SER 3620 Electronic-Metered Control Valve

Revision (11-05) 10 Alemite LLC

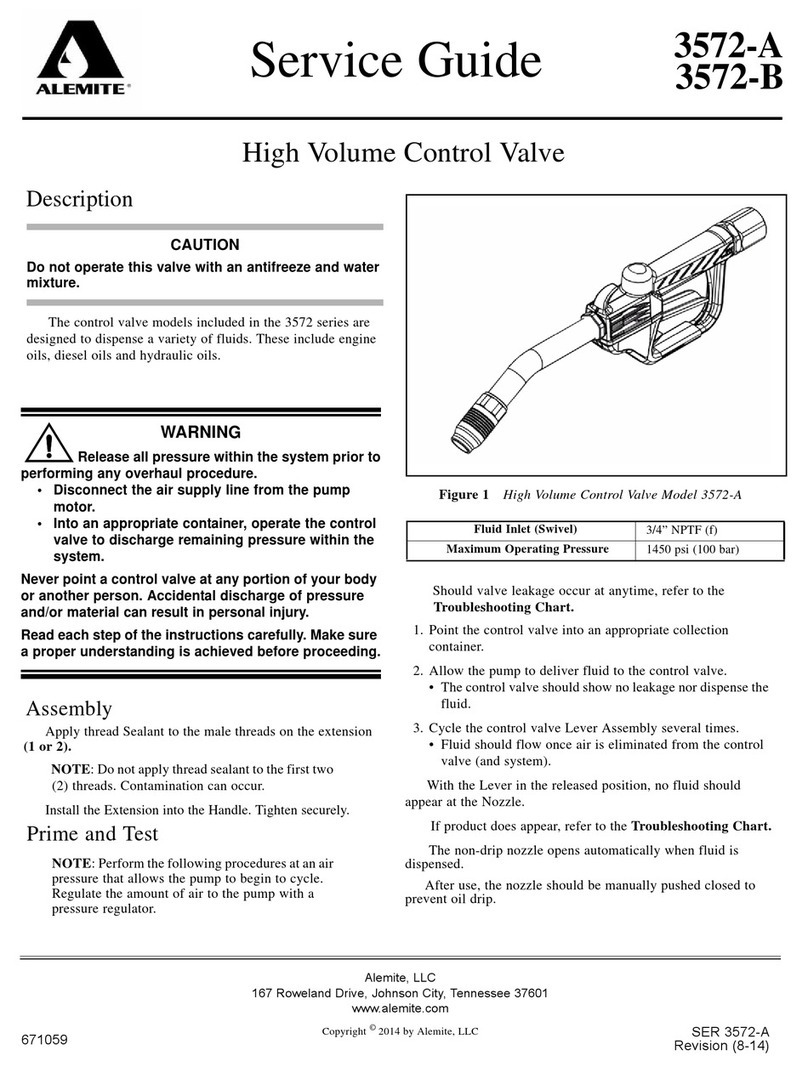

Prime and Test

NOTE: Perform the following procedures at

an air pressure that allows the pump to begin

to cycle. Regulate the amount of air to the

pump with a pressure regulator.

Should valve leakage occur at anytime, refer

to the Control Valve Troubleshooting

Chart.

5. Point the control valve into an appropriate collection

container.

6. Allow the pump to deliver fluid to the control valve.

• The control valve should show no leakage nor

dispense the product.

7. Cycle the control valve Lever Assembly several times.

• Product should flow once air is eliminated from the

control valve (and system).

If the control valve does not dispense the product, refer

to the Control Valve Troubleshooting Chart.

With the Lever in the released position, no product

should appear at the Nozzle. If product does appear, refer to

the Control Valve Troubleshooting Chart.

Should the electronic meter not function properly, refer

to Service Guide SER 3630 for details.

Control Valve Troubleshooting Chart

Control Valve Indications Possible Problems Solutions

Continuous product flow 1. Foreign material on Seal (33)

2. Seal (33) worn or damaged

1. Disassemble, clean, and inspect

seat area. Check mating surfaces

and replace Seal (33) as necessary.

Locate and eliminate source of

foreign material. Clean Strainer

(37)

2. Use Kit 393676

No product flow Manual Nozzle (8, 12,or 16) not open Open Nozzle (8, 12,or 16)

Leakage at Swivel

Assembly (39)1. Initial tightening of Swivel Assembly (39)

not sufficient

2. O-Ring (38) worn or damaged.

1. Tighten Swivel Assembly (39)

2. Replace O-Ring (38)

Leakage at Cam (43) O-Rings (42) worn or damaged. Replace O-Rings (42)

Leakage at front end of Nozzle Nozzle damaged Replace Nozzle

Leakage at Extension Assembly 1. Initial tightening not sufficient

2. Thread sealant missing or inadequate 1. Tighten leaking connection

2. Apply thread sealant* to male pipe

threads

Safety on Lever Assembly (40)

does not engage 1. Broken spring in Lever Assembly (40)

2. Foreign material in Lever Assembly (40)

3. Worn or damaged Compression Spring (36)

1. Use Kit 393677

2. Clean Lever Assembly (40)

3. Replace Compression Spring (36)

Latch on Lever Assembly (40)

does not release 1. Broken spring in Lever Assembly (40)

2. Foreign material in Lever Assembly (40)

3. Worn or damaged Compression Spring (36)

1. Use Kit 393677

2. Clean Lever Assembly (40)

3. Replace Compression Spring (36)

* Do not apply thread sealant to the first two (2) threads. Contamination can occur.

Changes Since Last Printing

Added Model 3621-B