Fastrax Hellfire 900 Guide

Part No. HF18948.Rev.3.04 November 2018 Printed in Canada

ANSI Z83.7-2017 / CSA 2.14-2017

Gas Fired Unvented Construction Heaters (Unattended Type)

IMPORTANT INSTRUCTIONS - SAVE THESE INSTRUCTIONS

Read all instructions before installing or using the heater. Please adhere to instructions published in this manual.

Failure to do so may be dangerous and may void certain provisions of your warranty.

Fastrax®is a registered trademark of Thermon Heating Systems, Inc.

Copyright©2018. All rights reserved.

ISO 9001

2014

HELLFIRE 900

Gas Fired Railway Switch Heater

Installation, Operation, & Maintenance Instructions

TABLE OF CONTENTS

A. Important Notices And Warning Symbols 4

B. Identification 6

B.1 Heater Labels ........................................................6

B.2 Model and Serial Number Tag...............................6

B.3 Components Diagram...........................................6

B.4 Control Panel Diagram - 240V Single Phase

Example Shown ....................................................7

B.5 Gas Manifold Diagram...........................................7

C. Pre-Operation Inspection 8

C.1 Important Notices..................................................9

C.2 Prior to Heater Start-Up ........................................9

D. Operation 11

D.1 Introduction......................................................... 11

D.2 Modes................................................................. 11

D.3 Start-Up Sequence (All Modes)........................... 11

D.4 Occurrences During Normal Operation ............... 11

D.5 Heat Output Adjustment ..................................... 11

E. Controls & Indications 13

E.1 AAR Signal Wiring - For non SCADA installations 13

E.2 Controller.............................................................13

E.3 Controls...............................................................14

E.4 Indications ...........................................................14

E.5 Terminal Blocks ...................................................15

E.6 Data Communications.........................................16

E.7 Controller EEPROM Memory ...............................16

E.8 Activating a COMMUNICATION Parameter..........16

E.9 Mode Parameters ................................................16

E.10 Activating MODE Parameter................................. 17

E.11 Fan Mode.............................................................17

E.12 Local EMS Mode.................................................. 17

E.13 RAIL THERMOSTAT Mode, Normal...................... 17

E.14 RAIL THERMOSTAT Mode, Reverse ....................17

E.15 Failure Shutdowns and Alarm Indications.............17

E.16 Fault Conditions ................................................... 17

E.17 Aggressive Retry Feature .....................................18

E.18 R e s et ...................................................................18

E.19 Energy Management System (EMS).....................19

E.20 Terminal Blocks ...................................................20

E.21 Inputs and Outputs..............................................20

F. Troubleshooting 21

G. Installation 25

G .1 O v e r v i e w .............................................................25

G.2 Recommended Tools..........................................25

G.3 Site Preparation - Typical Clearances .................25

G.4 Site Preparation ..................................................28

G.5 Heater Installation ...............................................28

G.6 Gas Supply Piping and Minimum Pressure Drop 28

G.7 Electrical Power Connections .............................28

G.8 Power Connections ............................................29

G.9 Thermostat Installation........................................31

G.10 Energy Management System (EMS) Options .....31

G.11 Inspection and Commissioning............................34

H. Heater Specifications 35

H .1 P e r f o r m a n c e........................................................35

H.2 Gas Firing............................................................35

H.3 Gas Conversion ..................................................35

H.4 Electrical .............................................................35

H.5 Controls ..............................................................35

H.6 Wiring Terminations.............................................35

H.7 Safety Features ...................................................35

H.8 Controller Terminal Identification .........................36

H.9 SchematicsMaintenance.....................................37

I. Maintenance 43

I.1 Thermostat Removal .............................................43

I.2 Motor/Impeller/Base Removal...............................43

I.3 Impeller Removal ..................................................43

I.4 Flame Rod and Spark Igniter Removal..................44

I.5 Burner Removal....................................................44

I.6 Burner Defroster Removal.....................................44

J. Service 45

J.1 Recommended Service Schedule........................45

J.2 Gas Supply Pressure ...........................................46

J.3 Gas Supply Leak Test ..........................................46

J.4 Manifold Leak Test...............................................46

J.5 Main And Safety Gas Solenoid Valves Leak Test .47

J.6 Dirt Trap And Strainer ..........................................47

J.7 Motor ...................................................................47

J.8 Vibration Specifications and Measurement..........47

J.9 Lubrication...........................................................47

J.10 Flame Safety Relay (FSR)......................................47

J.11 Flame Signal.......................................................48

J.12 Air Switch .............................................................48

J.13 Air Switch Calibration .........................................48

J.14 High Temperature Limit ........................................48

J.15 AAR Terminals, Signals, and Communications.....49

J.16 Burner ..................................................................49

J .17 D e f r oste r ..............................................................49

K. Parts 50

K.1 Parts - Heater Body.............................................50

K.2 Parts - Control Panel, 240V Single Phase............ 51

K.3 Parts - Control Panel, 208V Three Phase ............51

K.4 Parts - Control Panel, 460V/575V

ThreePhasewith120V Duplex Receptacle .........52

4

4

Important Notices and Warning Symbols

A. IMPORTANT NOTICES AND WARNING SYMBOLS

Keep this manual with the machine at all times. The purpose of

this manual is to provide owners, operators, and installers with

the precautions and procedures essential for the safe and proper

operation for its intended purpose.

WARNING

CAUTION. This symbol indicates a potentially

hazardous situation, which, if not avoided, may result in

personal injury or damage to the equipment.

WARNING

WARNING. This symbol indicates an imminently

hazardous situation, which, if not avoided, can result

in serious injury or damage to the equipment.

.

WARNING

WARNING. Read and adhere to the following. FAILURE

TO DO SO MAY RESULT IN SEVERE OR FATAL

INJURY. Warranty will be void.

NOTE: “NOTE:” indicates information or a company policy that

relates directly or indirectly to the safety of personnel or

protection of property.

Table 1 – Operation Warning/Avertissements (Intended for Signal Maintainers)

Symbol Description

English French

Risk of electrical shock or electrocution.

Disconnect electrical power prior to servicing.

Risque de choc électrique ou d’électrocution.

Couper le courant avant d’entreprendre l’entretien.

The heater is designed and approved for use as a

commercial heater (gas) – railway switch, class 2902 05

in accordance with ANSI Z83.7 / CSA 2.14. Check with

local authority, if you have questions about applications.

Cet appareil a été conçu et approuvé pour être utilisé comme

radiateur commercial (gaz) - aiguillage de voie ferrée de

classe 2902 05, conformément à la norme ANSI Z83.7 / CSA

2.14. Communiquez avec les autorités locales pour plus de

renseignements sur le lieu d’utilisation de cet appareil.

General hazard warning failure to comply with the

precautions and instructions provided with this heater,

can result in death, serious bodily injury and property

loss or damage from hazards of re, explosion, burn,

asphyxiation, carbon monoxide poisoning, and / or

electrical shock.

Only persons who can understand and follow the

instructions should use or service this heater. If you

need assistance or heater information such as an

instructions manual label, etc. Contact the manufacturer.

Mises en garde générales le non·respect des mises en garde

et des instructions fournies avec ce radiateur peut entraîner

la mort, des graves blessures et des pertes matérielles ou

des dommages à la propriété résultant d’un incendie, d’une

explosion, de brûlures, d’asphyxie, d’empoisonnement au

monoxyde de carbone et/ou d’un choc électrique.

Seules les personnes aptes à comprendre et à suivre les

instructions devraient se servir de ce radiateur ou le réparer.

Si vous avez besoin d’aide ou d’informations concernant ce

radiateur, soit une notice d’instructions, une étiquette, etc.,

Prière de communiquer avec le fabricant.

Fire, burn, inhalation, andexplosion hazard. Keep solid

combustibles, such as building materials, paper, or

cardboard, a safe distance away from the heater as

recommended by the instructions. Never use the heater

in spaces which do or may contain volatile or airborne

combustibles, or products such as gasoline, solvents,

paint thinner, dust particles or unknown chemicals.

Risque d’incendie, de brûlures, d’inhalation et d’explosion.

Garder les combustibles solides, tels les matériaux de

construction, le papier et le carton, à bonne distance de ce

radiateur, comme il est recommandé dans les instructions.

Ne jamais utiliser cet appareil dans des endroits qui

contiennent ou pourraient contenir des combustibles volatiles

ou en suspension dans l’air tels l’essence, les solvants, les

diluants pour peinture, les particules de poussières ou des

produits chimiques inconnus.

Not for home or recreational vehicle use. Ne pas utiliser dans une maison ou un véhicule de camping.

All persons employed in handling propane or natural

gas shall be trained in proper handling and operating

procedures, as required by local authorities having

jurisdiction.

