4

INDEX

1 TECHNICAL SPECIFICATIONS ............................................................................................ 5

1.1 MACHINE DESCRIPTION ...................................................................................................................................... 5

1.2 APPLIED RUGULATIONS ....................................................................................................................................... 5

1.3 WORK STATION ..................................................................................................................................................... 6

1.4 PROTECTIONS ........................................................................................................................................................ 6

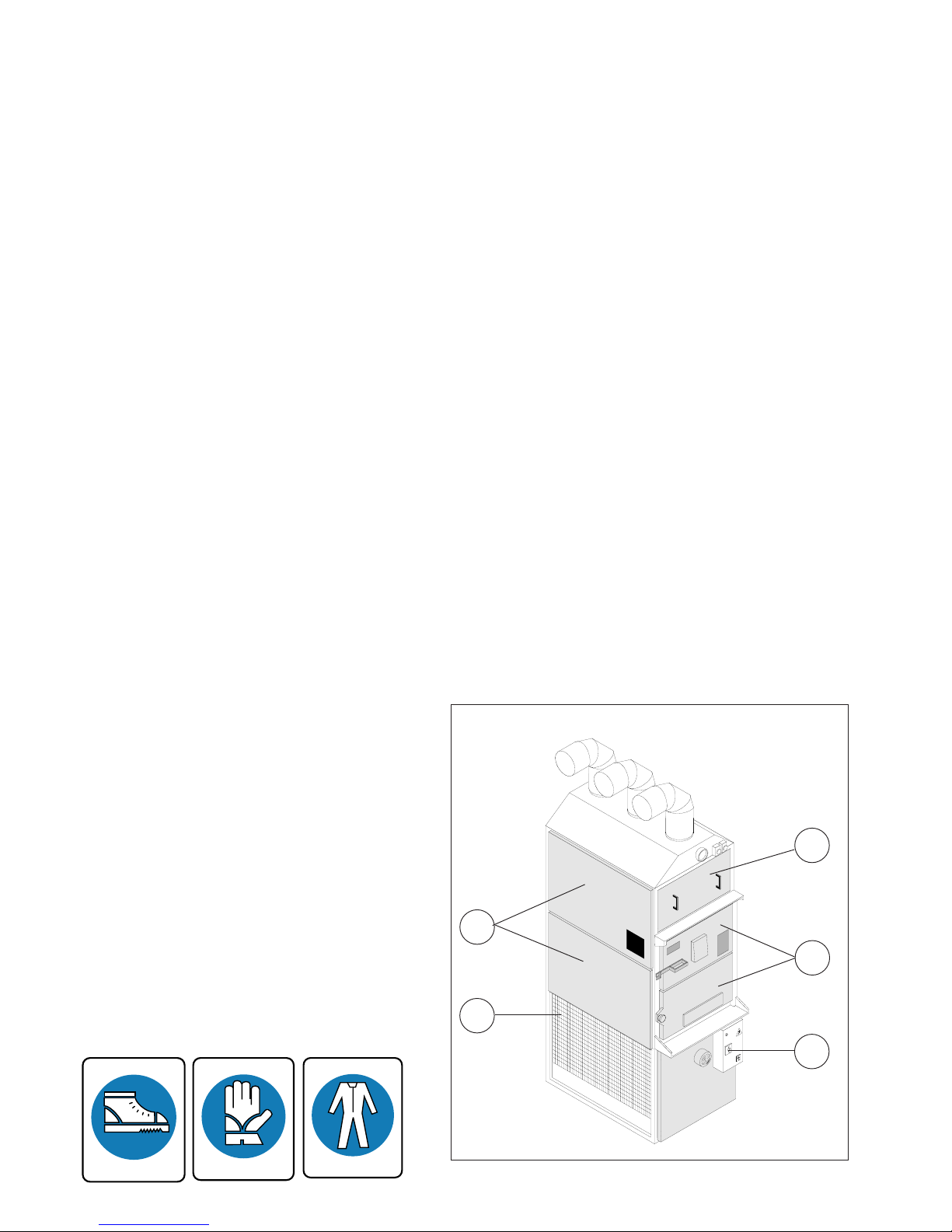

1.5 MODELS .................................................................................................................................................................. 7

