Faulhaber MC 5010 Use and care manual

WE CREATE MOTION

Communications

Manual

MC 5010

MC 5005

MC 5004

MCS

EN

Imprint

2

Version:

4th edition, 9-11-2018

Copyright

by Dr. Fritz Faulhaber GmbH & Co. KG

Daimlerstr. 23 / 25 · 71101 Schönaich

All rights reserved, including those to the translation.

No part of this description may be duplicated, reproduced,

stored in an information system or processed or

transferred in any other form without prior express written

permission of Dr. Fritz Faulhaber GmbH & Co. KG.

This document has been prepared with care.

Dr. Fritz Faulhaber GmbH & Co. KG cannot accept any

liability for any errors in this document or for the

consequences of such errors. Equally, no liability can be

accepted for direct or consequential damages resulting

from improper use of the equipment.

The relevant regulations regarding safety engineering

and interference suppression as well as the requirements

specified in this document are to be noted and followed

when using the software.

Subject to change without notice.

The respective current version of this technical manual is

available on FAULHABER's internet site:

www.faulhaber.com

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Content

3

1 About this document ....................................................................................................... 5

1.1 Validity of this document ...................................................................................... 5

1.2 Associated documents ............................................................................................ 5

1.3 Using this document .............................................................................................. 5

1.4 List of abbreviations ............................................................................................... 6

1.5 Symbols and markers ............................................................................................. 7

2 Overview ........................................................................................................................... 8

2.1 Basic arrangement of a CANopen device ............................................................. 8

2.2 Pre-conditions for communication ........................................................................ 9

2.3 FAULHABER Motion Manager ............................................................................... 9

2.4 Saving and restoring parameters ........................................................................ 10

2.4.1 Saving parameters ................................................................................ 10

2.4.2 Restoring settings ................................................................................. 11

2.4.3 Changing the parameter set ................................................................ 11

3 CANopen protocol description ...................................................................................... 14

3.1 Introduction .......................................................................................................... 14

3.2 Communication services ....................................................................................... 15

3.3 Identifier distribution ........................................................................................... 16

3.4 PDO (Process Data Object) ................................................................................... 17

3.4.1 PDO configuration ................................................................................ 18

3.4.2 PDO mapping in the standard configuration (status as delivered) ... 18

3.4.3 Dealing with mapping errors ............................................................... 20

3.4.4 Dummy Mappings................................................................................. 20

3.5 SDO (Service Data Object) .................................................................................... 21

3.5.1 Expedited transfer ................................................................................ 21

3.5.2 SDO error description ........................................................................... 23

3.6 Emergency object (error message) ...................................................................... 24

3.7 SYNC object .......................................................................................................... 26

3.7.1 Triggering synchronous PDOs .............................................................. 26

3.8 NMT (Network Management) ............................................................................. 27

3.8.1 Boot up .................................................................................................. 29

3.8.2 Monitoring functions............................................................................ 29

3.8.2.1 Node guarding....................................................................... 30

3.8.2.2 Heartbeat ............................................................................... 31

3.8.3 Setting the monitoring functions ........................................................ 32

3.9 Entries in the object dictionary ........................................................................... 32

3.10 Error handling ...................................................................................................... 33

3.10.1 CAN error............................................................................................... 33

3.10.2 Equipment faults................................................................................... 34

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Content

4

4 Trace ................................................................................................................................ 36

4.1 Trace recorder ....................................................................................................... 36

4.1.1 Trace settings ........................................................................................ 36

4.1.2 Reading the trace buffer ...................................................................... 38

4.1.3 Typical execution of the trace function............................................... 39

4.2 Trace logger .......................................................................................................... 39

5 Communications settings .............................................................................................. 40

5.1 Setting via the CAN network ............................................................................... 40

5.1.1 Setting the node number ..................................................................... 40

5.1.2 Setting the baud rate ........................................................................... 41

5.1.3 Automatic adjustment of the COB-IDs ................................................ 41

5.2 Setting the node number via the object dictionary ........................................... 42

6 Parameter description .................................................................................................... 43

6.1 Communication objects to CiA 301 ..................................................................... 43

6.2 Manufacturer-specific objects ............................................................................. 51

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

About this document

5

1 About this document

1.1 Validity of this document

This document describes:

Communication with the drive via CANopen

Basic services provided by the Communication structure

Methods for accessing the parameters

Drive from the viewpoint of the communication system

This document is intended for software developers with CAN-BUS experience, and for CAN-

BUS project engineers.

All data in this document relate to the standard versions of the drives. Changes relating to

customer-specific versions can be found in the according data sheet.

All data in this document relate to the firmware revision G.

1.2 Associated documents

For certain actions during commissioning and operation of FAULHABER products additional

information from the following manuals is useful:

These manuals can be downloaded in pdf format from the web page www.faulhaber.com/

manuals

.

1.3 Using this document

Read the document carefully before undertaking configuration.

Retain the document throughout the entire working life of the product.

Keep the document accessible to the operating personnel at all times.

Pass the document on to any subsequent owner or user of the product.

Manual Description

Motion Manager 6 Operating instructions for FAULHABER Motion Manager PC software

Quick start guide Description of the first steps for commissioning and operation of FAULHABER Motion

Controllers

Drive functions Description of the operating modes and functions of the drive

Technical manual Instructions for installation and use of the FAULHABER Motion Controller

CiA 301 CANopen application layer and communication profile

CiA 402 CANopen device profile for drives and motion control

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

About this document

6

1.4 List of abbreviations

Abbreviation Meaning

Attr. Attribute

CAN Controller Area Network

CiA CAN in Automation e.V.

