The multiport valve with a handle of 6 positions covers all the necessary operations to obtain

the maximum efficiency of the filter.

IMPORTANT: Before changing the position of the multiport valve handle, always switch off the

pump.

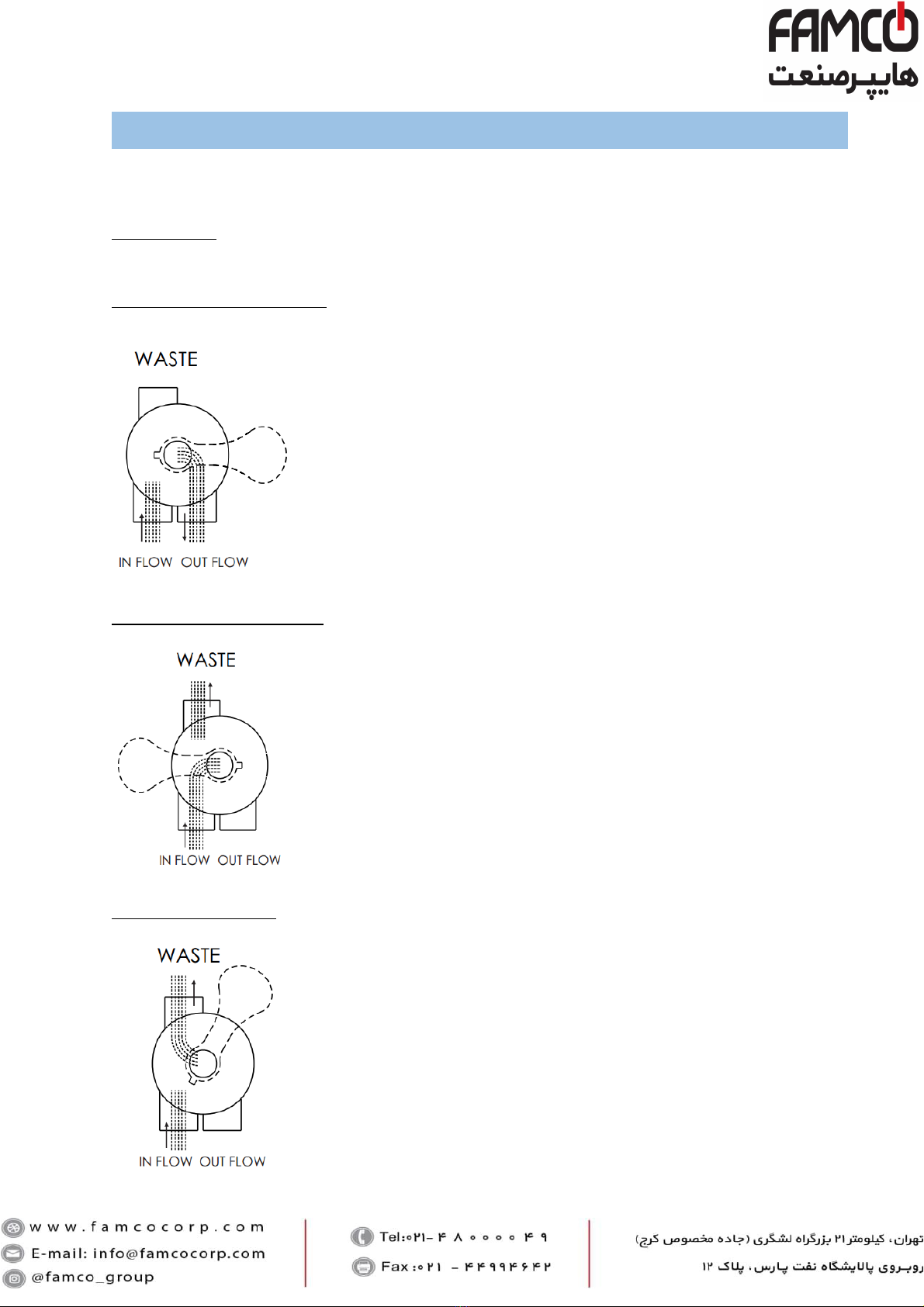

POSITION 1: FILTRATION

Switch off your filtration pump and place the handle of the multiport

valve in the “Filtration” position. Switch on the pump.

During filtration, it is recommended to control the pressure on valve’s

pressure gauge. Filtration medium forms thousands of channels while

the water is descending through the filter, and retains the suspended

solids. Gradually the number of suspended solids retained in filtration

medium increases and block the channels, getting more difficult for

water to pass through. This is why the pressure raises up inside the

filter. When the pressure reaches 3.5 bars (50 psi), the filter is

saturated and backwash is required.

