Fleck 9500 User manual

IMPORTANT: Fill in pertinent information on page 2 for future reference.

MODEL 9500

Service Manual

MODEL 9500 ECONOMINDER

Job Specification Sheet

Printed in U.S.A.

• JOB NO. __________________________________________________________

• MODEL NO. _______________________________________________________

• WATER TEST______________________________________________________

• CAPACITY PER UNIT ____________MAX. ___________PER REGENERATION

• MINERAL TANK SIZE DIA.________HEIGHT_________

• BRINE TANK SIZE &

SALT SETTING PER REGENERATION: _________________________________

Page 2

* 9500 CONTROL VALVE SPECIFICATIONS

1) Type of Timer

A) 82 minute available regeneration time, 1/15 RPM

B) 164 minute available regeneration time, 1/30 RPM

2) Type of Meter

A) Std. range 625 to 10,625 gal. setting

B) Ext. range 3,125 to 53,125 gal. setting

3) Meter Gallon Setting ____________________________gal. (see pages 6 & 7)

4) Regeneration Program Setting (see page 5)

A) Backwash _________________________________min.

B) Brine & Slow Rinse _________________________min.

C) Rapid Rinse _______________________________min.

D) Brine Tank Refill ____________________________min.

5) Drain Line Flow Control__________________________gpm

6) Brine Refill Rate________________________________gpm

7) Injector Size __________________________________

Printed in U.S.A.

Page 3

MODEL 9500 ECONOMINDER

General & Commercial Installation Checklist

WATER PRESSURE: A minimum of 25 pounds of water pressure is required for the valve to operate effectively.

ELECTRICAL FACILITIES: A continuous 110 volt, 60 Hertz current supply is required. Make certain the current supply

is always hot and cannot be turned off with another switch.

EXISTING PLUMBING: Condition of existing plumbing should be free from lime and iron buildup. Piping that is built up

heavily with lime and/or iron should be replaced. If piping is clogged with iron, a separate iron filter unit should be

installed ahead of the water softener.

LOCATION OF SOFTENER AND DRAIN: The softener should be located close to a drain.

BY-PASS VALVES: Always provide for the installation of a by-pass valve.

CAUTION: Water pressure is not to exceed 125 p.s.i., water temperature is not to exceed 110°F, and the unit cannot

be subjected to freezing conditions.

1. Place the softener tank where you want to install the unit, making sure the tanks are level and on a firm base.

2. All plumbing should be done in accordance with local plumbing codes. The pipe size for the drain line should be the

same size as the drain line flow control connection.

3. Both tanks must be the same height and diameter and filled with equal amounts of media The 1-1/2 distributor tube

should be cut flush with top of each tank.

4. Lubricate the distributor O-Ring seal and tank O-Ring seal with silicone lubricant. Place the main control valve on

one tank and the tank adapter on the second tank.

5. NOTE: The 1-1/2″copper tubing to interconnect the tanks must be soldered prior to assembly on the main control

valve and tank adapter.

6. Solder joints near the drain must be done prior to connecting the Drain Line Flow Control fitting. Leave at least 6″

between the DLFC and solder joints when soldering. Failure to do this could cause damage to the drain module.

7. Teflon tape is the only sealant to be used on the drain fitting.

8. Make sure that the floor is clean beneath the salt storage tank and that it is level.

9. Place approximately 1″of water above the grid plate (if used) in your salt tank. Salt may be placed in the unit at this

time.

10. On units with a by-pass, place in by-pass position. Turn on the main water supply. Open a cold soft water tap

nearby and let run a few minutes or until the system is free from foreign material (usually solder) that may have

resulted from the installation.

11. Place the by-pass in service position and let water flow into the mineral tanks. When water flow stops, open a cold

water tap nearby and let run until air pressure is relieved.

12. Electrical: All electrical connections must be connected according to codes. Plug unit into electrical outlet. Do not

insert meter cable into the meter yet.

INSTALLATION AND START-UP INSTRUCTIONS

1-1/2″COPPER

OUTLET

INLET METER DOME

MUST FACE UP

CONTROL VALVE

TANK #2

TANK ADAPTER

TANK #2

Printed in U.S.A.

Page 4

MODEL 9500 ECONOMINDER

General & Commercial Installation Checklist (Cont’d.)

13. Tank #1 has control

valve.

Tank #2 has the

adapter.

Look on the right side

of the control valve, it

has indicators which

tell you which posi-

tion the control valve

is in during regenera-

tion and which tank is

IN SERVICE. Photo

on the right indicates

the valve is in the ser-

vice position and tank

#1 is supplying condi-

tioned water. Tank #2

is on standby.

NOTE: Make sure the meter cable is not inserted in the

meter dome. Swing the timer out to expose the program

wheel Figure 2 (to swing timer out) grab onto the lower

right corner of timer face Figure 1 and pull outward.

14. Cycle timer into backwash position. Turn manual knob

(figure 1) so that the micro switch is riding on the 1st

set of pins (figure 2). In this position the tanks will

switch (lower piston) and the control valve will move

to the backwash position (upper piston). You must

wait until the positioning of upper and lower pistons

has stopped before advancing the timer further. If

advanced too fast the control will not home into the

service position (it will not advance to any other

position). To correct this, rotate the manual knob back

to service and start again into backwash. Note: once

valve has positioned itself into the backwash cycle,

the homing circuit is locked in.

With all the air backwashed out, slowly cycle the timer

to the brine position; rapid rinse; and brine tank refill.

You must wait for the control drive motor to position

itself in each cycle and stop, before advancing on to

the next position.

Once back in the service position, cycle the control

valve again into the backwash position. The tanks will

switch again, and you will backwash the air head out

of the other tank. Cycle the control back to the service

position. Leave the timer in the open position.

