SPECIFICATIONS

Always access risk factors

• Even when used as prescribed it is not possible to

eliminate all residual risk factors. ALWAYS use with

caution.

Clean work area

• Accidents occur where work areas are cluttered or

dirty. Work areas should be kept clear and clean at all

times. Avoid working where an area is slippery due to

water, oil, paint or other contaminates on the ground.

Children

• Children should always be kept at a safe distance

from any work area. Make any work area or

workshop child-proof. Lock tools away where children

cannot gain access to them.

Don’t use excess force

• Do not force your Jack. It will provide better service if

you do not use excessive force when using it.

Use the correct tool

• Do not attempt to use this jack for a purpose that it

was not designed for.

Wear correct clothing

• Do not wear loose clothing, neckties or jewellery or

other items which may get caught in moving parts.

Wear non-slip footwear, cover or tie back long hair,

roll long sleeves above the elbow.

Protect your head, eyes and hands

• Wear safety goggles at all times, glasses do not

provide adequate eye protection, as lenses are not

impact resistant and could shatter.

• Wear suitable gloves.

Keep your balance

• Don’t over reach and keep a proper footing at all

times to ensure correct balance.

Never stand on your tool

• Standing on your jack could cause injury if the jack

tips. Do not store materials above or near the jack so

that it is necessary to stand on the jack to reach them.

Check damaged parts

• Before use inspect the jack, if any part of the jack

shows signs of wear or damage, do not use the tool.

Maintain your tool

• Keep your jack in good working order, keep it

clean and oiled. Follow the Instructions for changing

accessories and lubrication. Check carefully that it will

operate properly and perform its intended operation.

If any parts are damaged do not use this tool.

WARNING: DEATH OR SERIOUS INJURY CAN

RESULT WITH IMPROPER USE OF THIS TOOL

Familiarize yourself with these rules and the

application, limitations and potential hazards

of using the jack.

• DO NOT use a trolley jack for any other application

other that lifting.

• DO NOT exceed the maximum lifting capacity as

stated on the product or it the operating manual.

• DO NOT allow the vehicle to move during a

jacking operation, or use the jack to move a vehicle.

• DO NOT operate the jack if any parts are

damaged or worn prior to use.

• DO NOT top up the hydraulic system with brake uid.

Use hydraulic jack oil only with a rating of SAE 10.

• DO NOT use a ‘cheater’ pipe, lever, or other device to

extend the handle length for additional leverage.

• DO NOT adjust the safety overload valve. This is

correctly set at the factory and no further readjustment

is necessary.

• DO NOT use a jack to support a lifted load.

Appropriate rated axle stands should be correctly

positioned and the load lowered as soon as possible,

to provide a safe working environment.

• DO NOT work under the vehicle until axle stands

have been correctly positioned under the vehicle.

• DO NOT lift the vehicle if there is a likelihood of

spillage of fuel, battery acid, oil or other dangerous

uids.

• DO NOT allow an untrained or young person to

operate the jack without full supervision.

• ALWAYS inspect the jack before use.

• ALWAYS use the jack on level solid ground,

concrete is preferable. Avoid tarmac surfaces as

these are prone to sinking.

• ALWAYS ensure the engine is switched o and that

there are no passengers in the vehicle.

• ALWAYS ensure the vehicle handbrake is engaged

and transmission is in gear or “PARK” if the vehicle

has an automatic gear box.

• ALWAYS chock the wheels of the vehicle to be

jacked at the non-lifting end.

• ALWAYS place the jack under the lifting point

recommended by vehicle manufacturer, check the

vehicle handbook if in doubt. Check that the lifting point

is sound and centred on the jack saddle prior to lifting.

• ALWAYS ensure a minimum distance of 0.5m

between the vehicle and any static objects such as

walls, doors or other vehicles to allow for the vehicle

tilting during lifting.

• ALWAYS Ensure the jack wheels are free to move

and that there are no obstructions.

• ALWAYS store the jack in is retracted position in a

safe, dry place.

General Safety Instructions Important Safety Rules

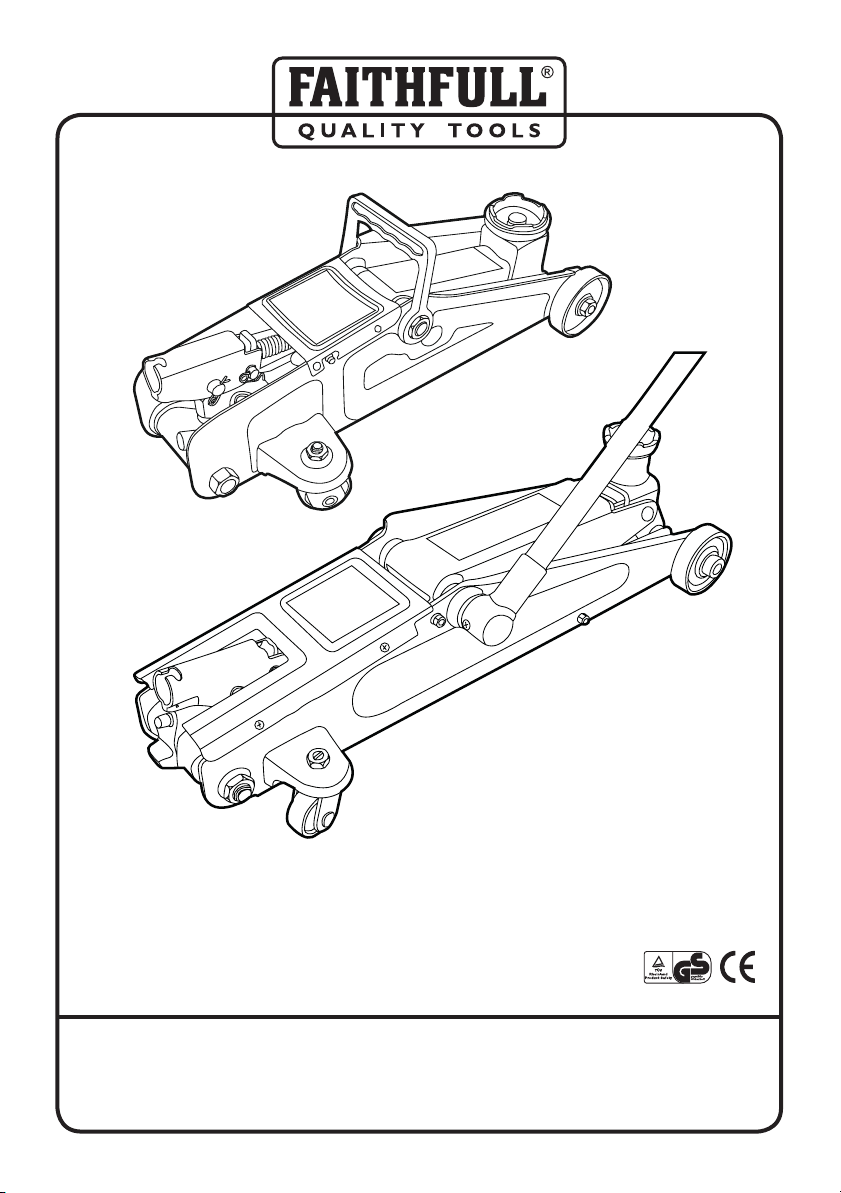

Part Identier