FASTRON. DTC1 Series User manual

DTC1Series

IntelligentTemperature/HumidityPID

Controllerwith60StepProgramControl

UserManualV1.0

ThankyouforpurchasingFastronDTCseriesPID

Temperature/HumidityController.Thismanualexplains

howtoinstallandoperateyournewPIDController.

Beforeoperation,pleasereadthismanualfirsttofully

understandtheoperationofthisproduct.Thiscontroller

shouldbeinstalledbyaqualifiedElectricalEngineer,

TechnicianorElectrician.Forspecifictechnicalsupport

pleasecontactyouragentorrepresentative.

SafetyWarning

1a)AvoidtouchingtheACpowerterminalsafterthecontrollerispowered

on.

1b)Alwaysensurethesupplypowerisofffirstbeforeconnectingany

wires.

1c)Donotoperatethisinstrumentinplacesfullofexplosiveand

combustiblegases.

2.IncorrectConnectionofthePowerSupplycancausepermanent

damage.

3.Themaximumtorqueoftheterminalsshouldnotexceed8KN.

4.Pleasedonotuseinthefollowingcircumstances:

●wherethetemperaturechangesdramatically

●Placeswherehumidityistoohigh(~85%)andwaterisproduced

●Wherevibrationorimpactishigh

●Wherecorrosivegasesordustarepresent

●splashofwater,oilandchemicals

6.AllWiringshouldbekeptawayfromhighvoltage,highcurrentpower

ImprovedFeatures

(1)Slopevalueoffsetcompensation.

(2)2in(input)2out(output):1to2isolatedtransmission,2to1isolatedtransmission

(Optional)

(3)Multiplealarmmodes

(4)TransmissionofPV,SVandMV:forward,reverseanddifferencevaluein8ways.

(5)Outputsoftstartfunction.

(6)Dehumidificationfunction.

(7)ServoMotorControl(Optional)

