8 DO NOT pull or carry the appliance by the power cable.

9 DO NOT use worn or damaged cables, plugs or connectors. Immediately have any faulty

item repaired or replaced by a qualified electrician.

10 The mains lead is made from high temperature cable, not a standard PVC cable and as

such should not be replaced without consulting a suitable qualified electrician.

11 Use of an extension cord is not recommended. However, should one be used, ensure the

extension cord is in good condition, of the right current rating and that it is fully extended.

General Safety Instructions

1 Remove all packaging and store it away from children, check the package and drier

for visible damage or tampering.

2 Familiarise yourself with the applications and limitations of the drier.

3 Ensure the drier is in good order and condition both physically and electrically before

use. If in any doubt, do not use the unit and contact an electrician.

Only use recommended attachments and parts. To use unauthorised parts may be

dangerous and will invalidate your warranty.

4 Check that the lamp guards are in place, undamaged and firmly attached.

5 eep tools and other items away from the drier when it is in use.

6 eep the work area clean and clear of unnecessary items.

7 eep children and unauthorised persons away from the heater, as it gets very hot.

8 Disconnect from mains and allow to cool before moving or attempting any cleaning or

maintenance.

9 DO NOT use in areas where hazardous vapours may be present.

10 DO NOT subject the heater lamps to exposure to water. The product is IP20 rated.

11 DO NOT touch the heater lamps, even when cold.

12 DO NOT disassemble the drier for any reason. This unit must be checked by qualified

personnel only.

13 DO NOT use this drier to perform a task for which it has not been designed.

14 WARNING! If the 10 Amp fuse blows, disconnect from the mains supply and ensure it is

replaced with an identical fuse type.

15 Store the heater carefully in a safe, dry, child proof location.

16 WARNING! Never touch the lamps directly with your fingers. Use a soft cloth; otherwise

the tubes may get damaged.

17 WARNING! Ensure the heater lamps are never closer than 500mm (20in.) from the

object it is drying.

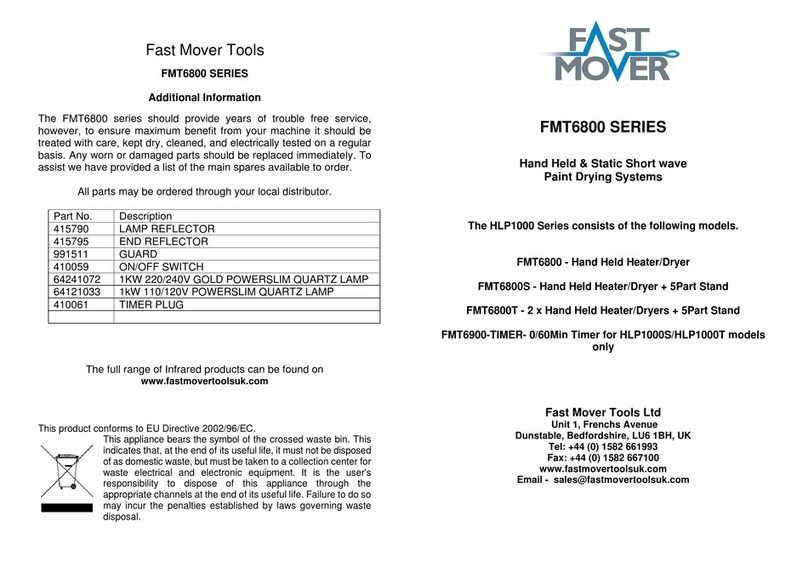

Lamp Fitting And Replacement

Should it be necessary to change a lamp on the cassette, please follow these instructions.

i CAUTION: Before examining or carrying out any maintenance ensure the heater has

cooled down and is disconnected from the mains supply.

ii The lamp used in this fitting is robust and if knocks and shock vibrations are avoided, will

last for around 5000 hours.

To Replace The Lamp

1 Ensure the power is turned off and remove plug from socket. Allow to cool. When cool lie

fitting on surface with guard pointing upwards.

2 Remove the first two screws from one end of an end reflector, this will release the guard

and expose the lamp connection.

3 Now remove the other two screws and end reflector from the other end of the cassette,

exposing the other end lamp connection.

4 The in-line connectors can be separated by hand, but a better solution is to use two pairs

of long nosed pliers. One to hold each connector when separating wires.

5 Remove old lamp and insert replacement one taking care to hold lamp by porcelain caps

PLEASE EEP THIS MANUAL SAFE FOR FUTURE REFERENCE

Fast Mover Tools Ltd

Unit 1 Frenchs Avenue, Dunstable, Bedfordshire, LU6 1BH, U

www.fastmovertoolsuk.com