DO NOT INSERT METER CABLE YET.

NOTE: 2 motors are available, 1/15 RPM will have a 82

min. reg. time available.

BRINE & RINSE

SECTION

(2 MIN. PER HOLE)

PIN STORAGE

PROGRAM

WHEEL FOR

CONTROL OF

REGENERATION

CYCLE

RAPID

RINSE

SECTION

(2 MIN.

PER PIN)

BRINE TANK

REFILL

SECTION

(2 MIN.

PER HOLE)

BACKWASH

SECTION

(2 MIN. PER PIN)

Figure 2

Printed in U.S.A.

Page 5

MODEL 9500 ECONOMINDER

Regeneration Cycle Program Setting Procedure

(Brine Tank Refill Separate From Rapid Rinse)

How To Set The Regeneration Cycle Program:

The regeneration cycle program on your water conditioner

has been factory preset, however, portions of the cycle or

program may be lengthened or shortened in time to suit

local conditions.

To expose cycle program wheel, grasp timer in lower right

hand corner and pull, releasing snap retainer and

swinging timer to the left. Meter cable must be removed

from meter dome before opening timer.

To change the regeneration cycle program, the program

wheel must be removed. Grasp program wheel and

squeeze protruding lugs towards center, lift program

wheel off timer. (Switch arms may require movement to

facilitate removal.)

Return timer to closed position engaging snap retainer in

back plate. Make certain all electrical wires locate above

snap retainer post

How To Change The Length Of The Backwash Time:

The program wheel as shown in the drawing is in the

service position. As you look at the numbered side of the

program wheel, the group of pins starting at zero deter-

mines the length of time your unit will backwash.

FOR EXAMPLE: If there are six pins in this section, the

time of backwash will be 12 min. (2 min. per pin). To

change the length of backwash time, add or remove pins

as required. The number of pins times two equals the

backwash time in minutes.

How To Change The Length Of Brine And Rinse Time:

The group of holes between the last pin in the backwash

section and the second group of pins determines the

length of time that your unit will brine and rinse. (2 min.

per hole.)

To change the length of brine and rinse time, move the

rapid rinse group of pins to give more or fewer holes in the

brine and rinse section. Number of holes times two

equals brine and rinse time in minutes.

How To Change The Length Of Rapid Rinse:

The second group of pins on the program wheel deter-

mines the length of time that your water conditioner will

rapid rinse. (2 min. per pin.)

To change the length of rapid rinse time, add or remove

pins at the higher numbered end of this section as

required. The number of pins times two equals the rapid

rinse time in minutes.

NOTE: Program wheels having 0 to 82 min. cycle times,

use “1” min. per pin or hole to set regeneration times. The

layout of pins and holes on the program wheel follow the

same procedure as on this page.

How To Change The Length Of Brine Tank Refill Time:

The second group of holes on the program wheel

determines the length of time that your water conditioner

will refill the brine tank (2 min. per hole.)

To change the length of refill time, move the two pins at

the end of the second group of holes as required.

The regeneration cycle is complete when the outer micro-

switch is tripped by the two pin set at end of the brine tank

refill section. The program wheel, however, will continue

to rotate until the inner micro-switch drops into the notch

on the program wheel. See page 6 for salt setting

calculations, and page 25 for general timer settings.

BRINE & RINSE

SECTION

(2 MIN. PER HOLE)

PIN STORAGE

PROGRAM

WHEEL FOR

CONTROL OF

REGENERATION

CYCLE

RAPID

RINSE

SECTION

(2 MIN.

PER PIN)

BRINE TANK

REFILL

SECTION

(2 MIN.

PER HOLE)

BACKWASH

SECTION

(2 MIN. PER PIN)

.

Printed in U.S.A.

Page 6

MODEL 9500 ECONOMINDER

Time Brine Refill & Meter Setting Procedure

PROGRAMMING

1. Your control valve has been factory set for backwash; brine and slow rinse; rapid rinse and brine tank fill times. Any

of these times can be changed by repositioning the pins and holes or adding more pins (see pg. 5). Note that two

different speed timer motors are used, one allows for an 82 minute maximum regeneration time (each pin or hole

=1 min.). The other allows for 164 minute maximum regeneration time (each pin or hole = 2 min.).

2. The 9500 Control has a separate brine tank fill cycle. Your desired salt setting must be calculated, using the brine

line flow control rate of refill (in gpm) times your timer setting. Then using one gallon of fresh water dissolving

approximately 3 lbs. salt, calculate your refill time.

ie: A desired 30 lb. salt setting: The unit has a 1.0 gpm refill rate, we will need a 10 gallon fill. (10 gal. x 3 lb./gal. =

30 lb. salt). The timer refill section would have to be set at 10 minutes. (10 min. x 1.0 gpm = 10 gal. fill)

Note: There always must be 2 pins at the end of your refill time. This is to stop the fill cycle. With your

regeneration times now set, place timer back to its original position, making sure the lower right hand

corner snaps back into the backplate and the meter cable slides through the backplate and does not bind.

3. Setting the gallon wheel

Knowing the amount of resin you have in each tank and your salt setting per regeneration, calculate the gallons

available, using the following capacities as a guide:

One Cubic Foot of Resin

Salt Setting at Capacity per Regeneration

15 lb 30,000 grains

10 lb 27,000 grains

8 lb 24,000 grains

6 lb 20,000 grains

ie: 35 grain water; each tank having 7 cubic feet of resin and salted at 56 lb. of salt, yielding a usable 168,000

grain capacity: 4,800 gallons available = 168,000 gr. capacity

35 gr. water

DO NOT SET THIS FIGURE - GO TO STEP 4

4. Since the 9500 Valve regenerates with soft water from the other tank, you must subtract the water used for

regeneration. Take each of your regeneration cycles and calculate the water used. (Use the injector Slow Rinse

rate chart supplied, see pg. 24.)

ie: Unit is set up for a 21 tank having 7 ft3of resin and salting at 8 lbs. per ft3, 12.0 gpm backwash, 4C injector, 2.0

gpm brine refill, and 60 psi and timer set up for 10 min. backwash, 42 min. brine and rinse, 10 min. rapid rinse,

10 min. brine tank fill.

