2Eastwood Technical Assistance: 800.544.5118 >> techelp@eastwood.com

The FAIRMOUNT 10 TON HYDRAULIC GEAR PULLER is designed for universal use with versatile 2 or

3 arm configurability. Reversible arm positing accommodates outside or inside pulls equally well. The

self-contained Hydraulic Ram design provides greatly amplified pulling force. This tool, constructed of

robust, high-strength steel alloy forgings, will provide years of reliable service.

CONTENTS

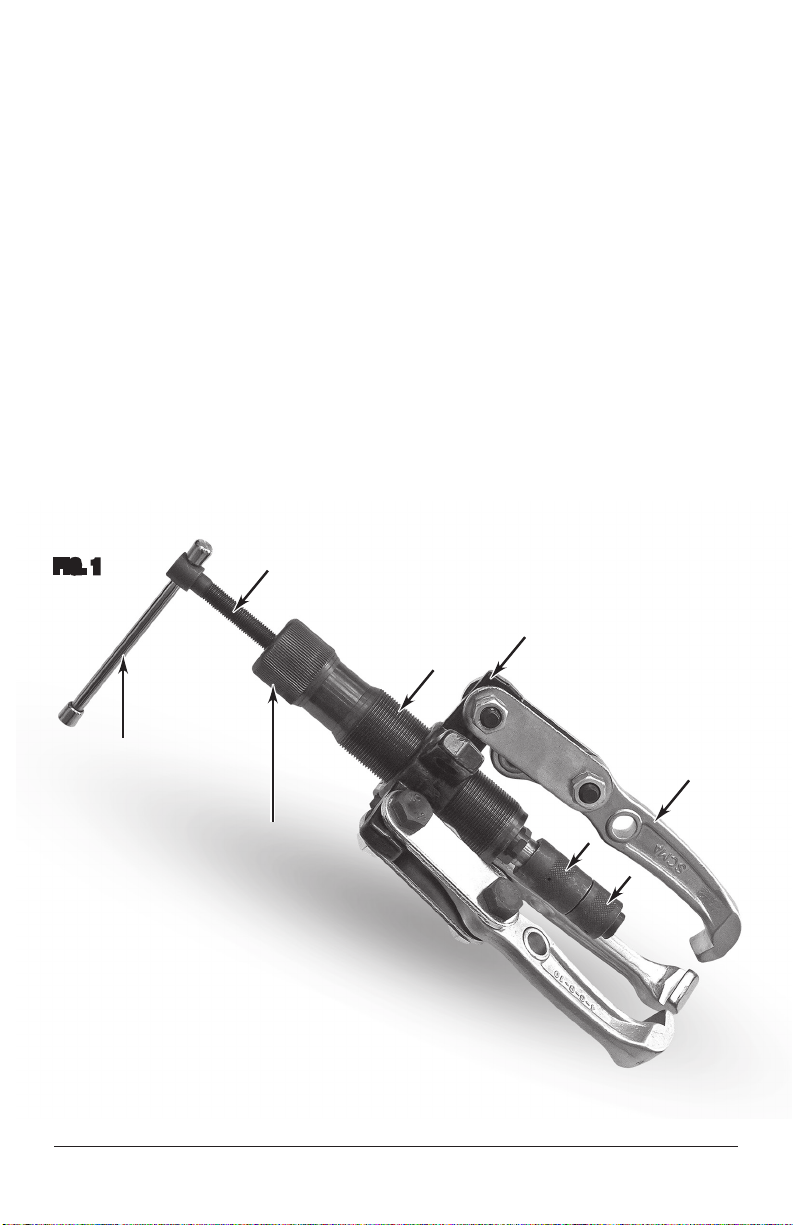

(3) Puller Arms - A

(6) Nut, Bolt & Washer Sets - B

(6) Puller Arm Links - C

(1) Center Yoke - D

(1) Drive Ram - E

(1) Drive Ram Button - F

(1) Drive Ram Button Extension - G

(1) Heavy-Duty, Blow Molded Case

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION used with the safety alert symbol, indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

SAFETY INFORMATION

The following explanations are displayed in this manual, on the labeling, and on all other information

provided with this product:

A

A

BD

C

C

EG F

Stem

“T” Handle Plunger