CONTENTS

TABLE OF CONTENTS ----------------------------------------------------------------------- 1

CLONING MODE ----------------------------------------------------------------------------4~5

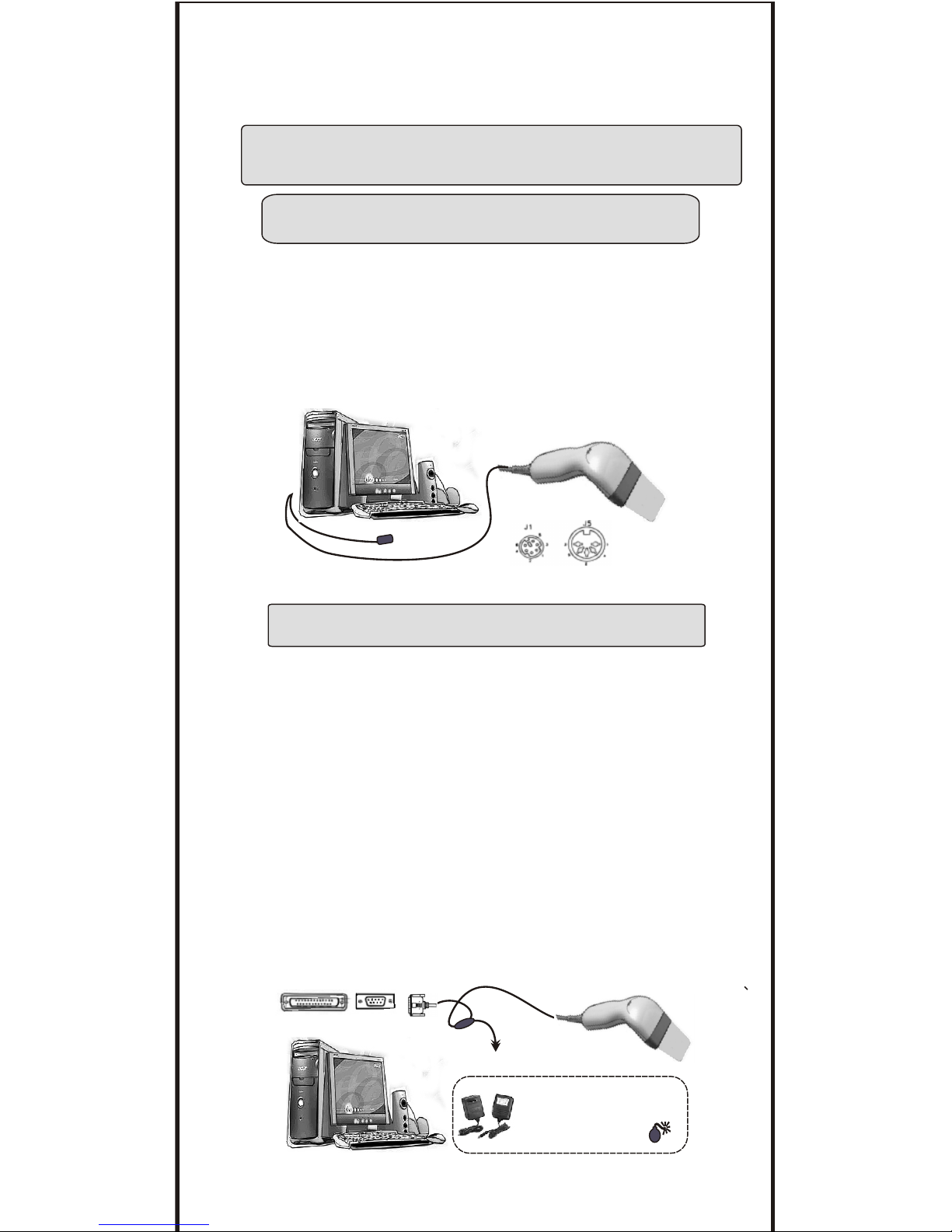

GETTING STARTED

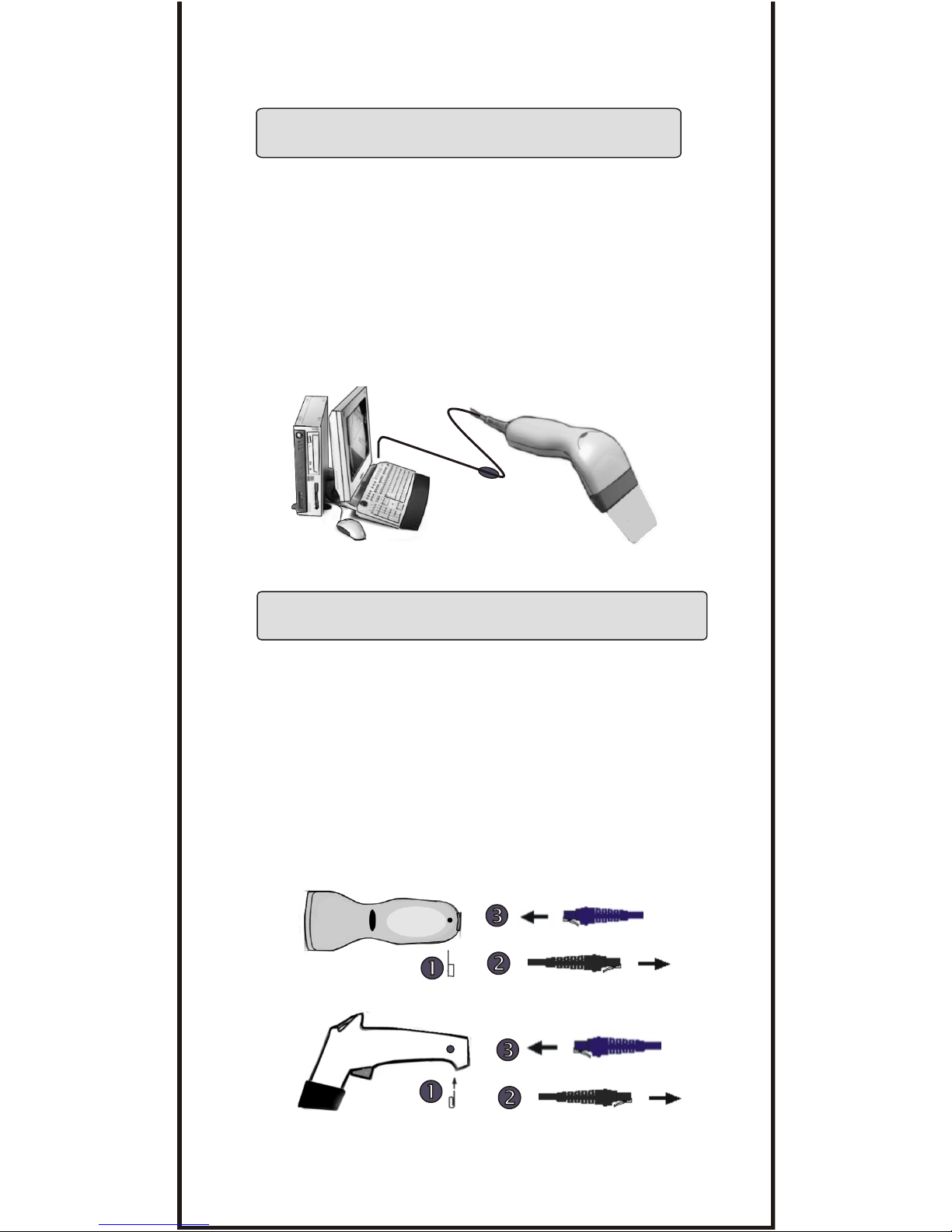

>>> HOW TO FIX THE SCANNER TO THE TERMINAL -----------------------6~7

>>> HOW TO CHANGE A CABLE -------------------------------------------------------- 7

>>> HOW TO SETUP THE PARAMETER.---------------------------------------------- 8

GROUP 1 >>>> INTERFACES SELECTION, COMPUTER TYPE, DEFAULT. ---------- 9

GROUP 2 >>>> READING MODE SETTING. -------------------------------------------- -------10

GROUP 3 >>>> CHECK VERSION, BEEP TONE, CAPLOCK MODE.-------------------- 11

GROUP 4 >>>> PREAMBLE AND POSTAMBLE.-----------------------------------------------12

GROUP 5 >>>> ACCURACY ADJUSTMENT.----------------------------------------------------13

INTRODUCTION, EZ TROUBLESHOOTING ----------------------- --- ----------- 2~3

GROUP 6 >>>> ENABLE AND DISABLE CODE ID.------------------------------------------- 14

GROUP 7 >>>> SYMBOLOGIES CODE ID IDENTIFIER., SET ID --------------- -------- 15

GROUP 8~9 >> CODE ID CONFIGURATION: SET CODE ID ----------------------- 16~17

GROUP 10 >>> DELAY BETWEEN BLOCK AND CHARACTER.-------------------------- 18

GROUP 11 >>> TERMINATOR AND KEYBOARD LAYOUT. -------------------------------- 19