Toute personne qui manipule le propane ou le gaz naturel

doit avoir suivi une formation sur les bonnes procédures de

manipulation et d’utilisation qui est conforme aux exigences

des autorités locales compétentes.

5

Important Notices & Warning Symbols

Symbol Description

English French

If you smell gas; immediately extinguish all sources of

ignition and turn off gas source. Call qualied service

technician to repair leak.

S’il y a une odeur de gaz : fermer immédiatement toute

source d’allumage et de gaz. Faire réparer la fuite par un

technicien qualié.

Do not attempt to manually light burner.

Heater equipped with an automatic electronic ignition

system.

Ne pas allumer le brûleur manuellement.

Radiateur équipé d’un système d’allumage électronique.

Risk of cutting ngers or hand.

Disconnect fan power prior to removing combustion

chamber access panel or air intake.

Risque d’amputation des doigts ou de la main.

Couper le courant au ventilateur avant d’enlever le panneau

d’accès à la chambre de combustion ou l’entrée d’air.

Heater can start automatically.

Exercise caution when in close proximity.

Attention : le radiateur peut démarrer automatiquement.

Faire preuve de prudence près du radiateur.

Burn hazard / hot surfaces.

Do not touch track ducts, nozzles or any non-insulated

duct connected downstream of heater during operation.

Surface chaude; risque de brûlure.

Ne pas toucher les conduits latéraux à la voie ferrée, les

buses ni aucun conduit non isolé branchés en aval d’un

radiateur en marche.

Sheet metal edges can be sharp.

Wear protective clothing when handling track duct,

insulted ducts and any other sheet metal components.

Risque de coupure.

Les rebords de la tôle sont coupants. Porter des vêtements

protecteurs lors de la manipulation des conduits isolés et tout

autre composant en tôle.

For use with ductwork only. Pour utilisation avec réseau de gaines seulment.

Retain manual for future reference. Conserver le manuel pour consultation ultérieure.

6

6

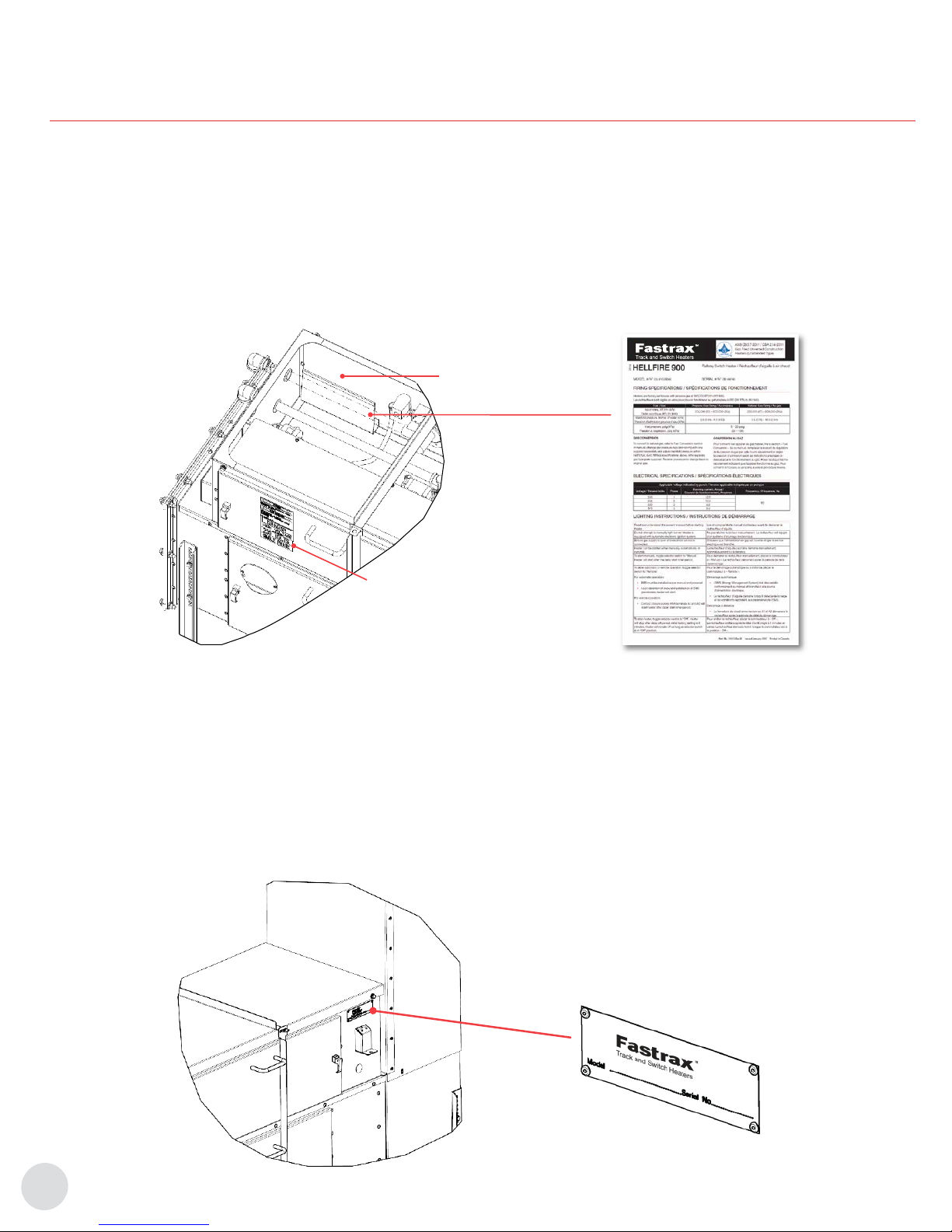

B. IDENTIFICATION

B.1 Heater Labels

1. Each heater has a ratings label, a logo label, a model and

serial number tag and a voltage label.

2. The ratings label contains all identication and safety

information. It is fastened by a lanyard and stored in the

manual pocket inside the control enclosure next to the gas

manifold. The electrical specications are indicated with a

punch mark.

3. The logo, located on the side of the air intake hood

identies the series as HELLFIRE, and the size, either 400

or 900.

4. The model / serial number tag is a blue aluminum plate.

The model number is applied to an adhesive backed label

bonded to the tag, and the serial number is engraved. The

serial number is a sequential 6-digit number.

Installation & Instruction

Manual Location

Voltage Label

Rating Label

B.2 Model and Serial Number Tag

1. The tag is located on the front and above the selector

switch.

2. This is true for all congurations including heaters supplied

with the bungalow option.

3. Congurations are identied on the tag as model “HF 900”

followed by a 5-digit number, an optional 2-digit dash

number and a revision letter. For example,

HF900 12345-01A (HF900 BUNG XXXXX-XXX - for

bungalow enclosed heaters).

4. The operating voltage label is found on the electrical

access panel. Have this information available when

requesting parts or service.

