................................................................12

5.1. General.............................................................................................................................12

5.2. Starting-up the controller...................................................................................................13

5.3. Main menu / Setpoint entry and display for channels 1, 2 and 3.......................................13

5.4. Description of individual codes for controller programming...............................................14

5.5. Application-specific changes to default settings................................................................15

5.5.1. Code C001 for channel 1, (feed rate output 1, bowl feeder).......................................15

5.5.2. Code C002 for channel 2, (feed rate output 2, vibratory or belt hopper) ....................15

5.5.3. Code C012 for channel 3, (feed rate output 3, vibratory or belt drive)........................16

5.5.4. Code C003 Seal setpoint ...........................................................................................16

5.5.5. Code C004 sensor input 1 and code C005 sensor input 2.........................................16

5.5.6. Code C006 Sensor linkage.........................................................................................17

5.5.7. Code C008 cycle monitoring ......................................................................................18

5.5.8. Code C009 Show status.............................................................................................19

5.5.9. Code C200 Inhibiting all code entries.........................................................................19

5.5.10. Code C143 Saving parameters...............................................................................20

5.5.11. Code C210 Retrieving parameters..........................................................................20

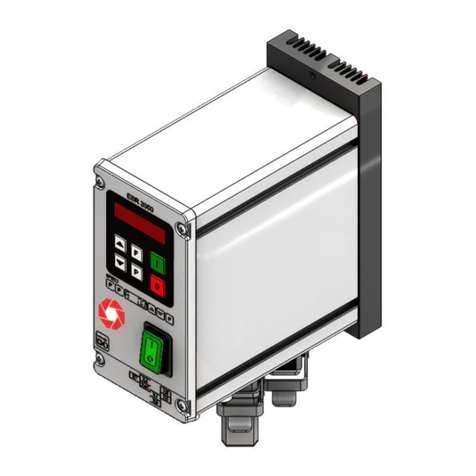

6. Dimensioned drawing...........................................................................................................21

7. Connection diagram.............................................................................................................22