COB ID Communication Object Identifier

CS Command Specifier

EEPROM Electrically Erasable Programmable Read-Only Memory

EMCY Emergency

HB High Byte

HHB Higher High Byte

HLB Higher Low Byte

LB Low Byte

LHB Lower High Byte

LLB Lower Low Byte

LSB Least Significant Byte

LSS Layer Setting Service

MSB Most Significant Byte

NMT CANopen network management

OD Object Dictionary

PDO Process Data Object

PP Profile Position

PV Profile Velocity

ro read only

RTR Remote Request

rw read-write

RxPDO Receive Process Data Object (PDO received from the drive)

SDO Service Data Object

PLC Programmable Logic Controller

Sxx Data type signed (negative and positive numbers) with bit size xx

SYNC Synchronisation Object

TxPDO Transmit Process Data Object (PDO sent from the drive)

Uxx Data type unsigned (positive numbers) with bit size xx

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

About this document

7

1.5 Symbols and markers

NOTICE!

Risk of damage.

Measures for avoidance

Pre-requirement for a requested action

1. First step for a requested action

Result of a step

2. Second step of a requested action

Result of an action

Request for a single-step action

Instructions for understanding or optimising the operational procedures

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Overview

8

2 Overview

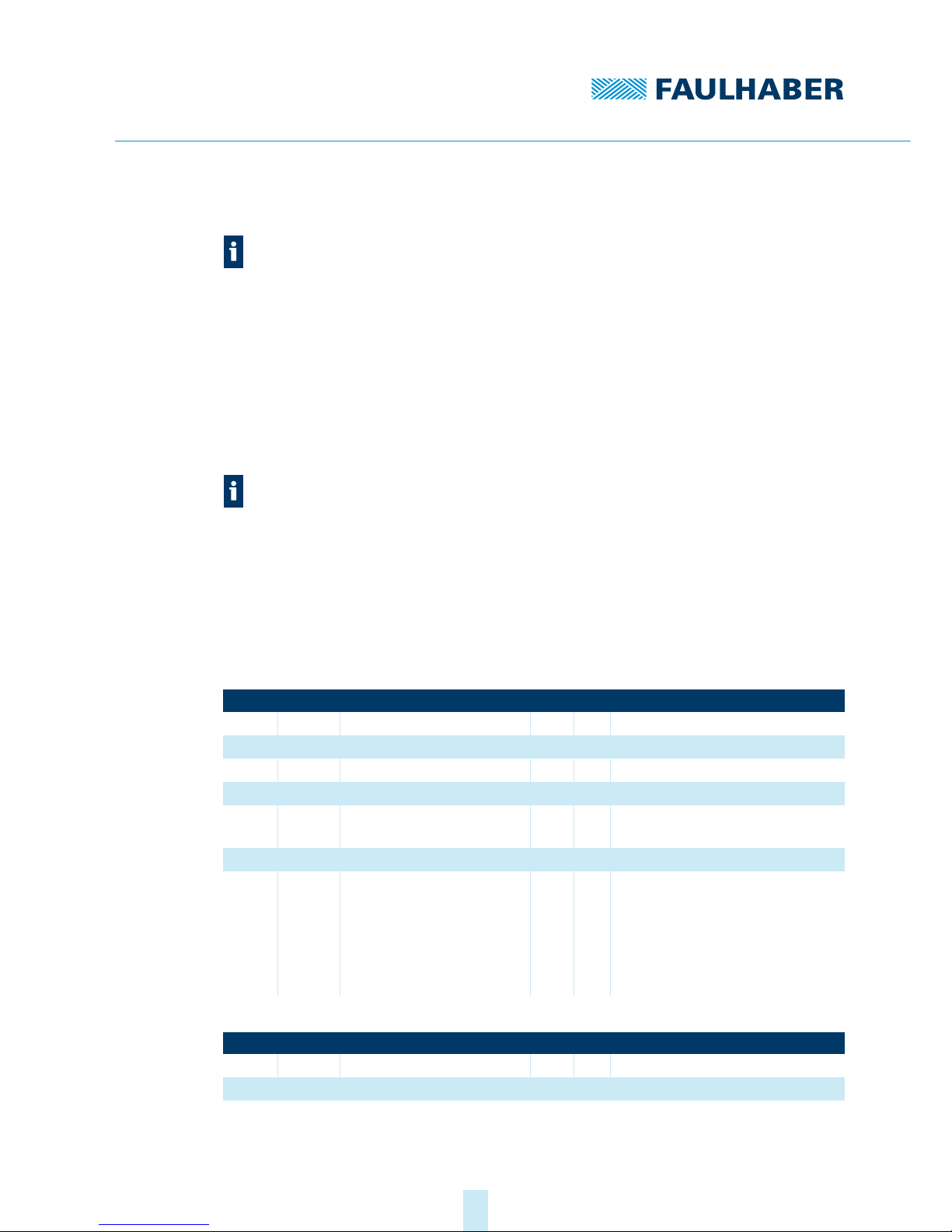

2.1 Basic arrangement of a CANopen device

Fig. 1: Basic arrangement of a CANopen device

Communication services

The CANopen master communicates with the object dictionary via the bus system and use

of the communication services (see chap. 3.2, p. 15).

Object Dictionary

The object dictionary contains parameters, set values- and actual values of a drive. The

object dictionary is the link between the application (drive functions) and the communica-

tion services. All objects in the object dictionary can be addressed by a 16-bit index number

(0x1000 to 0x6FFF) and an 8-bit subindex (0x00 to 0xFF).

The values of the parameters can be changed by the communication side or by the drive

side.

Application part

The application part contains drive functions corresponding to CiA 402. The drive functions

read parameters from the object dictionary, obtain the setpoints from the object dictionary

and return actual values. The parameters from the object dictionary determine the behav-

iour of the drive.