(8)Optional60Segment,MultiSequence,ProgramControl

ProgrammingMenu

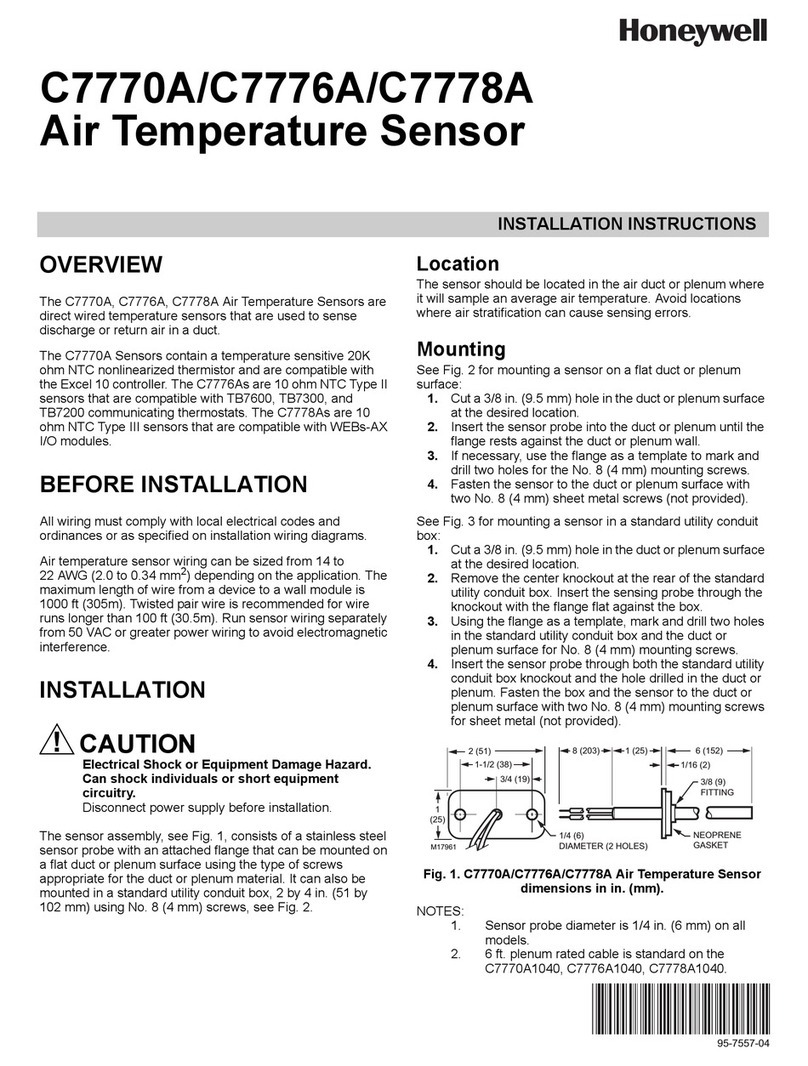

WiringConfiguration

Forapplicationnotesandexamplespleasevisit

https://fastron.com.au/blogs/pidtemperaturecontrollers

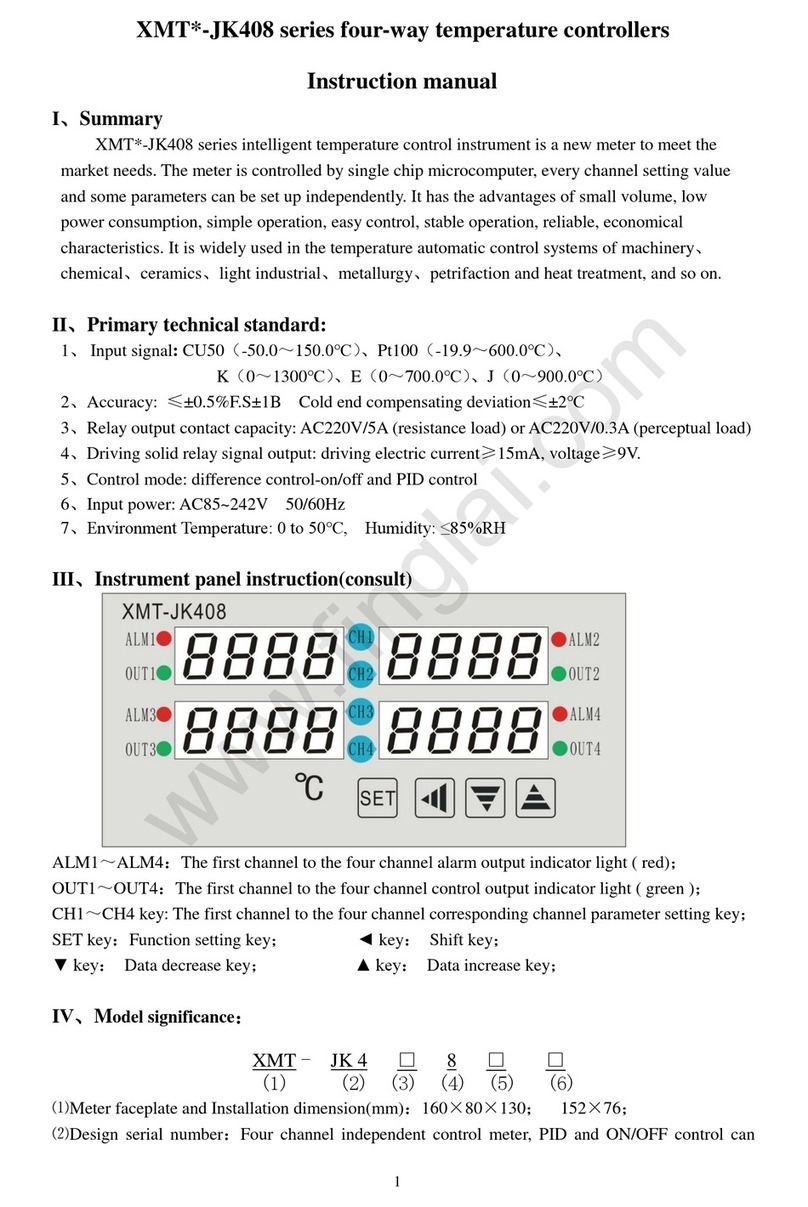

1.SensorTypeSetting

A.PressSET+◄keytoenterLEVEL3

B.OnceyoureachINPPress◄andtheSV

displaywillblink

C.Press▼or▲selecttheinputtype(refertothe

signalinputselectiontable).PressSETtoconfirm

E.Atthesametime,pressSET+◄toreturnto

LEVEL1

2.AL1/AL2Alarmmodesetting

A.PressSETfor5secondstoenterLEVEL2

B.PressSETseveraltimestoaccessAD1,thenpressthe

◄keyandthedisplaywillstarttoflash.