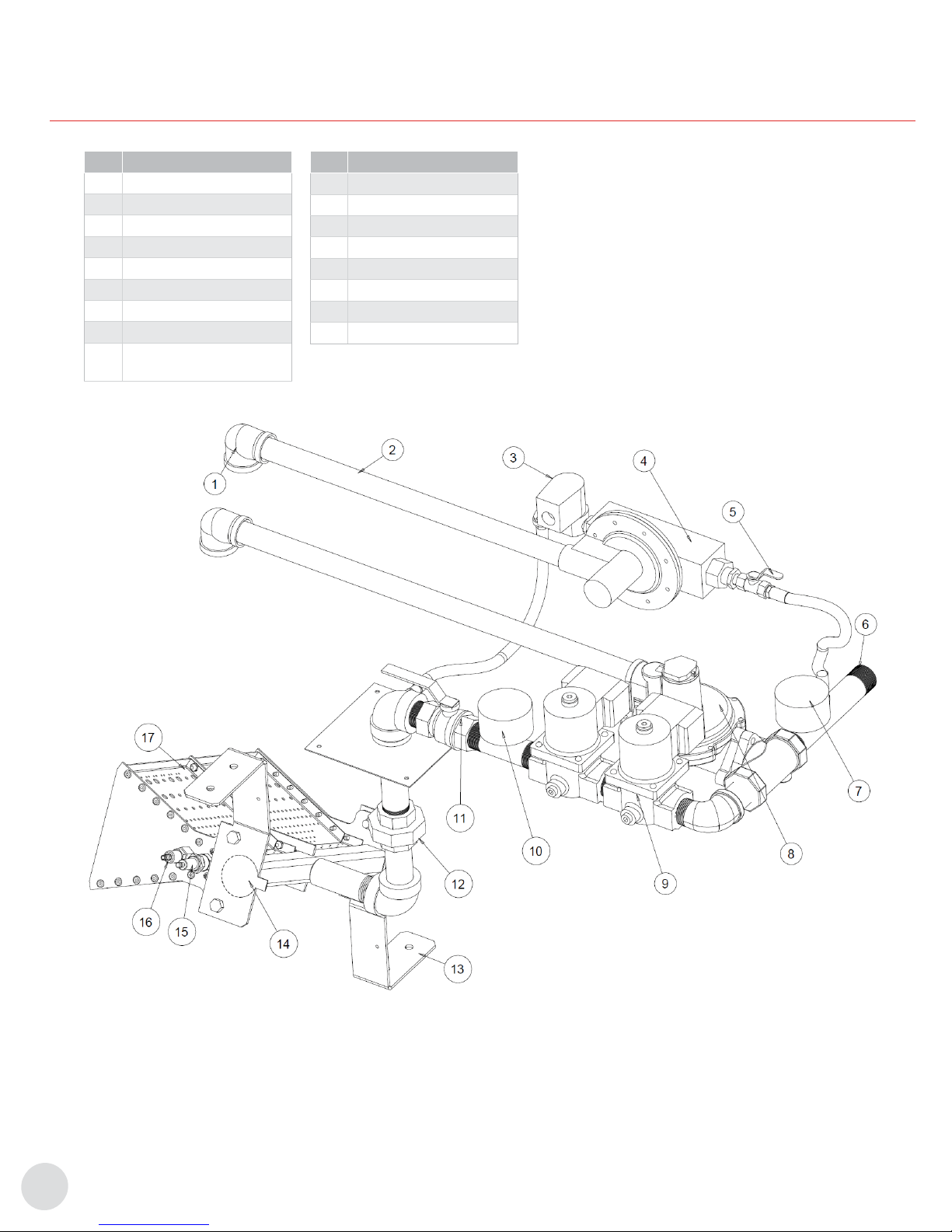

B.3 Components Diagram

5. The following component names are referred to in this

manual. See Section L - Parts for part numbers and

ordering.

