1.

2.

3.

Shutoffthevalvethatissupplyingairtotransducer. It

is not necessary to remove the Transducer from

the air line.

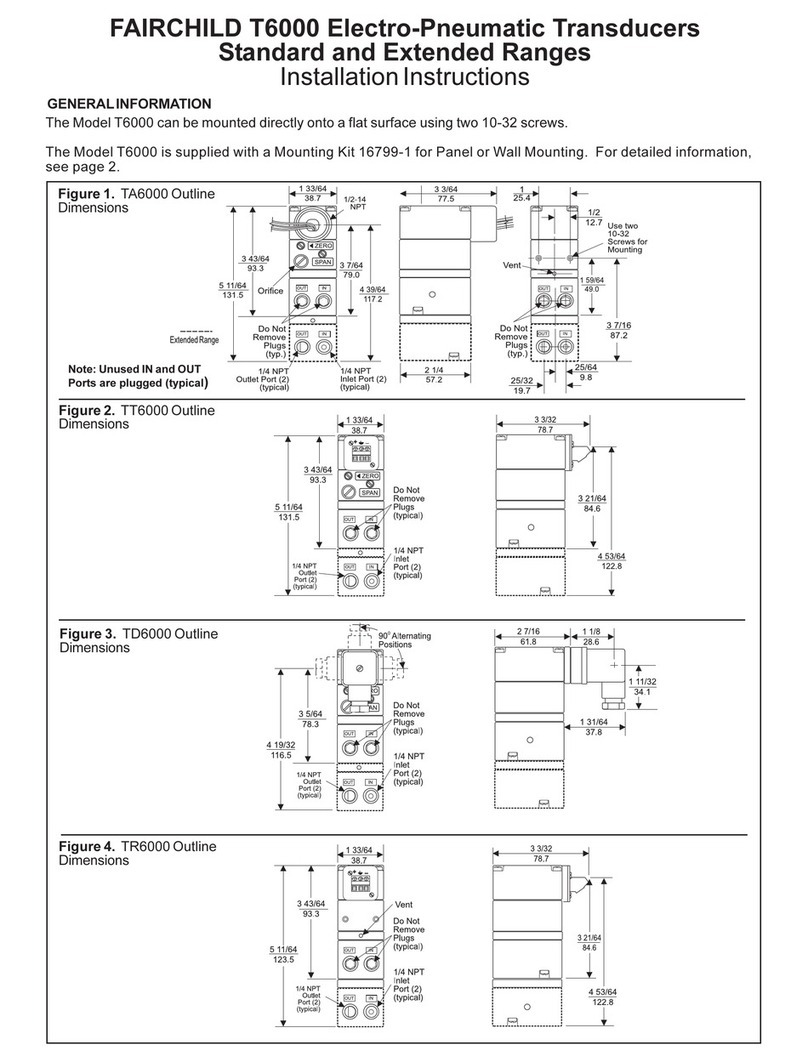

Remove the Orifice Assembly from the unit. For

detailedinformationseeFigure1 “T6000Calibration

Configurationonpage1.

Cleanwith alcohol and dry with compressedair.

To clean the Orifice, use the following procedure:

MAINTENANCE

Parts must be completely dry before reas-

sembling.

If the standard maintenance procedure

doesnotcorrectthetrouble,installService

Kit EA-16798-1. (SoldSeparately)

NOTES:

TROUBLE-SHOOTING

Table 1. Trouble-Shooting.

Problem Solution (check)

SupplyPressure

CloggedOrifice

InputSignal

PneumaticConnections

ZeroandSpanAdjust

SupplyPressureLow

OutputLeakage

DCSignal

LooseWires orConnections

Liquid inAir Supply

DirtinMagnetGap

NoOutput

Leakage

LoworImproper

SpanAdjust

ErraticOperation

WARNING: FailureofTransducercouldresultinout-

put pressure increasing to supply pres-

surepossiblycausing personal injury or

damage to equipment.

OM-50T6000S

Litho in USA

Rev. C 01/04

CALIBRATIONS/ADJUSTMENTS

Equipment Required for Calibration:

