Exit Light ESC-200P User manual

MANUAL

Addressable Combination System

ESC-200P

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Quick Start

1. Install the panel using mounting holes.

2. After luminaires are installed (please note that the luminaires are suited for ESC-200P

system), connect cables of loops to central panels.

•Panel has 10, 16 and 24 sections for addressable luminaires. These are divided into

two loops (L1 and L2), half-by-half: 5 + 5, 8 + 8 and 12 + 12.

•In section could be mixed with emergency lights and exit lights.

•Maximum 20 luminaires can be attached on one section, in total 200 luminaires per one

panel.

•Do not connect luminaires with live voltage on panels!

•Make sure that +, - and G markings are connected right way around.

3. Panel has three (3) outputs for 230V emergency lights. Do not under any circumstance

connect addressable LED emergency lights to these outputs. Outputs are only applicable to

be used for 230V emergency lights.

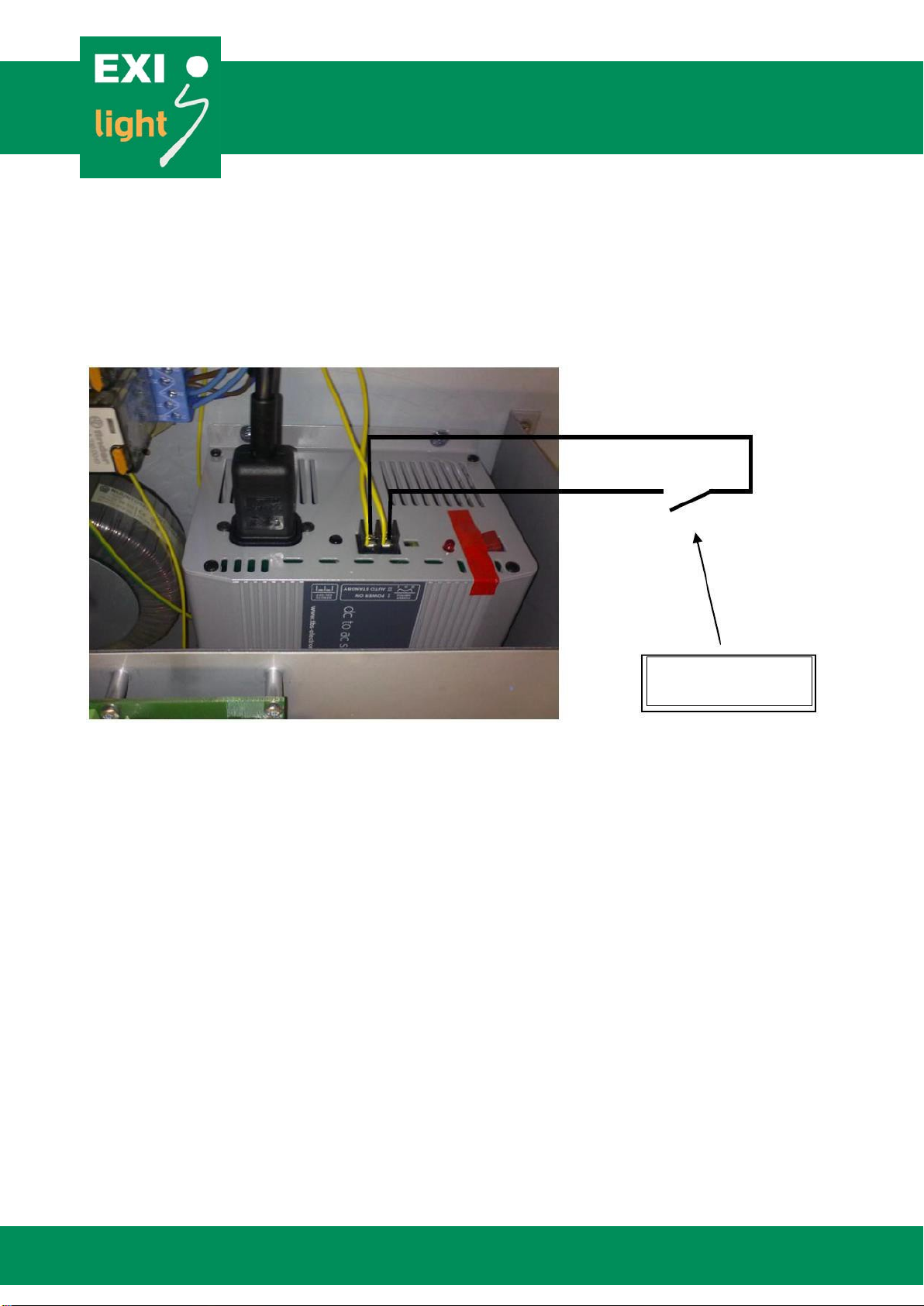

4. Connect the small NiMH battery to panel printed circuit board and 12 V backup batteries to

panels battery cables. Backup batteries of panels have a voltage of 12 V.

5. Connect power to central panel power supply.

6. From control panel, choose ”INVERTER USE” and choose either ”ON + BATT. CHECK” to

operate as central battery system and to have monitoring for both batteries and inverter.

