INSTRUCTIONS FOR USE

GUARANTEE 4

SAFETY MEASUREMENTS & REQUIREMENTS 4

TOOL IDENTIFICATION 5

MAIN COMPONENTS 5

TECHNICAL DATA 5

HOW TO USE YOUR RIVETING TOOL 5

TOPPING UP OIL-DYNAMIC CIRCUIT 6

MAINTENANCE & CHANGE OF SIZE 7

DISPOSAL OF THE RIVETING TOOL 7

INDEX

GUARANTEE

FAR riveting tools are covered by a 12-month warranty.

The tool warranty period starts on the date of delivery to

the buyer, as specified in the relevant document. The war-

ranty covers the user/buyer provided that the tool is pur-

chased through an authorized dealer and only if it is used

for the purposes for which it was conceived. The warranty

shall not be valid if the tool is not used or maintained as

specified in the instruction and maintenance handbook. In

the event of defects or failures, FAR S.r.l. shall undertake

solely to repair and/or replace the components it judges to

be faulty.

• The tool needs a thorough six-monthly overhaul.

• Repairing and cleaning operations must be done when

the tool is not fed.

• If it is possible, we suggest a safety balancer.

• If the A-weighted emission sound pressure level is more

than 70 dB (A), you must use some hearing protections

(anti-noise headset, etc.).

• The workbench and the work surface must be always

clean and tidy. The untidy can cause damages to people.

• Do not allow unauthorized persons to use the working

tools.

• Make you sure that the compressed air feeding hoses

have the correct size to be used.

• Do not carry the connected tool by pulling the hose. The

hole must be far from any heating sources or from cutting

parts.

• Keep the tools in good conditions; do not remove either

safety parts or silencers.

• After repairing and/or adjusting, make sure you have al-

ready removed the adjusting spanners.

• Before disconnecting the compressed air hose from the

tool make sure that there is no pressure in the hose.

• These instructions must be carefully followed.

SAFETY MEASURES & REQUIREMENTS

• Read the instructions carefully before using the tool.

• For all maintenance and/o r repairs please contact FAR

s.r.l. authorized service centers and use only original

spare parts. FAR s.r.l. may not be held liable for

damages from defective parts caused by failure to ob-

serve what above mentioned (EEC directive 85/374).

• The tool must be used only by expert workers.

• A protective visor and gloves must be put on when us-

ing the tool.

• Use equipment recommended in the maintenance

chapter to do any maintenance and/or regulation of the

tool.

• For topping up the oil, we suggest using only fluids in

accordance with the features specified in this working

book.

• If any drop of oil touches your skin, you must wash with

water and alkaline soap.

• The tool can be carried and we suggest putting it into its

box after using.