FULLRANGEOPERATION

Forward Acting Mode Adjustment

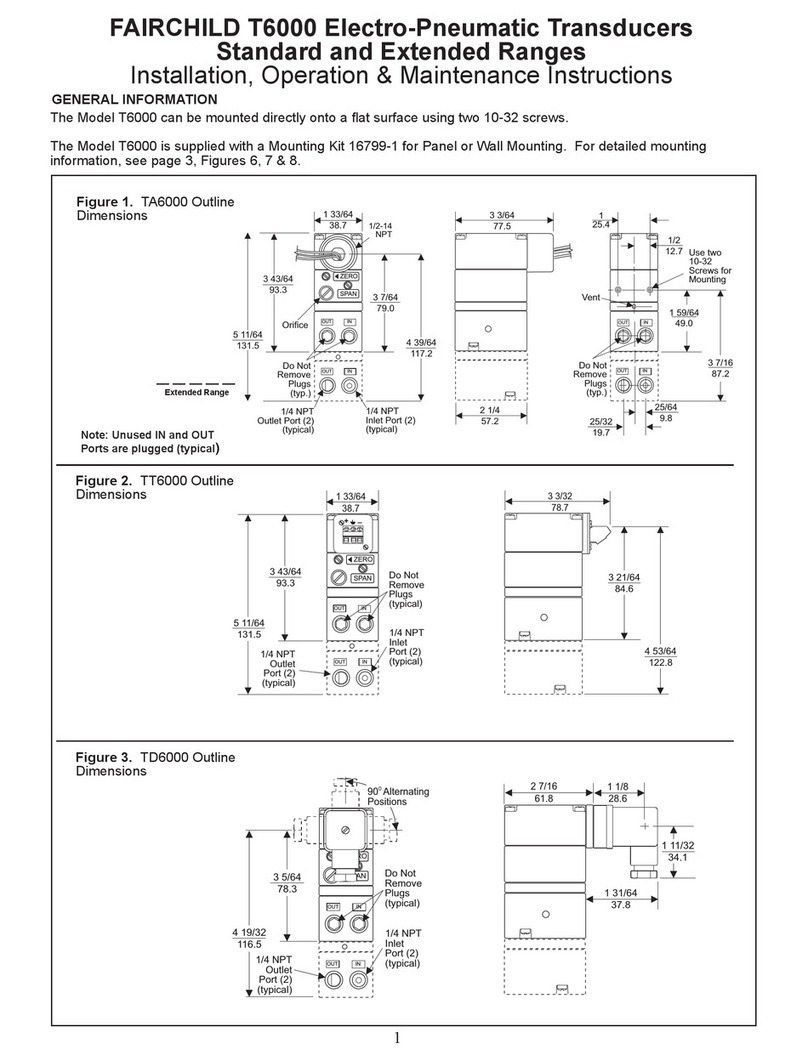

1. Connecttheinputsignaltothetransducerasshown

intheInstallationInstructions,II-50T6000S.

Repeat steps 2-3 until the desired output range is

obtained. For detailed information, see Figure 1

“T6000CalibrationConfiguration”onpage1.

• PneumaticSupplycapableofdeliveringupto150psig.

•Current Supply capable of delivering up to 60 mA.

• PressureGagecapableofadigitalreadoutupto50psig

with an accuracy of .1%.

• DigitalVoltMetercapableofareadoutupto60mAwith

an accuracy of .02%.

4.

• ForwardActingCalibration-Zero

2. Apply the minimum input signal and adjust the Zero

screw for minimum output pressure. Turn screw

clockwise to increase pressure and counterclock-

wiseto decreasepressure.

ApplythemaximuminputsignalandadjusttheSpan

screw for maximum output pressure. Turn screw

clockwise to increase pressure and counterclock-

wiseto decreasepressure.

ReverseActing ModeAdjustment

5. Connecttheinputsignaltothetransducerasshown

intheInstallationInstructions,II-50T6000S.

• ReverseActingCalibration-Zero

6. Apply the minimum input signal and adjust the Zero

screw for maximum output pressure. Turn screw

clockwise to increase pressure and counterclock-

wiseto decreasepressure.

• ForwardActingCalibration-Span

3.

8.

• ReverseActingCalibration-Span

7. ApplythemaximuminputsignalandadjusttheSpan

screw for minimum output pressure. Turn screw

clockwise to decrease pressure and counterclock-

wisetoincrease pressure.

Repeat steps 6-7 until the desired output range is

obtained. For detailed information, see Figure 1

“T6000CalibrationConfiguration”onpage1.

SPLITRANGEOPERATION

Allunitshavethecapabilitytobesplitrangedorsetforany

outputinthe range aslongastheOutput Spanis equalto

orgreaterthan the minimum Span.

Theinformationsetforthintheforegoing Operation

andMaintenance Instructionsshall not bemodified

or amended in any respect without prior written

consent of Fairchild Industrial Products Company.

In addition, the information set forth herein shall be

furnished with each product sold incorporating

Fairchild's unit as a component thereof.

LEGALNOTICE:

INDUSTRIAL PRODUCTS COMPANY

3920 WEST POINT BLVD. WINSTON-SALEM, NC 27103-6708

TEL 336-659-3400

www.fairchildproducts.com

FAX 336-659-9323

R

ISO 9001:2000

FM NO. 25571