Index Assignment of the objects

0x1000 to 0x1FFF Communication objects

0x2000 to 0x5FFF Manufacturer-specific objects

0x6000 to 0x6FFF Objects of the drive profile to CiA 402

No further details of the application part are given in this document. The communica-

tion with the drive and the associated operating modes are described in the separate

“Drives Functions” manual.

CAN Bus

Process

Object

Dictionary

Communication Application

Communication object

Communication object

Communication object

Communication object

Application object

Application object

Application object

Application object

0x1###

0x2###

0x3###

0x6###

...

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Overview

9

2.2 Pre-conditions for communication

FAULHABER drives are delivered in the unconfigured state. For operation in a CAN net-

work, a unique node number must be assigned and a Baud rate set at commissioning (see

chap. 5, p. 40).

After switching on and initialising, the Motion Controller is at first in the Pre-Operational

state. In order to be able to perform drive functions, the Motion Controller must be

brought into the Operational state (see chap. 3.8, p. 27).

1. Connect the controller to a power supply (supply at least to the electronics).

2. Connect CAN_H, CAN_L, GND to the respective terminals of a host-side CAN connection.

3. Switch on the power and establish a connection via the configuration application.

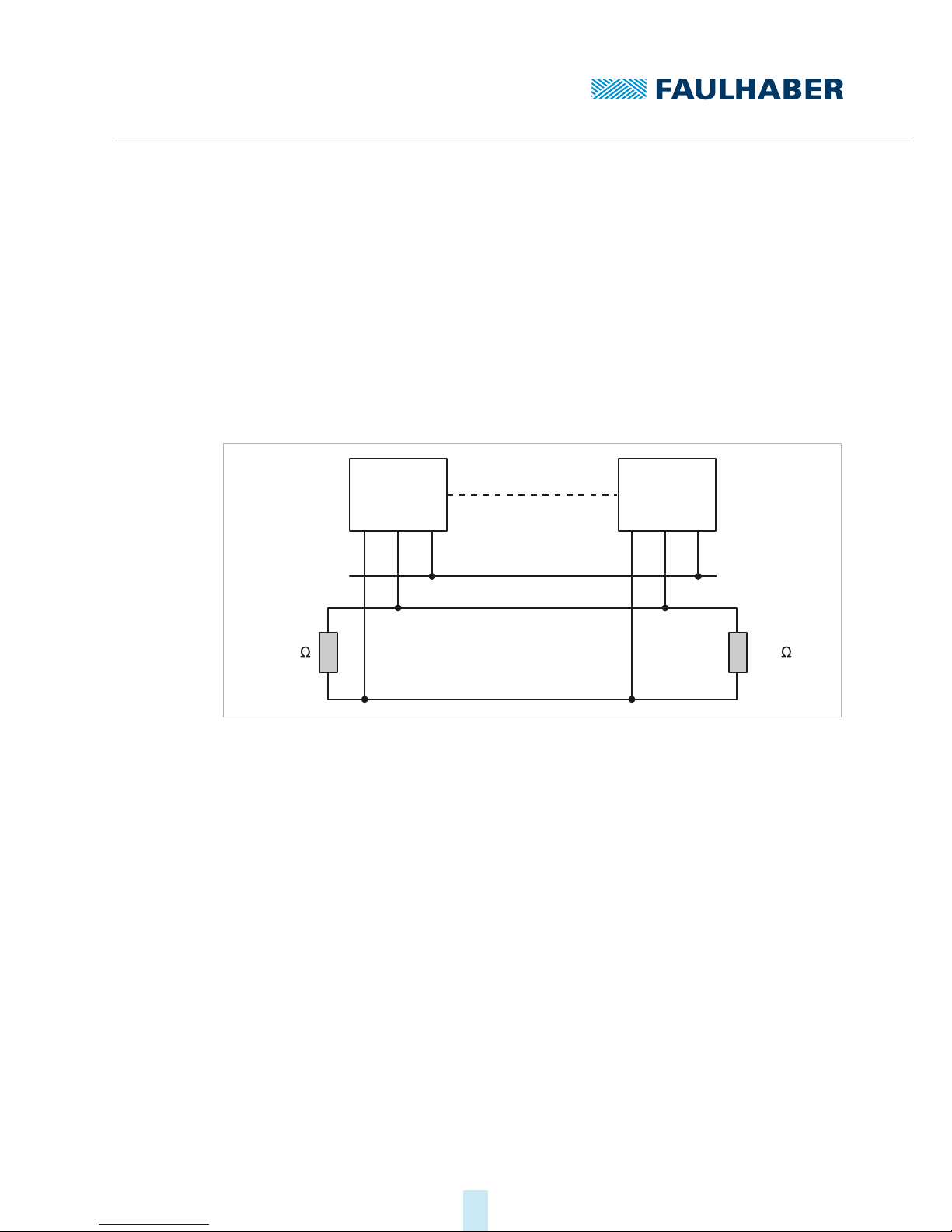

Fig. 2: Connection to the CANopen network

2.3 FAULHABER Motion Manager

We recommend that the first commissioning of a FAULHABER drive is performed using

“FAULHABER Motion Manager“ software.

The FAULHABER Motion Manager permits simple access to the settings and parameters of

the connected motor controller. The graphical user interface allows configurations to be

read, changed and reloaded. Individual commands or complete parameter sets and pro-

gram sequences can be input and loaded to the controller.

Wizard functions support the user when commissioning the drive controllers. The wizard

functions are arranged on the user interface in the sequence they are normally used:

Connection wizard: Supports the user when establishing the connection to the con-

nected controller

Motor wizard: Supports the user when configuring an external controller to the con-

nected motor, by selecting the respective FAULHABER motor

Control setting wizard: Supports the user in optimising the control parameters.

The software can be downloaded free of charge from the FAULHABER Internet page.

