www.eyc-tech.com

‧‧‧

3

DST01 Universal Isolation Signal Converter / Splitter

Table of Contents

1. Introduction ........................................................................................ 4

1.1 Introduction ......................................................................................... 4

1.2 Features ............................................................................................. 4

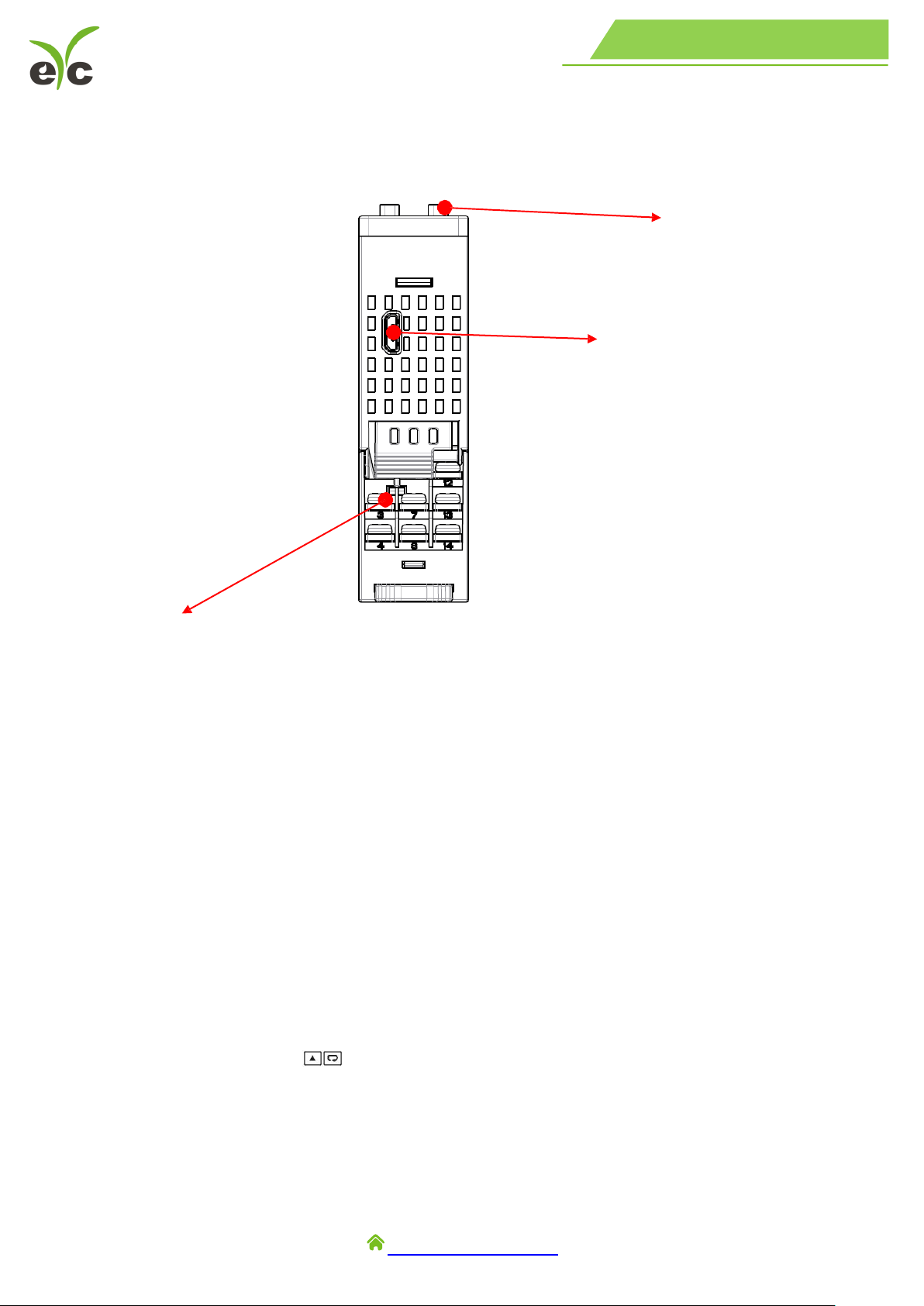

1.3 Programming Port .............................................................................. 5

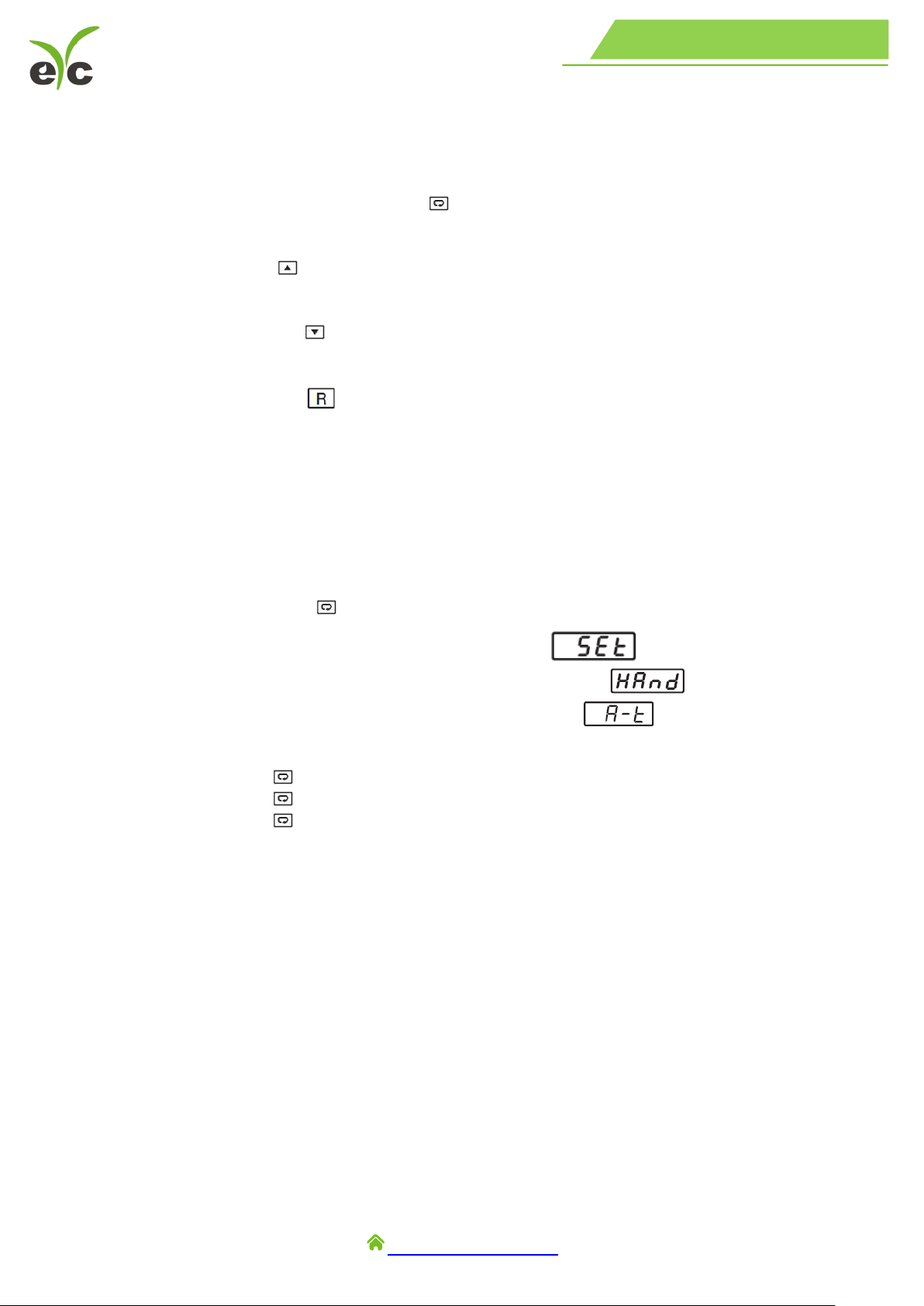

1.4 Display Board Keys ............................................................................ 6

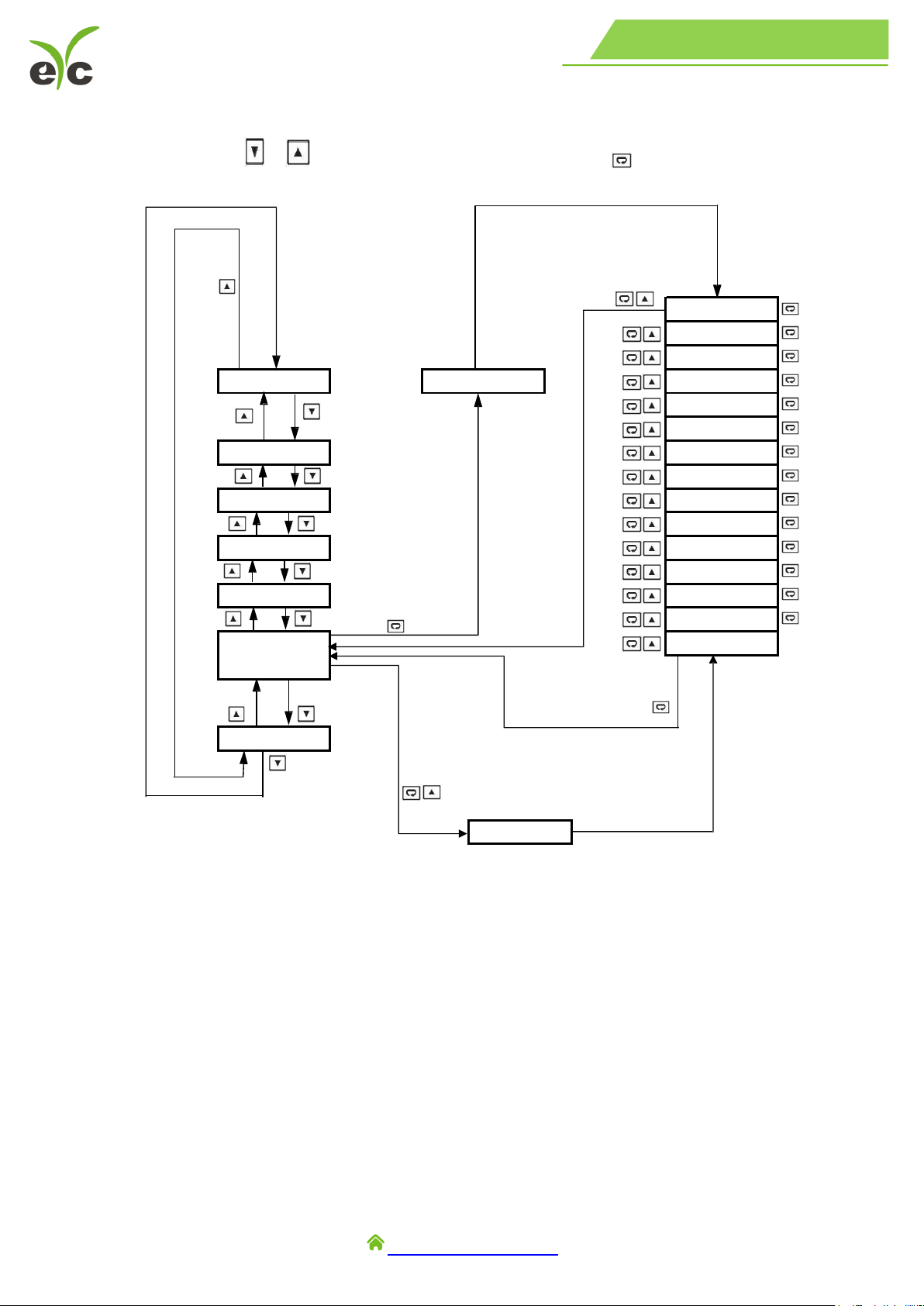

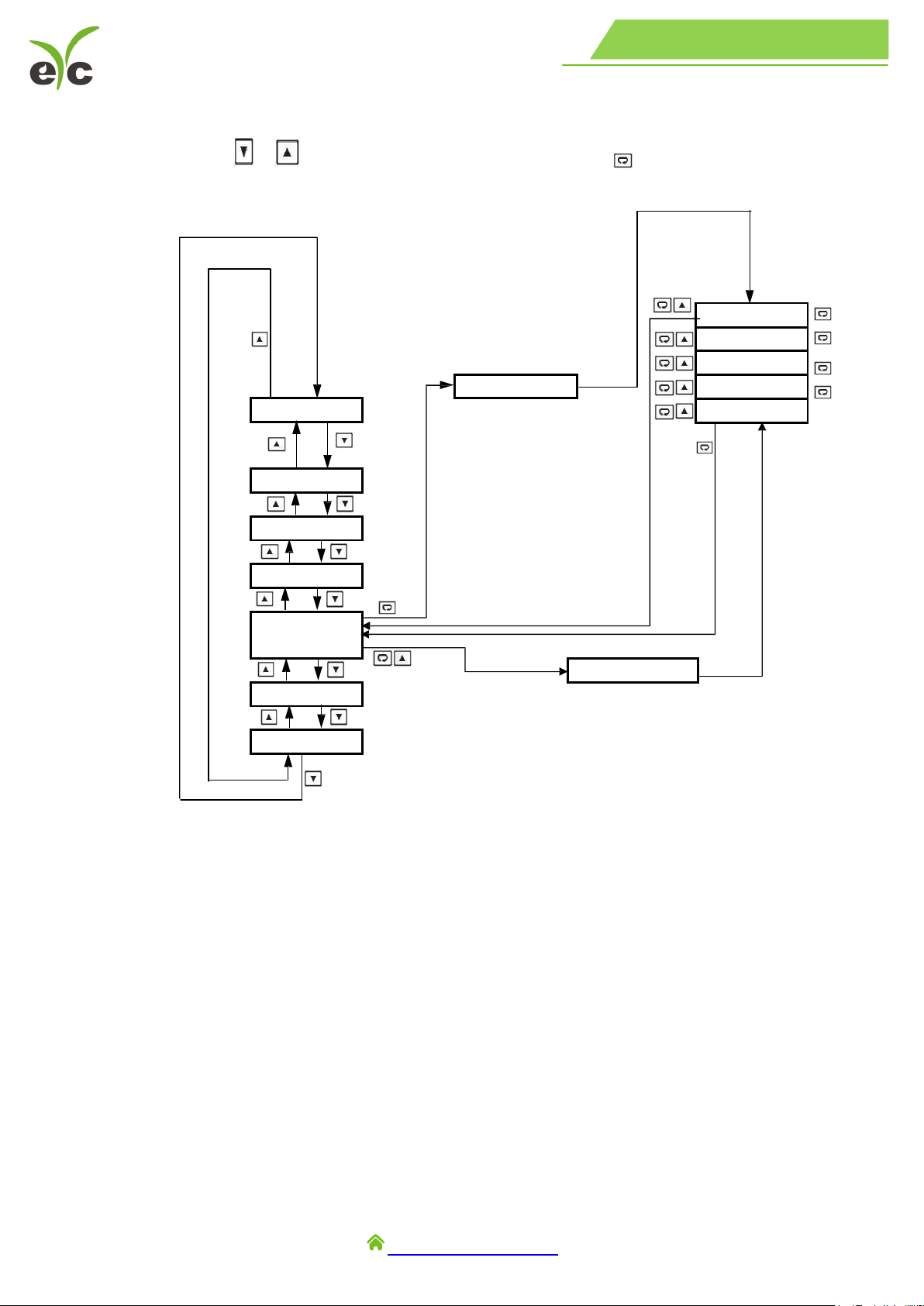

1.5 Menu Flowchart .................................................................................. 8

1.6 Parameter Availability Table ............................................................... 12

