4

x FTM post hole diggers are designed and

manufactured solely for the purpose of bor-

ing holes earth and clay materials. Under

no circumstances should they be used for

any other purpose.

x Before using the post hole digger carefully

read and ensure you understand the con-

tents of this manual and the contents of the

operators manual for the associated tractor,

including all relevant safety instructions.

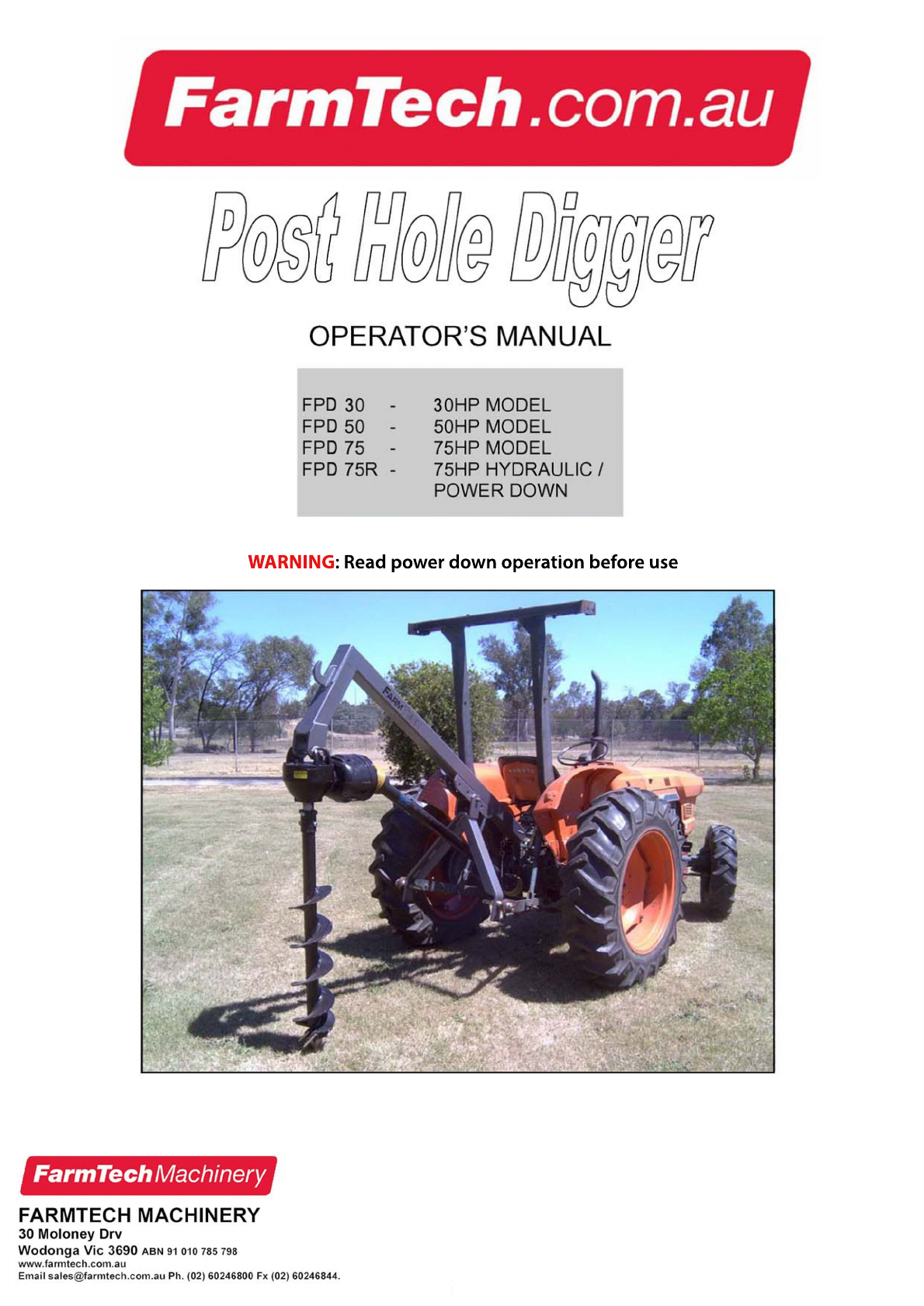

x Before operating the post hole digger read

all the safety warnings that are carried on

the machine. Refer to the next page for the

location and the wording of these warnings.

x Never allow an inadequately trained person

to attach or operate the post hole digger.

x Do not operate the post hole digger whilst

wearing loose clothing, unrestrained long

hair, jewelery or anything which could be-

come entangled in rotating parts or limit

your vision.

x Only operate the post hole digger on a trac-

tor fitted with a roll-over protective structure

(ROPS), or a cab incorporating a ROPS,

complying with AS1636 or equivalent.

x Wear ear protection when operating the

post hole digger on a tractor that is not fitted

with a sound proofed cabin.

x Ensure that the tractor engine power and

linkage capacity match the requirements of

the post hole digger. Refer to the tractor

operator’s manual for safe working loads,

including any counter-weighting that may be

required to balance the weight of the post

hole digger.

x Do not operate the post hole digger without

all its safety shields and the tractor safety

shields in place.

x Before operating the post hole digger in-

spect the area to be worked to ensure that

you are familiar with the ground conditions.

x Ensure that there are no underground elec-

trical cables, telephone cables, gas, water,

sewerage or drainage pipes in the area to

be drilled. If in doubt about any of the

above do not start digging until the circum-

stances have been fully investigated and it

is safe to begin.

x Exercise extreme care when operating in

wet or slippery conditions or on sloping or

uneven terrain. Allow for the effect that

the weight of the post hole digger has on

the tractor’s stability. Refer also to the

tractor manufacturer’s operating and

safety instructions.

x Do not operate the post hole digger with

people or animals in the vicinity where

they could be caught in the mechanism

or injured by the machine. Keep onlook-

ers at least 6 metres from the digger

whilst in operation.

x Always operate the post hole digger from

the tractor seat.

x Never clear earth away from the auger

whilst it is operating or allow any helper

to do so.

x Never allow a person to pull down on the

digger boom or attach any type of coun-

terweight to the boom to increase pene-

tration.

x Before dismounting from the tractor or

allowing any person to approach the post

hole digger, disengage the PTO, switch

off the tractor engine and apply the park-

ing brake.

x Ensure the tractor engine is switched off

and the parking brake is applied before

performing any inspection or mainte-

nance on the digger. If it is necessary to

raise the machine for such work ensure it

is properly supported. Do not rely on the

tractor hydraulics for support.

x Never allow any person to ride on the

post hole digger or the tractor when the

digger is attached.

x Relieve all hydraulic pressure before dis-

connecting hoses on hydraulic diggers.

Oil escaping under pressure can pene-

trate the skin, causing serious injury.

Seek medical advice immediately if in-

jured by escaping oil.

Whilst your FTM post hole digger has been designed and manufactured to incorporate all necessary

safety features it is essential that any person who operates or works on the machine is aware of the

safety precautions that should be exercised.

Before operating the post hole digger read the following safety instructions.

Failure to comply with these warnings may result in serious injury or death.