A. Backwash - 10 mins. x 12.0 gpm = 120.0 gallons

B. Brine and Rinse - 42 mins. x 1.95 gpm = 81.9 gallons

(See injector chart slow rinse flow, pg. 24)

C. Rapid Rinse - 10 mins. x 12.0 gpm = 120.0 gallons

D. Brine Tank Fill - 10 mins. x 2.0 gpm = 20.0 gallons

Total Regeneration Water = 341.9 gallons

Gallons available = Capacity per Cubic Foot.

Compensated Hardness of H2Ox Cubic Feet of Resin per Tank

Printed in U.S.A.

Page 7

MODEL 9500 ECONOMINDER

Time Brine Refill & Meter Setting Procedure (Cont’d.)

If we have 4800 gallons available from Step 3, we want to subtract the regeneration water used from the total water

available.

4800 gallons available - 342 gallons used (in regeneration, step 4) = 4458 gallons setting

5. NOW set Meter wheel at approximately 4458 gallons. Lift the inner dial of the meter program wheel so that you can

rotate it freely. Position the white dot opposite the 4458 gallon setting (see diag. below).

NOTE: There is a slight delay time from the time the meter zeros out and when the cycle starts. Units using the 1/15

rpm motor, 82 minute regeneration time available have a 9 minute delay. Units using the 1/30 rpm motor,

180 minute regeneration time available have an 18 minute delay. Typically on residential equipment this

delay period is not critical. On commercial applications, this must be taken into consideration and

continuous flows for 9 minutes or 18 minutes should be subtracted from water available.

NOW 1. Insert Meter cable into Meter.

2. Check Bypass.

3. Plug unit in.

Printed in U.S.A.

Page 8

MODEL 9500 ECONOMINDER

1 - SERVICE POSITION

Hard water enters the unit at the valve inlet, flows

around the lower piston, and down through the mineral

in the first tank. Conditioned water enters the center

tube through the bottom distributor, flows up through

the center tube, around the lower piston, through the

meter, and out the valve outlet. The second mineral

tank is regenerated and on standby.

2 - TANKS SWITCHING

(the meter has initiated a regeneration)

Hard water enters the unit at the valve inlet, flows

around the lower piston, through the pipe leading to the

second mineral tank, and down through the mineral in

the second tank. Conditioned water enters the center

tube of the second tank through the bottom distributor,

flows up through the center tube, through the pipe

leading back to the main valve, around the lower piston,

through the meter, and out the valve outlet. The

depleted first mineral tank is out of the flow path, and

ready for regeneration.

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

Printed in U.S.A.

Page 9

MODEL 9500 ECONOMINDER

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

3 - BACKWASH

Conditioned water from the second mineral tank flows

around the lower piston, around the upper piston,

through the center of the lower piston, down the center

tube, up through the mineral, around the upper piston,

and out the drain line.

4 - BRINE DRAW

Conditioned water from the second mineral tank flows

around the lower piston, around the upper piston, into

the injector housing, and down through the nozzle and

throat to draw brine from the brine tank. Brine flows

around the upper piston, down through the mineral, into

the center tube through the bottom distributor, up the

center tube, through the center of the lower piston,

through the center of the upper piston, and out through

the drain line.

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

Printed in U.S.A.

Page 10

MODEL 9500 ECONOMINDER

5 - SLOW RINSE

Conditioned water from the second mineral tank flows

around the lower piston, around the upper piston, into

the injector housing, down through the nozzle and

throat, around the upper piston, down through the

mineral, into the center tube through the bottom

distributor, up the center tube, through the center of the

lower piston, through the center of the upper piston,

and out through the drain line.

6 - RAPID RINSE

Conditioned water from the second mineral tank flows

around the lower piston, around the upper piston, and

down through the mineral in the first tank. Rinse water

from the mineral bed enters the center tube through the

bottom distributor, flows up the center tube, through the

center of the lower piston, through the center of the

upper piston, and out through the drain line.

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

Printed in U.S.A.

Page 11

MODEL 9500 ECONOMINDER

7 - BRINE TANK FILL POSITION

Conditioned water from the second mineral tank flows

around the lower piston, around the upper piston, into

the injector housing, through the brine line flow control,

through the brine valve, and into to brine tank. No water

flows through the first mineral tank.

8 - SERVICE (TANKS SWITCHED)

Hard water enters the unit at the valve inlet, flows

around the lower piston, through the pipe leading to the

second mineral tank, and down through the mineral in

the second tank. Conditioned water enters the center

tube of the second tank through the bottom distributor,

flows up through the center tube, through the pipe

leading back to the main valve, around the lower piston,

through the meter, and out the valve outlet. The

regenerated first mineral tank is out of the flow path,

and ready for use when the second mineral tank

becomes depleted.

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

BRINE VALVE

FLOW CONTROL

DRAIN

MINERAL TANK #1 BRINE TANK

Printed in U.S.A.

Page 12

MODEL 9500 ECONOMINDER

Drive Assembly

(See Opposite Page for Parts List)

1

3

4

5

6

7

89

10

11

12

14

15

16 17 18 19 20

21

22

23

25

26

27

28 29

30

32

33

34

35

36

37

1

2

3

2

34

24

41

Printed in U.S.A.

