FEDERAL PIONEER H-2 Maintenance manual

V

.

CONTENTS

GENERAL

DESCRIPTION

General

Basic

Breaker

Types

Breaker

Description

RECEIVING

,

HANDLING

AND

STORAGE

PAGE

2

2

2

4

BREAKER

OPERATION

Drawout

Mounted

Breakers

.

Drawout

Racking

Mechanism

Fixed

Mounted

Breakers

.

.

.

Power

Terminal

Connections

Secondary

Control

Circuits

.

Pre

Service

Inspection

Manual

Closing

Electrical

Closing

4

4

4

4

4

4

6

6

BREAKER

MAINTENANCE

Removing

the

Faceplate

Lubrication

Close

Latch

Adjustment

Mechanism

Latching

and

Trip

Shaft

Adjustment

.

.

Spring

Discharge

Interlock

Shunt

Trip

UnderVoltageTripTypes

A

&

B

Shunt

Close

Closing

Spring

Charging

Motor

Motor

Closing

Spring

Limit

Switch

Latch

Check

Switch

Contact

Maintenance

Main

Power

Contacts

Contact

Differential

Main

Moving

Contact

Deflection

Arcing

Contacts

Slow

Close

Device

Arc

Chutes

Arc

Chute

Hood

Overload

Protection

Fuse

Mounting

Anti

-

Single

Phase

Device

and

Blown

Fuse

Indicator

Secondary

Control

Contacts

Auxiliary

Switch

Door

Interlock

Key

Interlocks

Spare

Parts

6

>

6

8

10

11

11

12

13

14

14

14

15

15

15

16

16

16

19

19

19

19

19

20

20

20

20

21

Page

1

Courtesy of store.ips.us

This

manual

applies

to

breakers

commencing

Serial

number

BH

.

For

breakers

with

serial

numbers

TH

consult

Instruction

Manual

C

-

3

-

211

-

1

dated

March

1976

.

For

breakers

with

serial

numbers

T

consult

Instruction

Manual

C

-

3

-

414

dated

August

1966

.

C

Before

placing

in

service

read

this

instruction

man

-

ual

completely

and

perform

the

pre

-

service

inspec

-

tion

(

see

page

4

)

.

L

Courtesy of store.ips.us

GENERAL

Type

H

-

2

&

HL

-

2

power

Air

Circuit

Breakers

are

suitable

for

controlling

and

protecting

low

voltage

power

circuits

up

to

250

volts

dc

and

600

volts

ac

.

They

are

a

means

of

safely

switching

loads

and

automatically

clearing

circuits

when

abnormal

con

-

ditions

occur

such

as

undervoltage

,

sustained

overloads

,

and

short

circuits

.

The

proper

INSTALLATION

,

MAINTENANCE

and

OPERATION

of

these

breakers

is

a

prime

safety

consideration

for

the

protection

of

personnel

and

equipment

.

Reference

to

this

manual

and

adherence

to

its

recommendations

will

enhance

the

performance

of

these

breakers

under

all

conditions

.

This

manual

does

not

purport

to

cover

all

details

or

variations

of

equipment

nor

to

provide

for

every

possible

contingency

to

be

met

in

connection

with

receiving

,

storage

,

installation

,

maintenance

or

operation

.

Should

further

information

be

required

or

particular

problems

arise

which

are

not

covered

suf

-

ficiently

,

please

refer

to

Federal

Pioneer

Limited

.