Node 1

CAN Bus Line

Node n

GND

CAN_H

CAN_L

120 120

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Overview

10

The FAULHABER Motion Manager is described in the separate “Motion Manager 6” man-

ual. The contents of the manual are also available as context-sensitive online help within

the FAULHABER Motion Manager.

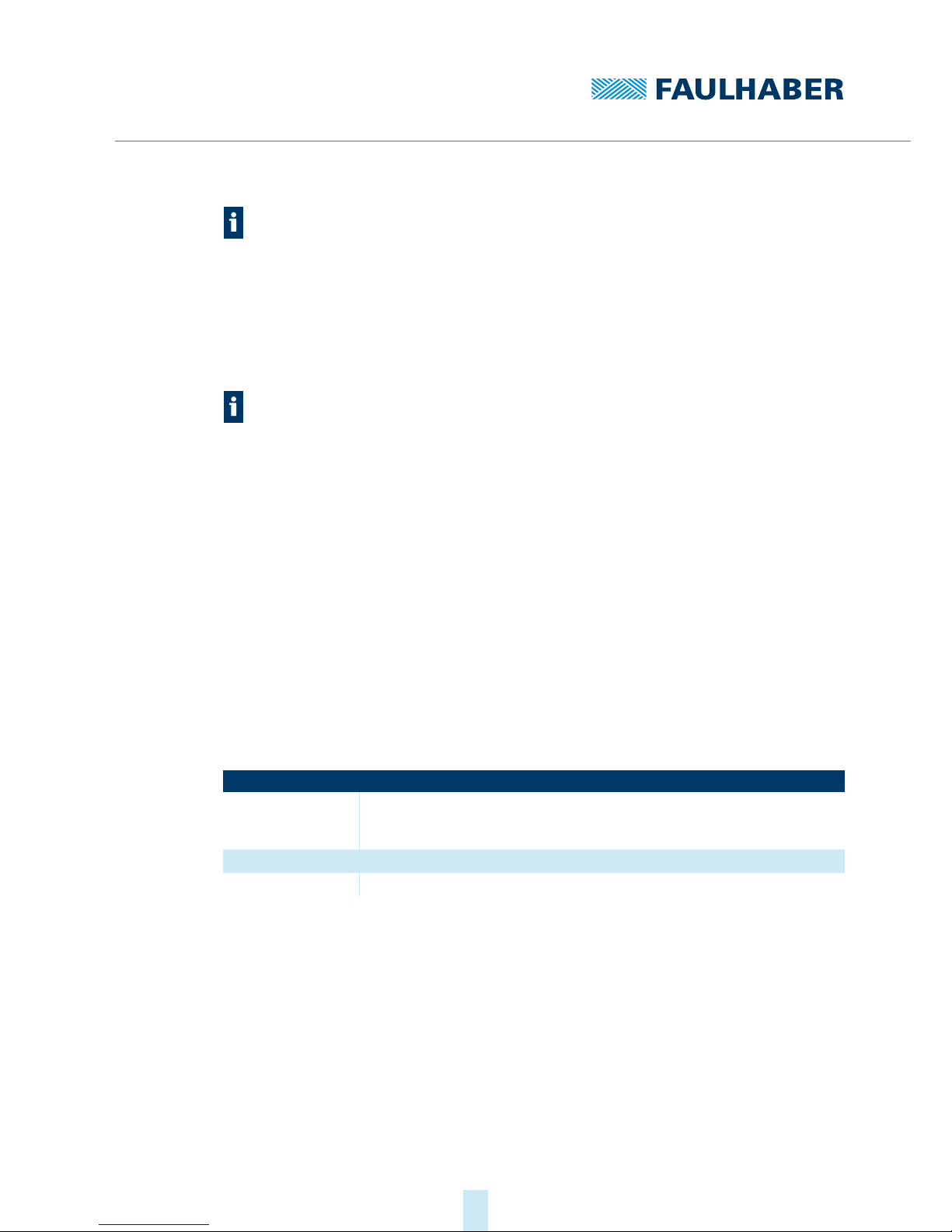

2.4 Saving and restoring parameters

So that changed parameters in the OD remain active in the controller when it is switched

on again, the “Save” command must be executed to save them permanently in the non-vol-

atile memory (application EEPROM) (see chap. 6.1, p. 43). When the motor is switched on,

the parameters are loaded automatically from the non-volatile memory into the volatile

memory (RAM)

Fig. 3: Saving and restoring parameters

The following parameters can be loaded using the “Restore” command (see chap. 6.1,

p. 43):

Factory settings

Parameters saved using the “Save” command

2.4.1 Saving parameters

The current parameter settings can be saved in the internal EEPROM (SAVE) (see Tab. 21),

either completely or for individual ranges.

Write the “Save” signature to the subindex 01 to 05 of the object 0x1010 (see Tab. 22).

We recommend always using the latest version of the FAULHABER Motion Manager.

RAM EEPROM

Save command

Power Supply ON

or

Restore command

Device

control

Communication

command

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Overview

11

2.4.2 Restoring settings

Factory settings or last saved parameter settings can be loaded from the internal EEPROM

at any time, completely or for specific ranges (RESTORE) (see Tab. 23).

1. Write the “Load” signature to the subindex 01 to 06 of the object 0x1011 (see Tab. 24).

After Restore Factory (01), Restore Communication (02) and Restore Application

(03), the parameters are updated only after a reset.

2. Application parameters (04), together with record 1 and record 2 of the special applica-

tion parameters (05/06) can be updated with the “Reload” command.

The “Reload” command overwrites the values last saved as application parameters.

2.4.3 Changing the parameter set

The saved application parameters (motor data, I/O configuration, controller parameters,

operating mode etc.) contain a comprehensive basic set of parameters (App) and alongside

this there is a saved data area for parameters which often must be modified to cater for

variations in the load situation (App1/App2):

Speed controller and filter

Position controller

When the drive is next switched on, the saved parameters are loaded automatically.