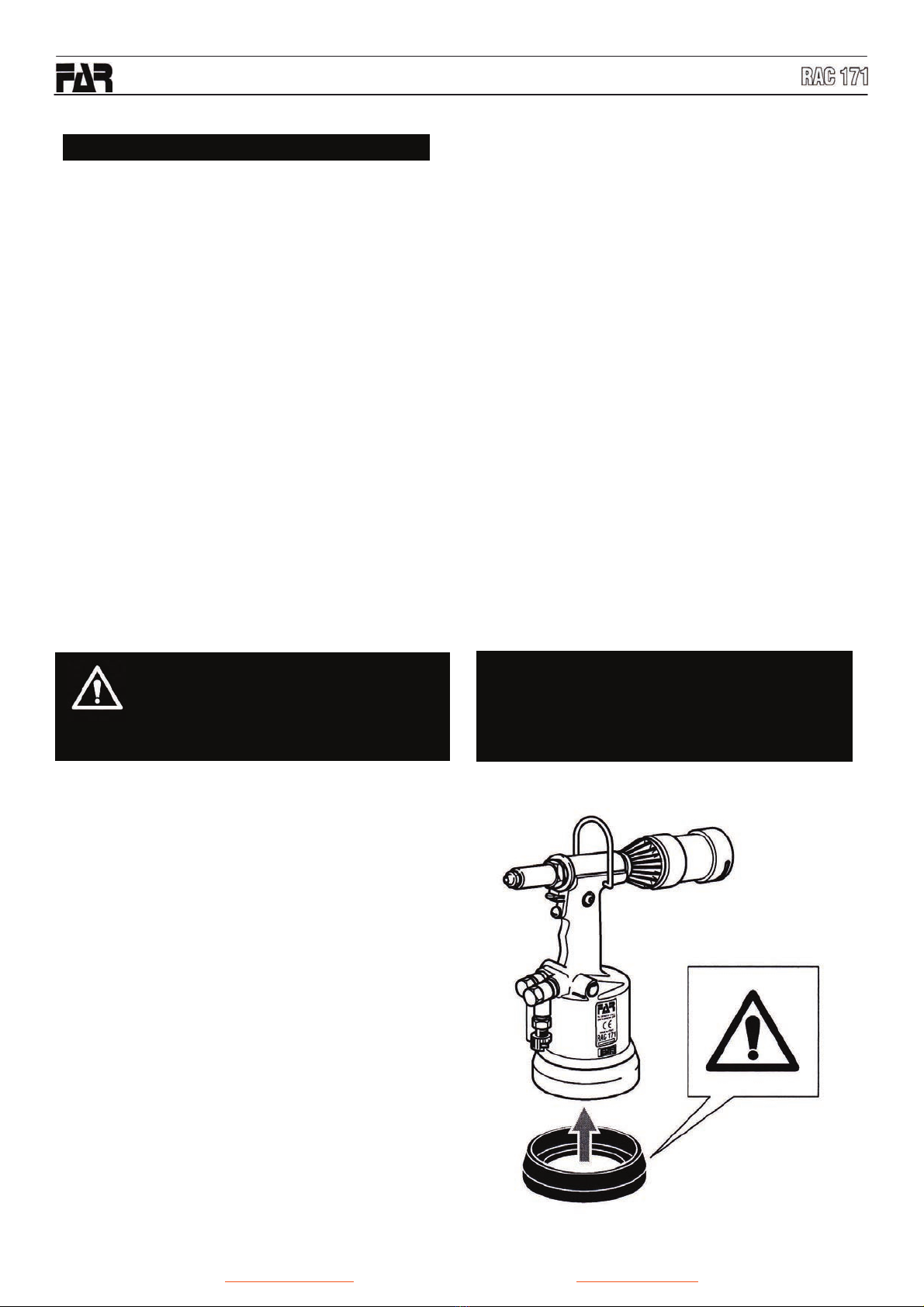

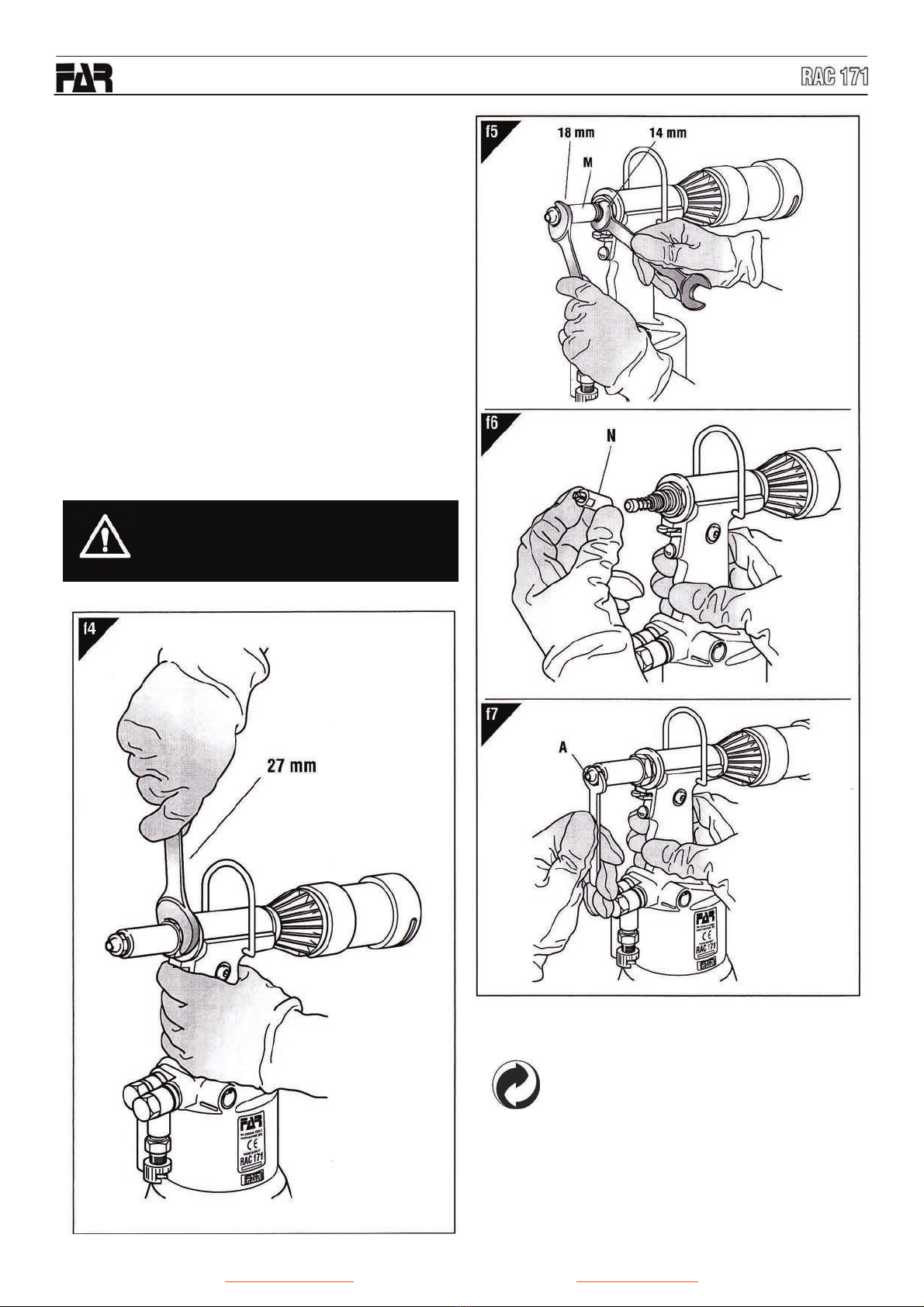

WARNING!

Before using the tool, assemble the protectionbottom sup-

plied with the tool, as indicated in the picture below.

FAR has no responsibility for any damages of the tool,

person or things caused by lack of the protection.

CAUTION!!!

All the operations mustbe done in conformity with

the safety requirements, in order to avoid any

consequence for your and other people’s security

and to allow the best tool work way.