”ON + BATT.CHECK” is default mode of ESC-200P panel.

7. Press the MENU-button and go to ”START NEW INSTALLATION”. You can scroll the menu

with UP and DOWN buttons. New commissioning is started by pressin MENU-button. On

display there is a note “INSTALLATION IN PROGRES” and ”TIME ABOUT 30 MIN”. Panel

writes to its memory found luminaires from each line. Luminaire inventory can be scrolled

with LEFT and RIGHT buttons. After commissioning has been executed panel returns to a

normal state.

Control panel has two lines for luminaires. Maximum capacity of lines are 100

luminaires per loop, 200 luminaires per one panel.

8. When panel has found all luminaires in loops, “EVERYTHING OK” is appeared on display.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

9. SETTING THE TIME AND DATE

Set the time and date in ”SET” ”SET DAY+TIME” (choose with LEFT-button). Choose

time with SET-button. Time format is dd.mm.yyyy hh:mm. as an example ”08.03.2007

12:10”. Parameters can be scrolled with UP and DOWN buttons. Parameter is entered with

SET button and panel will be moved to next parameter. New time will be set if all

parameters are configured. If one leaves the view with RIGHT button before all parameters

are set, new time is not entered into system.

10. LUMINAIRES

Address information is pre-provisioned into luminaire. Two address stickers are provided

with luminaire. One is to be attached in to luminaire and one to electrical design

documentation.