C.Press▼or▲selectthealarmtype(seealarmselection

table)

D.PressSETtoconfirm

E.PressSETtoreturntoLEVEL1

Step(3):SetalarmvalueAL1/AL2

SeeAL1andAL2inalarmmodeTable

A.PressSETkeyseveraltimestoaccessAL1

selection,andthenpress◄toenablethe

selection.

B.Press▲or▼toSETthevalue,andthenpress

the◄keytomovetothenextdigitanddoBoth

AL1andAL2canchoosealarmmodefrom0to10,

whichcanthesamesetting.

C.Aftersetting,pressSETkeytoconfirm.Pattern

EndoutputcanbeselectedasAlarmmode11.

Thereisalsoaconstanttemperatureandtiming

alarmmode19

D.PressSETtoreturntoLEVEL1settingandtest

thealarmfunctionorpatternendoutput.

Step(5):Autotuning(AT)Function

A.Onceinstalledinthefield,carryoutselftuningtoallow

thecontrollertodeterminetheoptimumATparameters.

B.ATcalculationwillchoosetheoptimumPIDParameters

basedonthecontrollersautotuningalgorithm.

C.Themaximumvalueoftheprocesscurveshouldbe

about80%oftherangeofinstrumentdetection.

D.Beforetheprogramisnotstarted(fixedvaluecontrol

STA=0),itisbettertocarryoutATaroundthemaximum

valueoftheprocesscurve(SV=0.3).E.InLEVEL1

process,pressSETkeyseveraltimestoreachAToption,

thenpressandkeytoput"1"tostartATcalculation.

F.ThismachineisusedasafixedvaluecontrolwhenSTA

="0",andasaprogramcontrollerwhenSTA=1,2,3.

G.Oncethecontrollerispoweredon,aslongasSTAdoes

notequal0(theprogramcontrolmachinedoesnotstartthe

programoperation,thecontrollerhasnooutput.

RateofChange/SlopeTemperatureLimit

Whenyoursystemneedsasoftstart(SVpresetslopeheating),pleaseoperateinthefollowingorder:

SETSVvalue→atLEVEL1,pressSETkeytofindRAPtoSETslopetemperaturevalue,and→thenpressSET

keytofindRTMtoSETslopetimeinminutes(forexample,SETslopeto10/min,RAPto10.0,RTMto001.0)

→aftersetting,SVvaluewillbeSETimmediatelyfromthecurrentPVvalueto10/min,untilreachingtheSET

SVvalue.

SlopeheatingprocessPROTheoutputpercentageofnormaltemperaturelightsflashingcontrolprocessis

automaticallycontrolledbyPID

SoftStartFunction

OutputSoftStart

ToenablesimplesoftstartfeaturesettheSVasfollows;

SetSVvalue>Inlevel3pressSETkeytoreachDLY,SETtheoutputsoftstartvalueinseconds(I.e.ifDLYis

setto10,thenthesoftstarttimewillbe10seconds).Exitthemenubypressingsetuntilyoureturntothemain

screen.Nowthesoftstartfunctionisactivatedwhenthecontrolissettobeginheating.

1.Scopeofselection:FastronElectronicsDTCSeriesfittedwithRS485

ModbusRTU“C5”Option

2.Workrealization:dataexchangebetweeninstrumentandhostcomputer

(instrumentcanonlybeusedasslavetoreceiveinterrogationandreply)

3.Serialtransmissionmode:RTU

4.Transmissioninterface:RS485

5.Communicationmedium:shieldedtwistedpair

6.Communicationstacknumber:1~255.Theupperlimitofthenumberof

connectingmetersisrelatedtotheloadcapacityofthehost,typicallyover15

or31metersrequiresignalIsolator/amplifier.