Stand-Alone & Bungalow Enclosed Configurations

Identification Tag with Model and Serial Number

Identication

77

Identication

B.4 Control Panel Diagram - 240V Single Phase Example Shown

B.5 Gas Manifold Diagram

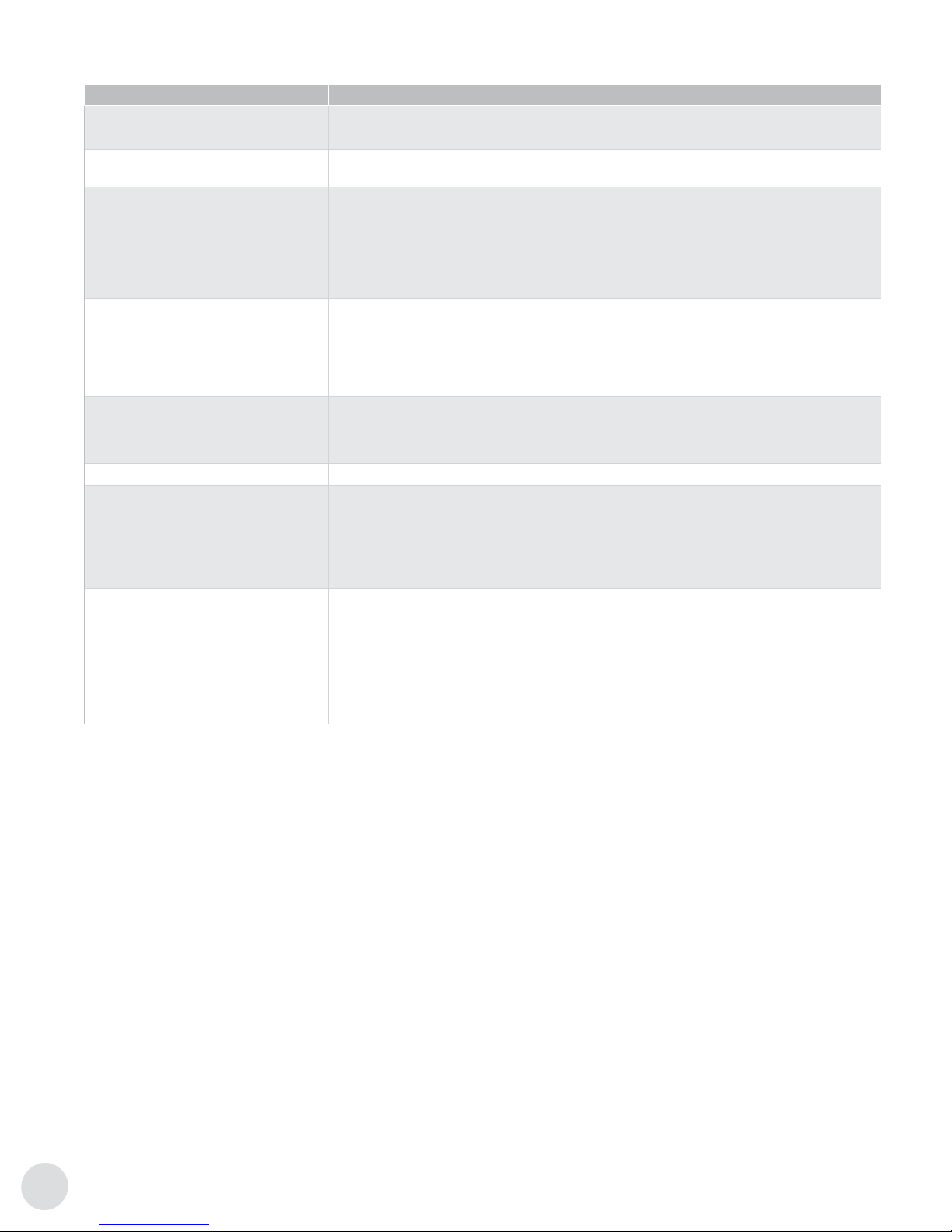

No. Label

1Track duct

2 Track duct elbow

3Rail mounting spring clip and pad

4Ballast retainer

5Thermostat box

6Precipitation detector

7Burner

8Regulator vents

9Condensation vent

10 Gas manifold

11 Control cabinet lid

12 Air intake hood

13 Ambient air temperature sensor

14 Air intake extension

15 Identication tag

16 Mode selector switch

17 Electrical control access panel

No. Label

18 Air intake plenum

19 Leveling leg

20 Control panel

21 Motor/Impeller/Base

22 Combustion chamber access panel

23 Transition duct

24 Sensor duct

25 Square to round adapter

26 Flex duct

27 Track duct deector

28 Tie duct

29 Rail thermostat

30 Point nozzle

31 Track duct mounting bracket

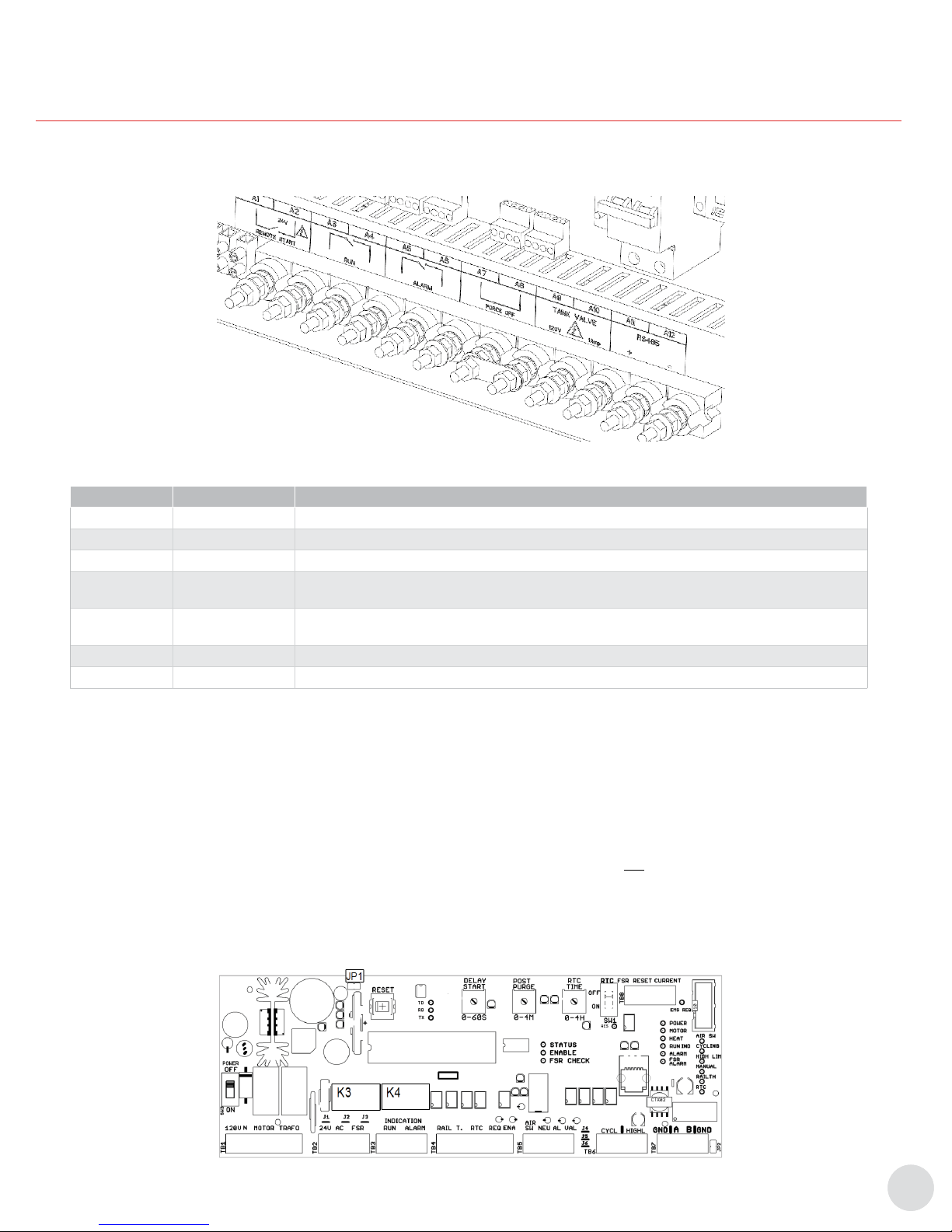

No. Label

1Ignition transformer

2Burner control / Flame Safety Relay

3 Purge timer card

4Reset module

5Controller

6Programming key

7EMS module

8Control circuit breaker

9 Motor circuit breaker

10 120V receptacle

11 Contactor

12 Control transformer

13 Power terminal block

14 Mode selector switch

15 Hour meter

16 Receptacle circuit breaker

17 Tank valve circuit breaker

18 Control and indication terminal block

19 Resettable fuse, burner defroster

20 Manifold terminal block

21 Rail thermostat receptacle

22 Precipitation detector receptacle

23 Flame signal amplier

8

8

C. PRE-OPERATION INSPECTION

Identication

No. Label

1Regulator vent

2Regulator vent pipe

3 Pilot gas solenoid valve

4Pilot gas pressure regulator

5Pilot manual shutoff valve

6Gas supply inlet

7Gas supply pressure gage

8Main gas pressure regulator

9 Main and safety gas

solenoid valves

No. Label

10 Manifold gas pressure gage

11 Main manual shutoff valve

12 Union

13 Burner mounting bracket

14 Burner defroster

15 Igniter

16 Flame rod

17 Burner

99

Pre-Operation Inspection

C.1 Important Notices

To ensure trouble free operation during the winter months, inspect

the system annually at the start of the season.

WARNING

WARNING. All persons employed in handling propane

or natural gas shall be trained in proper handling and

operating procedures, as required by local authorities

having jurisdiction.

Gas leaks shall be repaired immediately or, gas supply

valve closed until repairs can be made.

All work performed on railway property must be

carried out in accordance with local railway authorities

instructions.

CAUTION

CAUTION. Do not operate this machine until it has

been installed and commissioned according to

requirements specied in the installation section of this

manual.

NOTE: Perform inspection and operations in accordance with

the instructions provided in the service section of this

manual.

NOTE: This inspection guide assumes that all applicable service

bulletins have been implemented on the heater being

inspected.

NOTE: The outcome of any inspection items that differ from that

expected indicates further service is required.

C.2 Prior to Heater Start-Up

Table 2 – Heater Inspection List

Inspect Action

Condition of all ducting, particularly any

ex ducts Repair or replace damaged ductwork.

Inside of all tie duct and cross ducts Remove any blockages, such as debris and mud.

Track duct vents Close vents that do not direct air at tie plates or rods.

Set vent openings to 1/8” - 1/4” maximum.

Track duct mounting Verify track ducts do not interfere with normal movement of the switch points and do not interfere

with the signal system.

Flame rod and spark igniter

Remove and visually inspect for cracks in the ceramic, and evidence of soot. Replace any with

cracked ceramic.

If evidence of soot is found, clean rod and investigate condition of burner, gas manifold, and

inspect tie duct, cross ducts and air intake for blockage.

Flame rod and ignition wires Inspect boot for degradation, cracks and poor seals. Replace if necessary.

Inspect connectors for signs of corrosion. Clean connections, or replace wire if necessary.

Combustion chamber Verify it is clear of any obstructions or debris, ie. animal nests.

Cycling and high limit thermostat

installation

Verify thermostats are fastened and are in full contact with duct surface.

Replace any with damaged wire insulation.

Verify thermostat enclosure is sealed and dry inside.

Service surge protection Verify electric service has functioning surge protection.

Air switch port and vent Remove any obstruction.

Gas regulator vents Remove any obstruction.

Flame Safety Relay Verify it is installed and is in standby mode with ‘POWER’ LED blinking, and ‘ALARM’ LED off.

Gas source Verify propane tank is lled, or natural gas service is open and has pressure.

Open all manual gas shut off valves and inspect all gas lines for leaks.

Electrical service Verify electric service power is on. Close supply circuit breakers.

Flame Safety Relay Burner Control fault

histories

Using Honeywell display module S7800A1001 (Part number 9040-0021). Review and record the

last 6 stored fault history error codes. See Honeywell manual for description of faults.

H1 Code Hour Cycle

H2 Code Hour Cycle

H3 Code Hour Cycle

H4 Code Hour Cycle

H5 Code Hour Cycle

H6 Code Hour Cycle

10

10

Pre-Operation Inspection

Inspect Action

Electrical supply Verify correct line voltages at each heater. Must be within +/- 5% of nominal voltage.

Verify current draw is less than or equal to nameplate rating.

Gas supply Verify supply and manifold gas pressures are within nameplate limits when heater and all

connected loads are operating.

Flame signal strength

Verify ame signal strength is stable (+/- 0.5) and between 3.0 and 5.0 Vdc.

If signal strength is low:

– Clean or replace ame rod.

– Clean ame rod wire connections, or replace wire.

If cleaning or replacement of ame rod and wire does not increase strength, have burner serviced

or replaced.

Burner operation

Note current manifold pressure.

Set manifold pressure to maximum nameplate setting, measure point nozzle temperature, if

point nozzle temperature is 140°F or less above ambient air temperature have burner serviced or

replaced.

Return manifold pressure back to desired setting.

Air switch calibration

Block air intake 80%. Verify heater still operates.

Then block 90% and verify FSR alarms.

If heater fails with 80% or less blockage, recalibrate air switch.

Control and indication wiring Verify the correct control and indication wiring between the heater and the signal bungalow.

Energy Management System (EMS)

If heater is operated automatically by an Energy Management System:

– Verify EMS module is installed and connected with POWER LED lit.

– Verify controller is in AUTO mode.

– Verify precipitation detector and ambient temperature sensor installed and connected.

– Verify rail thermostat is mounted on rail and connected to surge isolator.

– Verify its operation.

Aggressive retry

Verify operation.

Turn gas supply off, toggle heater to “Manual”.

Verify three attempts made followed by lockout.

Return heater to desired operating mode.

Open gas supply.

Reset controller.

1111

Operation

D. OPERATION

D.1 Introduction

The switch heater is a gas red, hot air heating system that

keeps a turnout clear of ice and snow during winter storms

by blowing hot air, between the stock rail and moving

points, at the tie plates on which the points slide, and at the

gage rods.

D.2 Modes

The heater can be operated in the following modes:

1. MANUAL - by toggling the mode selector switch

to “MANUAL”, the heater will turn on and operate

continuously. If installed, the rail thermostat will cycle

the burner on and off as required to maintain the rail

temperature.

2. AUTO – With the controller congured for LOCAL AUTO

MODE, toggling the mode selector switch to “AUTO/

REMOTE”, and with an EMS module, precipitation and

ambient temperature sensor installed, the heater will turn

on or off as required based on the weather conditions. If

installed, the rail thermostat will cycle the burner on and

off as required to regulate the rail temperature.

3. REMOTE RTC- by toggling the mode selector switch

to “AUTO/REMOTE” and with a Rail Trafc Control, RTC

(dispatcher) operated control relay contact wired to

terminals A1 and A2 of the control and indication terminal

block. With RTC timer disabled, the heater will operate

continuously while the RTC contact is closed, if the RTC

timer is enabled, the heater will run for the duration of

the RTC timer then stop. RTC can restart the heater for

additional run time by resetting the request. If installed, the

rail thermostat will cycle the burner on and off as required

to maintain the rail temperature.

