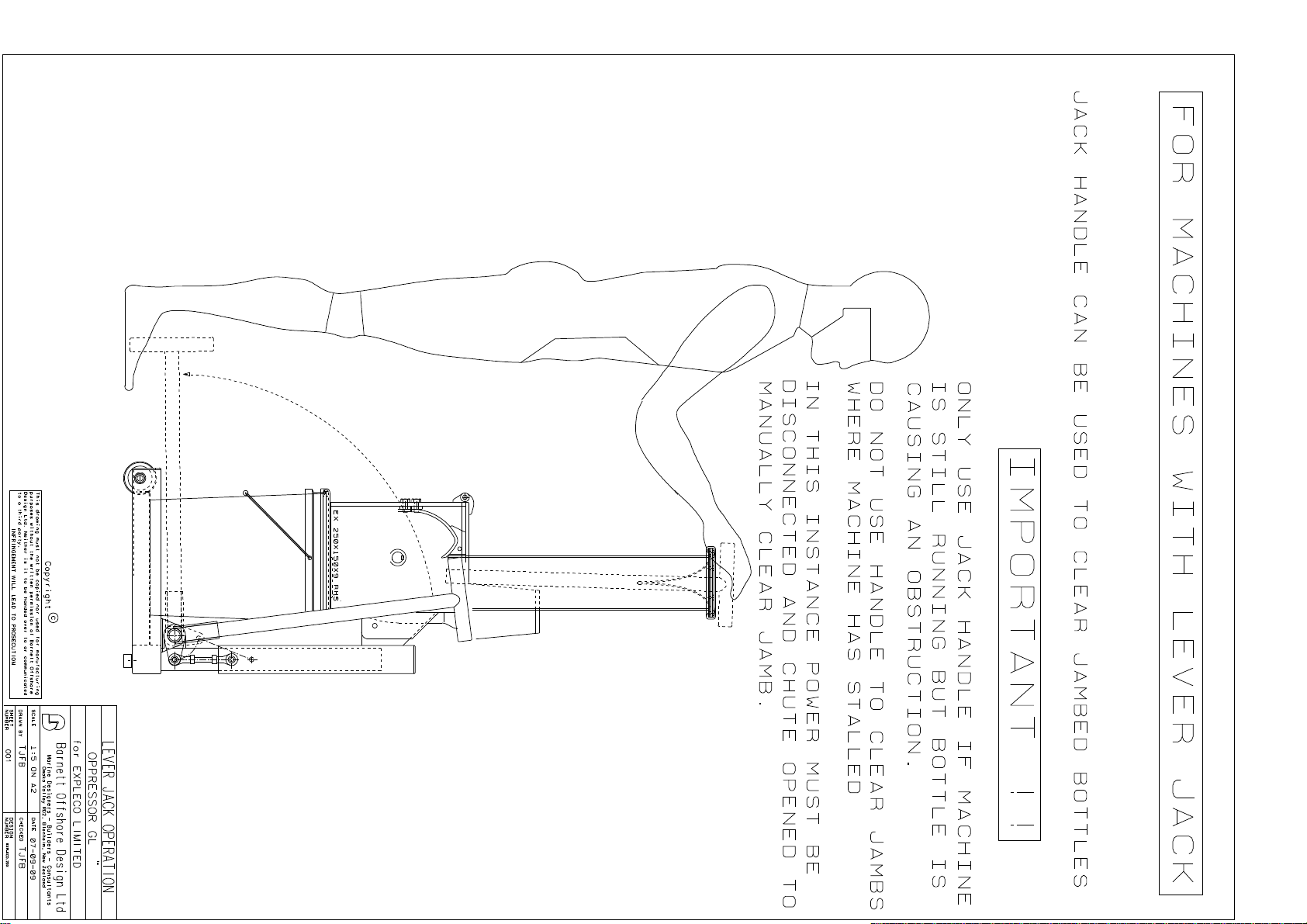

4

4. Clean glass grit from the rubber chute/housing gasket. Relocate the chute

and tighten the chute retaining bolt firmly – being sure that a proper seal is

attained. Do not overtighten.

5. If overload protector tripped during the jam you will need to reset the

overload on the switch housing by pushing it in.

6. Restart the machine.

Filter Clean/Replacement

1. If visible dust is seen coming from the filter or main inlet, it is an indication

that the filter needs cleaning or the bucket is overfull.

2. Primary filter clean can be achieved by tapping on top of filter with

knuckles so that the accumulated dust is dislodged from the primary filter

and falls down into bucket.

3. If visible dust is still coming from the main inlet or filter the primary filter will

need replacing. Please contact Expleco or the machine supplier for supply

of replacement primary filter.

Bearing and Jack stand grease.

1. Your Oppressor GL is supplied with a small grease gun.

2. The grease that must be used is Shell Albida EP2 High Temp Grease.

3. The machine is pre-greased in the factory. The grease gun is supplied full.

4. If the machine makes an intermittent or consistent squeak the main

bearing will need greasing.

5. With the machine running pump grease into the grease nipple on the top

of the main bearing. Wait between each pump and when squeak stops

give one more pump. Do not over grease.

6. As a rough rule of thumb you may find that you need to grease once every

2-3000 bottles.

7. Once or twice a year you can grease the nipple on the top of the jack

stand. Only a couple of pumps will be required.

Consumable Items

1. The Oppressor GL has specialised internal components which are made

from high tech abrasion resistant materials which eventually need

replacing. These parts are readily available for purchase from Expleco or

your machine supplier. The parts must be installed by a factory approved

service technician.

2. The consumable items and indicative life are as follows.

•12 x Oppressor Oscillating Flails - 50,000 bottles

•Main Screen GLS only - 25,000 bottles

•Top screen shroud GLS only - 50,000 bottles

•Main Bearing -50,000 bottles

•Motor Bearings -25,000 bottles

•Buckets – available as required. Only use the Expleco Bucket

These are average component lives. You may get a longer life from some components. If in

doubt contact your supplier or Expleco.