POSITION 2: BACKWASH

At high pressure the filtration medium is unable to withhold impurities

and must be washed as follows:

1. Switch off your filtration pump.

2. Turn the multiport valve handle to the “BACKWASH” position.

3. Switch on the pump and run it for around 2 minutes. The quality

of the water wasted can be checked in the sight glass placed in

the waste connection of the multiport valve.

4. When this operation is completed, the dirt blocking the filter will

have been removed.

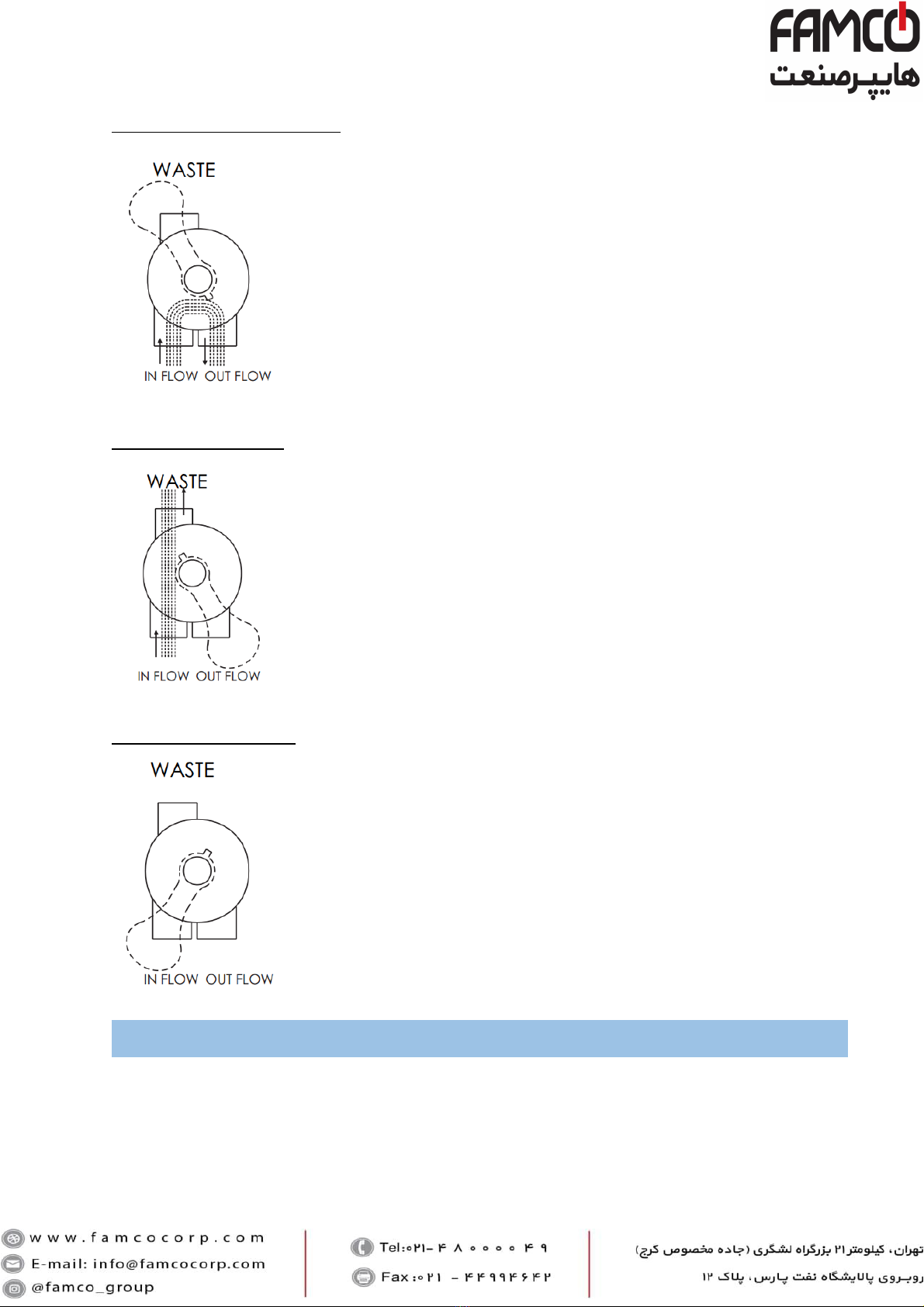

POSITION 3: RINSE

After the carrying out the backwash operation on the filter, the water

will be cloudy for a few seconds. Rinse prevents this water coming to

the pool.

Rinse is recommended immediately after the backwash for 1 minute.