H y p e r J R+

Features

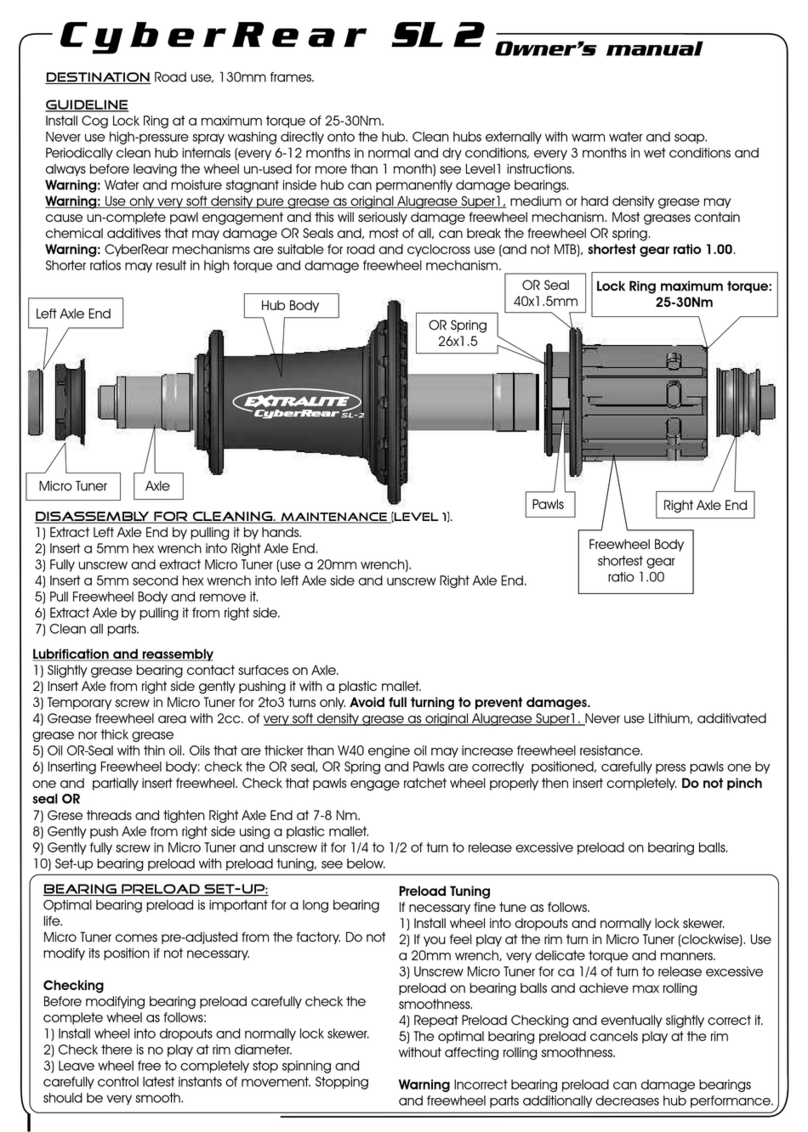

Hyper JR offers unique features like low friction external OR and

lip seals, front engagement freewheel system, multishaped

oversized axle, top quality sealed ball bearings, Micro-Tuner

bearing preload system, “hart coat” anodized cassette body

and axle ends.

Bearings: 2x 6903 2RS (hub body) and 2X 6803 2RS (freewheel).

Use it proper care and its absolute performance will last for

years. This manual provides the informations needed for the set

up and the basic cleaning-lubing-maintenance.

Sealing HyperRear hub features low friction Lip Seal and external OR seals. However, since it is impossible to completely seal a

hub and still have it spin freely, with use water/moisture can get in.

Guideline Periodically clean hub internals (every 6-12 months in normal and dry conditions, every 3 months in wet conditions

and always before leaving the wheel un-used for more than 1 month) see Level1 instructions next page.

Never use high-pressure spray washing directly on hubs. Clean hubs externally with warm water and soap.

WARNINg Un-correct greasing and/or maintenance of freewheel mechanism can lock and destroy it!

WARNING Even small debris inside freewheel engagement can damage mechanism permanently.

WARNING Water and moisture stagnant inside hub can permanently damage bearings.

Bearing preload set-up:

Optimal bearing preload is important for a long bearing life.

Micro Tuner comes pre-adjusted from the factory. Do not

modify its position if not necessary.

Checking

Before modifying bearing preload carefully check the

complete wheel as follows:

1) Install wheel into dropouts and normally lock skewer.

2) Check there is no play at rim diameter.

3) Leave wheel free to completely stop spinning and carefully

control latest instants of movement. Stopping should be very

smooth.

Preload Tuning

If necessary fine tune as follows.

1) Install wheel into dropouts and normally lock skewer.