4. REMOTE SCADA - With the controller congured for

REMOTE SCADA MODE, toggling the mode selector

switch to “AUTO/REMOTE” with the heater connected

to a Supervisory Control and Data Acquisition, SCADA,

network via the controllers’ RS-485 communications port,

and congured with a Remote Control and Monitoring

System (RCMS), software, the heater will operate

automatically.

If installed, the EMS module, precipitation detector,

ambient temperature sensor and rail thermostat provides

inputs to the RCMS software.

5. OFF – to disable the heater, toggle selector switch to

“OFF”.

D.3 Start-Up Sequence (All Modes)

Once a start request is received the control sequence begins.

NOTE: If the controller is in ‘REMOTE RTC’ mode then it waits

for the ‘DELAY START’ time before initiating.

Table 3 – All Modes

Conditions/Sequence Status LED

Heater is in an operational mode not OFF. ENABLE

Cycling thermostat is cold or closed. CYCLING

Motor contactor closed, fan starts. MOTOR

Air pressure develops, air switch closes. AIR SW

FSR requested, trial for ignition, burner lit. HE AT

Main gas valve opens. FSR CHECK

Run indication contact closed. RUN

To conrm the heater operation, the burner remains lit and the rail

thermostat status is ignored for the rst 2 minutes.

Normal operation Heater runs as long as requested.

D.4 Occurrences During Normal Operation

NOTE: The rail thermostat closes when the rail temperature is

above 9°C (49°F) and opens when below 3°C (37°F).

6. As long as the rail is cold and the thermostat is open, the

burner remains lit. Once the rail warms and the thermostat

closes, the burner is extinguished. This cycle repeats as

required while the heater operates. If the rail temperature

remains warm for more than the post purge time then the

fan is turned off. The run indication is maintained during

this time.

7. If the heater is in ‘REMOTE SCADA’ mode and the

‘Fastrax® RCMS’ software is requesting performance

operation, the burner will remain lit regardless of rail

thermostat status.

NOTE: The cycling thermostat limits the heated air temperature

to a maximum of 193°C (380°F). Under normal

circumstances the air temperature remains below this

limit.

8. If the heated air temperature becomes excessively hot,

the cycling thermostat limit opens, and the burner is

extinguished immediately. Once the air cools and the

thermostat closes the burner is lit and heating resumes.

Run indication is maintained during this time.

D.5 Heat Output Adjustment

1. Depending on the length of switch points, its’ priority,

local climate conditions, and experience, the operator

can increase or decrease the heat output accordingly.

The recommended heat output is in the range of 10,000

to 22,000 BTU/hr per foot of turnout length.

12

12

Operation

2. The factory default setting is 550,000 BTU/hr when

operated on LPG, or 390,000 BTU/hr on NG.

3. The heat output can be adjusted as follows:

3.1 With the heater running, unscrew and remove the

main regulator (8) cap.

3.2 Use a at blade screwdriver to turn the internal nut

clockwise to raise (shown) or counterclockwise

to lower pressure as indicated on the manifold

pressure gage (10).

3.3 Screw cap closed.

3.4 As a starting point, with the heater operating,

adjust the manifold gas pressure to attain an air

temperature of 121°C (250°F) above ambient as

measured at the near point nozzle.

WARNING

WARNING. Do not operate above maximum manifold

pressure as this can produce carbon monoxide in

excess of maximum allowable of 0.08 AFCO.

WARNING

WARNING. Do not operate above or below the rated

manifold pressure limits. Operating outside limits will

result in weak ame signal and unreliable operation.

WARNING

WARNING. Install cap once regulator adjustment is

complete. In the event of pressure relief, the cap must

be closed to vent gas to the exterior.

3.5 The heat output can be estimated from the manifold

pressure and the following formulas:

204,000 + ((Manifold pressure –2.5)/6.5)*696,000 for LPG or

230,000 + ((Manifold pressure –3.5)/12.5)*670,000 for NG

Pressure is in inches of water column.

NOTE: These formulas are simplied, assume the equipment is

in good condition, and are strictly for estimation only.

1313

Controls & Indications

E. CONTROLS & INDICATIONS

E.1 AAR Signal Wiring - For non SCADA installations

Table 4 – AAR Signal Wiring

Terminals Label Description

A1 - A2 REMOTE START A contact closure across these terminals starts the heater when the heater is in REMOTE RTC mode.

A3 - A4 RUN Dry contact closes to provide a run indication.

A5 - A6 ALARM Dry contact closes to provide alarm indication.

A7 - A8 FORCE OFF Default is closed. If FORCE OFF function is desired, remove shorting link and replace with customer

supplied relay contact. Open contact disables heater.

A9 - A10 TANK VALVE These terminals are intended to operate a 120V AC gas supply solenoid shut off valve. They energize

when the motor contact closes.

A11 RS-485 (+) Communications, RS-485 positive terminal (for RCMS operation only)

A12 RS-485 (-) Communications, RS-485 negative terminal (for RCMS operation only)

E.2 Controller

1. The controller manages the operation of the heater and

allows it to either operate on its own or be part of a

network of heaters.

2. The controller monitors various inputs, controls the heater

functions, communicates status and provides indication

LEDs.

3. The controller is DIN rail mounted and all wiring

connections are made with plug connectors to allow quick

replacement in the event of a failure.

4. With the addition of the EMS package, a stand alone

heater can operate automatically based on weather

conditions, or when connected to a network, act as a

weather station providing input to a SCADA system.

5. Its’ RS-485 serial communications port allows the heater

to interface with SCADA systems, and be operated and

managed by a Remote Control and Monitoring System,

such as the Fastrax® RCMS.

NOTE: Controllers are not interchangeable between HELLFIRE

400 (24VAC) and HELLFIRE 900 (120VAC).

14

14

Controls & Indications

E.3 Controls

1. Power: This switch turns the power supply to the board

‘ON’ or ‘OFF’.

WARNING

WARNING. 120VAC inputs to controller can remain

energized.

2. Reset: This push button is used to reset the controller in

case of a lockout.

3. Delay Start: This dial sets the length of the delay, 0 to 60

seconds, before starting the heater. It is intended to allow

the stagger start of multiple heaters connected to one

power service thereby reducing the maximum current

draw. This setting is true for REMOTE RTC mode only.

Under MANUAL, AUTO and REMOTE SCADA modes

there is no delay.

NOTE: This setting is overridden when operated in REMOTE

SCADA mode by the corresponding Fastrax® RCMS

software parameter.

4. Post Purge: This dial sets the length of the delay, 5

seconds to 4 minutes, once the heater is no longer

requested, before stopping the fan. It is intended to purge

the remaining heat and moisture from the combustion and

duct system. This setting is true for all modes.

5. RTC Time: (RTC stands for Rail Trafc Control dispatch)

This dial limits the run time between 20 minutes to 4 hours,

when requested by RTC dispatcher, and with the RTC

SW switch ON, and the heater is in REMOTE RTC mode.

When the RTC request exceeds the time limit, the heater

turns off, and the run indication is maintained as long as

the heater is requested.

Timer is reset once the RTC request is removed. RTC can

then request the heater for another cycle.

It is intended to save fuel by avoiding unnecessary heater

operation by the dispatcher. This setting is true for RTC

MODE only. Under MANUAL, AUTO, and REMOTE SCADA

modes there is no limit.

6. RTC SW: This switch enables the RTC TIME function when

in the ON position. When switched OFF, RTC TIME is

disabled and the heater runs as long as requested.

7. JUMPER, JP1: Used to congure controller parameters.

E.4 Indications

1. On the controller are a number of status LEDs intended

to aid the user’s understanding of the heater state of

operation. See Table 6 - Controller LED Descriptions for

full description.

NOTE: With the exception of the communications TD, RD, and

TX LED’s. Solid green, solid green with a red pulse, or

yellow LED’s indicates normal status. Solid red and

alternating LED’s indicate a failure. This is true for the

controller only, not the EMS module.

2. Refer to Section F - Troubleshooting for explanation of

problem condition LED codes.

3. The LEDs listed can be found on the controller from top

left to bottom right on the board.

Table 5 – Controller LED Descriptions

LED Name Description State Indication

TD, RD, TX RS-485

communications

TD, RD on and pulsing

TX off and pulsing Heater in REMOTE SCADA mode.

TX off

TD and RD on Heater in LOCAL AUTO mode.

TD, TX off and pulsing

RD on 8N1 COM communications mode.

Status Processor status

Solid green with a red

pulse Normal operation.

Alternating red and

green FSR failure alarm. Aggressive retry mode in process.

Solid red

Failure alarm.

Note any alternating LEDs and refer to Section F - Troubleshooting.