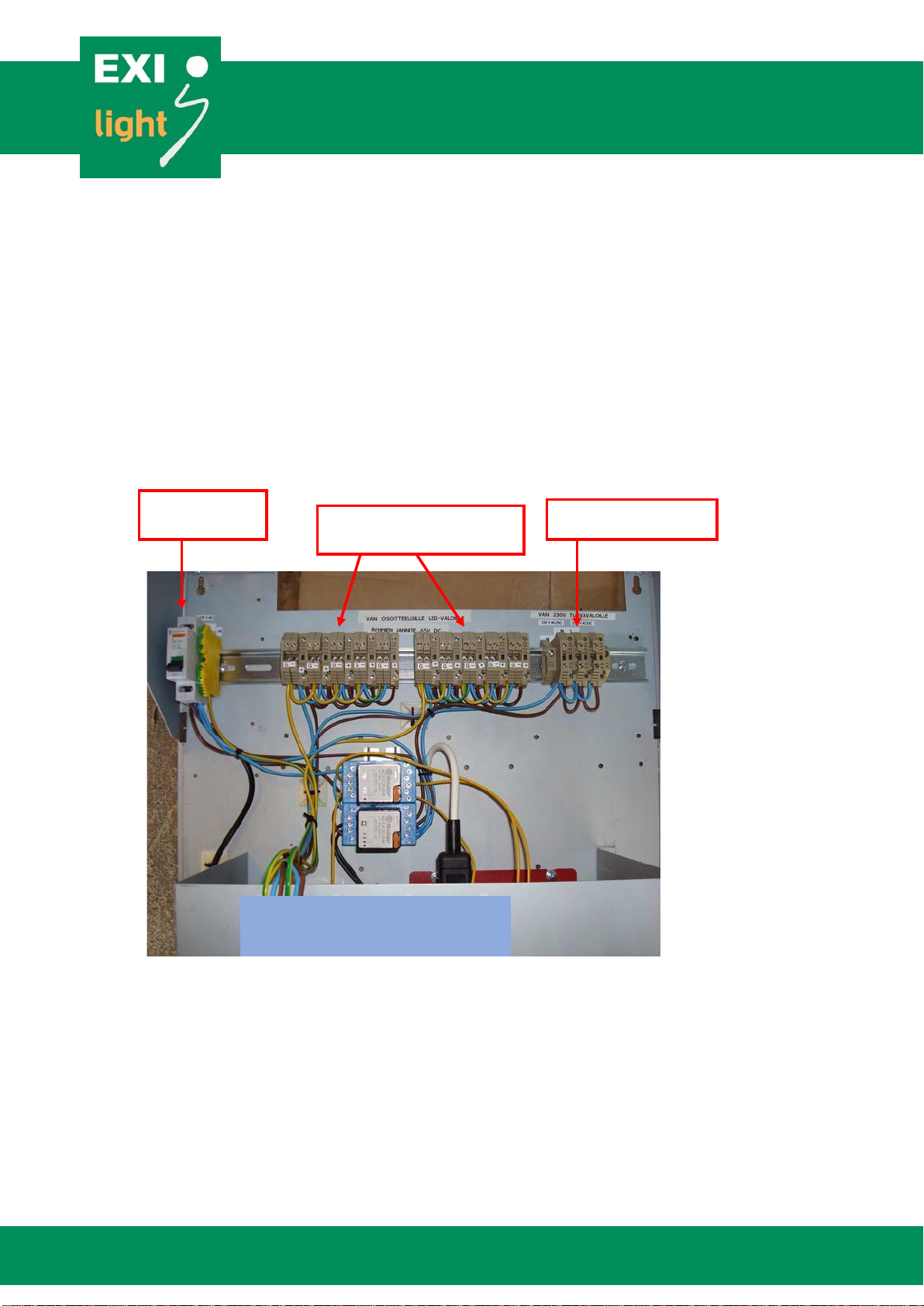

230 V AC

panel feed

Addressable outputs

Un = 65

V DC

230 V AC emergency

light output

ESC-200P PANEL

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

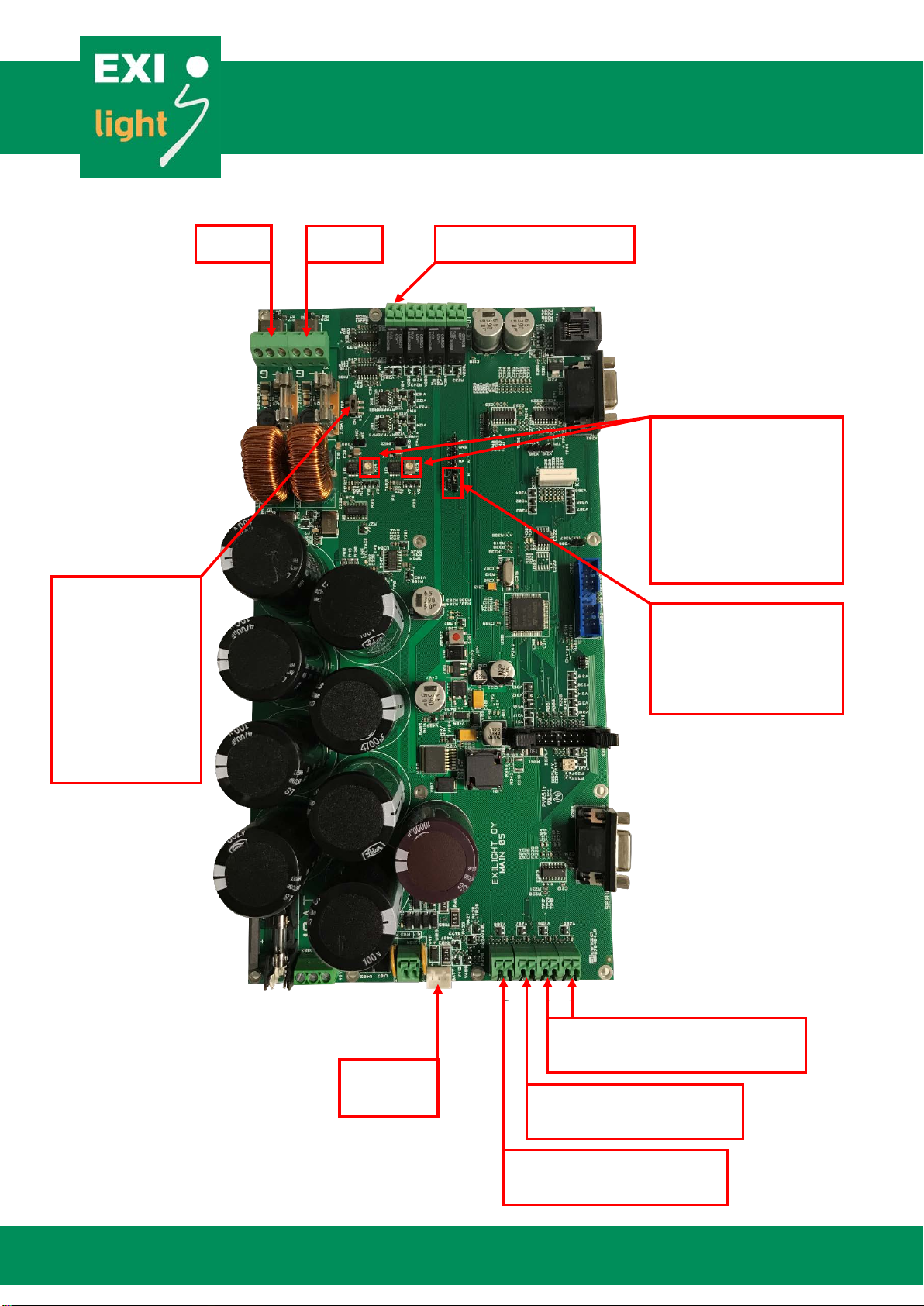

Loop 1

Loop 2

Dry contact output

Internal wiring

External control loop 2 dry

contact

External control loop 1 dry

contact

Battery

connector

Swith K3: Filter

ON/OFF (default

ON). If panel is to

be connected to

earlier generation

of ESC-200P set

filter OFF.

Jumpers X317 and

X318: Do not change.

By default they are

connected and enable

communication on line.

Trimmers R33 and R34:

Line output power. By

default same as

luminaire powers. Do

not change without

contacting supplier.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Operating the ESC-200P Panel

There is a 2 line LCD display (20 char. / line) and five operating buttons: “LEFT”, “RIGHT”, “UP”,

“DOWN” and “SET”.

Under the “SET” button there is a menu of rarely needed but never the less important

functions. These functions may come handy while operating the center.

The MENU includes:

1.

Normal status

a.

Everything Ok

b.

An Error code when something is wrong

2.

Browse error

3.

Annual test time

4.

LED test time

5.

Monthly test time

6.

Demo mode

7.

Start monthly test

8.

Start annual test

9.

Annual test duration

10.

Area monitoring

11.

Current measuring

12.

GND leakage set up

13.

Change language

a.

English

b.

Svenska = Swedish

c.

Suomi = Finnish

14.

Read address form PC

15.

Stop / Allow communication errors