If it is desired that the values currently loaded remain available after a “Restore”, these

must be saved to the PC using a suitable program (such as FAULHABER Motion Man-

ager).

Index Subindex Name Type Attr. Meaning

0x2344 0x01 Gain KPU32 rw Controller Gain [As 1e-6]

0x02 Integral time TN U16 rw Controller reset time [100 μs]

0x2346 0x01 Setpoint velocity filter time T_F U16 rw Filter time T_F [100 μs]

0x02 Setpoint Filter Enable U8 rw 0: inactive

1: active

0x2347 0x01 Gain factor U8 rw Gain factor (used by the velocity control-

ler in PP mode on the KP)

0: The gain factor of the speed controller

is reduced to 0 at the target

128: no variable gain

255: The gain factor of the speed control-

ler is doubled at the target

Index Subindex Name Type Attr. Meaning

0x2348 0x00 Number of entries U8 ro Number of object entries

0x01 Kv[1/s] U8 rw Range: 1-250

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Overview

12

Pre-controls

General settings

These parameters are stored twice. In operation the system can switch quickly between

these different pre-set values.

Index Subindex Name Type Attr. Meaning

0x2349 0x01 Torque/force feed forward factor U8 rw Factor for the torque or force control

0: 0% activation of the pre-control value

128: 100% pre-control

0x02 Torque/Force feed forward delay U8 rw Setpoint delay:

0: undelayed activation

1: Activation delayed by one sampling

0x234A 0x01 Velocity feed forward factor U8 rw Factor for the torque or force control

0: 0% pre-control

128: 100% pre-control

0x02 Velocity feed forward delay U8 rw Setpoint delay:

0: undelayed activation

1: Activation delayed by one sampling

Index Subindex Name Type Attr. Meaning

0x6060 0x00 Modes of operation S8 rw Select the operating mode

–4: ATC

–3: AVC

–2: APC

–1: Voltage Mode

0: Controller not activated

1: PP

3: PV

6: Homing

8: CSP

9: CSV

10: CST

0x6081 0x00 Profile Velocity U32 rw Profile velocity [in user-defined scaling]

0x6083 0x00 Profile acceleration U32 rw Profile acceleration [1/s2]

0x6084 0x00 Profile deceleration U32 rw Profile deceleration [1/s2]

0x6086 0x00 Motion Profile Type S16 rw Motion profile type:

0: Linear profile

1: Sin2velocity

0x60E0 0x00 Positive torque limit value U16 rw Value of the upper limit value [in relative

scaling]

0x60E1 0x00 Negative torque limit value U16 rw Value of the lower limit value [in relative

scaling]

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

Overview

13

Create an application

SAVE application parameters 1: Write the “Save” signature to the subindex 04 of the

object 0x1010.

The current data are saved as the application parameter set 1.

SAVE application parameters 2: Write the “Save” signature to the subindex 05 of the

object 0x1010.

The current data are saved as the application parameter dataset 2.

Activate an application

Reload Application Parameters 1: Write the “Load” signature to the subindex 05 of the

object 0x1011.

Current data from the application parameter set 1 are activated directly.

Reload Application Parameters 2: Write the “Load” signature to the subindex 06 of the

object 0x1011.

Current data from the application parameter set 2 are activated directly.

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

CANopen protocol description

14

3 CANopen protocol description

3.1 Introduction

CANopen

CANopen is a standard software protocol. A CAN hardware environment is required for

communication using CANopen. Up to 127 nodes can be addressed within a CANopen net-

work. The maximum transmission speed is 1 MBit/s.

CAN standardisation

The CiA defines the following aspects in CiA 301:

communications structure

Control and monitoring functions

CANopen device profiles have been defined for a wide range of device classes, such as:

CiA 402 for drives

CiA 401 for input and output devices

Structure of a CANopen telegram

A CANopen telegram has an 11-bit identifier and can contain up to 8 bytes of user data.

