41001379 Iss 01

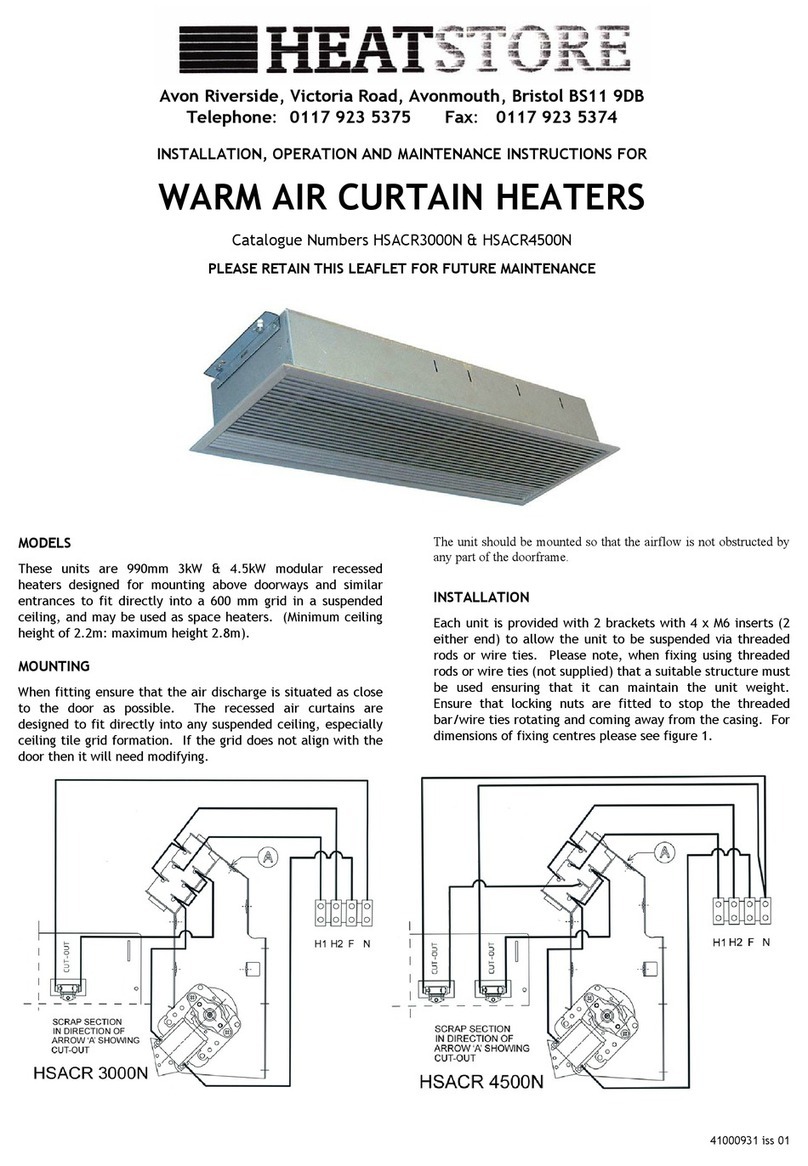

ELECTRICAL CONNECTIONS

The heater is suitable for connection to a 415 volt 3 phase 50Hz

supply. .

On full heat setting the load is 9, 12 or 14kW depending of the

model.

The connections between the unit and remote switch box are

shown on the rear of this instruction sheet, Fig 8.

FUSES

The motor and switch circuits are protected by two fuses

which have a 3 amp rating. Ensure that any replacement is of the

correct size and rating.

MAINTENANCE

ALWAYS ENSURE THAT THE MAIN EXTERNAL ELECTRICITY

SUPPLY IS SWITCHED OFF BEFORE SERVICING OF THIS

SCREEN-ZONE HEATER.

To obtain the best results from the heater it is essential to

avoid the accumulation of dust and dirt within the unit and on the

inlet and discharge grilles. Regular cleaning is necessary with

particular attention to the fronts and backs of the fan motor blades.