16.

Browse appliances

17.

Inverter use

18.

Print appliance ID

19.

Event log

20.

Remove appliance

21.

Print errors

22.

Start new installation

23.

Set day + time

24.

Emergency lights on

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

1. Normal status

Everything Ok: The display shows date and time

- “Everything Ok” “HH:MM”

Error code

- The display shows the latest error that has not been set off

- The top line in the display shows the amount of errors and the lower line shows the

appliance ID (D), the loop (L) and the error code (E). For example: Not set off 005/005 //

D06397 L2 E03

- You can what the error code means by pushing the “LEFT” button. It will indicate what the

error code actually means, For example “led disconnected”

- To set off the error codes you have to push the “RIGHT” button two times.

2. Browsing errors

By pushing “SET” you can browse the errors that have been detected in the past.

The errors will be shown chronologically so that the latest error will be the first to show up on the

display. You can browse the errors by pushing “UP” or “DOWN”.

The display shows when the error was detected, appliance ID (D), loop (L) and the error code (E).

All error codes can be found in table 1 and 2.

3. Annual test time

Set the time and date for annual duration test

4. LED test time

Set the time for LED blink test.

5. Monthly test time

Set the time and date for monthly test.

6. Demomode

Here you can set demomode on. Demomode is only for presentation.

When the demomode is on the errors come more quickly to the panel.