Controller must be reset.

Solid green or off Processor has stopped functioning.

ENABLE Heater enable On Mode selector switch is either in MANUAL or REMOTE/AUTO position.

Heater can be started in AUTO REMOTE RTC or REMOTE SCADA modes.

Off Mode selector switch is in OFF position. Heater is in OFF mode and will not start.

FSR CHECK Flame Safety

Relay check

On Gas valve energised. Used to conrm correct operation of FSR.

Alternating The FSR did not energized the main gas solenoid valves when expected.

RES FSR Reset On Controller clears FSR alarm.

1515

Controls & Indications

LED Name Description State Indication

EMS REQ EMS request On EMS module request for heater to run.

Heater only acts on this request if in AUTO mode.

POWER Power supply On Controller energized.

MOTOR Motor On Contactor closed, motor turned on.

HEAT Controller

request for heat On FSR requested. Ignition sequence started or burner operating.

RUN IND Heater run

indication On Indication contact closed. Turns on after 60 seconds of normal operation.

ALARM Heater alarm

indication On Alarm indication contact closed. Heater off and locked out. Controller must be

reset manually.

FSR ALARM Flame safety

relay alarm

On FSR in ALARM, or controller is preventing its operation.

Alternating FSR is in ALARM. Heater failed 4 times in 5 minutes.

AIR SW Air pressure

switch

On Contact closed. Sufcient air ow to allow burner operation.

Alternating Air switch did not operate as intended. Air switch either did not close with fan ON

or did not open with fan OFF.

Off with pulse on Continuous fan mode with selector switch in OFF position.

On with pulse off Continuous fan mode with selector switch in MANUAL or REMOTE/AUTO

position.

CYCLING Cycling

thermostat

On Thermostat closed. Heated air temperature is BELOW set point.

Alternating Cycling thermostat open for more than 10 minutes.

HIGH LIM High limit

thermostat

On Thermostat closed. Heated air temperature ABOVE set point.

Alternating High limit thermostat closed momentarily indicating air temperature exceeded

set point.

MANUAL Manual operation On Selector switch in “MANUAL” position. Heater in MANUAL mode.

RAIL TH Rail thermostat On Thermostat open. Rail temperature is BELOW set point.

RTC Rail trafc control

mode

On Indicates selector switch is in “REMOTE/AUTO” position and AAR terminals 1

and 2 are closed.

Off with pulse on Indicates selector switch is in “REMOTE/AUTO” position and requested by

RCMS.

On with pulse off Indicates selector switch is in “REMOTE/AUTO” position and requested by

RCMS and AAR terminals 1 and 2 are closed.

E.5 Terminal Blocks

1. The controller interconnects with the control panel by means of 8 board level headers, TB1 to TB8, which accept the various

wire harness plug connectors. The controller and EMS module connect via a ribbon cable that plugs into the 10-pin header

found on each.

Table 6 – Terminal Block Description

Name Description

JP1 Jumper. Used to congure EEPROM settings

TB1 120V power, transformer primary and motor contactor coil output

TB2 Transformer secondary 24V power and FSR request output

TB3 RTC run and alarm indication contacts outputs

TB4 Rail thermostat, RTC request, Manual, and Enable inputs

TB5 Air switch, FSR/DSI alarm, gas valve inputs

TB6 Cycling and high limit thermostats inputs

TB7 Communication port, RS-485

TB8 FSR reset and current transformer inputs

10-pin header* EMS module power and signal connection

*Located in the upper right corner next to TB8.

16

16

Controls & Indications

E.6 Data Communications

1. The RS-485 serial communications port, and an

EEPROM, allows the heater to be part of a Supervisory

Control and Data Acquisition (SCADA) network and

Remote Control and Monitoring System (RCMS) software.

2. The RS-485 port runs at 9600 baud and allows

communication over long distances of up to 1000’ and

possibly longer.

NOTE: Cable construction: Cat5 24 AWG twisted pair is a very

common cable type used for RS-485 systems. Adding

shielding to the cable enhances noise immunity, and

thereby allows greater distance. If used, connect one

end only of shield to ground.

3. The 8-bit memory address allows a maximum of 254

heaters to connect to the same communications bus.

E.7 Controller EEPROM Memory

1. EEPROM memory chip stores parameters and an address.

2. EEPROMs can be switched between controllers. In the

event a controller needs to be replaced the EEPROM can

be removed from the old and put in the replacement. The

parameters and address remain with the heater and no

RCMS software modications are required.

WARNING

WARNING. Electrostatic discharge can damage ICs.

Have qualied personnel remove and install EEPROM IC.

3. Parameters activated locally or remotely by the RCMS

software are stored on the EEPROM.

NOTE: There are two parameter types, ‘COMMUNICATION’ and

‘MODE’.

Table 7 – Communication Parameters (Activated Locally)

Name Setting1Function

LOCAL AUTO MODE 1 Disables communications and

enables local EMS control.

REMOTE SCADA

MODE 2

Enables RS-485 MODBUS

communication.

Disables local EMS control.

Enables weather station mode.

DEFAULT ADDRESS 3 Writes 254 to processor address.2

ADDRESS SET 4 Writes new address to EEPROM 2

8N1 COM 5Enables 8N1 communication.3

Enables local EMS control.

LOCAL EMS, enabled 6Enables local EMS control.

LOCAL EMS,

disabled 7Disables local EMS control.

FAN MODE ----

When enabled, the fan runs

continuously.4

When disabled, the fan runs only

when heating is requested.

1Setting number equals alarm LED/relay count.

2One time functions.

3The 8N1 conguration allows the heater to send status information only

and is intended to aid service technicians. This conguration does not allow

the heater to be part of a network.

4See CONTINUOUS FAN MODE section for instructions.

E.8 Activating a COMMUNICATION Parameter

NOTE: Read and understand the following procedure before

starting. COMMUNICATION parameters require a

hardware programming key to make changes, MODE

parameters do not.

1. Toggle mode selector switch to “OFF”. If installed,

disconnect EMS cable from controller. Plug programming

key into the mating EMS 10-pin connector. Then the red

LED on the key lights.

2. Press the RESET button, and short jumper JP1.

3. Release the RESET button. The RTC, MANUAL, CYCLING,

and AIR SWITCH LEDs will each pulse, one after the other

for one sequence. Then the RUN indication LED pulses

and the green LED on the programming key alternates on

and off.

4. After ve RUN indication pulses, the red ALARM LED lights

for 3 seconds. This cycle continues as long as the jumper,

JP1, is shorted.

5. Count the number of times the red ALARM LED lights.

6. Once the count equals the parameter number, remove

the jumper before the ALARM LED turns off. For example,

when the ALARM LED lights for the second time

removing the jumper will activate REMOTE SCADA MODE,

parameter #2.

7. Function performed.

8. Parameter or new address is stored on the EEPROM.

9. Repeat sequence as required to activate other parameters.

E.9 Mode Parameters

Table 8 – Mode Parameters

Name Parameter1Function

FAN MODE

ENABLE 1Turns the motor on and keeps it

running continuously.

FAN MODE

DISABLE 2Motor runs only when heater is

requested.

LOCAL EMS

MODE

ENABLE

3 Local EMS controls the heater.

LOCAL EMS

MODE

DISABLE

4The local EMS will not turn the

heater on.

RAIL

THERMOSTAT

MODE NORMAL

5

Congures operation to new

thermostat, open when cold,

closes on temperature rise (COR).

RAIL

THERMOSTAT

MODE

REVERSED

6

Congures operation to older rail

thermostats that are closed when

cold, open on temperature rise

(OOR).

1Parameter number equals alarm LED/relay count.

1717

Controls & Indications

E.10 Activating MODE Parameter

NOTE: Read and understand the following procedure before

starting.

1. The controller must be powered on for a minimum of 60

seconds, the mode selector switch toggled OFF, and

terminals A1 A2 open (i.e. no RTC request).

2. Short jumper JP1. The RUN indication relay and LED

pulses on and off. After ve RUN indication pulses, the red

ALARM LED lights for 3 seconds. This cycle continues as

long as the jumper, JP1, is shorted.

3. Count the number of times the red ALARM LED lights.

4. Once the count equals the parameter number, remove

the jumper before the ALARM LED turns off. For example,

when the ALARM LED lights for the second time removing

the jumper will activate FAN MODE DISABLE, parameter

#2.

5. Function performed.

6. Parameter or new address is stored on the EEPROM.

7. Repeat sequence as required to activate other parameters.

E.11 Fan Mode

1. When enabled for continuous operation, this mode can

be benecial for locations with difcult to detect drifting

snow conditions that cause snow accumulation in the

turnout and or in the duct system.