Cleaning of the fan is best carried out with a soft brush.

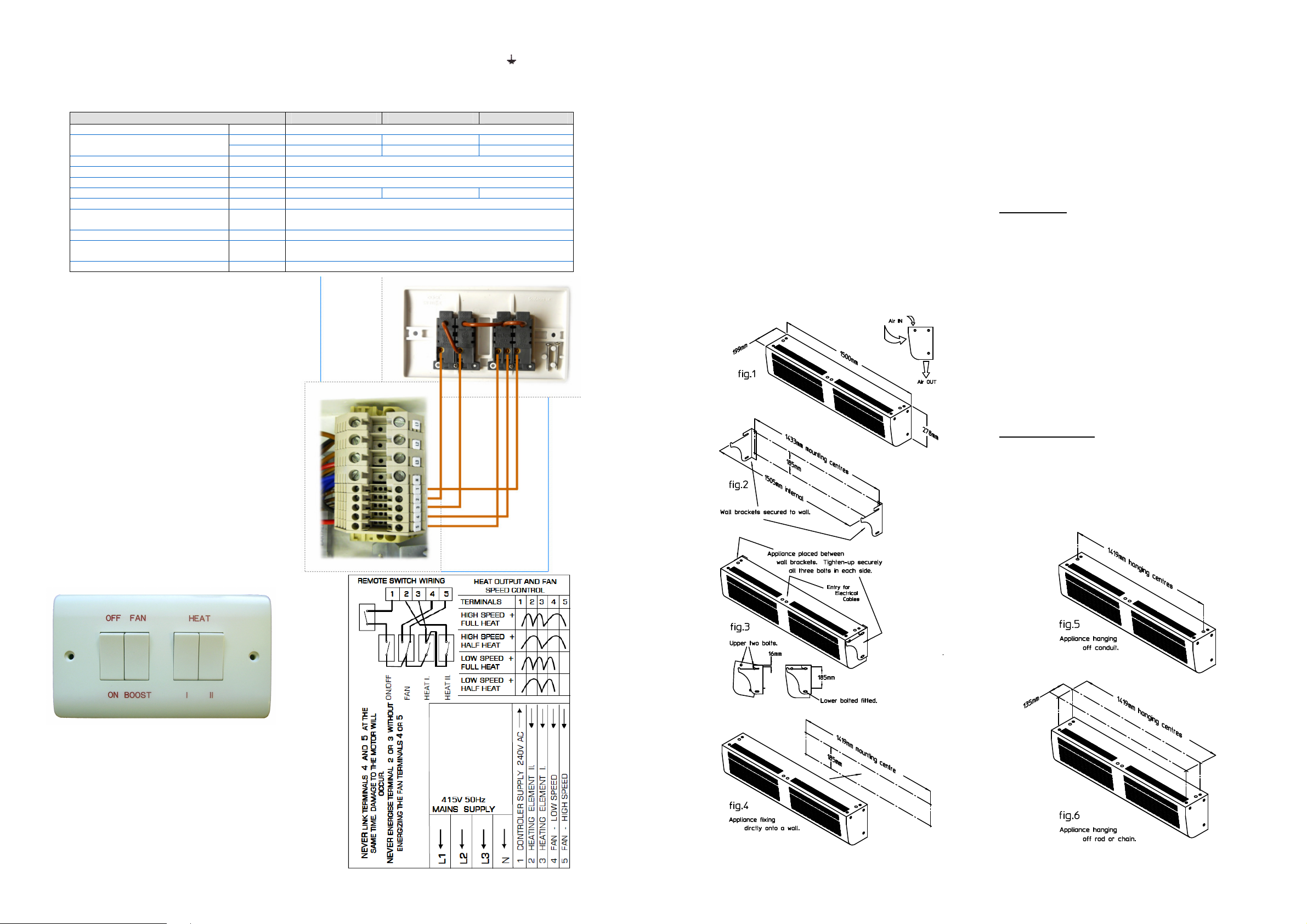

CONTROLS

The units are designed to provide 2 levels of heat ie half heat

and full heat, together with 2 fan speeds, normal and boost. The

remote control box houses 4 switches. The switch plate is marked

as shown below. The functions of the switches are as follows:-

SWITCH 1 (left-hand) ON/OFF

SWITCH 2 FAN SPEED CONTROL

SWITCH 3 ½ HEAT

SWITCH 3 + SWITCH 4 FULL HEAT

TO REPLACE A SWITCH IN THE CONTROL BOX

a) Switch off the mains supply

b) Remove the switch box cover.