Page 13

MODEL 9500 ECONOMINDER

Drive Assembly

Parts List

Item No. Quantity Part No. Description

1. . . . . . . . . . . . 2 . . . . . . . . . . . . .11335. . . . . . . . . . . . . . . . . . Screw

2. . . . . . . . . . . . 2 . . . . . . . . . . . . .18564. . . . . . . . . . . . . . . . . . Screw, Hex Washer, #6-20

3. . . . . . . . . . . . 2 . . . . . . . . . . . . .13363. . . . . . . . . . . . . . . . . . Washer

4. . . . . . . . . . . . 1 . . . . . . . . . . . . .14921. . . . . . . . . . . . . . . . . . Piston Rod Link, Upper

5. . . . . . . . . . . . 1 . . . . . . . . . . . . .15019. . . . . . . . . . . . . . . . . . Piston Rod Link, Lower

6. . . . . . . . . . . . 2 . . . . . . . . . . . . .18728. . . . . . . . . . . . . . . . . . Nut, Clip, #8-32

7. . . . . . . . . . . . 1 . . . . . . . . . . . . .15203. . . . . . . . . . . . . . . . . . Wiring Harness - Timer

8. . . . . . . . . . . . 1 . . . . . . . . . . . . .11838. . . . . . . . . . . . . . . . . . Power Cord

9. . . . . . . . . . . . 1 . . . . . . . . . . . . .15202. . . . . . . . . . . . . . . . . . Wiring Harness - Drive

10. . . . . . . . . . . . 1 . . . . . . . . . . . . .15134. . . . . . . . . . . . . . . . . . Drive Gear Assy, Lower

11. . . . . . . . . . . . 1 . . . . . . . . . . . . .15135-02 . . . . . . . . . . . . . . . Drive Gear Assy

12. . . . . . . . . . . . 1 . . . . . . . . . . . . .14896. . . . . . . . . . . . . . . . . . Geneva Wheel

14. . . . . . . . . . . . 4 . . . . . . . . . . . . .12681. . . . . . . . . . . . . . . . . . Wire Connector

15. . . . . . . . . . . . 2 . . . . . . . . . . . . .19367. . . . . . . . . . . . . . . . . . Cover Screw

16. . . . . . . . . . . . 1 . . . . . . . . . . . . .15175. . . . . . . . . . . . . . . . . . Position Decal

17. . . . . . . . . . . . 2 . . . . . . . . . . . . .14917. . . . . . . . . . . . . . . . . . Retaining Ring

18. . . . . . . . . . . . 1 . . . . . . . . . . . . .15199. . . . . . . . . . . . . . . . . . Ground Plate

19. . . . . . . . . . . . 1 . . . . . . . . . . . . .14430. . . . . . . . . . . . . . . . . . Screw, Hex Washer, #6

20. . . . . . . . . . . . 2 . . . . . . . . . . . . .19160. . . . . . . . . . . . . . . . . . Screw, Motor Mtg.

21. . . . . . . . . . . . 1 . . . . . . . . . . . . .18737. . . . . . . . . . . . . . . . . . Drive Motor - 24V., 50/60 Hz (Red Wires)

1 . . . . . . . . . . . . .18738. . . . . . . . . . . . . . . . . . Drive Motor - 120V., 60 Hz (Black Wires)

1 . . . . . . . . . . . . .18739. . . . . . . . . . . . . . . . . . Drive Motor - 220V., 50 Hz (Yellow Wires)

22. . . . . . . . . . . . 1 . . . . . . . . . . . . .15131. . . . . . . . . . . . . . . . . . Control Panel

23. . . . . . . . . . . . 2 . . . . . . . . . . . . .15172. . . . . . . . . . . . . . . . . . Screw, Flat Hd #4-40

24. . . . . . . . . . . . 2 . . . . . . . . . . . . .10340. . . . . . . . . . . . . . . . . . Washer, Lock, #4

25. . . . . . . . . . . . 1 . . . . . . . . . . . . .10218. . . . . . . . . . . . . . . . . . Micro Switch (Homing)

26. . . . . . . . . . . . 2 . . . . . . . . . . . . .10339. . . . . . . . . . . . . . . . . . Nut, Micro Switch

27. . . . . . . . . . . . 7 . . . . . . . . . . . . .15331. . . . . . . . . . . . . . . . . . Screw, Valve Mtg.

28. . . . . . . . . . . . 1 . . . . . . . . . . . . .15133. . . . . . . . . . . . . . . . . . Drive Gear Assy, Upper

29. . . . . . . . . . . . 1 . . . . . . . . . . . . .17331. . . . . . . . . . . . . . . . . . Triple Cam

30. . . . . . . . . . . . 1 . . . . . . . . . . . . .13547. . . . . . . . . . . . . . . . . . Strain Relief

31. . . . . . . . . . . . 1 . . . . . . . . . . . . .15810. . . . . . . . . . . . . . . . . . Retaining Ring, Drive Gear

32. . . . . . . . . . . . 1 . . . . . . . . . . . . .15323. . . . . . . . . . . . . . . . . . Guide Pin Upper Piston Rod Link

33. . . . . . . . . . . . 1 . . . . . . . . . . . . .17337. . . . . . . . . . . . . . . . . . Cable Guide

34. . . . . . . . . . . . 2 . . . . . . . . . . . . .15372. . . . . . . . . . . . . . . . . . Washer, Thrust

35. . . . . . . . . . . . 1 . . . . . . . . . . . . .17744. . . . . . . . . . . . . . . . . . Meter Cable Assy. - 20- 3/4″Long

36. . . . . . . . . . . . 2 . . . . . . . . . . . . .15692. . . . . . . . . . . . . . . . . . Spacer