2. Installation and Wiring ....................................................................... 15

2.1 Unpacking .......................................................................................... 15

2.2 Dimension .......................................................................................... 16

2.3 Wiring ................................................................................................. 17

3. Programming ...................................................................................... 22

3.1 User Security ...................................................................................... 22

3.2 Calibration Password .......................................................................... 22

3.3 Signal Input ........................................................................................ 22

3.4 Output Type ........................................................................................ 23

3.5 Retransmission ................................................................................... 23

3.6 Zero and Span Adjustment ................................................................. 23

3.7 Square Root Function(SQRT) ............................................................ 23

3.8 User Calibration .................................................................................. 24

3.9 Digital Filter ........................................................................................ 25

3.10 Manual Control ................................................................................... 25

3.11 Factory Default ................................................................................... 25

3.12 Data Communication .......................................................................... 25

3.13 Digital Input ........................................................................................ 26

4. Calibration ........................................................................................... 27

4.1 Equipment Required Before Calibration ............................................. 27

5. Communication .................................................................................. 30

5.1 Functions Supported .......................................................................... 30

5.2 Exception Responses ......................................................................... 31

5.3 Error Code .......................................................................................... 32

5.4 Mode .................................................................................................. 32

5.5 PROG Code ....................................................................................... 32

5.6 Scaling ................................................................................................ 33

5.7 Data Conversion ................................................................................. 33

5.8 Communication Examples .................................................................. 33