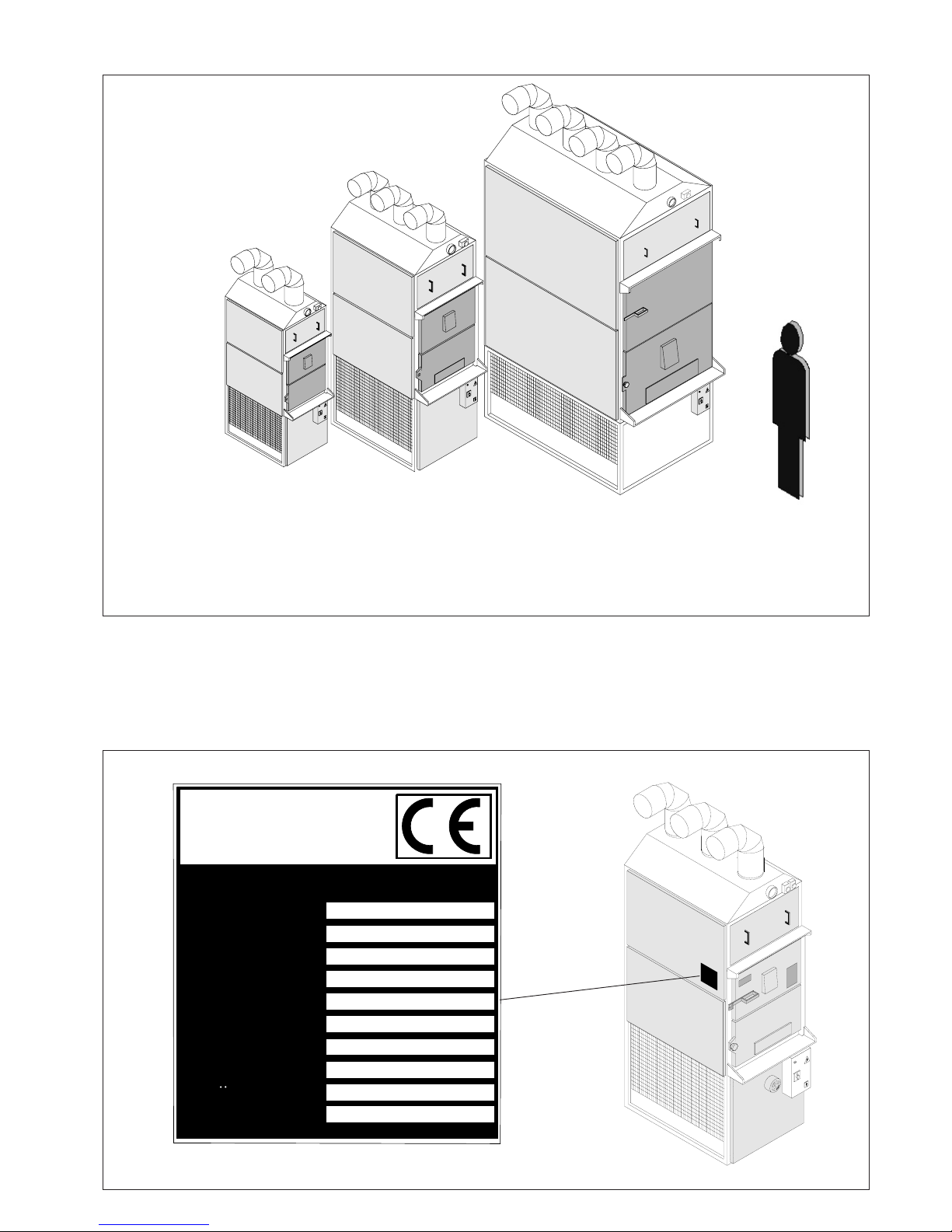

1.6 IDENTIFICATION ................................................................................................................................................... 7