37. . . . . . . . . . . . 1 . . . . . . . . . . . . .16433. . . . . . . . . . . . . . . . . . Micro Switch (Program)

38. . . . . . . . . . . . 1 . . . . . . . . . . . . .10302. . . . . . . . . . . . . . . . . . Insulator (not shown)

39. . . . . . . . . . . . 1 . . . . . . . . . . . . .18699- . . . . . . . . . . . . . . . . . Cover, Top (not shown)

40. . . . . . . . . . . . 1 . . . . . . . . . . . . .14779- . . . . . . . . . . . . . . . . . Cover, Bottom (not shown)

1 . . . . . . . . . . . . .19291-020 . . . . . . . . . . . . . . Cover, 1 Piece, Black (not shown)

41. . . . . . . . . . . . 2 . . . . . . . . . . . . .15173. . . . . . . . . . . . . . . . . . Screw

OPTIONAL AUX. DRIVE SWITCH 60320-10

1 . . . . . . . . . . . . .10218. . . . . . . . . . . . . . . . . . Switch

2 . . . . . . . . . . . . .10302. . . . . . . . . . . . . . . . . . Insulator

2 . . . . . . . . . . . . .16442. . . . . . . . . . . . . . . . . . Screw

2 . . . . . . . . . . . . .16443. . . . . . . . . . . . . . . . . . Spacer

1 . . . . . . . . . . . . .17765. . . . . . . . . . . . . . . . . . Cam. Switch

2 . . . . . . . . . . . . .10339. . . . . . . . . . . . . . . . . . Nut

Printed in U.S.A.

Page 14

MODEL 9500 ECONOMINDER

Control Valve Assembly

(See Opposite Page for Parts List)

1

2

3

4567

8

9

10

11

12

14

15 16

17

18

19

21

22

23

24

25

26

27

28

29

30

31

32

33

34

36

37

39

13

2

3

5

7

OPTIONAL

1600 INJECTOR

30

35

29

18

17

15

16

22

23

2

3

20

Printed in U.S.A.

Page 15

MODEL 9500 ECONOMINDER

Control Valve Assembly

Parts List

Item No. Quantity Part No. Description

1. . . . . . . . . . . .1. . . . . . . . . . . . 16919-01. . . . . . . . . . . . . . Valve Body

2. . . . . . . . . . . .16. . . . . . . . . . . 16101 . . . . . . . . . . . . . . . . Seal

3. . . . . . . . . . . .12. . . . . . . . . . . 16638-01. . . . . . . . . . . . . . Spacer

16638 . . . . . . . . . . . . . . . . Spacer Hot Water

4. . . . . . . . . . . .1. . . . . . . . . . . . 17110 . . . . . . . . . . . . . . . . Upper Piston

5. . . . . . . . . . . .2. . . . . . . . . . . . 14309 . . . . . . . . . . . . . . . . Retainer, Piston Rod

2. . . . . . . . . . . . 15110 . . . . . . . . . . . . . . . . Retainer, Piston Rod, H.W.

6. . . . . . . . . . . .1. . . . . . . . . . . . 16957 . . . . . . . . . . . . . . . . Upper Piston Rod

7. . . . . . . . . . . .2. . . . . . . . . . . . 17212 . . . . . . . . . . . . . . . . End Plug Assy.

2. . . . . . . . . . . . 17212-01. . . . . . . . . . . . . . End Plug Assy. H.W.

8. . . . . . . . . . . .1. . . . . . . . . . . . 17111 . . . . . . . . . . . . . . . . Lower Piston

9. . . . . . . . . . . .1. . . . . . . . . . . . 16956 . . . . . . . . . . . . . . . . Lower Piston Rod

10 . . . . . . . . . . .1. . . . . . . . . . . . 17092 . . . . . . . . . . . . . . . . Spacer Disk

11 . . . . . . . . . . .1. . . . . . . . . . . . 16955 . . . . . . . . . . . . . . . . End Plug

12 . . . . . . . . . . .3. . . . . . . . . . . . 16394 . . . . . . . . . . . . . . . . O-Ring -029

13 . . . . . . . . . . .1. . . . . . . . . . . . 14906 . . . . . . . . . . . . . . . . End Plate

14 . . . . . . . . . . .4. . . . . . . . . . . . 15137 . . . . . . . . . . . . . . . . Screw, End Plate

17657 . . . . . . . . . . . . . . . . Metric

15 . . . . . . . . . . .4. . . . . . . . . . . . 17052 . . . . . . . . . . . . . . . . Coupling, Pipe

16 . . . . . . . . . . .4. . . . . . . . . . . . 17224 . . . . . . . . . . . . . . . . O-Ring -224

17 . . . . . . . . . . .1. . . . . . . . . . . . 17061 . . . . . . . . . . . . . . . . Coupling Retainer

18 . . . . . . . . . . .8. . . . . . . . . . . . 10231 . . . . . . . . . . . . . . . . Screw, Retainer

17659 . . . . . . . . . . . . . . . . Metric

19 . . . . . . . . . . .1. . . . . . . . . . . . 11475 . . . . . . . . . . . . . . . . Injector Body Gasket, 1600

20 . . . . . . . . . . .2. . . . . . . . . . . . 17353 . . . . . . . . . . . . . . . . 90°Copper Elbow

21 . . . . . . . . . . .1. . . . . . . . . . . . 16916-01. . . . . . . . . . . . . . Second Tank Adapter

22 . . . . . . . . . . .2. . . . . . . . . . . . 13577 . . . . . . . . . . . . . . . . O-Ring -226

23 . . . . . . . . . . .2. . . . . . . . . . . . 16455 . . . . . . . . . . . . . . . . O-Ring -347