2. When enabled, and with the mode selector switch in either

the MANUAL or REMOTE/AUTO position, the fan will run

continuously, with heating requested or not.

NOTE: The fan will stop when the mode selector switch is in the

OFF position.

3. This parameter can be set, either, locally, or remotely by

the RCMS software.

4. Refer to RCMS documentation for remote activation.

E.12 Local EMS Mode

1. This parameter enables the locally installed EMS module

to control the heater according to the module set points.

If connected to a SCADA system, all weather data will be

transmitted to the system. No other functions are affected

by this mode.

2. The HEAT LED pulses to indicate that the local EMS

module can turn on the heater.

3. When disabled, the HEAT LED will not pulse. It will light up

when conditions are met, but it will not turn on the heater.

E.13 RAIL THERMOSTAT Mode, Normal

1. With the introduction of the 2014 model Hellre, the rail

thermostat operation was reversed. The thermostat now

opens when cold and closes when warm.

2. When enabled, the controller is congured to operate with

the new, close on rise (COR), thermostat.

E.14 RAIL THERMOSTAT Mode, Reverse

1. When enabled, the controller is congured to operate

with the previous, open on rise (OOR), thermostat.

E.15 Failure Shutdowns and Alarm Indications

1. In the event of a failure, the controller ceases the heater

operation and indicates alarm.

2. While the heater is shutdown and indicating alarm the

controller continues communications with the RCMS

software. All start requests, local or through the RCMS

software, are ignored until the problem is resolved.

3. The controller indicates the nature of the failure in three

ways. LED’s on the controller, an alarm contact closure,

and error codes communicated via the RS-485 serial port

when under RCMS control.

NOTE: With the exception of the communications TD, RD, and

TX LED’s. Solid green, solid green with a red pulse, or

yellow LED’s indicates normal status. Solid red and

alternating LED’s indicate a failure. This is true for the

controller only, not the EMS module.

4. There are two types of failure alarms, minor and major.

Both cease the heater operation, however, minor alarms

clear when the condition that caused the failure recties

itself. Major alarms, which are more serious and require

inspection, must be manually reset.

E.16 Fault Conditions

1. A failure exists when the STATUS and the ALARM LED’s

are solid red.

2. In addition, an alternating LED of equal duration on and off,

or red and green indicates the failure condition.

3. Heaters connected via the RS-485 port to a network and

RCMS software will communicate fault codes.

18

18

Controls & Indications

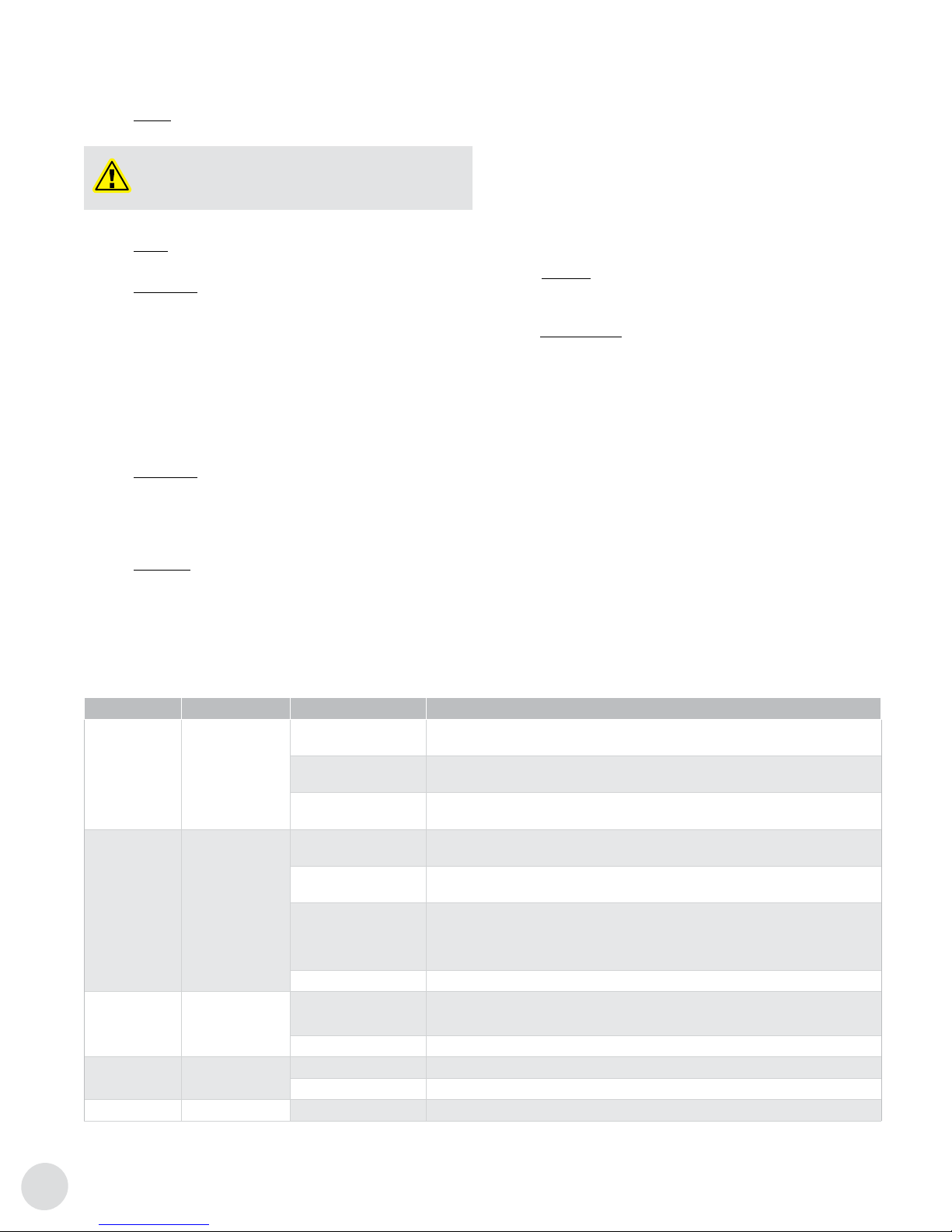

Table 10 – Fault Condition Codes and LED States

Code Alarm

Type Fault Condition LED State

1Minor

Selector switch left in

OFF position for more

than 60 minutes.

ENABLE Dark

2Major

Air switch does not

open after fan motor

turned off.

AIR SW Alternating

3Major

Air switch does not

close after fan motor

turned on.

AIR SW Alternating

10 Major Flame failure at start

up.

FSR

ALARM Alternating

11 Major Loss of ame signal

while running.

FSR

ALARM Alternating

12 Major 4 FSR alarms within 2

minutes.

FSR

ALARM Alternating

13 Major

Gas valve does

not energize when

expected.

FSR

CHECK Alternating

14 NA FSR in alarm. FSR

ALARM Solid Red

20 Minor

Cycling thermostat

failed to close after 10

minutes.

CYCLING Alternating

21 Major

Maximum output air

temperature exceed.

High limit thermostat

closed momentarily.

HIGH LIM Alternating

30 Minor

Controller in

conguration mode.

JP1 jumper shorted.

(none)

31 Minor EMS module TEST

switch on.

SENSOR

WET Solid Red

E.17 Aggressive Retry Feature

1. The controller has an aggressive retry feature. It is

intended to avoid nuisance failure shutdowns and

alarm indications due to temporary conditions, such as

condensation on the igniter and or ame rod, which are

rectied with repeated attempts.

2. In the event of an FSR alarm, as indicated by the FSR

ALARM LED, occurring at start up or under normal

operation, this feature will reset the FSR and allow up to 4

trials for ignition attempts within 2 minutes.

3. Between attempts the STATUS LED alternates red and

green and after 20 seconds the FSR is reset, as indicated

by a pulse of the RES LED and the clearing of the FSR

ALARM LED.

4. After 4 failures within 2 minutes, the heater ceases

operation, the controller locks out, the STATUS LED turns

solid red, the run indications are removed and the alarm

indications applied with the ALARM FSR LED alternating

on and off.

E.18 Reset

1. Prior to performing a reset:

WARNING

WARNING. If you smell gas; Immediately extinguish all

sources of ignition and turn off gas source.

Call qualied service technician to repair leak.

1.1 Toggle the selector switch to OFF.

1.2 Gain access to the controller by removing the

electrical access panel.

NOTE: Note the status of the controller LEDs, contactor thermal

overload relay reset (three phase models only), control

panel circuit breaker, and motor circuit breaker. Connect

a display module to the FSR and note the current and

past fault histories.

1.3 Close any tripped or open breakers. Green means

safe and red means danger circuit energized.

1.4 In the case of three phase models, if found tripped,

reset the thermal overload relay located on the panel

and connected to the contactor.