c) Disconnect the wiring to the switch.

d) Release the spring clips and push out the switch.

e)

Fit the replacement switch, reconnect the wiring and replace

the cover.

For safety reasons a good earth connection must ALWAYS be made to the

unit and the control box. On the heater the earth terminal is adjacent to the

terminal block and is clearly marked with the symbol .

The unit should be wired in accordance with BS7671 latest edition

requirements for electrical installations. The installer should ensure that a suitable

fused isolating switch is connected in the mains supply.

THERMAL CUT-OUTS

There are 2 thermal cut-outs protecting the heater, positioned along

the heater box. These cut-outs are connected in series and each or both

may operate in the event of fan failure or restriction to the free flow of air

through the unit. The unit is protected by manual type cut-outs which

may only be reset by hand when the heater is switched OFF and has

cooled down. If the cut-outs trip, check the inlet and outlet grilles for

airflow restrictions.

TO RESET THE CUT-OUTS

a) The cut-outs are reset by switching OFF mains power to the

appliance and allowing the appliance to cool for 20 minutes.

b) Remove the appliance lid and locate the 2 cut-outs. Ensure mains

power is OFF. Reset each cut-out by pressing the white 5 mm

square reset button located on each cut-out.

c) Replace appliance lid. Switch ON the appliance. The cut-outs will

be reset. If the cut-outs trip again a qualified electrician should be

consulted.

SPARES

It is essential when ordering spares or replacement parts to state

the model number HSACW9000, HSACW12000 or HSACW14000 and

the serial number on the rating place fixed to the top of the unit.

In the interest of progress the Company reserves the right to vary

specifications from time to time without notice. The material listed is

offered subject to the Company’s General Conditions of Sale, a copy of

which can be obtained on request.

MOUNTING

When mounted over a doorway, the unit should be mounted as low

as possible and not more than 3.4 metres above the floor. A single unit

will give adequate coverage for a 1.2 metre doorway. For wider

doorways, units may be mounted end to end. The heater should be

mounted so that the inlet or outlet air flow are not obstructed in any way.

A clearance of at least 300 mm should be maintained around the inlet

and outlet grilles.

INSTALLATION

Having removed the appliance lid, to acquire these Instructions, also

ensure that the Remote Control Switch Box, which is packed inside the

appliance with these Instructions, is removed and retained.