24 . . . . . . . . . . .1. . . . . . . . . . . . 14805 . . . . . . . . . . . . . . . . Injector Body Gasket, 1700

25 . . . . . . . . . . .1. . . . . . . . . . . . *14802 . . . . . . . . . . . . . . . Injector Throat

26 . . . . . . . . . . .1. . . . . . . . . . . . 17777 . . . . . . . . . . . . . . . . Injector Body

27 . . . . . . . . . . .1. . . . . . . . . . . . *14801 . . . . . . . . . . . . . . . Injector Nozzle

28 . . . . . . . . . . .1. . . . . . . . . . . . 14803 . . . . . . . . . . . . . . . . Injector Screen

29 . . . . . . . . . . .1. . . . . . . . . . . . 10229 . . . . . . . . . . . . . . . . Injector Cover Gasket

30 . . . . . . . . . . .1. . . . . . . . . . . . 11893 . . . . . . . . . . . . . . . . Injector Cover

31 . . . . . . . . . . .2. . . . . . . . . . . . 14804 . . . . . . . . . . . . . . . . Screw, Injector Body

17655 . . . . . . . . . . . . . . . . Metric

32 . . . . . . . . . . .1. . . . . . . . . . . . 16221 . . . . . . . . . . . . . . . . Air Dispenser

33 . . . . . . . . . . .1. . . . . . . . . . . . 17776 . . . . . . . . . . . . . . . . Injector Body

34 . . . . . . . . . . .1. . . . . . . . . . . . 10914-3. . . . . . . . . . . . . . . Injector Throat #3, Yellow

35 . . . . . . . . . . .1. . . . . . . . . . . . 10227 . . . . . . . . . . . . . . . . Injector Screen

36 . . . . . . . . . . .1. . . . . . . . . . . . 10913-3. . . . . . . . . . . . . . . Injector Nozzle #3, Yellow

37 . . . . . . . . . . .2. . . . . . . . . . . . 10692 . . . . . . . . . . . . . . . . Screw, Injector Body

17656 . . . . . . . . . . . . . . . . Metric

38 . . . . . . . . . . .1. . . . . . . . . . . . 60366 . . . . . . . . . . . . . . . . D.L.F.C. 1″NPT (not shown) - Specify Size

39 . . . . . . . . . . .2. . . . . . . . . . . . 17558 . . . . . . . . . . . . . . . . Spacer

40 . . . . . . . . . . .2. . . . . . . . . . . . 19608-15. . . . . . . . . . . . . . Disperser, Upper (not shown)

41 . . . . . . . . . . .1. . . . . . . . . . . . 11248 . . . . . . . . . . . . . . . . Pin (not shown)

*Injector Throat Injector Nozzle Size Color

14802-03 . . . . . . . . 14801-03 . . . . . . . . . . . #3C. . . . . . . . . . . Yellow

14802-04 . . . . . . . . 14801-04 . . . . . . . . . . . #4C. . . . . . . . . . . Green

14802-05 . . . . . . . . 14801-05 . . . . . . . . . . . #5C. . . . . . . . . . . White

14802-06 . . . . . . . . 14801-06 . . . . . . . . . . . #6C. . . . . . . . . . . Red

Printed in U.S.A.

Page 16

MODEL 9500 ECONOMINDER

1600 Series Brine System

PARTS LIST

Item No. Quantity Part No. Description

1 . . . . . . . . . . . 1. . . . . . . . . . . .12748. . . . . . . . . . . . . . . . Brine Valve Body

2 . . . . . . . . . . . 1. . . . . . . . . . . .16958. . . . . . . . . . . . . . . . Brine Valve Stem

3 . . . . . . . . . . . 1. . . . . . . . . . . .12626. . . . . . . . . . . . . . . . Brine Valve Seat

4 . . . . . . . . . . . 1. . . . . . . . . . . .11982. . . . . . . . . . . . . . . . O-Ring

5 . . . . . . . . . . . 1. . . . . . . . . . . .12747. . . . . . . . . . . . . . . . Flow Control Fitting w/Flow Control Label

6 . . . . . . . . . . . 1. . . . . . . . . . . .12550. . . . . . . . . . . . . . . . Quad Ring

7 . . . . . . . . . . . 1. . . . . . . . . . . .10249. . . . . . . . . . . . . . . . Brine Valve Spring

8 . . . . . . . . . . . 1. . . . . . . . . . . .10250. . . . . . . . . . . . . . . . Retaining Ring

9 . . . . . . . . . . . 1. . . . . . . . . . . .10269. . . . . . . . . . . . . . . . Nut, Jam

10. . . . . . . . . . . 3. . . . . . . . . . . .10332. . . . . . . . . . . . . . . .Tube insert 3/8″

11. . . . . . . . . . . 3. . . . . . . . . . . .10330. . . . . . . . . . . . . . . . Delrin Sleeve 3/8″

12. . . . . . . . . . . 3. . . . . . . . . . . .10329. . . . . . . . . . . . . . . . Fitting Nut 3/8″

. . . . . . . . . . . 3. . . . . . . . . . . .18698. . . . . . . . . . . . . . . . Nut & Sleeve Assy H.W.

13. . . . . . . . . . . 1. . . . . . . . . . . .10328. . . . . . . . . . . . . . . . 90°Elbow - 1/4 Pipe Thd. to 3/8″Tube

14. . . . . . . . . . . 1. . . . . . . . . . . .16960. . . . . . . . . . . . . . . . Brine Valve Tube

15. . . . . . . . . . . 1. . . . . . . . . . . .16922. . . . . . . . . . . . . . . . Bracket, B/V

16. . . . . . . . . . . 2. . . . . . . . . . . .15137. . . . . . . . . . . . . . . . Screw, B/V Bracket

17657. . . . . . . . . . . . . . . . Metric

1

2

3

4

5

6

78

9

10

11

12

14

15

16

13

10

11 12

10

11

12

Printed in U.S.A.