7. Start monthly test

Function test is done automatically every month but here you can start that test manually.

8. Start annual test

Annual duration test is done automatically every year but here you can start that test manually.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

9. Annual test duration

Choose annual test duration, 1h or 3h.

10. Area monitoring

Control area monitors connected to the system.

11. Current measuring

12. GND Leakage Set Up

Not valid in ESC-200P system.

13. Change language

Here you can set the operating language to be English, Swedish or Finnish.

14. Read address from PC

Appliance IDs can also be read form the PC.

15. Stop / Allow communication errors

Normally these communication errors are stopped.

The center checks if there is some communication errors with appliance IDs

16. Browse appliances

Here you can check all the appliances connected to the center.

First you have to choose Loop 1 or Loop 2 by pushing “SET” and then you can browse appliances

by pushing “UP” or “DOWN”.

17. Inverter use

This is supposed to be switched ON when using ESC-200P system with central battery.

18. Print appliance ID

19. Event Log

You can connect your PC with the ESC-200P and print out the events via Ethernet converter.

20. Remove appliance

When removing appliance from Loop 1 or Loop 2 you also have to remove that appliance from the

appliance list.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

- This is because the center is constantly checking the status of every appliance and if the

appliance has been removed it can’t communicate with the ESC-200 center.

You can remove appliance from the appliance list as follows:

- From the menu choose “Remove appliance”

- Then choose if the appliance is in Loop 1 or Loop 2

- Find the appliance that needs to be removed by browsing the list with “UP and “DOWN”

buttons

- When you find the right appliance ID that has to be removed push “SET” three times. This

is to make sure that you don’t accidentally remove appliance that you are not supposed to

remove.

21. Print errors

You can connect your PC with the ESC-200 and print out the errors.

22. Start new installation

By choosing “Start new installation” the center finds all the appliances connected to the system.

Center ask before new installation”delete memory” you can choose ”no” or ”yes”. If you choose

”yes” centter will delete luminaire addresses what is in memory.

23. Set day + time

Here you can set the date and time for the system

24. Emergency lights on

This is to start test for the system. This is used to check the communication between panel and

luminaires. Communication should be Ok if emergency luminaires are set ON with this test

