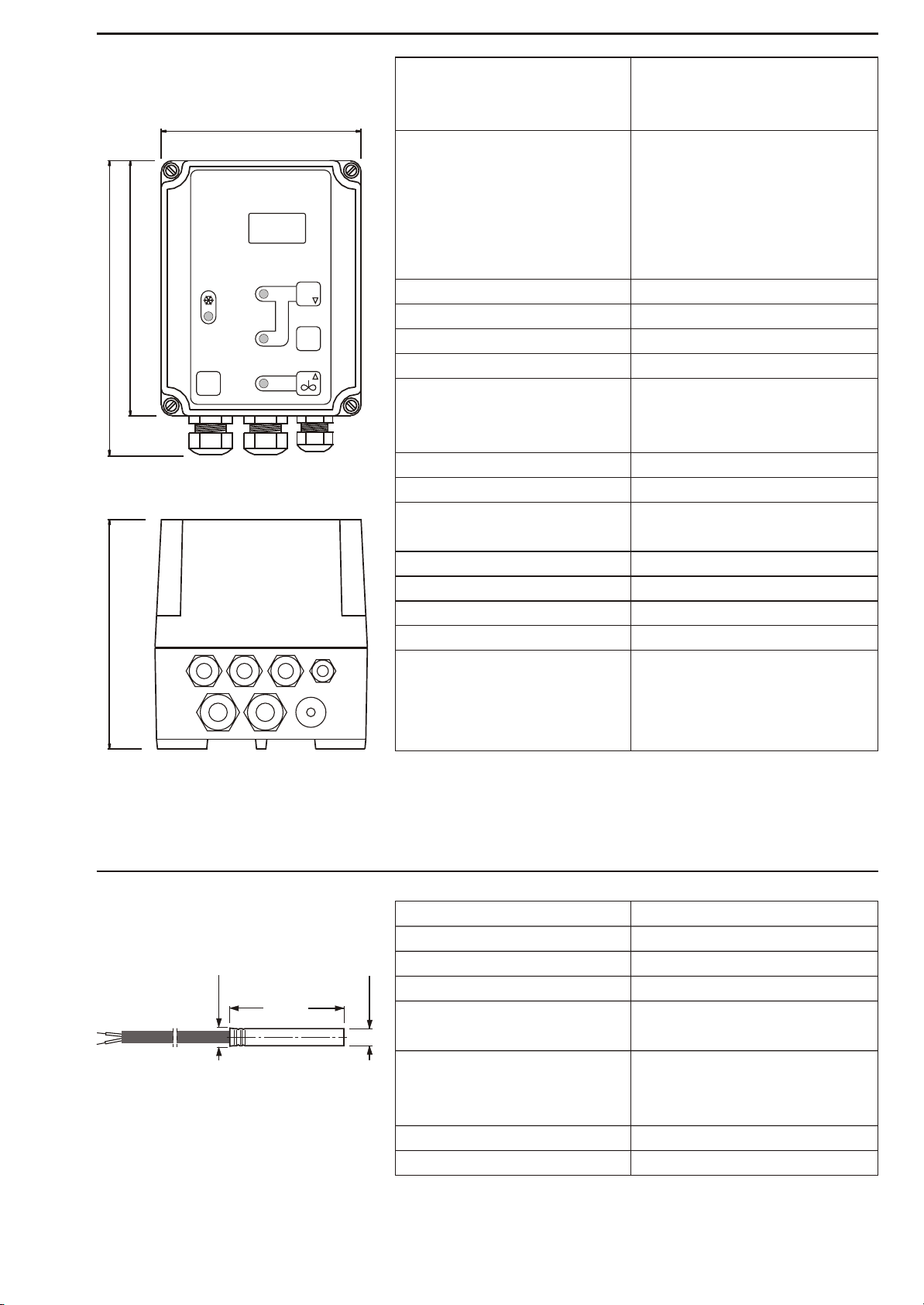

Function This control is a complete control cabinet for milkcooling tanks. The

integrated microprocessor regulator with automatic afterstirring has

separate relay contacts for the compressor contactor and the stirrer. The

measured milk temperature is shown constantly on the display, when

the cooling mode is switched on.

Two freely adjustable target temperatures may be selected by push

buttons. Should the milk temperature exceed the chosen target tempe-

rature (4° or 8°) by the hysteresis value, the compressor and stirrer are

automatically switched on. Once the target temperature is reached, the

compressor contactor switches off. The stirrer continues for the pro-

grammed period. During refrigeration pauses, the stirrer automatically

switches on again according to the programmed intervals, to ensure an

even temperature throughout the milk.

Independently of this, short or long "intermediate stirring" can be selec-

ted by pressing a button. Software can also be used to programme for

"permanent stirring", i.e. the agitator is switched on and off by pressing a

button.

