1.3. Acronym FNI FAS network interface

I Standard input port

PN Profinet

ECT EtherCAT

CCIEBS CC-Link IE Field Basic Slave

EIP Ethernet/IP

EMC Electromagnetic Compatibility

FE Functional ground

O Standard output port

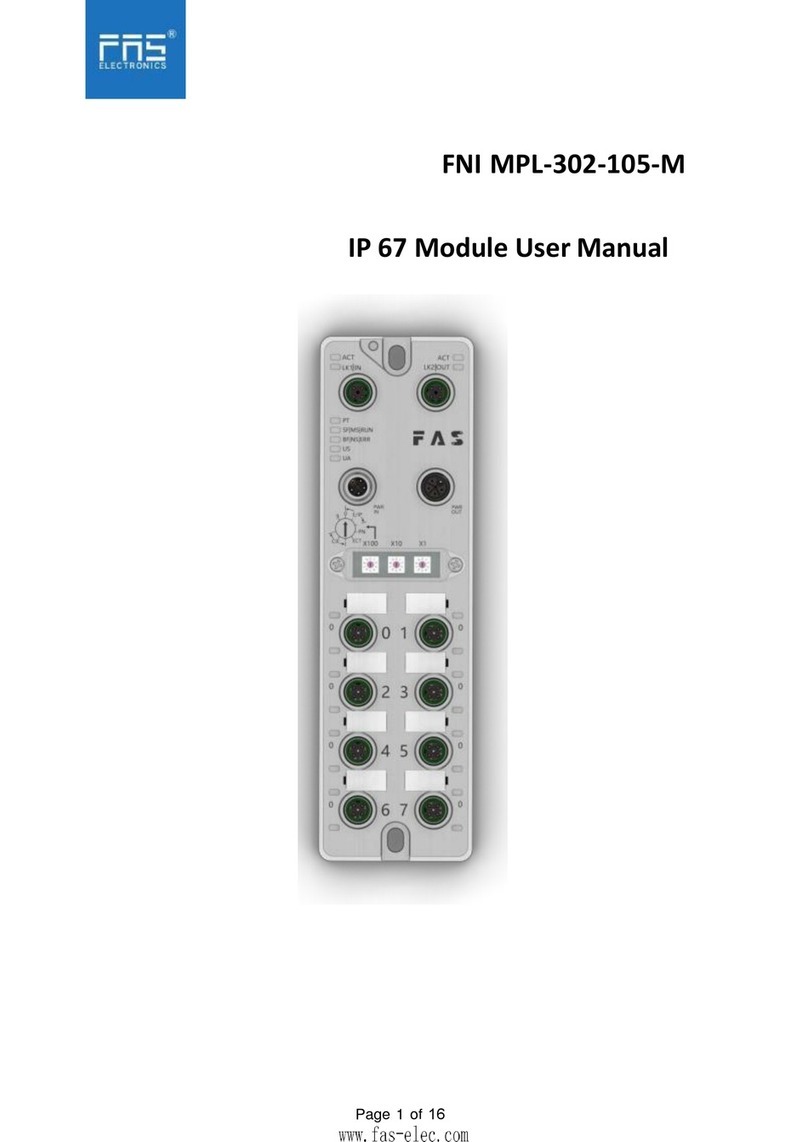

1.5.Viewing angle deviation Product views and explanations in this manual m

ay deviate from the actual product. They are on

ly used left and right to explain the material.

2 Safety

2.1.Expected usage This manual describes as a decentralized input and output module

for connection to an industrial network.

---------------------------------------------------------------------------------------------------

2.2. Install and start Precautions!

Installation and start-up should only be carried out by trained an

d specialized personnel. A qualified individual is one who is famili

ar with the installation and operation of the product and has the

necessary qualifications to do so. Any damage caused by unautho

rized operation or illegal and improper use is not covered by the

manufacturer's warranty. Equipment operators are responsible for e

nsuring compliance with appropriate safety and accident preventio

n regulations.

------------------------------------------------------------------------------------------------

2.3. General security Debug and check

Notes Before debugging, you should read the contents of the user manu

al carefully.

The system cannot be used in applications where the safety of pe

sonnel depends on the functionality of the equipment.

intended use

The manufacturer's warranty coverage and limited liability statement

do not cover damage caused by:

· Unauthorized tampering

· Improper use

· Handling, installation and operation that do not conform to the

instructions provided in the user manual

Owner/Operator Obligations

This device is an EMC Class A compliant product. This device gen