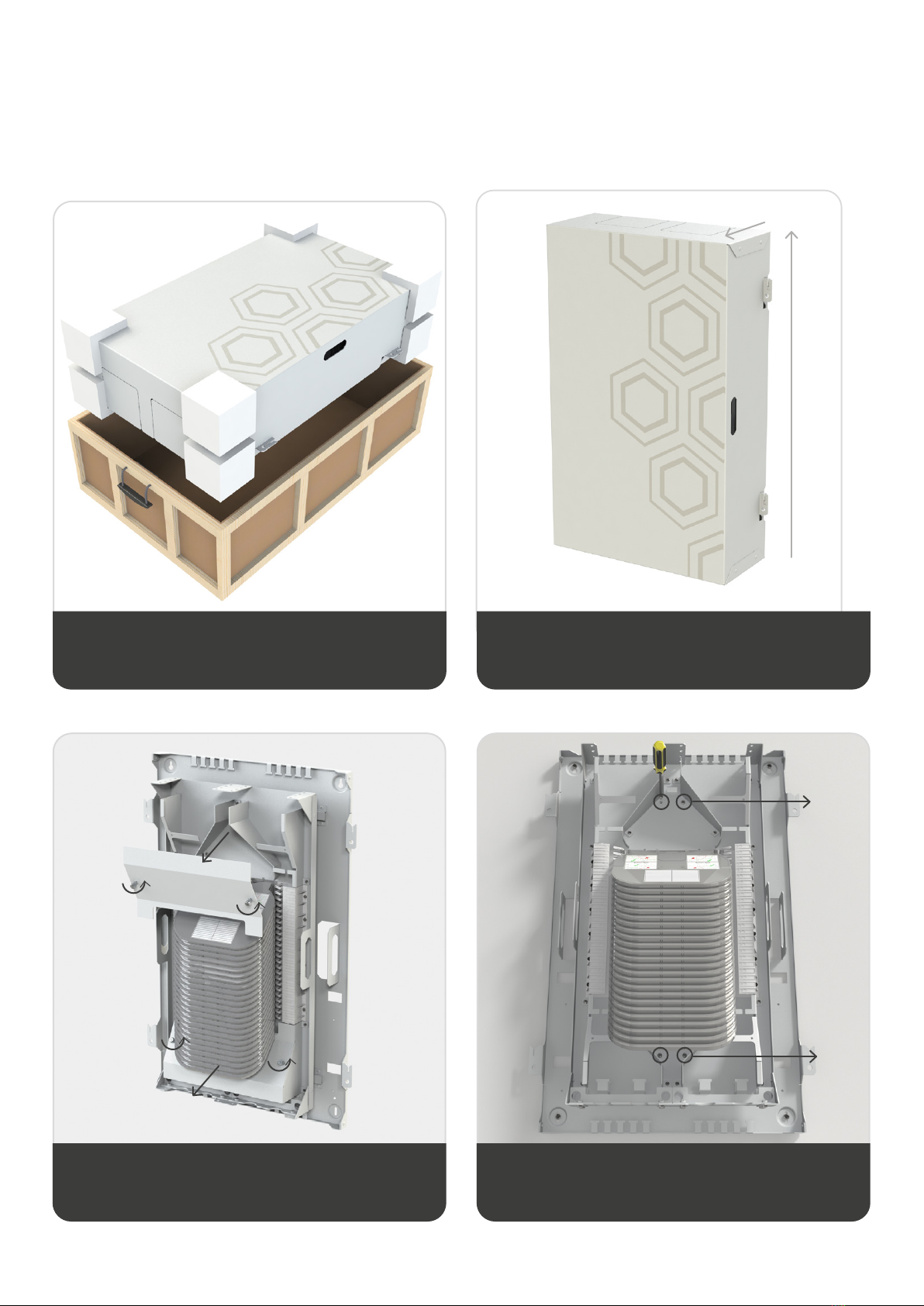

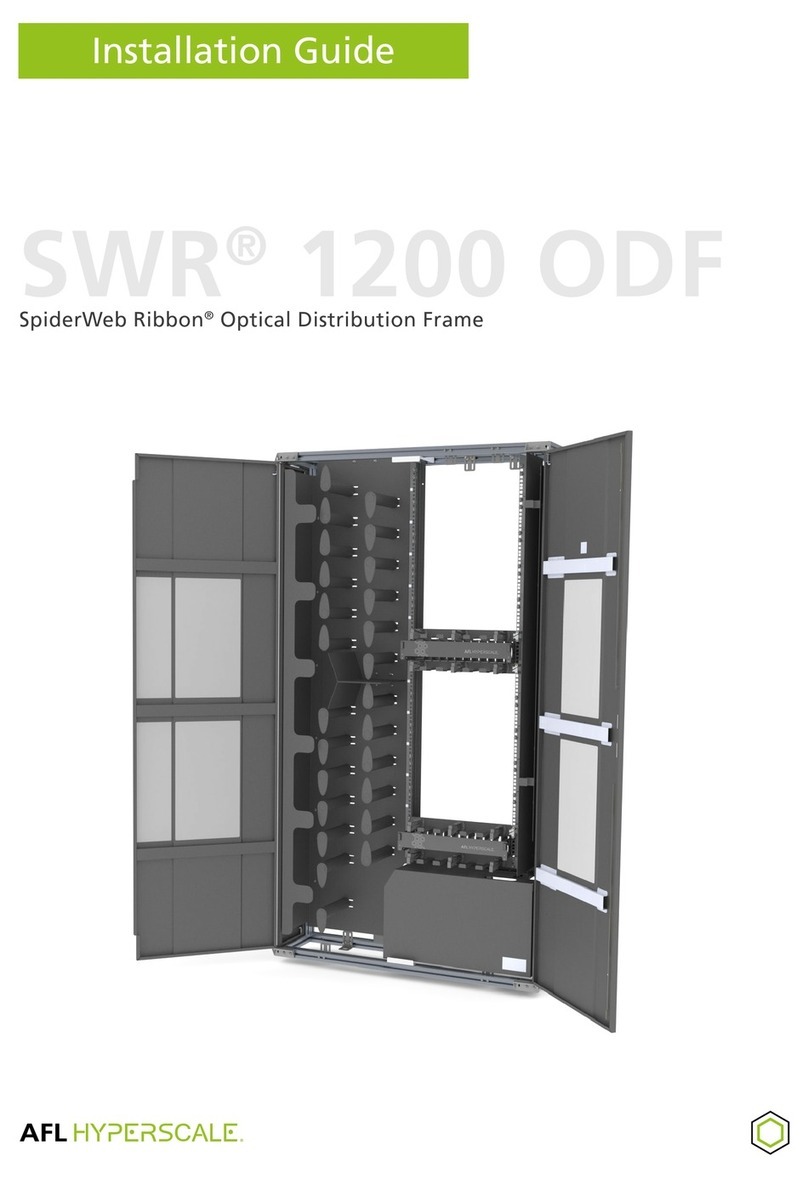

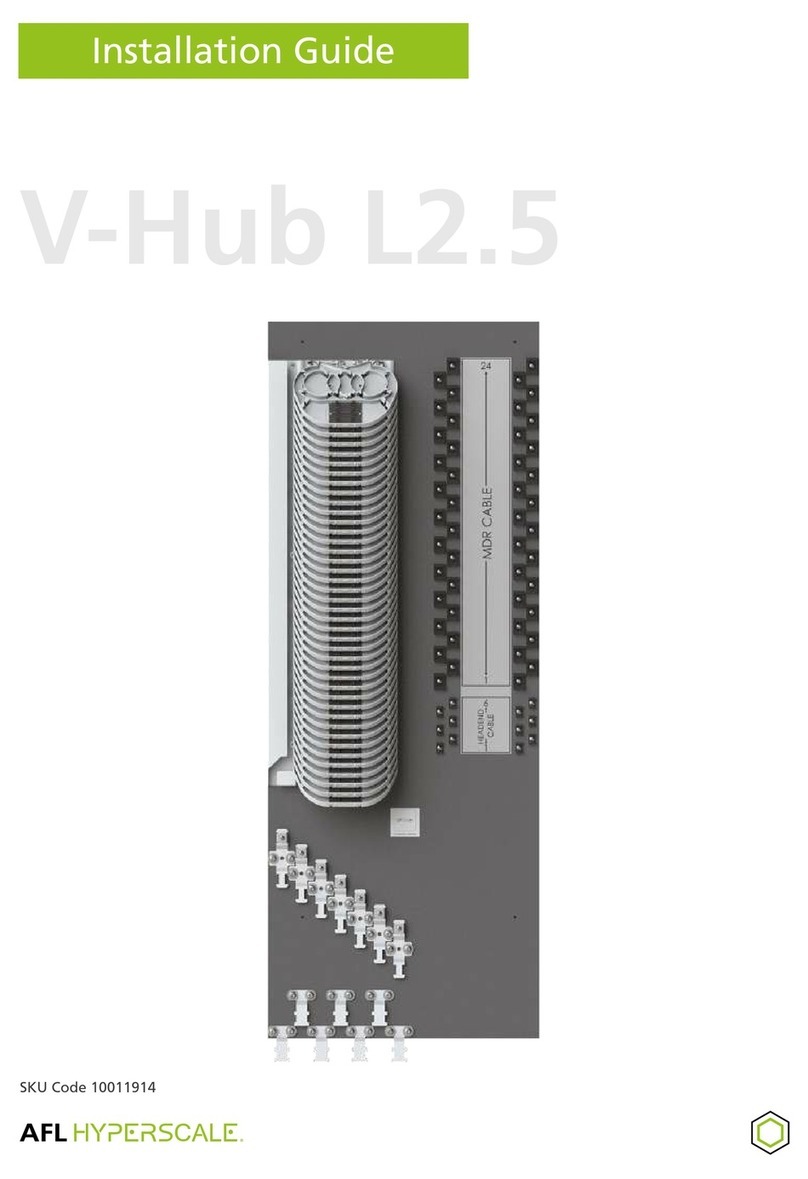

AFL Hyperscale 20RU User manual

Other AFL Hyperscale Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Alfalaval

