FarmChem | www.FarmChem.com

2

GENERAL SAFETY REGULATIONS

WORK AREA

• Keep work area clean, free of clutter and well lit. Cluttered and dark work

area can cause accidents

• Do not use your meter where there is a risk of causing a re or an explosion;

e.g. in the presence of ammable liquids, gases, or dust. Power tools create

sparks, which may ignite the dust or fumes

• Keep children and bystanders away while operating this meter. Distractions

can cause you to lose control, so visitors should remain at a safe distance from

the work area

• Be aware of all power lines, electrical circuits, water pipes and other mechan-

ical hazards in your work area, particularly those hazards below the work sur-

face hidden from the operator’s view that may be unintentionally contacted

and may cause personal harm or property damage

• Be alert of your surroundings. Using tools in conned work areas may put you in

danger

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating

this meter. Do not use this meter while you are tired or under the inuence of

drugs, alcohol or medication. A moment of inattention while operating this

meter may result in serious injury

• Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep

you hair, clothing and gloves away from moving parts. Loose clothes, jewelry

or long hair can get caught in moving parts. Air vents often cover moving parts

and should be avoided

• Use safety apparel and equipment. Use safety goggles or safety glasses with

side shields which comply with current national standards, or when needed, a

face shield. This applies to all persons in the work area. Also use non-skid safety

shoes, hardhat, gloves, dust collection systems, and hearing protection when

appropriate

• Do not overreach. Keep proper footing and balance at all time

• The meter is for professional use only

• Read all instructions, tags and labels before operating the meter

• Use the meter only for its intended purpose

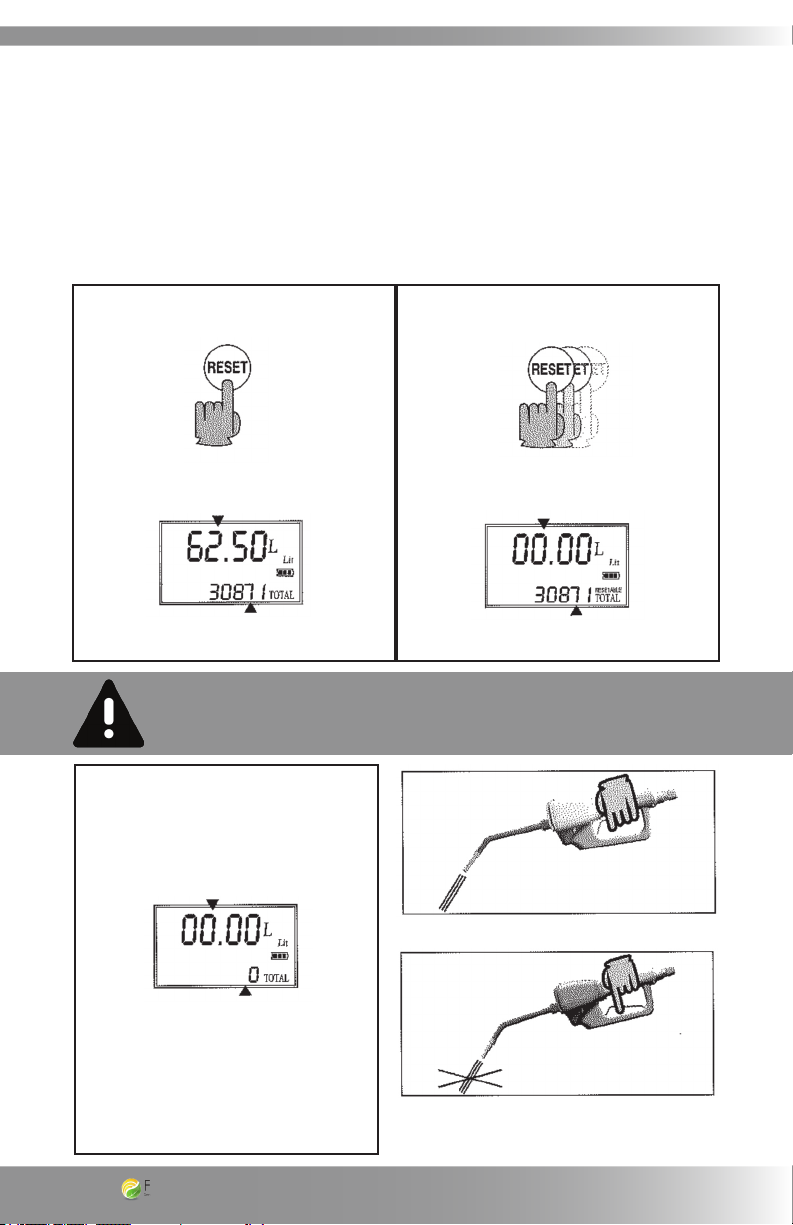

• Do NOT stop or deect leaks with hands, body, gloves or rags

• Do NOT dispense valves toward any person or any part of the body

• Do NOT place hands or ngers over the end of or into the dispense valve

WARNING: e warnings, cautions, and instructions discussed

in this instruction manual cannot cover all possible conditions or

situations that could occur. It must be understood by the operator

that common sense and caution are factors that cannot be built

into this product, but must be supplied by the operator.