GROUP 12 >>> RS232-BAUD RATE, DATA BITS & PARITY, STOP BITS.--------------- 20

GROUP 13 >>> HANDSHAKING, ------------------------------------------------------------------ 21

GROUP 14 >>> WAND EMULATION PARAMETER SETTING. --------------------------- 21

.

SYMBOLOGIES FORMATING (GROUP 15~ GROUP 31).

GROUP 15 >>> ENABLE AND DISABLE SYMBOLOGIES. -------------------------------- 22

GROUP 16 >>> ENABLE AND DISABLE SYMBOLOGIES. -------------------------------- 23

GROUP 17 >>> CHINA POST CODE ( TOSHIBA CODE), CODE 32.----------------- 24

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING -------------------- 25

GROUP 18 >>> UK PLESSEY CODE, MSI CODE. ----------------------------------------- 26

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING ------------------ 27

GROUP 19 >>> CODE IATA, CODE93.TELEPEN.-------------------------------------------- 28

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING -------------------- 29

GROUP 20 >>> INTERLEAVED 2 OF 5, CODE 11 .----------------------------------------- 30

APPEND 1 > >> NUMERIC TABLE, MIN/MAX LENGTHS SETTING ------------------- 31

GROUP 21 >>> CODABAR.------------------------------------------------------------------------- 32

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING---------------------- 33

GROUP 22 >>> ABC-CODABAR, CX CODE ----------------.--------------------------------- 34

