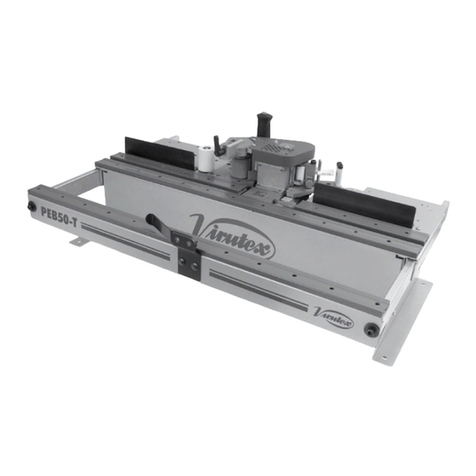

PRIS VBT-40 User manual

Vertical Bending Tool

PRIS VBT-40

2

Introduction and technical data

Contents

Introduction 2

Technical data 2

Use 2

Safety 3

Composition 4

Function and control elements 5

Assembly 5

Operating the VBT-40 5

Maintenance 5

Spare parts 5

Disposal and protection

of the environment 5

Warranty 6

Technical data

Type VBT - 40

Bending power:

Flat steel 40x5 mm

Steel rods -

Circular cross section 15 mm

Rectangular

cross section 15 x 15 mm

Steel profiles -

Circular cross section 40 x 40 x 2 mm

Rectangular

cross section 40 x 30 x 2 mm

Weight ca. 8,8kg

Technical and design changes can be made in

further development without a previous

warning. That is why not all dimensions,

notes and information are guaranteed in this

user’s manual. Hence it is not possible to

apply any legal requirements based on this

user’s manual.

Introduction

Thank you for trusting our products. By

purchasing this bending tool, you acquired a

tool that is known for its function. Please

check the machine for missing or damaged

parts first.

Use

The bending tool is required to be used only

with a suitable bench vice. The tool is suitable

for cold bending steel, aluminium, brass and

rods or profiles made of other materials. It is

intended to be used in metalworking and car

repair shops as well as in production of

commercial and non-commercial

constructions. This tool is to be used by adults

only.

The bending tool is to be used only

for jobs described above. PRIS is not

responsible for any damages or injuries

caused by incorrect use of the tool. In such

cases the warranty is void.

3

Safety

Please read and adhere to the

following safety measures and user

instructions. Please keep this user’s

manual close by. Hand it down to all

successors so that the information may

always be available.

Safe working space

- Keep your working space clean.

Malfunction of the tool may lead to

accidents. Do not leave any other

tools or objects in your immediate

workspace. When you are done with

the job, safely store the tool to

prevent injuries to the workers or

damage to the tool.

- Be aware of your surroundings while

working with the tool. Keep away from

children

Make sure that no one is in your

immediate workspace. Children

under the age of 16 are not allowed to

use the bending tool. Adolescents

above the age of 16 and adults not

acquainted with this manual require

supervision.

Safe work

- Pay attention to your hands and fingers!

Keep your hands and fingers away

from clamping and bending areas.

There is a risk of crush injury.

- Wear safety goggles and appropriate work

clothes!

Do not wear jewellery or loose

clothes while working. It could lead to

injury.

WARNING! The workpiece may have

sharp edges. Be very cautious while

working with sheet metal. Always

wear safety gloves resistant to cuts.

- Make sure the bending tool is assembled

correctly!

All parts must be assembled properly

to ensure correct operation of the

tool.

- Keep safe operation in mind!

Before every use, check the bending

tool for damage or missing parts and

ensure the free movement of moving

parts. All parts must be assembled

correctly. If the tool is damaged do

not use it anymore.

- Watch the workpiece and the bending tool

while working!

Never use the tool while distracted.

Never use the tool while under the

influence of alcohol or drugs.

- Be cautions while working with the bending

tool!

Do not overload the tool, work only

with approved materials mentioned

on page 2. Overloading may lead to

damage to the tool.

- Further safety precautions

For the work to be safe, the bending

tool must be correctly placed and

secured in a bench vice. Do not use

the tool if it is not stable and secure.

Loss of stability may lead to injury.

Read the user’s manual carefully to use the

bending tool correctly. Follow the listed

instructions.