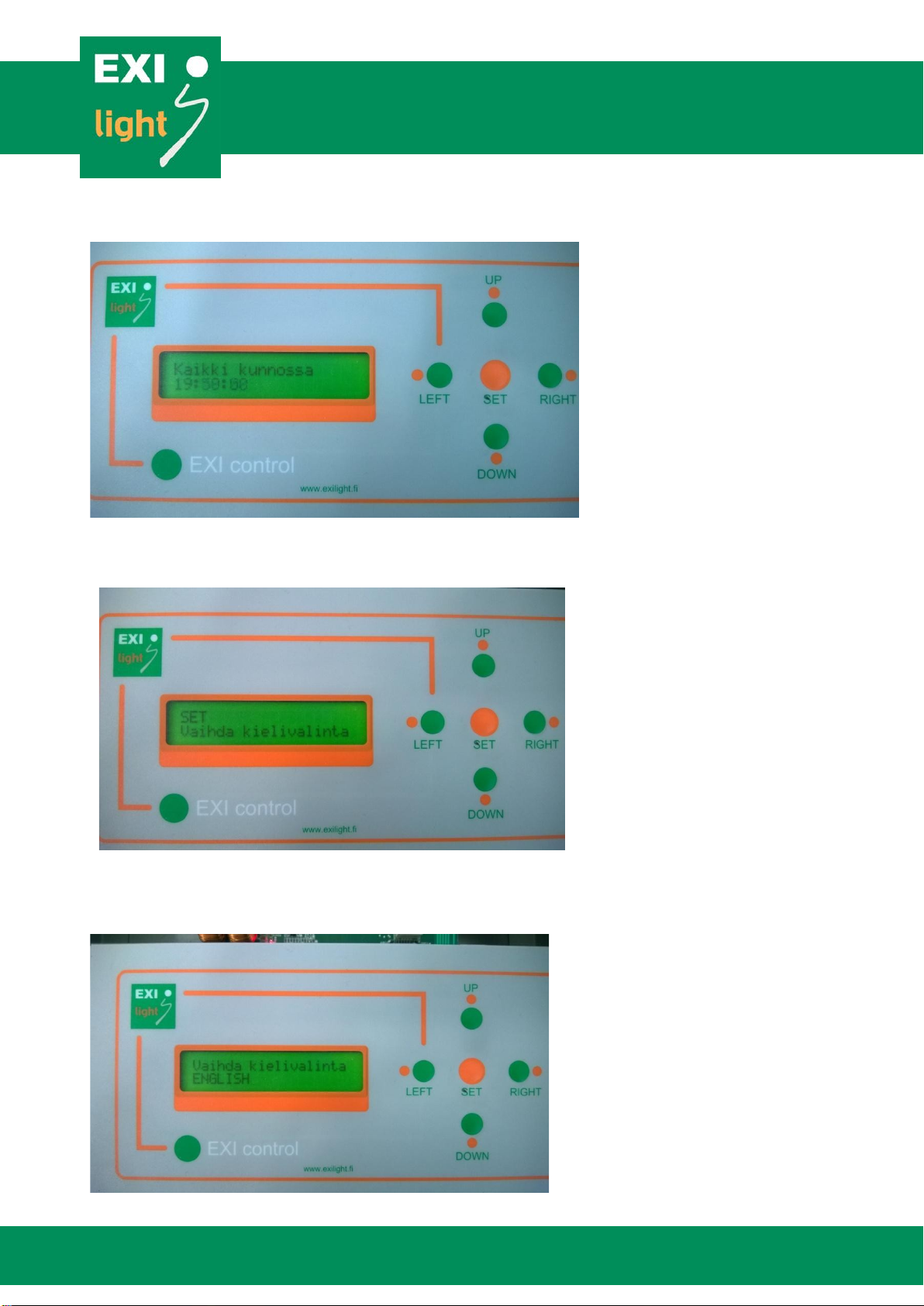

Changing the Operating Language

If the ESC-200P emergency lighting center is delivered to you with settingsin

Finnish, here is how you can change the language toEnglish.

You start by pushing the “SET”button when you have the operating status shownin the

picture 1.

Then push the “DOWN”button three (3) times to get the display of picture2.

After that push “SET”and by “UP”or “DOWN”button choose “ENGLISH”asshown in

the picture 3. Push “SET”to select thelanguage.

Now you have the ESC-200P Emergency Lighting Center set inEnglish.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Picture 1.

Picture 2.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Picture 3.

Checking Error Status

If the display is showing an Error Code (Picture 4 and 5), you can set it off (Picture 6 and

7) to make sure it is actually a real Error. If the Error is real it will come back to the display

within few minutes.

You can set off the Error Code by pushing the ”RIGHT”button two (2) times inthe

display shown in pictures 4 and 5 (demonstrated in pictures 6 and7).

If the Error Code returns to the display and it’s a real Errorthen:

-

Find out what the Error Code stands for (Picture 5).

-

Find out where in the building that Emergency or Exit light is located and go

check the lights status.

Picture 4. Reading the Error Code from the ESC-200 display.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Picture 5. You can see what the Error Code actually means by pushing ”LEFT”

button.

Picture 6. Set off the Error Code by pushing ”RIGHT”.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