Tab. 1: Schematic structure of a CANopen telegram

11-bit identifier up to 8 bytes user data

11-bit 8-bit 8-bit 8-bit 8-bit 8-bit 8-bit 8-bit 8-bit

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

CANopen protocol description

15

3.2 Communication services

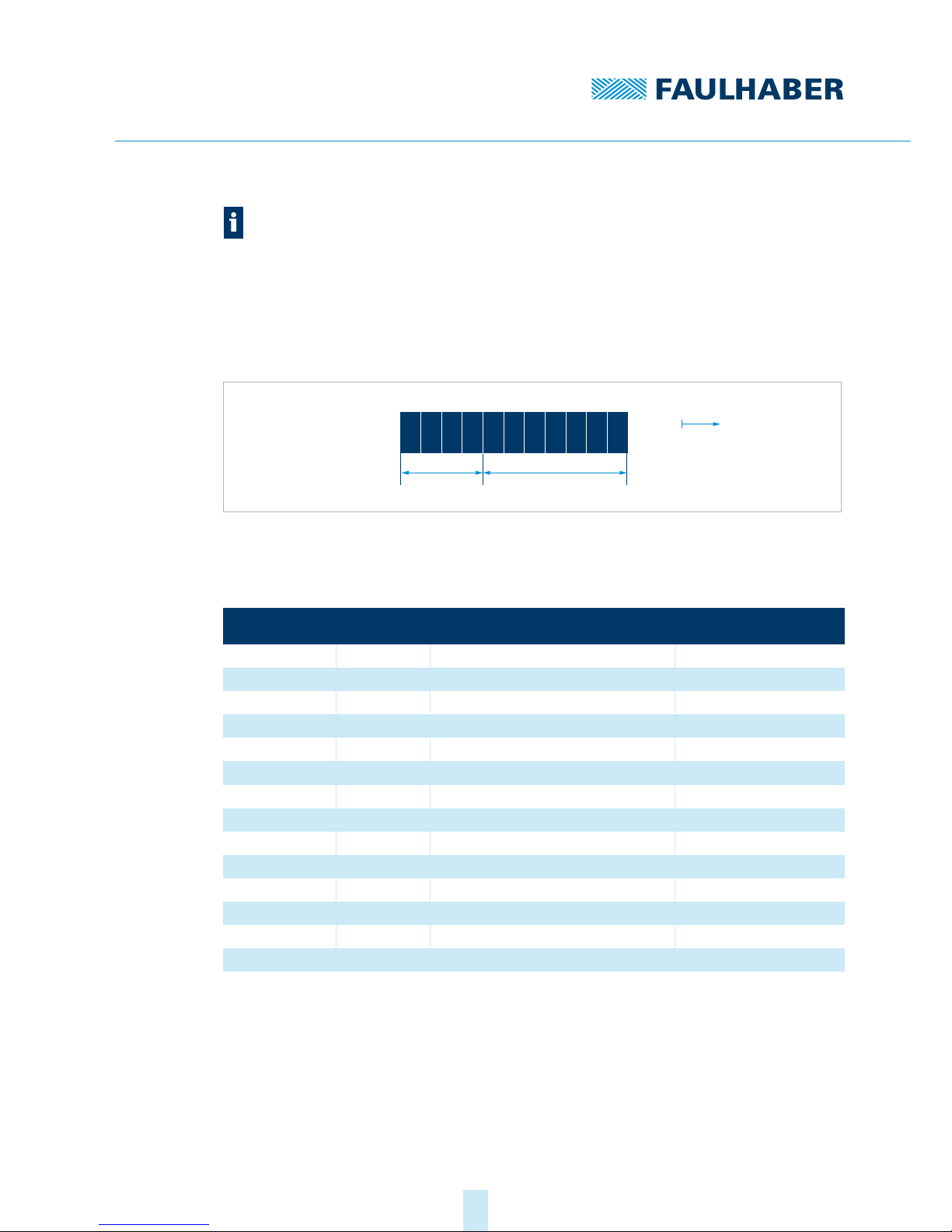

Fig. 4: Communication services of the Motion Controller

The communication part contains communication services as specified in CiA 301.

Tab. 2: Communication services to CiA 301

Communications profile

FAULHABER Motion Controllers support the CANopen communications profile to

CiA 301 V4:

4 transmission PDOs

4 receipt PDOs

1 server SDO

Emergency object

NMT with node guarding and heartbeat

SYNC object

Communication services Description

NMT (Network Management) Activates nodes and monitors the current status of a node (see chap. 3.8, p. 27).

SDO (Service Data Object) The CANopen master uses the SDO to access parameters within a node. Each

SDO access reads or writes exactly one parameter. An SDO can only address one

node in a network (see chap. 3.5, p. 21).

PDO (Process Data Object) The PDO is used to access real-time data. A PDO can use a CAN message to

access multiple drive parameters concurrently. The parameters sent or received

in a PDO can be freely configured (see chap. 3.4, p. 17).

SYNC object SYNC objects are used to synchronise different applications on the CAN-BUS

(see chap. 3.7, p. 26).

EMCY (Emergency Object) An emergency message is used to inform the CANopen master about errors. A

CAN message conveys the error code asynchronously so that the status of the

CANopen slave need not be interrogated after an error (see chap. 3.6, p. 24).