Alfalaval T35 instruction manual

HIK VISION

HIK VISION DS-K3B601SX Series quick start guide

Strack

Strack PowerMax SN5650-PMO-0330 operating instructions

MYPV

MYPV AC-THOR i Assembly instructions

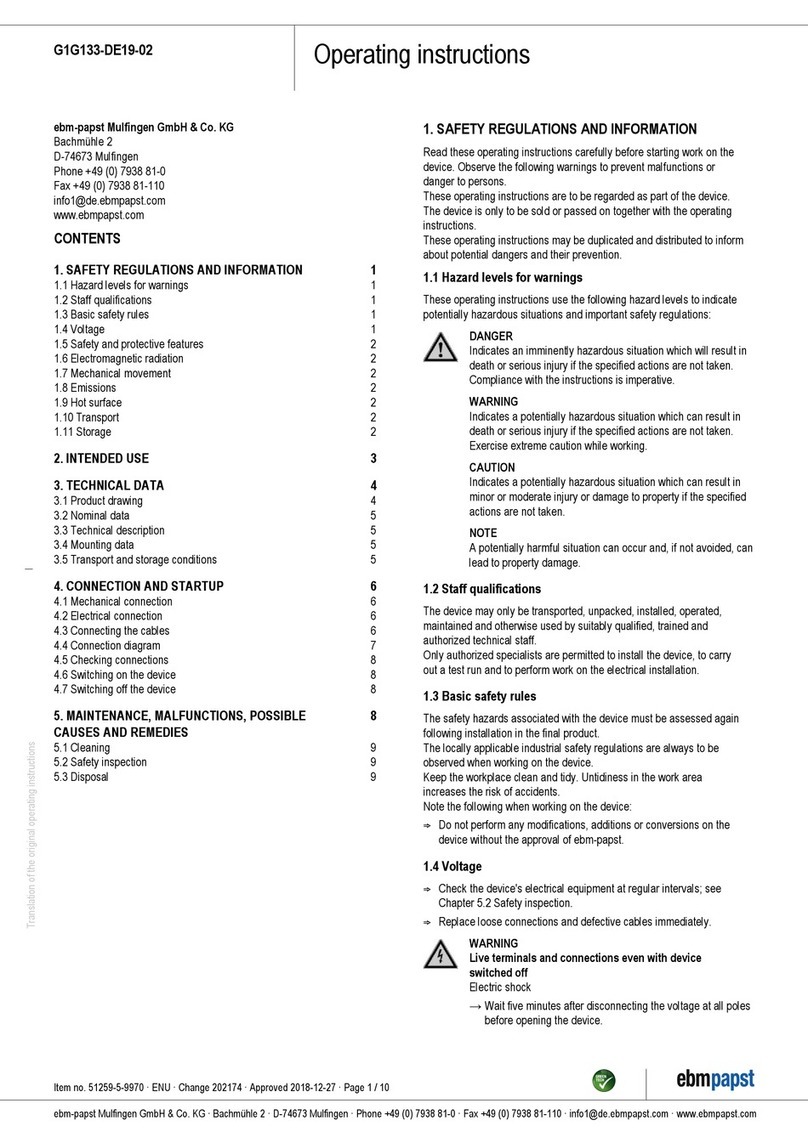

Ebmpapst

Ebmpapst G1G133-DE19-02 operating instructions

Self Climat

Self Climat DN 50 Fitting and operating instructions

KEBCO

KEBCO COMBISTOP 38 Instructions for use

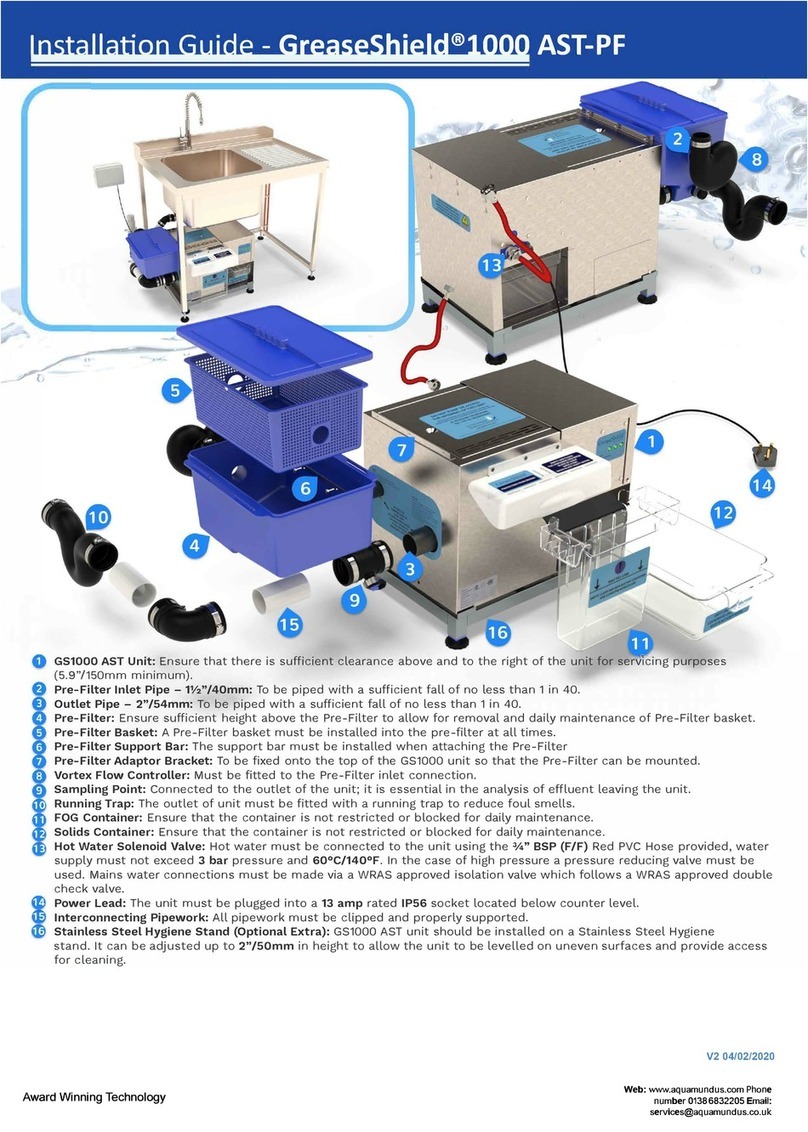

aquamundus

aquamundus GreaseShield 1000 AST-PF installation guide

Oriental motor

Oriental motor EZS II Series operating manual

Cold Jet

Cold Jet PE50 PRE-INSTALLATION

Home Fires

Home Fires Skytech 4000 Series troubleshooting guide

Mark

Mark GSW+ Maintenance instructions

Strack

Strack PowerMax light SN5650-PMOL-0065 operating instructions

TAN Bead

TAN Bead Maelstrom 4810 user manual

woodmizer

woodmizer CBT-430 Safety, Operation, Maintenance & Parts Manual

CustomCrimp

CustomCrimp D105-T420 SERIES Operator's manual

woodmizer

woodmizer BMT 150-1 Safety, Operation, Maintenance & Parts Manual

Gema

Gema OptiFlex 2 V Operating instructions and spare parts list