WARNING

WARNING. Risk of cutting ngers or hand.

Open motor circuit breaker before opening combustion

chamber access panel. Keep clear of fan.

1.5 In the case of single phase models, OPEN THE

MOTOR CIRCUIT BREAKER. Remove the

combustion chamber access panel and, if tripped,

reset the thermal overload switch found on the

motors junction box. Close the combustion chamber

access panel and close the motor circuit breaker.

2. Press and release the controller reset.

1919

Controls & Indications

E.19 Energy Management System (EMS)

Adding the EMS allows a heater to operate automatically,

or to act as a weather station when part of a network of

heaters controlled by the Fastrax® RCMS.

The system includes a module, a precipitation detector,

ambient temperature sensor, and rail thermostat. Once

installed, the controller recognizes the EMS module and

works in conjunction with it.

Controls:

NOTE: These settings are true for AUTO mode only, with the

exception of the TEST switch.

These setting are overridden when operated in REMOTE

SCADA mode by the corresponding Fastrax® RCMS

software parameter.

1. SNOW-RAIN:

1.1 This dial adjusts the temperature set point between

-12°C to +12°C.

1.2 Precipitation detected when the ambient

temperature is below this set point is considered

snow or above it is rain.

2. LOW TEMP:

2.1 This dial adjusts the temperature set point between

–55°C to +5°C.

2.2 The EMS will not request the heater to operate when

the ambient temperature is below this set point and

snow is detected.

3. DE L AY ON:

3.1 This dial sets the length of the delay, 0 to 30 minutes,

before making the heater request.

3.2 When snow is sensed continuously for the duration

of the delay on period the heater request is made. If

at any time during the delay snow is not sensed the

timer is reset.

4. DELAY OFF:

4.1 This dial sets the length of the delay, 0 to 60 minutes,

before removing the heater request.

4.2 When snow is no longer sensed the heater request

is held for the duration of the timer. If at any time

during the delay snow is sensed the timer is reset.

5. TEST:

5.1 This switch simulates precipitation when ON. Used

to test the module operation.

6. SENSITIVITY:

6.1 This dial adjusts the precipitation detector sensitivity

between the least, 1, and most, 6. For example,

when set at 1 the detector has to be very wet to

indicate precipitation.

7. INDICATIONS:

7.1 On the module are a number of status LED’s

intended to aid the user’s understanding of the state

of operation. See table for full description.

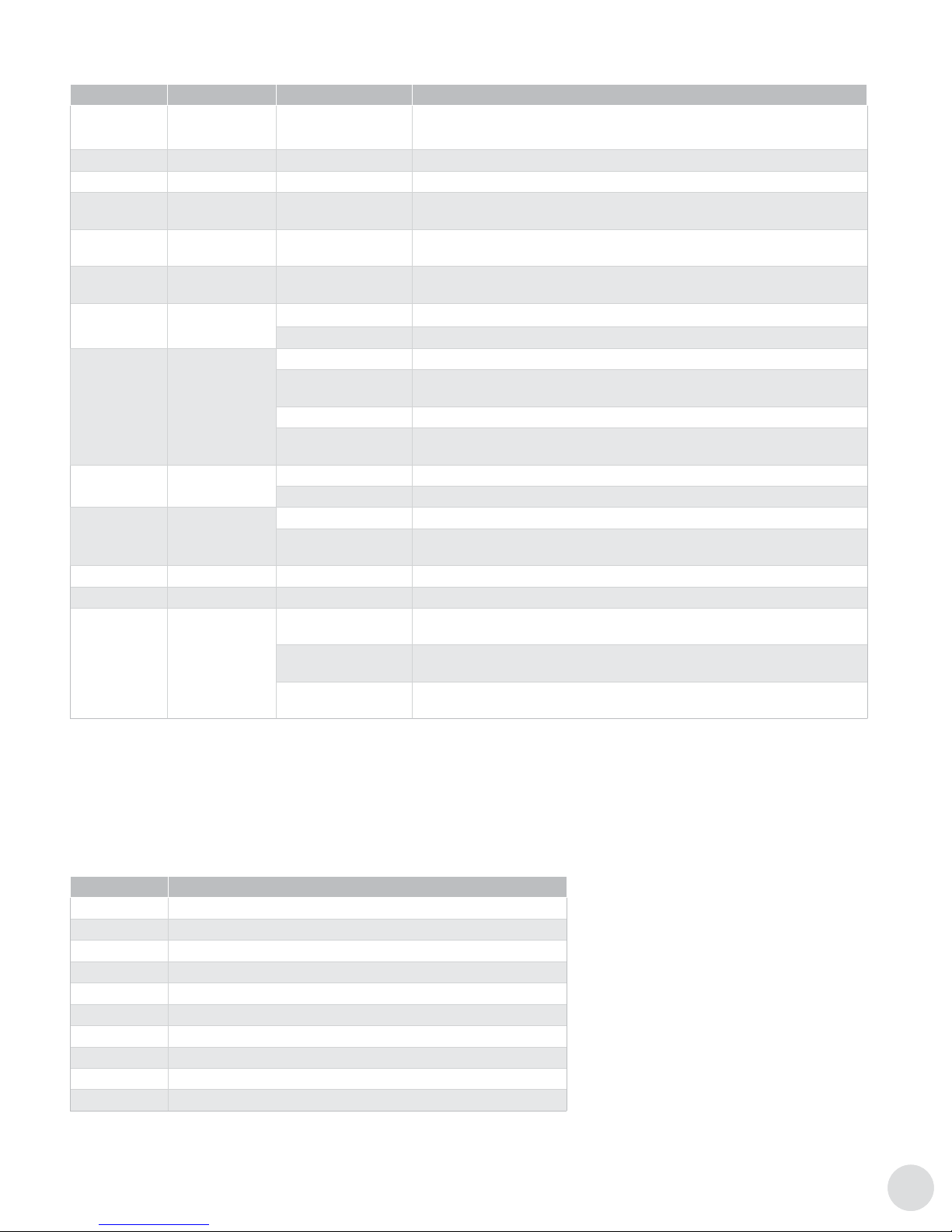

Table 11 – Status LED’s

LED Name Description State Indication

STATUS Processor status

Green with

a red pulse

Processor

functioning normally.

Off

Solid green

Solid red

Processor failed.

POWER Power supply On Module energized.

COMM Communications Flashing

Indicates

communications

with controller.

HEAT ON Heater request On EMS request to turn

on heater.

LOW

TEMP Low Temperature On

Ambient

temperature is

below set point.

Heater will turn off

or not turn on if

requested.

DEL AY

TIME Delay Time

On with a

pulse off

Delay active.

Delay on when

HEAT ON is off.

Delay off when

HEAT ON is on.

Off with a

pulse on No delay.

SENSOR

WET

Precipitation

sensor wet On Precipitation above

set point.

20

20

Controls & Indications

E.20 Terminal Blocks

1. The controller interconnects with the control panel by

means of 2 board level headers, TB-1 and TB-2, which

accept wire harness plug connectors.

2. The controller and EMS module connect via a ribbon cable

that plugs into the 10-pin header found on each. The

ambient temperature sensor connects via the RJ11 header.

Table 12 – Terminal Blocks

Name Description

TB -1 Precipitation detector 24VAC power supply

TB-2 Precipitation detector

JP1 Ambient air temperature sensor RJ11 header

10-Pin header* EMS power and signal connection

* Located in the upper left corner.

E.21 Inputs and Outputs

1. PRECIPITATION DETECTOR: As its name implies, it

senses precipitation that can be in the form of rain or

snow.

Snow landing on the detectors heated cone and heated

sensing grid, melts to form water drops that can be sensed.

The head design draws blowing snow into the detector

where it can be sensed.

See the installation section for mounting instructions.

There are no adjustments on the detector itself. Sensitivity

adjustments are made on the controller.

2. AMBIENT TEMPERATURE SENSOR: The ambient

temperature sensor is mounted beneath the air intake

hood. The controller compares the measured temperature

to the SNOW-RAIN and the LOW TEMP set point.

3. RAIL THERMOSTAT: The rail thermostat optimizes

fuel consumption and performance while the heater is

requested. It functions independently of the EMS module,

cycling the heater off when the rail temperatures rises

above 9°C (49°F) then back on again once the temperature

drops below 3°C (37°F).

Table of contents

Popular Heater manuals by other brands

Gabarron

Gabarron ADL 5030/14 Installation instructions and user guide

Bionaire

Bionaire BCH4175 instruction manual

Fakir

Fakir prestige HL 300 Instructions for use

Somogyi

Somogyi home FKF 54202 instruction manual

Heatstore

Heatstore HSACW9000 Installation, operation and maintenance instructions

LIFEPLUS

LIFEPLUS QH-80B owner's manual