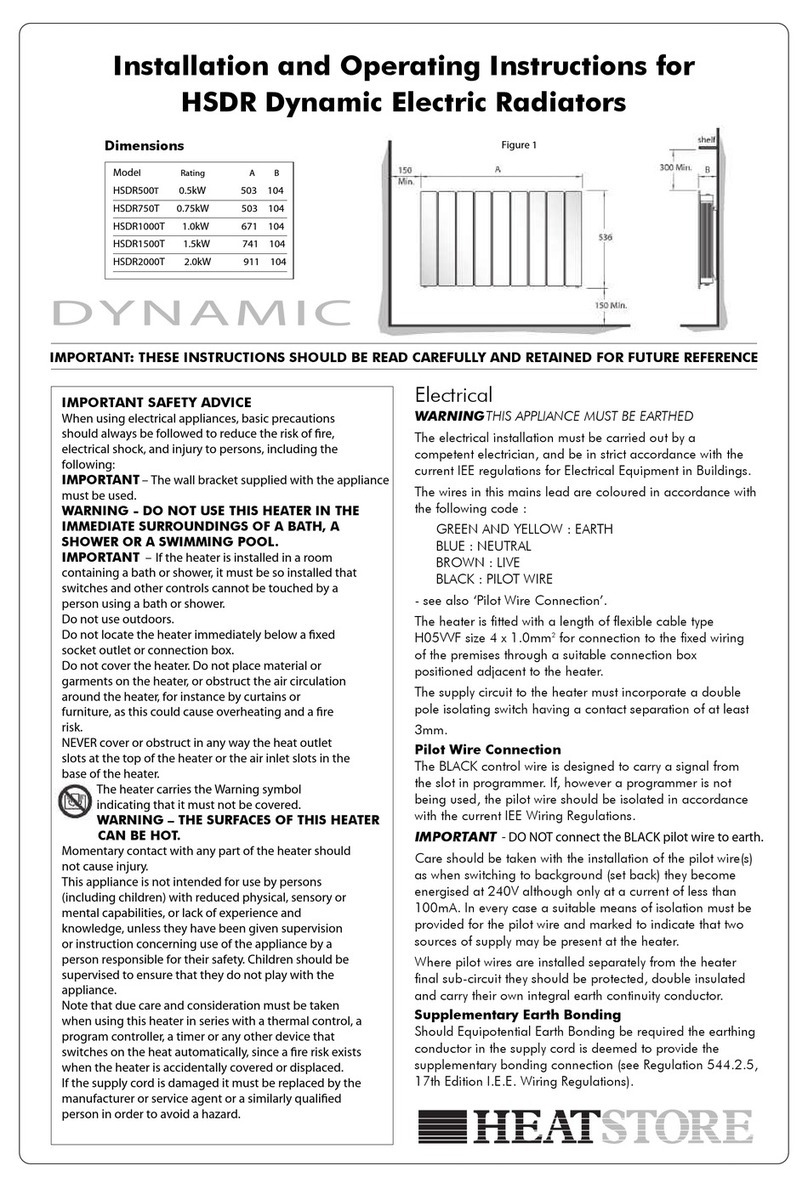

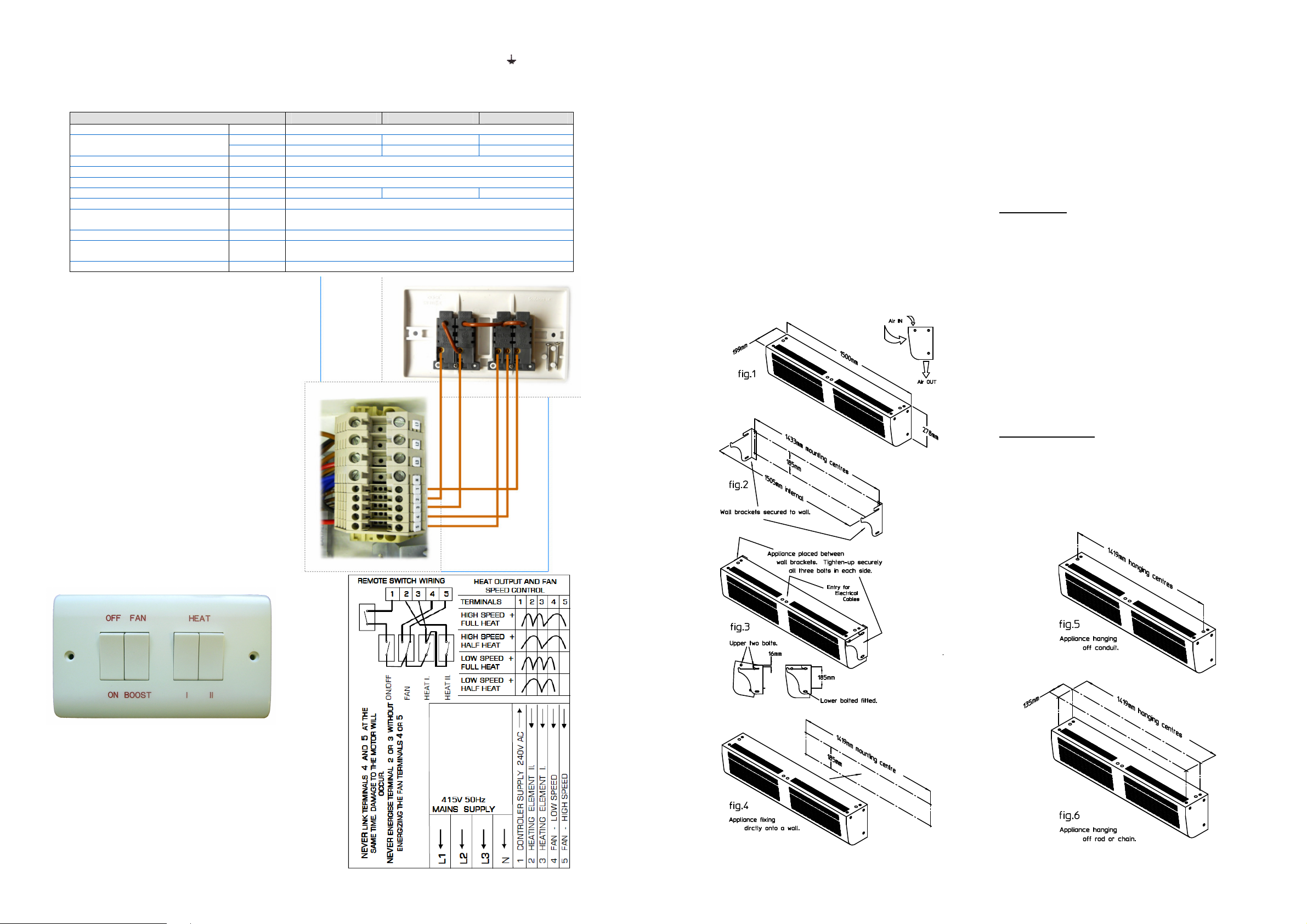

The appliance ‘air flow’ and ‘external dimensions’ are shown in Fig 1.

The heater may be mounted in one of several ways ie:-

1. Wall Mounting

a. Using WALL BRACKETS supplied.

Onto a suitable vertical wall or bearers, the 2 wall brackets are

secured at the centres shown in Fig 2. The appliance, with 2 upper bolts

threaded securely into each face, is then fitted onto/between the wall

brackets as shown in Fig 3. The lower fixing bolts are then fitted through

each wall bracket into each side of the appliance.

The upper 2 bolts allow the appliance to be slipped onto, and held

by, the wall brackets. The fitting of the lower bolts in each side locks the

appliance to the brackets.

Tighten-up securely all 3 bolts in each side.

b. DIRECTLY to a suitable vertical wall or bearers.

Using 4 x No.12 wood screws. Screw through the holes in the

appliance case rear, at the centres shown in Fig 4. Keyhole slots are

provided for the upper 2 fixing screws, allowing the appliance to be

initially located. The lower 2 fixing screws pass through the appliance

rear, supporting the appliance and preventing any movement up off the

upper 2 screws.

The wall surface to which the appliance is to be mounted must be

flat to avoid any distortion of the appliance casing.

2. Suspended/Hanging

a. Using Ø20mm CONDUIT.

The appliance may be suspended by Ø20mm conduit via two

suitable holes provided in the top of the appliance, see Fig 5.

b. Studding.

The heater offers four M8 threaded holes as shown in Fig 6. from

which the appliance may be suspended.

Electrical Data HSACW9000 HSACW12000 HSACW14000

Supply voltage 415V three phase 50Hz

kW 9 12 14Total load

A/pha 12.6 16.7 19.6

Motor power W 60

Max Running current Amps 0.6

Internal fuse size amps Amps 3

External fuse size amps A/pha 16 20 25

Cable terminal size 10mm

2

Max

Mains terminal block position Centre of base unit.

Terminals N; L1; L2 & L3

Control terminal block cable size 4mm

2

Max

Control terminal block position Centre of base unit.

Terminals 1-5

Control terminal block current Amps 0.6