Page 17

MODEL 9500 ECONOMINDER

1700 Series Brine System

PARTS LIST

Item No. Quantity Part No. Description

1. . . . . . . . . . . . 1 . . . . . . . . . . . . .14792. . . . . . . . . . . . . . . . . . End Plug

2. . . . . . . . . . . . 1 . . . . . . . . . . . . .13201. . . . . . . . . . . . . . . . . . O-Ring, End Plug

3. . . . . . . . . . . . 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Washer Flow Control (specify size)

4. . . . . . . . . . . . 1 . . . . . . . . . . . . .14785. . . . . . . . . . . . . . . . . . Flow Control Retainer

5. . . . . . . . . . . . 2 . . . . . . . . . . . . .14811. . . . . . . . . . . . . . . . . . Piston Seal

6. . . . . . . . . . . . 1 . . . . . . . . . . . . .14798. . . . . . . . . . . . . . . . . . Spacer

7. . . . . . . . . . . . 1 . . . . . . . . . . . . .14795. . . . . . . . . . . . . . . . . . Brine Valve Piston

8. . . . . . . . . . . . 1 . . . . . . . . . . . . .16929. . . . . . . . . . . . . . . . . . Brine Valve Stem

9. . . . . . . . . . . . 1 . . . . . . . . . . . . .14790. . . . . . . . . . . . . . . . . . Brine Valve Body

10. . . . . . . . . . . . 1 . . . . . . . . . . . . .12550. . . . . . . . . . . . . . . . . . Quad Ring, Brine Stem

11. . . . . . . . . . . . 1 . . . . . . . . . . . . .15310. . . . . . . . . . . . . . . . . . Spring, Brine Valve

12. . . . . . . . . . . . 1 . . . . . . . . . . . . .10250. . . . . . . . . . . . . . . . . . Retaining Ring

13. . . . . . . . . . . . 1 . . . . . . . . . . . . .16922. . . . . . . . . . . . . . . . . . Bracket, B/V

14. . . . . . . . . . . . 2 . . . . . . . . . . . . .15137. . . . . . . . . . . . . . . . . . Screw, B/V Bracket

15. . . . . . . . . . . . 1 . . . . . . . . . . . . .10269. . . . . . . . . . . . . . . . . . Nut, Jam

16. . . . . . . . . . . . 2 . . . . . . . . . . . . .15414. . . . . . . . . . . . . . . . . . Nut, Tube

17. . . . . . . . . . . . 1 . . . . . . . . . . . . .16124. . . . . . . . . . . . . . . . . . Sleeve

18. . . . . . . . . . . . 1 . . . . . . . . . . . . .15415. . . . . . . . . . . . . . . . . . Insert

19. . . . . . . . . . . . 1 . . . . . . . . . . . . .15413. . . . . . . . . . . . . . . . . . Elbow

20. . . . . . . . . . . . 1 . . . . . . . . . . . . .16959. . . . . . . . . . . . . . . . . . Brine Valve Tube

21. . . . . . . . . . . . 1 . . . . . . . . . . . . .16123. . . . . . . . . . . . . . . . . . Nut, Tube

1

2345

6

7

8

910

11 12

14

15

16

17

19

20

21

13

18

16

Printed in U.S.A.

Page 18

MODEL 9500 ECONOMINDER

Air Check

PARTS LIST

Item No. Quantity Part No. Description

1 . . . . . . . . . . . 1. . . . . . . . . . . .10332. . . . . . . . . . . . . . . . Tube Insert 3/8″

2 . . . . . . . . . . . 1. . . . . . . . . . . .10330. . . . . . . . . . . . . . . . Ferrule

3 . . . . . . . . . . . 1. . . . . . . . . . . .10329. . . . . . . . . . . . . . . . Tube Nut 3/8″

4 . . . . . . . . . . . 1. . . . . . . . . . . .Not Supplied . . . . . . . . . . Brine Line Tube (3/8 Flexible Tube)

5 . . . . . . . . . . . 1. . . . . . . . . . . .12794. . . . . . . . . . . . . . . . 90°Elbow - 3/8″T to 3/8″T

1. . . . . . . . . . . .13555. . . . . . . . . . . . . . . . 90°Elbow - 3/8″T to 3/8″T, HW

6 . . . . . . . . . . . 1. . . . . . . . . . . .60002. . . . . . . . . . . . . . . . #500 Air Check Assembly

1. . . . . . . . . . . .60003. . . . . . . . . . . . . . . . #500 Air Check Assembly, HW

For Use With 2 GPM Flow Control

10. . . . . . . . . . . . . . . . . . . . . . . .15415. . . . . . . . . . . . . . . . Tube Insert 1/2″

11. . . . . . . . . . . . . . . . . . . . . . . .16123. . . . . . . . . . . . . . . . Ferrule 1/2″

12. . . . . . . . . . . . . . . . . . . . . . . .16124. . . . . . . . . . . . . . . . Tube Nut 1/2″

13. . . . . . . . . . . . . . . . . . . . . . . .15413. . . . . . . . . . . . . . . . Elbow

14. . . . . . . . . . . . . . . . . . . . . . . .60009. . . . . . . . . . . . . . . . #900 Air Check Assembly

60009-01 . . . . . . . . . . . . . #900 Air Check Assembly, HW

2

3

4

5

6

10

11

12

13

1

Printed in U.S.A.