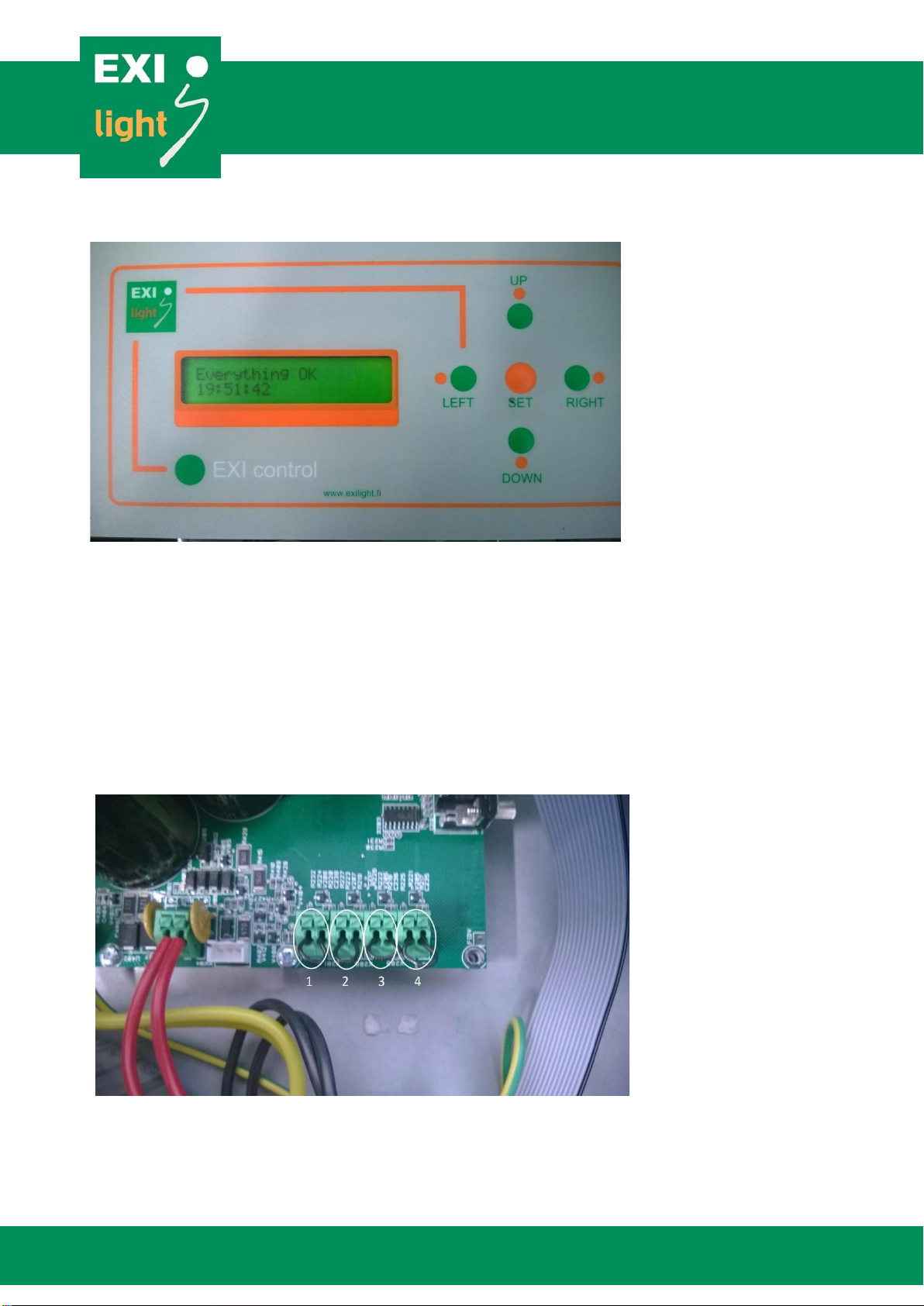

Picture 7. When the Error is set off the display will show “Everything OK”.

Remote controlling the Emergency lights

In case that there are some Emergency lights lit along with the Exitlights:

Make sure that the Remote Control is not on (Picture 8.).

-

Remote controlling the Emergency lights is operated with NCcontact. If there is no

remote controlling the lights, there is a loop in the terminals as shown in Picture 8.

-

If there is a blackout or the remote control is on, the buttons in Centers display

stops working. This is for as long as the blackout or remote control is on.

Picture 8. Remote controlling the ESC-200 Center. Input 1 controls Emergency lights

in Loop 1, input 2 controls Emergency lights in Loop 2, inputs 3 and 4 controls all the

emergency lights connected to the ESC-200 Center.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Setting the luminaire location

Connect the panel to your PC.

Open EXIL2 software and choose the right port and language.

Press the read button. After the software has read all the addresses you can write or

change the locations. Maximum letter is 16 in one location.

Write button write the locations to the panel.

With import button you can bring file which include the addresses. The file must be written

in the following way: every lane has Loop information, address information, location

information and it must be separate with comma. The file must be text file. For example:

Loop1,17515,Hall 1

Loop1,17670,Hall 2

Loop1,17701,Corridor

Loop1,17793,Garage

Loop2,17753,Garage2

Loop2,17792,Hall 3

With export button you transfer the tex file to the panel.

