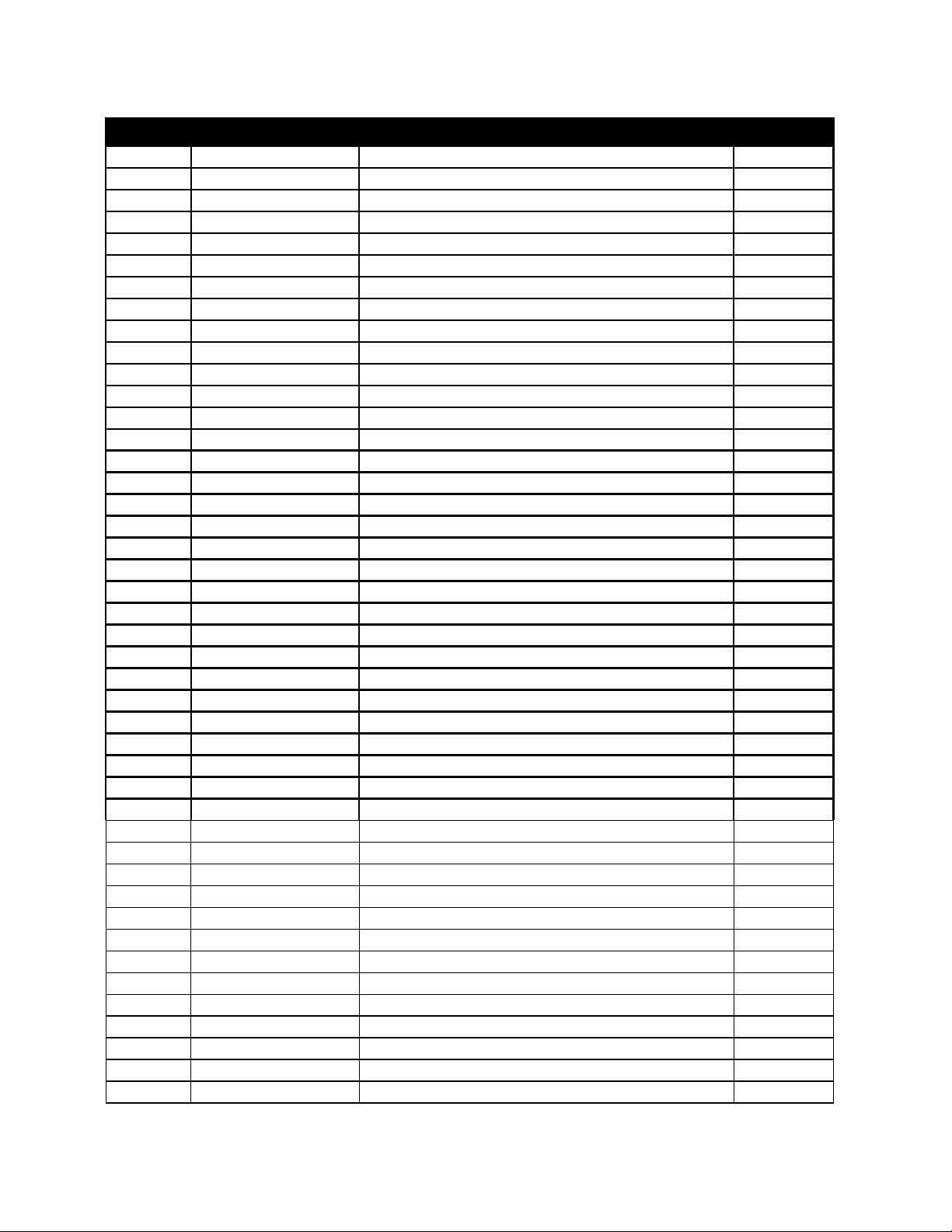

4

ITEM # PART NO. DESCRIPTION Qty Req

1 08-50M-00-630 BODY ASSEMBLY 1

2 08-50M-00-150 FOOT 1

3 08-50M-00-380 DRIVING BLADE 1

4 07-50M-00-370 PLUNGER 1

5 08-250-00-450 PLUNGER SPRING 1

6 08-250-00-410 PLUNGER SPRING PIN 1

7 08-250-00-640 ROLLER PIN 1

8 08-250-00-740 1/4-20 X 1-3/4 S.H.C.S. (FOOT) 4

9 08-250-00-750 1/4-20 FLANGE NUT 4

10 09-200-3034 PUSHER SPRING 1

11 09-200-3057 #10-32 X 1/2 F.H.C.S. SLOTTED (PAD) 4

12 09-200-3035 SPOOL SET 1

13 09-50P-3005 ADAPTER FOOT 1

14 09-50P-3008 CHANNEL 1

15 09-50P-3042 GATE 1

16 09-50P-3017 GATE PLATE 1

17 09-50P-3038 SHIM 4

18 09-50P-3037 .200 THICK UHMW PLASTIC PAD 1

19 09-445-29745 #10-32 X 1-1/4 S.H.C.S.(KNOB) 1

20 09-445-29754 #10-32 X 1/2 S.H.C.S. (FOOT) 4

21 09-445-29822 #10-32 x 3/4" S.H.C.S. (GATE) 3

22 09-445-29741 1/8 X 5/8 ROLL PIN 2

23 09-445-29735 NAIL PUSHER 1

24 09-445-29735.2 KNOB 1

25 09-445-29756 STANDOFF 2

26 09-445-29750 #8-32 X 1-1/2 F.H.C.S. 2

27 09-445-29751 #8-32 LOCKNUT 2

28 08-45-00-580 BLADE RETAINER 1

29 08-45-00-610 COTTER PIN 1

30 09-50P-3040 CHANNEL PLATE 1

31 09-50P-3041 #6-32 X 3/8 B.H.C.S 2

54 09-445-29758 1/4 Split Ring Lock Washer (Foot) 4

70 09-50P-3070 FLEX Foot 1

71 09-50P-3071 FLEX Foot Bracket 1

72 09-50P-3072 FLEX Foot Cam 1

73 09-50P-3073 FLEX Foot Cam Plate 1

74 09-50P-3074 FLEX Foot Pad 1

75 09-50P-3075 SHCS 1/4-28 x 1.25" 2

76 09-50P-3076 Washer .281 IDx.62 ODx.051" T 2

77 09-50P-3077 BHCS #10-32 x .50" 2

78 09-50P-3078 1/4 SH DIA x .50" SH. Bolt 1

79 09-50P-3079 Belleville Disc Spring 1

80 09-50P-3080 FLEX Foot Wrench Clip (No longer available) 1

93 09-50P-3090 FLEX Adapter Foot 1

Model 50M FLEX Parts List