1.7 ENCUMBRANCE .................................................................................................................................................... 8

1.8 LABELLING ............................................................................................................................................................ 8

1.9 TECHNICAL SPECIFICATIONS ............................................................................................................................ 9

2 INSTALLATION .......................................................................................................................... 10

2.1 TRANSPORT ............................................................................................................................................................ 11

2.2 LIFTING AND HANDLING .................................................................................................................................... 11

2.3 ACCESSORIES ........................................................................................................................................................ 11

2.4 ENVIRONMENTAL SPECIFICATIONS ................................................................................................................ 12

2.5 INSTALLATION ...................................................................................................................................................... 13

2.6 MAINTENANCE SPACE ........................................................................................................................................ 13

2.7 ELECTRIC PLUG-IN ............................................................................................................................................... 14

3 OPERATION ................................................................................................................................ 16

3.1 PRELIMINARY CONTROLS (version F85 CV - F120 - F240) .............................................................................. 16

3.2 STARTUP ................................................................................................................................................................... 16

3.2.1 STARTUP (summer) ............................................................................................................................................... 16

3.3 TWIN THERMOSTAT FUNCTIONING ................................................................................................................. 17

3.3.1 FAN FUNCTIONING ............................................................................................................................................. 17

3.3.2 LIMIT FUNCTIONING ......................................................................................................................................... 17

3.3.3 PLUGGING AND CALIBRATION ....................................................................................................................... 17

3.1 PRELIMINARY CONTROLS (version F85 SV) ...................................................................................................... 18

3.1.2 CONTROLS DESCRIPTION ................................................................................................................................. 18

3.2 STARTUP ................................................................................................................................................................... 18

3.2.1 STARTUP (summer) ............................................................................................................................................... 19

3.4 OPERATION .............................................................................................................................................................. 20

3.5 REGULAR STOP ...................................................................................................................................................... 20

4 ORDINARY MAINTENANCE .................................................................................................. 21

4.1 PRELIMINARY CONTROLS ................................................................................................................................... 21

4.2 CLEANING THE WARM AIR GENERATOR ......................................................................................................... 21

4.2.1 WIPING OFF THE ASH ......................................................................................................................................... 22

4.2.2 CLEANING THE FLUE ......................................................................................................................................... 22

4.2.3 CLEANING THE HEAT EXCHANGER ............................................................................................................... 22

4.3 FANBELT STRETCHING ......................................................................................................................................... 22

4.4 REPLACING THE THERMOSTAT PROBE (version F85 SV) ............................................................................... 23

4.5 REPLACING THE FUSE (version F85 SV) ............................................................................................................. 23

5 END OF SERVICE ..................................................................................................................... 24

6 ACOUSTIC POLLUTION ......................................................................................................... 24

7 SPARE PARTS CATALOGUE .................................................................................................. 25

TAV. 1 SPARE PARTS F85 ............................................................................................................................................. 26

TAV. 2 SPARE PARTS F120-240 ................................................................................................................................... 27

TAV. 3 ELECTRIC PLAN F85-1SV ................................................................................................................................ 28

TAV. 4 ELECTRIC PLAN F85-2SV ................................................................................................................................ 29

TAV. 5 ELECTRIC PLAN F85-1CV ............................................................................................................................... 30

TAV. 6 ELECTRIC PLAN F85-2CV ............................................................................................................................... 31

TAV. 7 ELECTRIC PLAN F120-1 ................................................................................................................................... 32

TAV. 8 ELECTRIC PLAN F120-2 ................................................................................................................................... 33

TAV. 9 ELECTRIC PLAN F240-1 ................................................................................................................................... 34

TAV. 10 ELECTRIC PLAN F240-2 ................................................................................................................................. 35