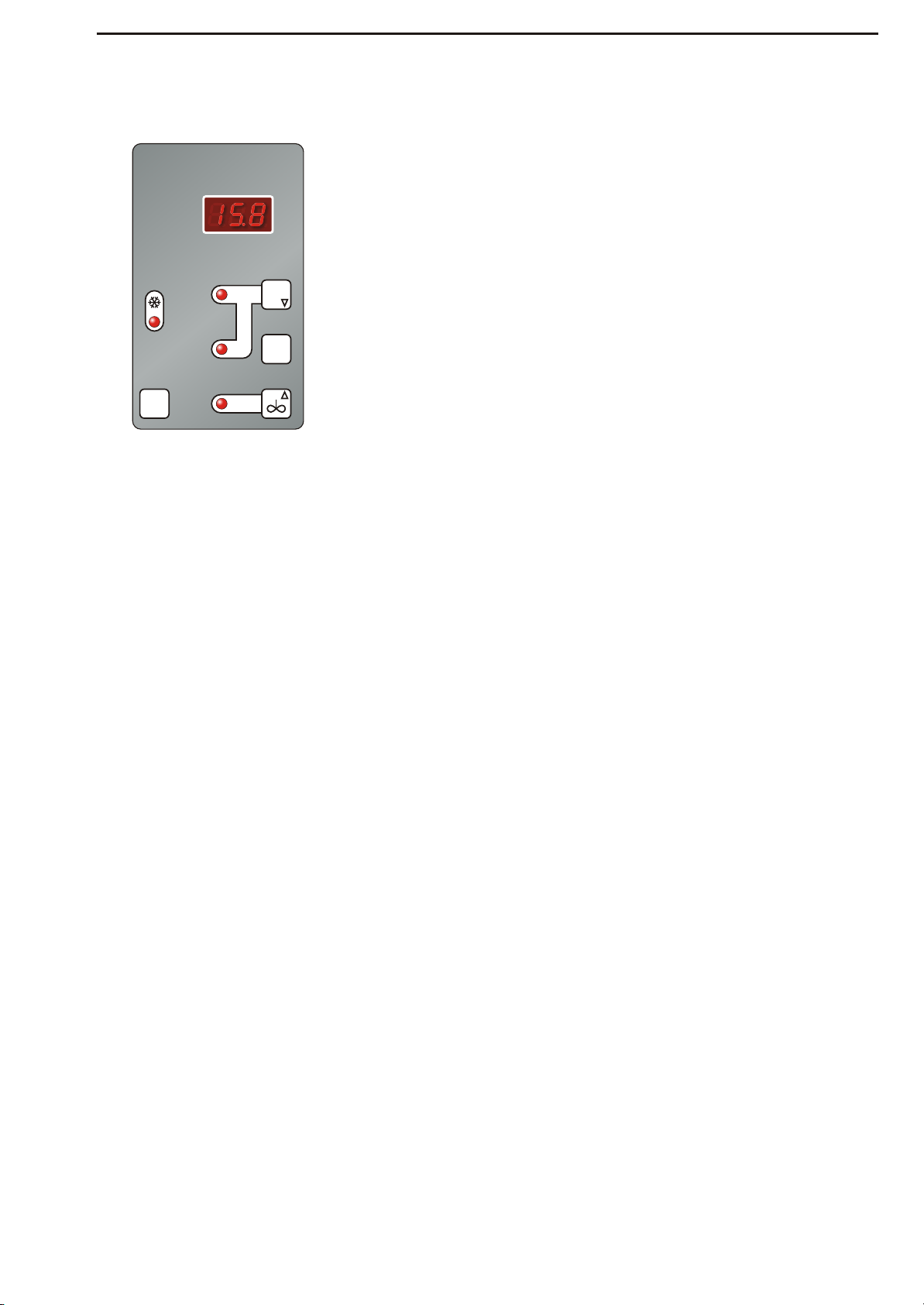

Cooling mode

Press the "4°/8°" button: the compressor and agitator operate automati-

cally. In between cooling periods (agitator and compressor LEDs off),

intermediate stirring can be activated.

Stirring mode

If stirring mode is active: (temperature shown in display)

!"Short" intermediate stirring:Briefly press the "Agitator" button."sho"

appears in the display, and the agitator starts to operate.

!"Long" intermediate stirring:Press and hold down the "Agitator" button

for 5 seconds."lon" appears in the display, and the agitator starts to

operate.

!Continuous stirring (only if set at parameter level):Press the"Agitator"

button. "On" appears in the display. The agitatoroperates continuously

until the "Agitator" button is pressed again.

If OFF mode is active: (Display is dark)

!Continuous stirring while cooling is switched off:Press the "Agitator"

button. A rotating bar is shown in the display, and the agitator operates

continuously, until you press the button 'STOP'.

Off mode

The regulator can be switched off using the "STOP" button (Display and

LEDs dark). Both the output relays for the agitator and compressor are

deactivated.

CAUTION: The regulator is live even when switched off.

4° / 8°

Switch between target temperatures (when cooling mode is active only)

Page 3