GROUP 23 >>> CODABAR COUPLING, ------------------------------------------------------- 35

GROUP 24 >>> CODE 128, STANDARD CODE 39, FULL ASCII CODE 39.----------- 36

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING -------------------- 37

GROUP 25 >>> INDUSTRIAL 2 OF 5, MATRIX 2 OF 5.------------------------------------- 38

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING--------------------- 39

GROUP 26 >>> UPC-E. ----------------------------------------------------------------------------- 40

GROUP 27 >>> UPC-E(0), (1) ,UPC-E & UPC-A EXPAND ----------------------------- 41

GROUP 28 >>> UPC-A..----------------------------------------------------------------------------- 42

GROUP 29 >>> EAN 8. ------------------------------------------------------------------------------ 43

GROUP 30 >>> EAN 13 ----------------------------------------------------------------------------- 44

GROUP 31 >>> EAN/ UCC 128 -------------------------------------------------------------------- 45

GROUP 32 ~ 39 >>>> FULL ASCII TABLE ( CODE 39 --------------------- 46 ~53

GROUP 40 >>>>> NUMERIC ( CODE 39 ) TABLE. --------------------------- 54

GROUP 41~ 42 >>>> FUNCTION CODE ( CODE 39 ) FOR PC AT.----- 55~56

GROUP 43~ 46 >>>> TROUBLE SHOOTING --------------------------------- 57~60

Ms6262 CONTROL CODE LIST FOR Rs232. -------------------------------------------61

GENERAL

SETTING GROUP

1