After the panel has read the file, locations should be now in your panel. You can now

remove the port cable.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Picture 9. Luminaire location setting PC software.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Working Principles of ESC-200P

Data transfer protocol is called DC Power Line Communication

-

The information runs in the same cable with the voltage

The Center is constantly checking the lights operatingstatus

-

The first error doesn’t show up on the display. The Error Code shows uponly if

the same light/address gives the error ten (10)times.

oThis is how we can reduce failures coming from othernetworks.

oThere are no external signs about the Center checking theoperating

status.

-

How long does it take to Error Code to show up on Centers display depends on

how many lights you have in the system and how they areinstalled.

-

Checking the LEDs makes the Emergency light blink briefly about once a

day.

The ESC-200P Center makes the battery test every month.

-

The Center makes the luminaires to work with batteries during the test. The

voltage (65VDC) still remains in the line.

-

The test lasts for 30 minutes and the Emergency lights light up duringthe

test.

-

The automatic testing cannot be turnedoff.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Controlling 230V emergency lights with external

control

Three (3) 230V emergency light outputs can be turned on with dry contact by connecting inverter to

external control according to picture 9.

Picture 9: 230V emergency light outputs control

ESC-200P design and cabling principles

In order for the proper functioning of system, please use following design and cabling principles:

•Always use shielded FRHF-cable.

•Keep lines as short as possible (maximum distance around 300 m).

•Maximum number of 100 luminaires per line.

•Place the luminaires to lines with as even spacing as possible.

•If long spans are needed, prepare own line for it and do not include any other luminaires on

the way.

•Cable crimping should be kept to a minimum on luminaires and switch boxes.

•In luminaire connections take care that positive and negative connections are connected

right way around. Also take care to connect earth conductor.

•2 Area Monitoring Units(AMUSs) is comparable to one luminare. So if you have 80

luminaires on line, maximum AMUs is 40 per line. (max100 luminare per line)

•If Area Monitoring Units (AMUs) are being used, ensure that between AMUs and controlled

luminaires there are more than 5 meters of cable to ensure proper communication.

For example AMU

can be used.

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Example cabling

•TVK is same as Control Panel ESC-200P

•Cabling FRHF

•AV is same as AMU

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

Service and Maintenance

Service and maintenance of system has to be conducted by person with professional and

knowledgeable person. Constant maintenance is needed in order to ensure the proper function of

the system.

Warranty

Warranty terms under the supplier’s standard terms. In case of system faults always consult your

sales representative:

EXILIGHT OY

Hermiankatu 6–8 A

FI-33720 Tampere

Finland

+358 10 773 5400

info@exilight.com

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

ESC system error codes

Table 1: Luminaires’ errors

ERROR REMARK ERROR

CODE

Battery disconnected

Not to be noted in central battery use.

E01

Short circuit in battery

Not to be noted in central battery use.

E02

Led disconnected

E03

Short circuit in LED

E04

Battery condition fail

Not to be noted in central battery use.

E05

Battery failed during test.

Not to be noted in central battery use.

E08

Battery disconnected

Not to be noted in central battery use.

E01

Table 2: Central panel errors

ERROR REMARK ERROR

CODE

Communication error

Error in the communication between

luminaire and panel.

E14

Blackout

Not an actual error. Doesn’t need to be set

off. Is noted in the error log.

E15

Low control voltage

Control voltage drops, but doesn’t cause a

blackout.

E16

Loop 1 dead

Control voltage too low or fuse is broken.

E17

Loop 2 dead

See above.

E18

Earth leakage in loop 1

E19

Earth leakage in loop 2

E20

Excess current in loop 1

Overload in loop 1

E21

Excess current in loop 2

Overload in loop 2

E22

Inverter or battery fail

Inverter fail during test

E23

Inverter or battery fail

Battery fail during test

E24

Hermiankatu 6–8, 33720 Tampere | +358 10 773 5400 | info@exilight.com |

MANUAL

This page is intentionally left blank.

Table of contents

Popular Safety Equipment manuals by other brands

KRATOS SAFETY

KRATOS SAFETY FA 10 401 00 manual

Petzl

Petzl DUAL CANYON GUIDE TECHNICAL NOTICE

Roger Technology

Roger Technology R85 Series Instruction and warnings for the installer

RIB

RIB F97I Guide

South-Tek Systems

South-Tek Systems N2-BLAST FPS-500 O & M Manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use