Communication Application

Motor

CAN

n , Pos∗∗

Motor Control

Control Word

Status Word

n, Pos

EMCY

PDO1 … PDO4

SDO

CiA 301 CANopen

Statemachine

NMT

Guarding

CAN Bus

Error Handling Object Dictionary

CiA 402 Drive

Statemachine

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

CANopen protocol description

16

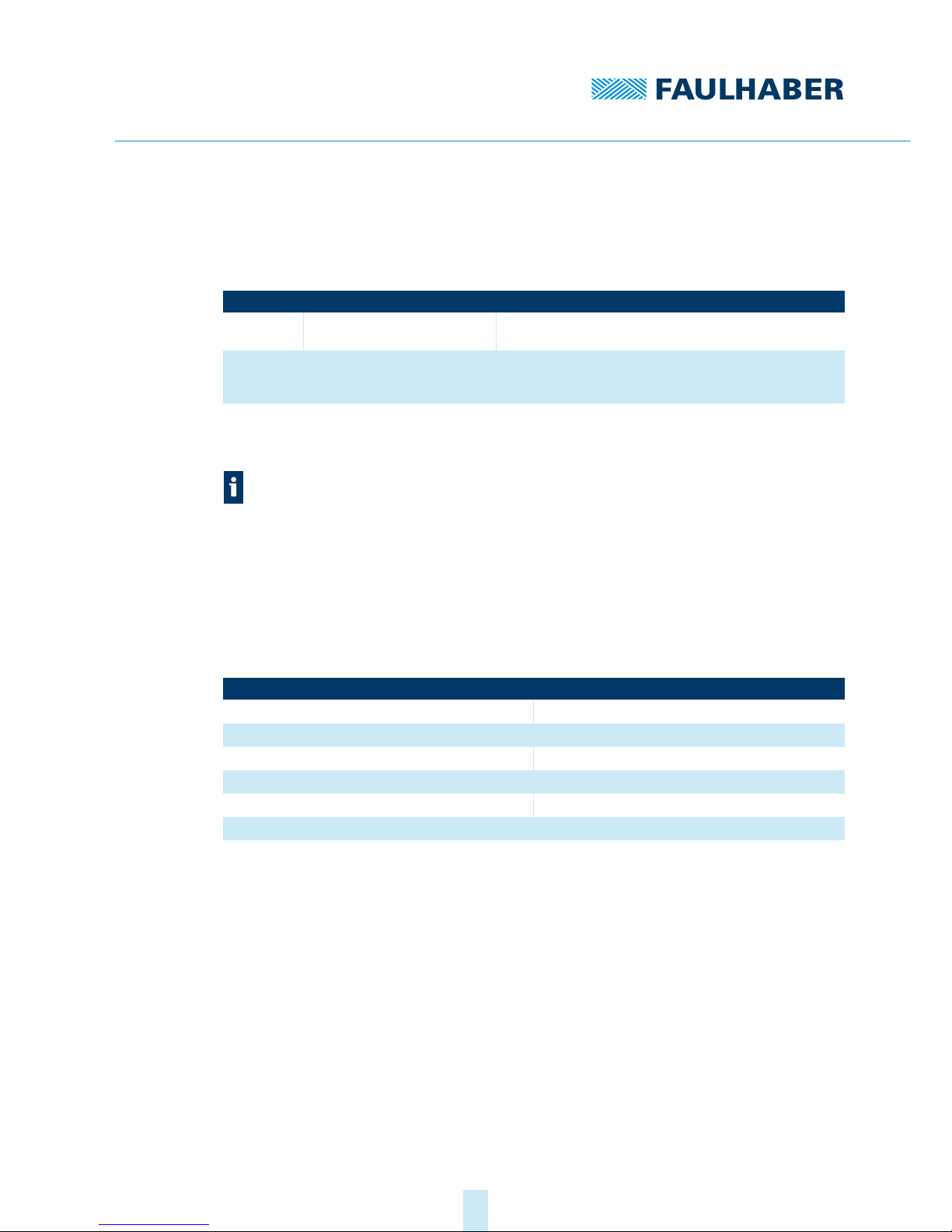

3.3 Identifier distribution

The Communication Object Identifier (COB-ID) consists of a 7-bit node address (Node-ID)

and a 4-bit function code.

Fig. 5: Identifier distribution

The Predefined-Connection-Set defines the standard identifier for the most important

objects.

Tab. 3: Standard identifier

The COB-IDs of the PDOs, the SYNC objects and the emergency objects can be changed via

the communication parameters in the object dictionary. The COB-ID of the SDO telegram

cannot be changed and is always derived from the node number.

The data assignment of the PDOs is pre-set to the “PDO set for servo drive” as specified

in CiA 402 V3, but can be changed by the user (dynamic PDO mapping).

Object Function code

(binary)

Resulting COB-ID Object index for communica-

tion setting

NMT 0000 0 –

SYNC 0001 128 (80 h) 1005 h

EMERGENCY 0001 129 (81h) to 255 (FFh) 1014 h

PDO1 (tx) 0011 385 (181h) to 511 (1FFh) 1800 h

PDO1 (rx) 0100 513 (201h) to 639 (27Fh) 1400 h

PDO2 (tx) 0101 641 (281h) to 767 (2FFh) 1801 h

PDO2 (rx) 0110 769 (301h) to 895 (37Fh) 1401 h

PDO3 (tx) 0111 897 (381h) to 1023 (3FFh) 1802 h

PDO3 (rx) 1000 1025 (401h) to 1151 (47Fh) 1402 h

PDO4 (tx) 1001 1153 (481h) to 1279 (4FFh) 1803 h

PDO4 (rx) 1010 1281 (501h) to 1407 (57Fh) 1403 h

SDO (tx) 1011 1409 (581h) to 1535 (5FFh) 1200 h

SDO (rx) 1100 1537 (601h) to 1663 (67Fh) 1200 h

NMT error control 1110 1793 (701h) to 1919 (77Fh) –

Function

Code

10Bit-No.:

COB-Identifier Priority

0

Node-ID

0

10 high

low

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

CANopen protocol description

17

3.4 PDO (Process Data Object)

PDOs are CAN messages with up to 8 bytes user data. PDOs contain process data for con-

trolling and monitoring the behaviour of the device. The drive makes the distinction

between receipt PDOs and transmission PDOs.

Receipt PDOs (RxPDO): are received by a drive and typically contain control data

Transmission PDOs (TxPDO): are sent by a drive and typically contain monitoring data

PDOs are evaluated or transmitted only when the device is in the NMT Operational state

(see chap. 3.8, p. 27).

The transmission of PDOs can be triggered in various different ways. The behaviour can be

set for each PDO via the transmission type parameter of the communication parameters in

the object dictionary:

Tab. 4: Types of PDO transmissions

As delivered the system is configured with the node number 1. The COB-IDs are pre-set

correspondingly:

RxPDO: 201h, 301h, 401h and 501h

TxPDO: 181h, 281h, 381h and 481h

EMCY: 81 h

RxSDO: 581 h

TxSDO: 601 h

If the node number is changed from 255 (unconfigured CANopen node) to a value

>127 using the LSS protocol, the COB-IDs which depend on this node number are auto-

matically adjusted.

Transmission Type Description

Event-driven Event-driven RxPDOs are processed immediately on receipt.

Event-driven TxPDOs are sent when the statusword of the device is contained and has

been changed.

Remote request (RTR) Data are sent in response to a request message.

Synchronised Data are sent after receipt of a SYNC object (see chap. 3.7, p. 26).

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

CANopen protocol description

18

3.4.1 PDO configuration

A maximum of 4 parameters can be mapped in one PDO.

The data assignment of PDOs can be changed via the objects 0x1600 to 0x1603 and

0x1A00 to 0x1A03. The mapping procedure necessary for this is described in CiA 301. A

suitable tool (such as FAULHABER Motion Manager or System Manager for the PLC con-

troller than is used) is necessary for performance of the mapping procedure.

