For more information call 1-800-654-8168 or go to www.ez-dock.com. 7

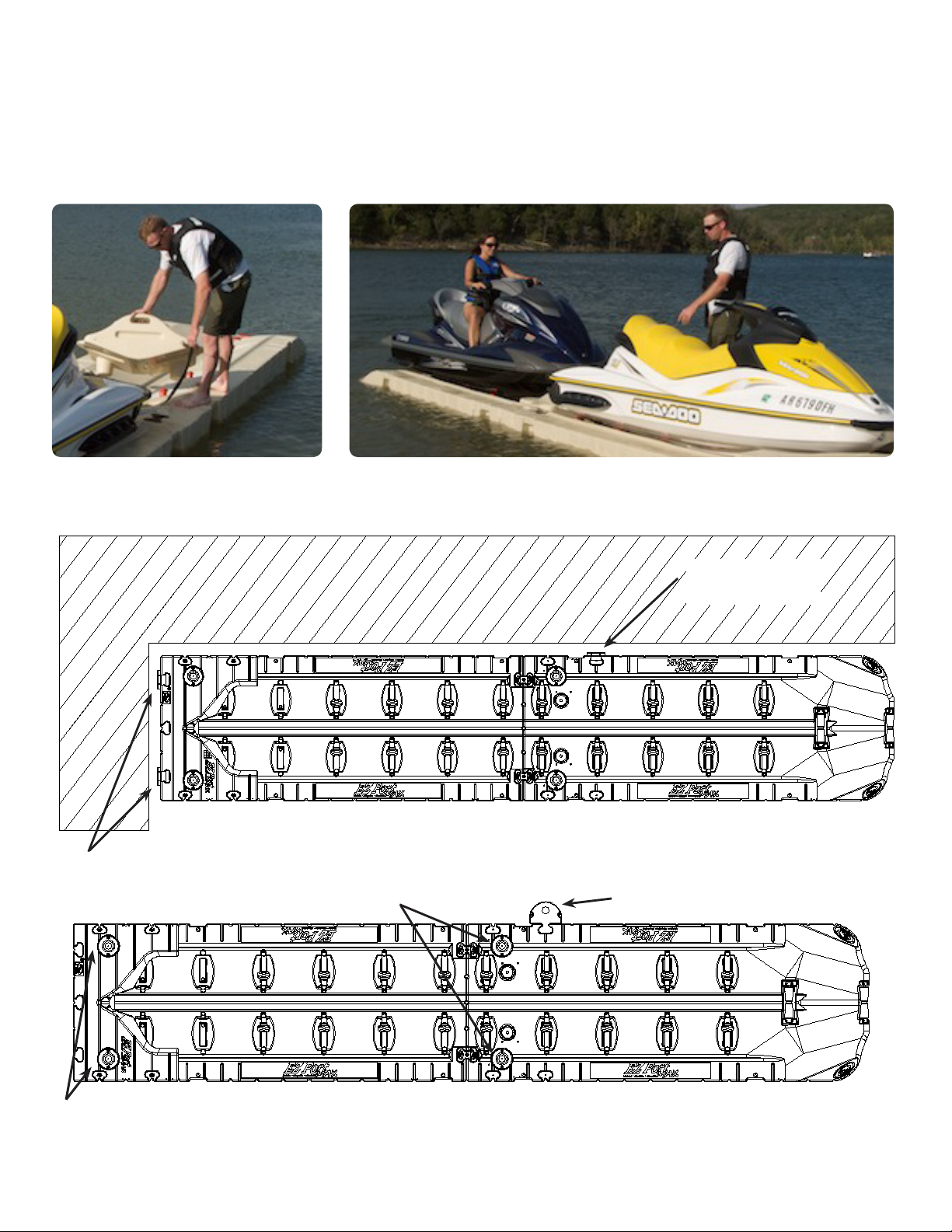

Selecting your Installation/Attachment Method

The EZ Port MAX must oat freely on the water surface, moving up and down with any changes in water level. To

accomplish this there are a number of anchoring/installation methods available for use with the EZ Port MAX.

Site Conditions to be Considered

Every EZ Port MAX installation will be site specic and must be congured specically for the end user’s intended

application. Some factors that must be taken into consideration when determining the components necessary for a

proper installation are: intended usage, water conditions, soil/bed conditions, and climatic conditions. There are a few

simple rules to follow when determining layout conguration.

Be certain that your installation conguration is designed to accommodate the daily intended use of your EZ Port MAX.

Please take into account the following:

Commercial application needs•

Public access requirements•

Private docking needs•

Scale of operation and use (size of PWCs, number of people, etc.)•

Other special considerations affecting your daily use•

Be aware of the unique characteristics of the specic body of water and consider how such conditions will affect the

installation. Take into account:

Overall area of the body of water•

Water depth (at the shore and at the furthest point from shore)•

Normal and greatest wave action•

Water level uctuation•

Fresh, brackish, or salt-water•

Normal ice thickness and movement•

Lakebed and soil conditions (sand, rock, mud, etc.)•

Usage

Understand and consider installation/performance requirements then evaluate your ability to fulll them.