7.Functioncodeimplementation:readholdregister(03),writesingleregister

(06),writemultipleregisters(10)

8.Datalength:

8a)Whenwritingdatatothecontroller,amaximumof16consecutive

instructions(32bytes)canbewrittenatonetime.

8b)Whenreadingthemenudatainsidethemachine,thenonprogrammed

menucanread16consecutivemenusatatime(theunrealizedaddress

outsidetheparameteraddresstableis0),whiletheprogrammedmenucan

onlyread16consecutivemenusatatime

9.Numericalformat:signed16bitbinarycomplement;Thedatareadis10.0

timeslarger;Beforewritingthedata,enlargethedata10.0timesbefore

sendingit;Noticethetransition.

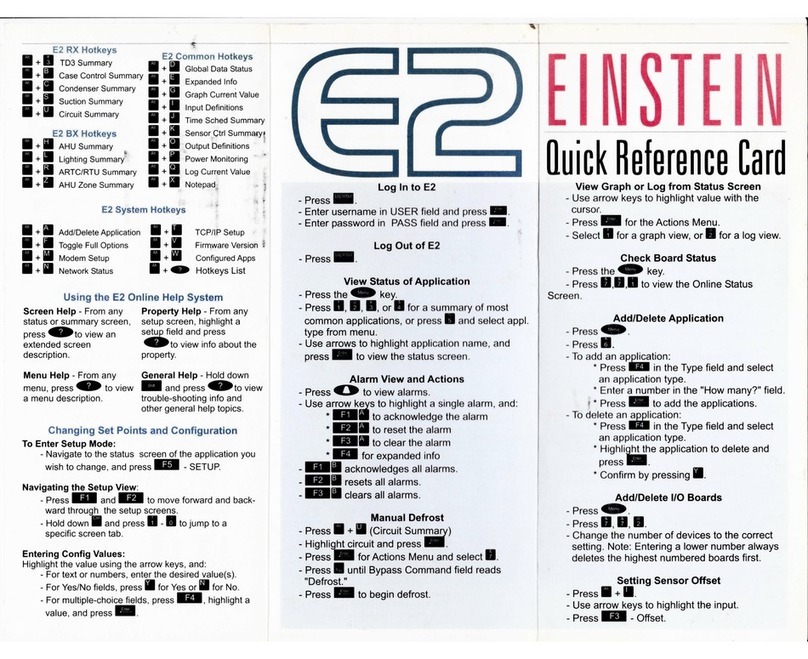

RS485MODBUSRTUcommunication

protocol

Baudrate:4800,9600,19200,38400,76800,

153600bps

Startposition:1

Databit:8

Checkbit:E(even),N(none)Stopbits:1,2

Framecheckmethod:(CRC16)

Messageformat:(N=2)

Troubleshooting

CommunicationApplicationNotes

1.ReadAMandAM1(coldcontrolmanual)menus,0represents

manualstate,1representsautomaticstate.

2.RAPistheprogramcontrolmenu,read,return0X0000

representstheprogramcontrolclose,return0X0001represents

theprogramcontrolstart:write0X0000toclosetheprogram

control,write0X0001tostarttheprogramcontrol,write0X0002

tostoptheprogramcontrol,write0X0002toendthe

suspension,continuetoruntheprogramcontrol.

3.Beforewritingtheprogramcontrolledmenu,pleasewrite

0x0000toRAPtoclosetheprogramcontrolledmenu.

4.BeforewritingMV/MV1threshold,pleasefirstwrite0x0000to

AM/AM1tomakethesystemswitchtomanualcontrol.

5.Whenthemultiplieris10,thereturneddataismagnified10

times.

6.PV1andPV2arereadonlyparameters.

7.Thereshouldbea150ms+timeintervalbetweenwrite

instructions,nomatterthesameaddressornotnot.instrument

failure,andthetimeintervalshouldbenolessthan150

milliseconds.

DTC1C5CommunicationsManual

This manual suits for next models

1

Table of contents

Other FASTRON. Temperature Controllers manuals