The transmission types and COB-ID of the PDOs can be changed via the objects 0x1400

to 0x1403 and 0x1800 to 0x1803.

The transmission type parameters can be used to change the behaviour of a PDO:

Tab. 5: Transmission type of a PDO

3.4.2 PDO mapping in the standard configuration (status as delivered)

RxPDO1: Controlword

The RxPDO1 contains the 16-bit controlword to CiA DSP402. The controlword controls the

state machine of the drive unit and points to the object index 0x6040 in the object diction-

ary. The bit distribution is described in the documentation for the drive functions.

TxPDO1: Statusword

The TxPDO1 contains the 16-bit statusword to CiA 402. The statusword indicates the status

of the drive unit an and points to the object index 0x6041 in the object dictionary. The bit

distribution is described in the documentation for the drive functions.

Transmission Type Meaning

0 synchronous, acyclical

A PDO is sent or executed once after a SYNC object when the contents of the PDO have

changed (see chap. 3.7, p. 26).

1 to 240 synchronous, cyclical

A PDO is sent after every SYNC object (see chap. 3.7, p. 26). The value is then equal to the

number of SYNC objects that must be received before the PDO is sent again (1 = PDO is

sent for every SYNC object)

252 TxPDOs only: asynchronous

On a SYNC signal, the contents of the TxPDO are stored

On request (RTR) the TxPDO is sent to the master

253 TxPDOs only: asynchronous

On request (RTR) the TxPDO is sent to the Master

255 asynchronous (event-driven)

11-bit identifier 2 bytes user data

0x200 (512d) +

node ID

LB HB

11-bit identifier 2 bytes user data

0x180 (384d) +

node ID

LB HB

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

CANopen protocol description

19

RxPDO2: Controlword, target position (PP)

The RxPDO2 contains the 16-bit controlword and the 32-bit value of the destination posi-

tion (object 0x607A) for the Profile Position mode (PP).

TxPDO2: Statusword, Position Actual Value

The TxPDO2 contains the 16-bit statusword and the 32-bit value of the actual position

(object 0x6064).

RxPDO3: Controlword, target velocity (PV)

The RxPDO3 contains the 16-bit controlword and the 32-bit value of the set speed

(object 0x60FF) for the Profile Velocity mode (PV).

TxPDO3: Statusword, Velocity Actual Value

The TxPDO3 contains the 16-bit statusword and the 32-bit value of the actual speed (object

0x606C).

RxPDO4: Controlword, target torque

The RxPDO4 contains the 16-bit controlword and the 16-bit value of the target torque

(object 0x6071) for Cyclic Torque Mode (CST).

TxPDO4: Statusword, torque actual value

The RxPDO4 contains the 16-bit statusword and the 16-bit value of the actual torque

(object 0x6077) for Cyclic Torque mode (CST).

11-bit identifier 6 bytes user data

0x300 (768d) +

node ID

LB HB LLB LHB HLB HHB

11-bit identifier 6 bytes user data

0x280 (640d) +

node ID

LB HB LLB LHB HLB HHB

11-bit identifier 6 bytes user data

0x400 (1024d) +

node ID

LB HB LLB LHB HLB HHB

11-bit identifier 6 bytes user data

0x380 (896d) +

node ID

LB HB LLB LHB HLB HHB

11-bit identifier 6 bytes user data

0x400 (1024d) +

node ID

LB HB LLB LHB HLB HHB

11-bit identifier 6 bytes user data

0x380 (896d) +

node ID

LB HB LLB LHB HLB HHB

4th edition, 9-11-2018 7000.05050, 4th edition, 9-11-20187000.05050

CANopen protocol description

20

3.4.3 Dealing with mapping errors

If the mapping procedure specified in CiA 301 is not complied with, one of the following

SDO errors will be returned:

Tab. 6: SDO errors in response the incorrect mapping procedure

If the number of mapped objects is 0, the PDO will be flagged internally as invalid and will

not be operated.

3.4.4 Dummy Mappings

RxPDOs can be configured so that more than one participant can respond to them. In this

case it may be desirable that only part of the data contained in the PDO is evaluated in one

of the devices.

For data that are not used locally, Dummy Mapping on one of the data types that is used

can be entered in the PDO mapping table:

Example

An RxPDO contains the target positions for two axes.

Mapping for the node that should respond to the first target position:

0x160x.00 = 2

0x160x.01 = 0x607A0020

0x160x.02 = 0x00040020

Mapping for the node that should respond to the second target position:

0x160x.00 = 2

0x160x.01 = 0x00040020

0x160x.02 = 0x607A0020

SDO error Meaning Cause

0x06090030 General value range error The mapping parameter lies outside that specified in the map-

ping procedure.

0x06020000 Object not present in the object

dictionary

The value for the number of mapped objects is greater than

the number of valid entries in the respective subindexes for

the mapping parameter objects.

Other mapping errors are described in the SDO error table (see chap. 3.5.2, p. 23).

Index Type

0x0002 S8

0x0003 S16

0x0004 S32

0x0005 U8

0x0006 U16

0x0007 U32

Other manuals for MC 5010

3

This manual suits for next models

3

Table of contents

Other Faulhaber DC Drive manuals

Popular DC Drive manuals by other brands

Dorner

Dorner 3200 Series Installation, maintenance & parts manual

Danfoss

Danfoss VLT HVAC Drive FC 102 operating instructions

GFA

GFA ELEKTROMAT SI 75.20 FU-55,00 installation instructions

Invertek Drives

Invertek Drives Optidrive ODE-2-12005-1H01 01 Series user guide

Leadshine Technology

Leadshine Technology DM432 user manual

ABB

ABB ACH580 Series Quick start up guide