2) If you feel play at the rim turn in Micro-Tuner (clockwise). Use a

21mm wrench, very delicate torque and manners.

3) Unscrew Micro-Tuner for ca 1/4 of turn to release excessive preload

on bearing balls and achieve max rolling smoothness.

4) Repeat Preload Checking and eventually slightly correct it.

5) The optimal bearing preload cancels play at the rim without

affecting rolling smoothness.

Warning Incorrect bearing preload can bring to serious damages:

- Too tight --> bearings damage and premature wear

- Too loose -->permanent freewheel damage

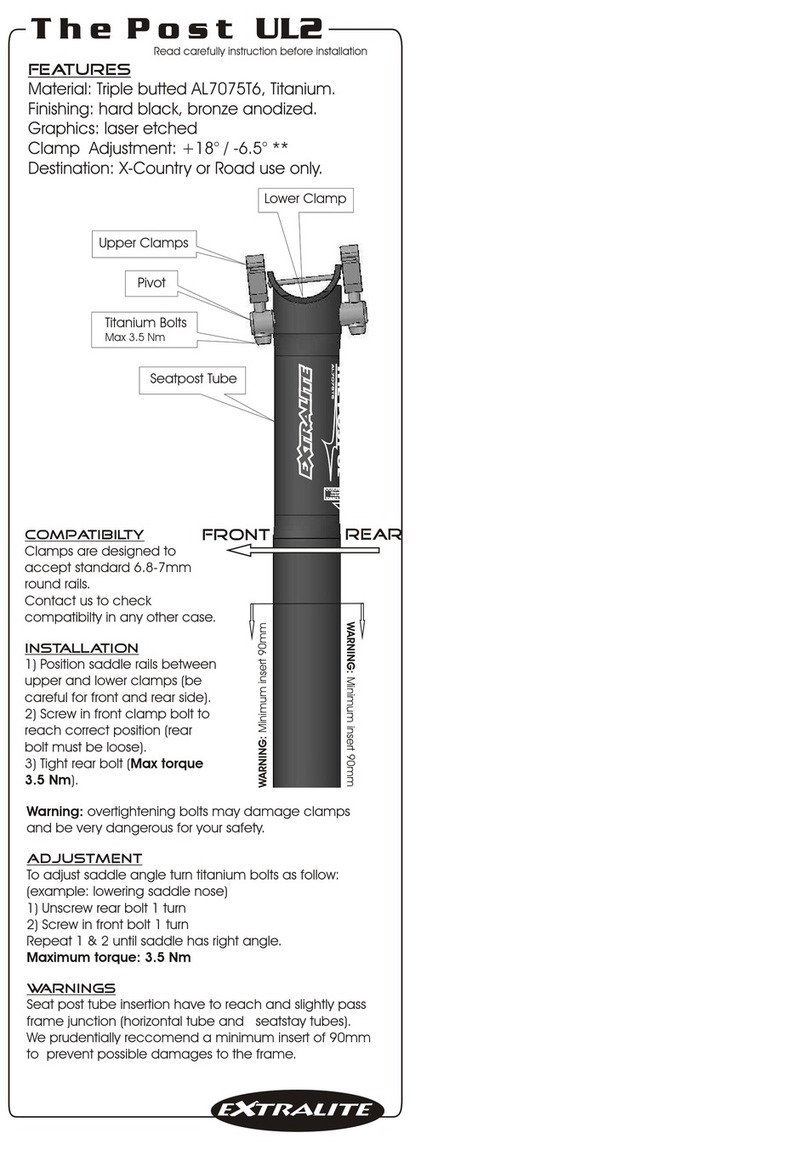

Dimension for wheel building

Spoke hole Ø: 2.5mm

Right flange drilling Ø: 55.6mm

Disc flange drilling Ø: 55.6mm

Center to right flange: 23mm

Center to disc flange: 35mm

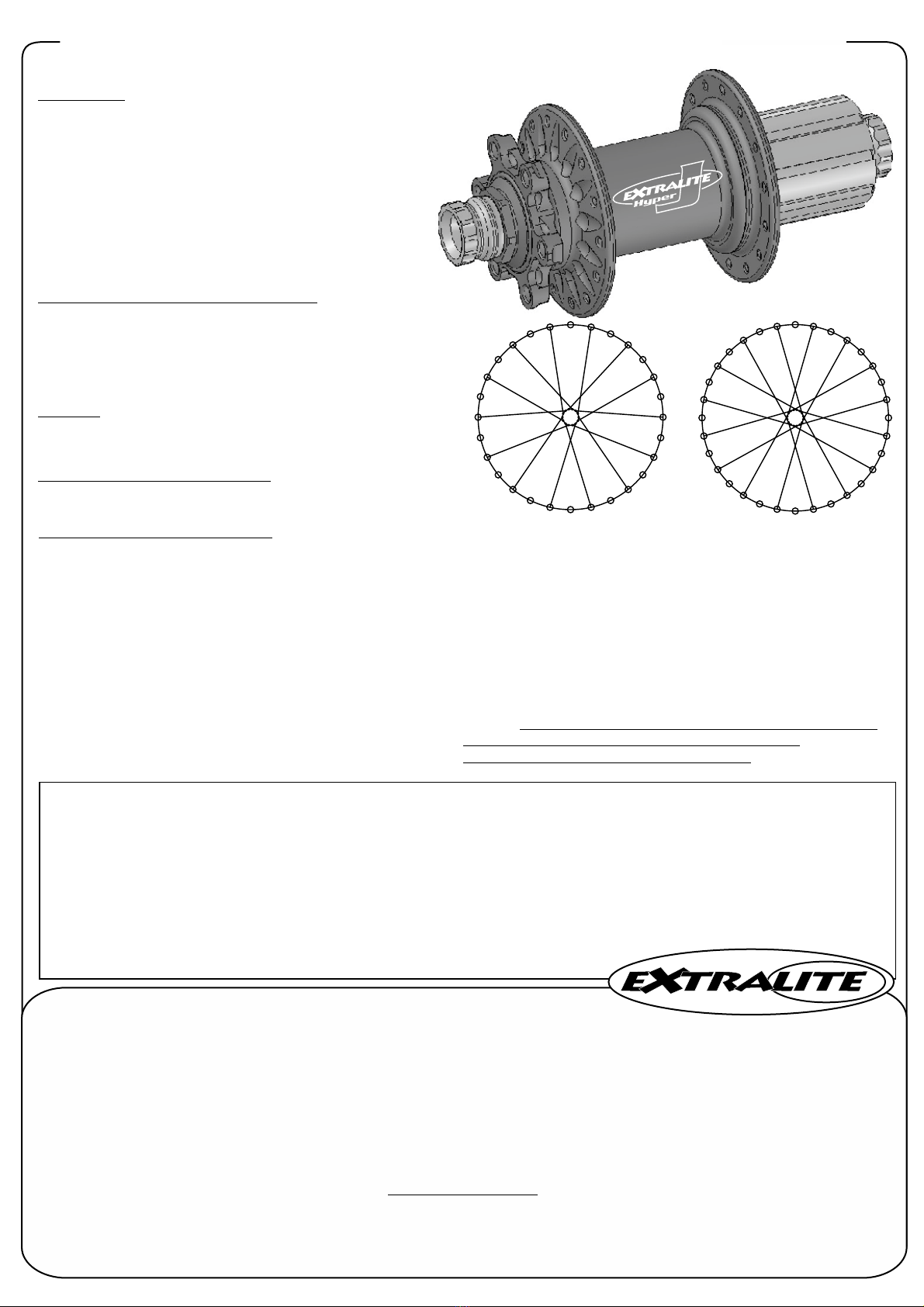

Lacing

See www.extralite.com to find spoke lengths.

Respect 28h or 32h lacing patterns (see drawings).

maximum spoke tension:

Drive side 130kgf

Disc side 90kgf

135mm / 142mm / XD Drive / Shimano

Extralite Limited Warranty

Extralite products are warranted against defects in materials and/or workmanship for a period of two years from original date of purchase to the original o w n e r o n l y.

Any Extralite product that is returned and found by Studio Riva to be defective in materials and/or workmanship will be repaired or replaced at the sole discretion of Studio

Riva. This warranty is the sole and exclusive remedy. Studio Riva shall not be held liable for any indirect, special or consequential damages. The warranty is expressly limited

to repair or replacement of the product that has been returned and found to be defective by Studio Riva and are the sole remedy of the warranty. No credits or refunds

will be issued.

The warranty does not cover: normal wear, tear and fatigue; damage or failure due to accident or collision. Improper assembling, poor maintenance, alterations or

modifications, installation of parts not compatible with Extralite products void this warranty. Warranty does not cover damage arising from crash, abuse and/or misuse or

any other circumstances in which the product had been subjected to forces or loads beyond its design.

Immediately replace the component after crash and violent shock, or after continuos heavy use.

Improper use, modification and/or part changing, including surface finishing, could irreparably damage the component.

All labor charges for warranty service are responsibility of the product owner.

INSTALLATION WARNING:

Extralite components are extremely performing and lightweight, crafted with very high quality, they request adequate installation and maintenance care. We strongly

recommended that a professional bike shop install and service your Extralite components.

Improper assembly and/or adjustment may significantly compromise strength and durability of the component causing serious personal injury.

Carefully check proper tightening torque of every bolt. Always respect installation recommendations.

Extralite components are designed for a specific use X-Country or Road or Downhill, respect product specific destination.

Note: the rider assumes all the risks regarding use and installation of Extralite components.

28H 32H