Determine whether your installation will be attended and inspected on a regular basis.•

Become acquainted with the normal movement associated with oating structures.•

Determine whether you are capable of performing your own installation, or whether it is best to hire a•

professional.

Once you have considered and worked out the issues above, the next step is to select the installation mounting

method that is best for you. Since no two installations are ever exactly the same, each and every EZ Port MAX

installation must be designed and congured for the specic and intended application.

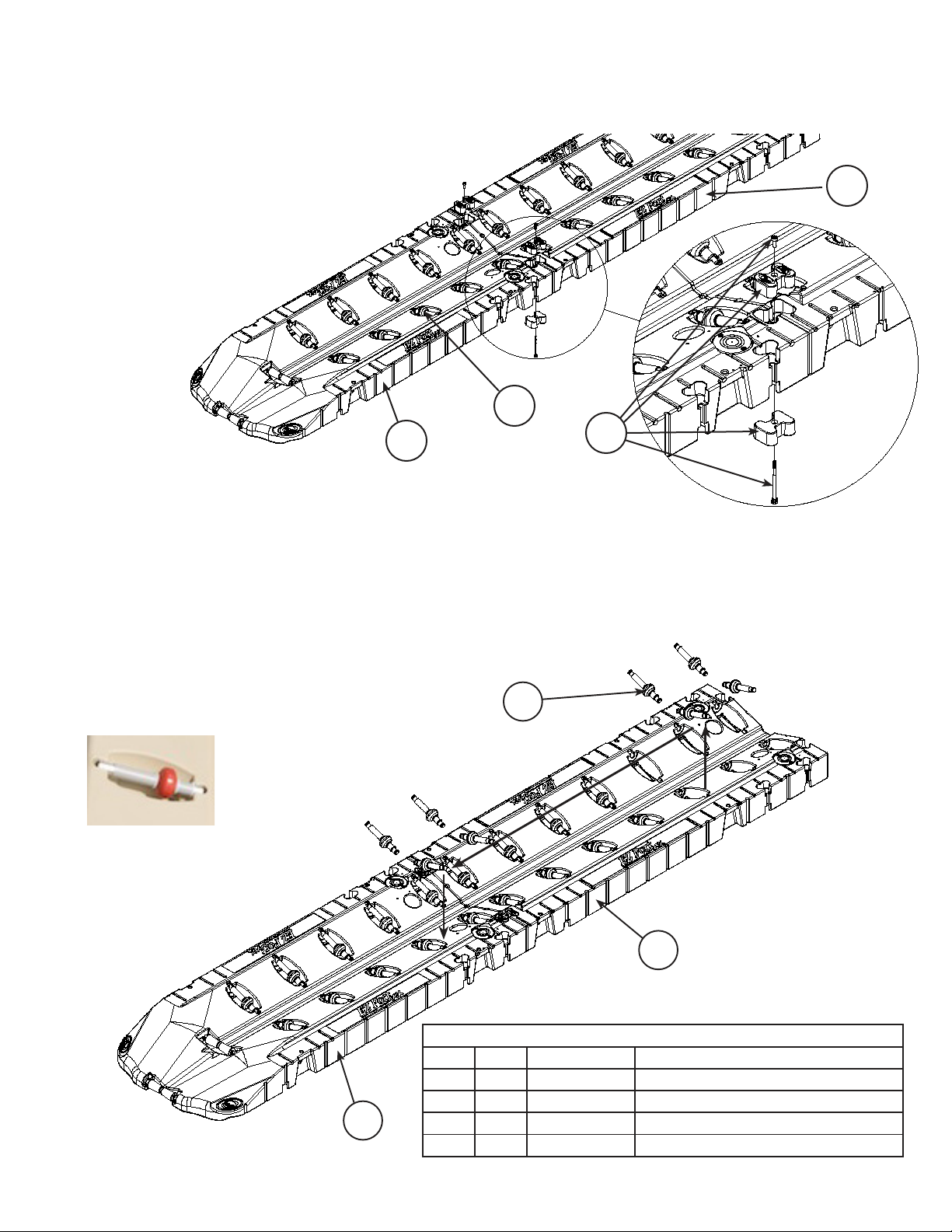

Installation with an EZ Dock System (Section 3.):• When installing the EZ Port MAX on an EZ Dock system,

simply use standard EZ Dock coupler sets to connect the EZ Port MAX to the EZ Dock. (refer to the installation

instruction section 3).

Installation with Pipes (Section 4.):• Anchoring the EZ Port MAX with pipes allows for stand alone installations.

The integrated pipe brackets are utilized for these installations (refer to the installation instruction section 4 for

stationary/xed piers , docks bulkheads, seawalls, etc.).

Installation with other oating dock systems (Section 5. & 6.):• The EZ Port MAX can be attached to other

oating docks with the oating dock adapter hinge kit (refer to the installation instruction section 5 for when Small

Bow Section is used and 6 for Full Bow Section).