4

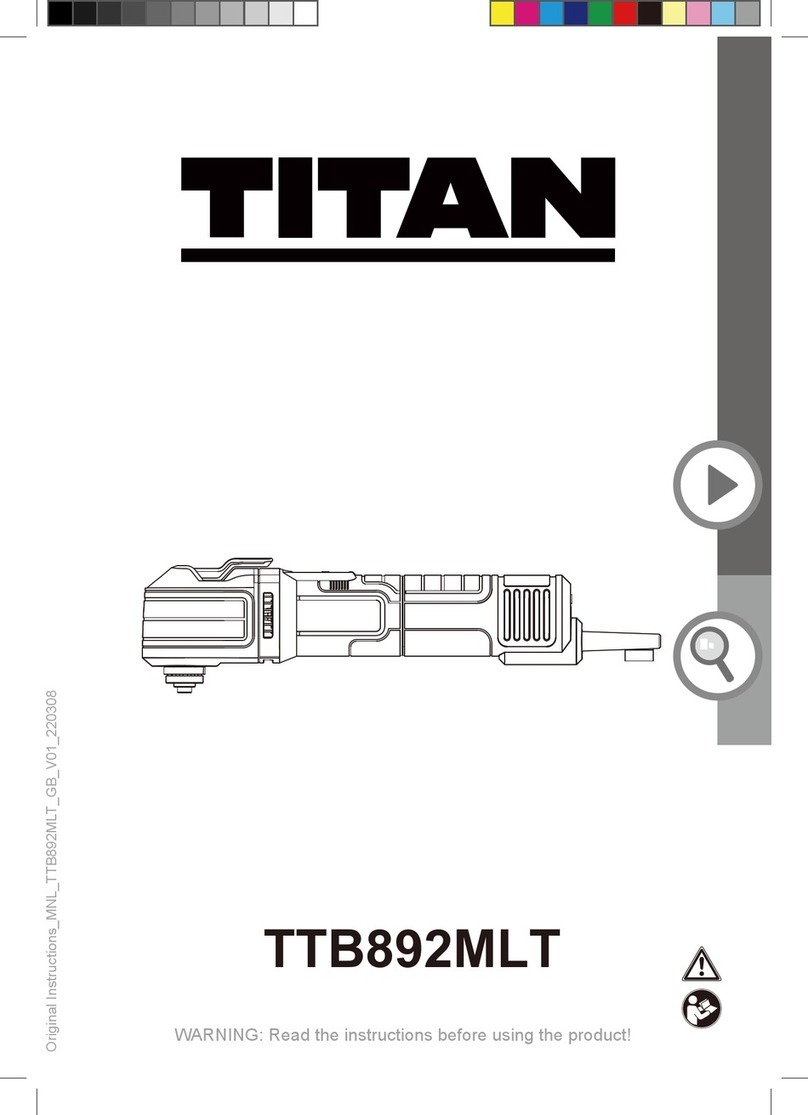

2

2

3

1

4

5

3

5

Assembly, operation,

and maintenance

Function and control elements

1 Pulley with the lever

2 Polyamid-6 pulleys

3 Opening for vice jaws

4 Lever pin

5 Carry handle

Assembly

The bending tool must be secured in

an adequately sized bench vice.

Workbench must be stable enough

to not move while bending is in process.

Secure the tool’s lever with the included pin

to the center pulley.

Operating the bending tool

WARNING! Workpiece may be

sharp. Caution is advised.

Work gloves are required while

working with the tool.

Securing the workpiece for bending:

- To lock the tool in place, spread the vice jaws

as wide as possible.

- Insert the bending tool in the vice so that the

jaws slide into the openings (3) and the

pulleys (2) with the lever (1) point upwards.

- Insert the workpiece between the pair of

pulleys (2) and the pulley with lever attached

(1). Tighten the vice so thatthe lever-pulley (1)

presses the workpiece against the pair of

pulleys (2).

Bending:

- Tighten the bench vice until you feel slight

resistance of the material –at about 1 to 2 mm

steps.

- Turn the lever (1) clockwise until the end of

the workpiece reaches the left pulley (2),

then turn the lever (1) counter clockwise until

the opposite end of the workpiece reaches

the right pulley (2).

- Tighten the bench vice.

- Repeat the steps above until you reach the

desired bend radius.

- The bending tool is equipped with a ruler

under the left pulley for higher degree of

repeatability and bend radius tracking.

- You can also watch our instructional video at

- http://pristools.com/zakruzovacka/

Maintenance

The VBT-40 is largely maintenance-free. Keep

the tool clean. All moving parts must be

lubricated regularly with acid-free lube.

Spare parts

Spare parts are available at the manufacturer

Ing. Martin Ďurkovic, cell: +421 945 461 917 or

email info@pristools.com

Disposal and protection of the

environment

Tools do not belong into

communal waste. Dispose of your

machine environmentally friendly

way and hand it over at your local

scrap yard or other dedicated

location. All oils and lubricants as well as rags

soaked in oil or lubricant do not belong into

communal waste and are dangerous for the

environment.

6

Warranty

Warranty

We offer 24 months warranty in accordance

with local and national law. Damage caused

by natural wear and tear, as a result of

incorrect use or overload is not covered by

warranty. Damage caused by faulty material

or manufacture will be rectified by charge-

free repair or by a replacement tool. The tool

must be returned to the manufacturer with

the receipt or other eligible proof of

purchase. Wore down parts are not covered

by warranty. If the bending tool shows signs

of negligence and moving parts are not

lubricated regularly, warranty is voided.

Damage caused by insufficient packaging is

not covered by warranty.

Table of contents