Page 19

MODEL 9500 ECONOMINDER

1-1/2″Meter Assembly

PARTS LIST

Item No. Quantity Part No. Description

1. . . . . . . . . . . 1 . . . . . . . . . . . 17569 . . . . . . . . . . . . . . . Meter Body

2. . . . . . . . . . . 1 . . . . . . . . . . . 13882 . . . . . . . . . . . . . . . Impeller Post

3. . . . . . . . . . . 1 . . . . . . . . . . . 13509 . . . . . . . . . . . . . . . Impeller

4. . . . . . . . . . . 1 . . . . . . . . . . . 13847 . . . . . . . . . . . . . . . O-Ring - Meter Cover

5A . . . . . . . . . . 1 . . . . . . . . . . . 15218 . . . . . . . . . . . . . . . Meter Cover Assembly (St.d)

5B . . . . . . . . . . 1 . . . . . . . . . . . 15237 . . . . . . . . . . . . . . . Meter Cover Assembly (Extended Range)

6. . . . . . . . . . . 4 . . . . . . . . . . . 12112 . . . . . . . . . . . . . . . Screw - Meter Cover

7. . . . . . . . . . . 1 . . . . . . . . . . . 17542 . . . . . . . . . . . . . . . Flow Straightener

8. . . . . . . . . . . 1 . . . . . . . . . . . 12733 . . . . . . . . . . . . . . . O-Ring

9. . . . . . . . . . . 1 . . . . . . . . . . . 17544 . . . . . . . . . . . . . . . Nipple - Quick Connect

10 . . . . . . . . . . 1 . . . . . . . . . . . 17543 . . . . . . . . . . . . . . . Nut - Quick Connect

1

2

3

4

5A

6

5B

10

7

9

8

Printed in U.S.A.

Page 20

MODEL 9500 ECONOMINDER

Timer Assembly

(See Opposite Page for Parts List)

1

2

3

4

56

7

8910

11

12

14

15 16 17

18

19

20

22 23 24 25

26

27

28

29

30

31

32

33 35

36

37

38

39

40

13

41

26

26

20 17

Table of contents

Other Fleck Control Unit manuals

Popular Control Unit manuals by other brands

Panduit

Panduit TX6 PLUS installation instructions

Villeroy & Boch

Villeroy & Boch Emotion Control Start-up and operation

aFe Power

aFe Power 77-84013 instruction manual

Honeywell

Honeywell RM7800L1087 installation instructions

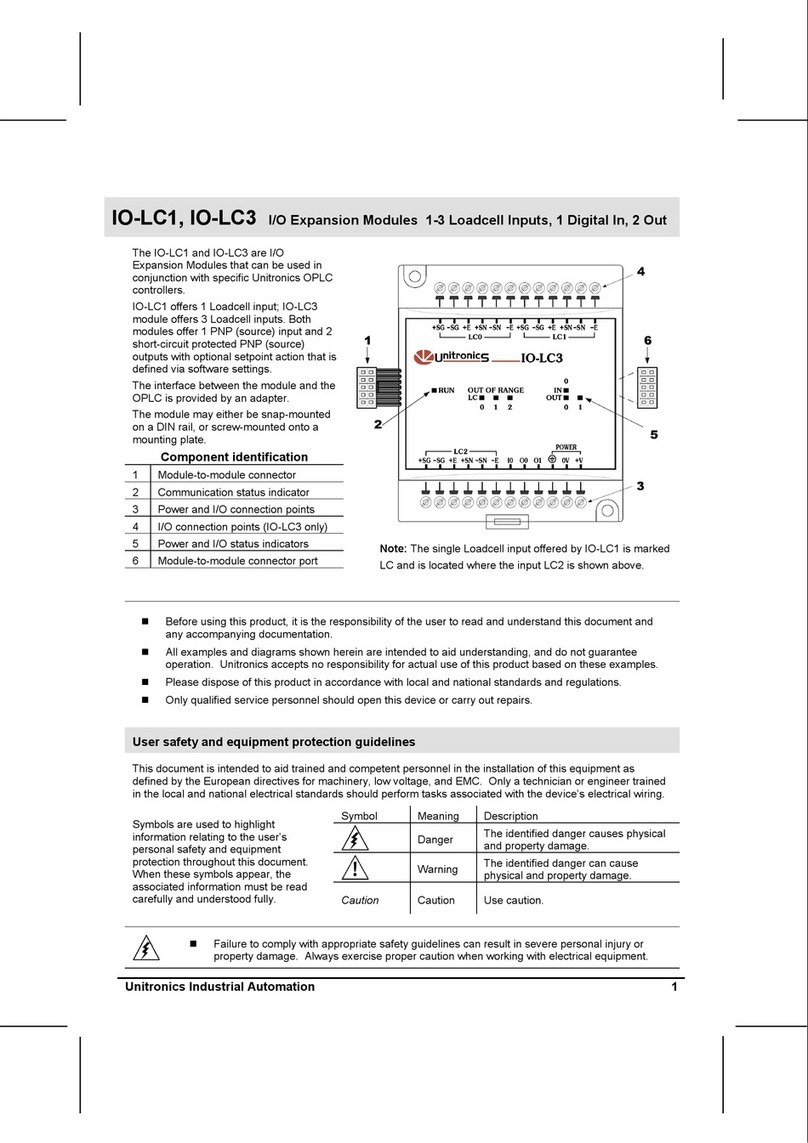

Unitronics

Unitronics IO-LC1 manual

ICP DAS USA

ICP DAS USA GTP-230 quick start guide

Microdyn Nadir

Microdyn Nadir AQUADYN FZ50 Hollow Operation manual

Grundfos

Grundfos CIM 500 Installation and operating instructions

Clearfield

Clearfield Clearview Blue installation manual

Comelit

Comelit 1622 Technical instructions

LOVATO ELECTRIC

LOVATO ELECTRIC ATL DPS1 operating manual

SKF

SKF SGA-011 Assembly instructions