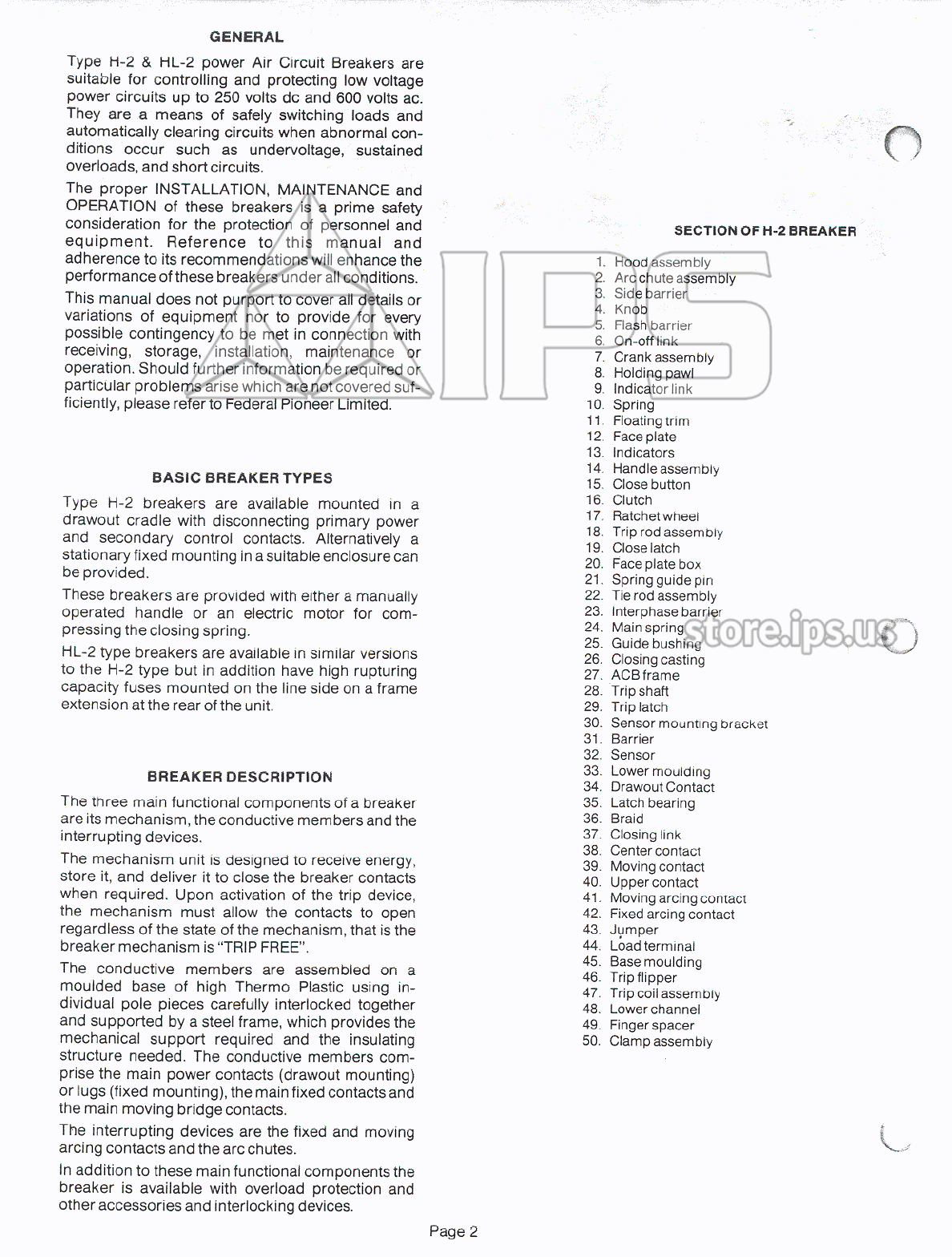

SECTION

OF

H

-

2

BREAKER

1

.

Hood

assembly

2

.

Arc

chute

assembly

3

.

Side

barrier

4

.

Knob

5

.

Flash

barrier

6

.

On

-

off

link

7

.

Crank

assembly

8

.

Holding

pawl

9

.

Indicator

link

10

.

Spring

11

.

Floating

trim

12

.

Faceplate

13

.

Indicators

14

.

Handle

assembly

15

.

Close

button

16

.

Clutch

17

.

Ratchet

wheel

18

.

Trip

rod

assembly

19

.

Close

latch

20

.

Face

plate

box

21

.

Spring

guide

pin

22

.

Tie

rod

assembly

23

.

Interphase

barrier

24

.

Mainspring

25

.

Guide

bushing

26

.

Closing

casting

27

.

ACB

frame

28

.

Trip

shaft

29

.

Trip

latch

30

.

Sensor

mounting

bracket

31

.

Barrier

32

.

Sensor

33

.

Lower

moulding

34

.

Drawout

Contact

35

.

Latch

bearing

36

.

Braid

37

.

Closing

link

38

.

Center

contact

39

.

Moving

contact

40

.

Upper

contact

41

.

Moving

arcing

contact

42

.

Fixed

arcing

contact

43

.

Jumper

44

.

Load

terminal

45

.

Base

moulding

46

.

Trip

flipper

47

.

Trip

coil

assembly

48

.

Lower

channel

49

.

Finger

spacer

50

.

Clamp

assembly

BASIC

BREAKER

TYPES

Type

H

-

2

breakers

are

available

mounted

in

a

drawout

cradle

with

disconnecting

primary

power

and

secondary

control

contacts

.

Alternatively

a

stationary

fixed

mounting

in

a

suitable

enclosure

can

be

provided

.

These

breakers

are

provided

with

either

a

manually

operated

handle

or

an

electric

motor

for

com

-

pressing

the

closing

spring

.

HL

-

2

type

breakers

are

available

in

similar

versions

to

the

H

-

2

type

but

in

addition

have

high

rupturing

capacity

fuses

mounted

on

the

line

side

on

a

frame

extension

at

the

rear

of

the

unit

.

BREAKER

DESCRIPTION

The

three

main

functional

components

of

a

breaker

are

its

mechanism

,

the

conductive

members

and

the

interrupting

devices

.

The

mechanism

unit

is

designed

to

receive

energy

,

store

it

,

and

deliver

it

to

close

the

breaker

contacts

when

required

.

Upon

activation

of

the

trip

device

,

the

mechanism

must

allow

the

contacts

to

open

regardless

of

the

state

of

the

mechanism

,

that

is

the

breaker

mechanism

is

“

TRIP

FREE

”

.

The

conductive

members

are

assembled

on

a

moulded

base

of

high

Thermo

Plastic

using

in

-

dividual

pole

pieces

carefully

interlocked

together

and

supported

by

a

steel

frame

,

which

provides

the

mechanical

support

required

and

the

insulating

structure

needed

.

The

conductive

members

com

-

prise

the

main

power

contacts

(

drawout

mounting

)

or

lugs

(

fixed

mounting

)

,

the

main

fixed

contacts

and

the

main

moving

bridge

contacts

.

The

interrupting

devices

are

the

fixed

and

moving

arcing

contacts

and

the

arc

chutes

.

In

addition

to

these

main

functional

components

the

breaker

is

available

with

overload

protection

and

other

accessories

and

interlocking

devices

.

Page

2

Courtesy of store.ips.us

RECEIVING

,

HANDLING

AND

STORAGE

Receiving

Immediately

upon

receipt

of

the

breaker

an

ex

-

amination

should

be

made

for

damage

sustained

in

transit

.

If

damage

has

occurred

or

there

is

evidence

of

rough

handling

a

claim

should

be

filed

im

-

mediately

with

the

transportation

company

and

Federal

Pioneer

Limited

should

be

notified

.

Check

all

parts

against

the

packing

list

to

make

sure

all

the

correct

items

have

been

received

.

Except

for

the

mounting

the

following

instructions

for

fixed

mounted

breakers

equally

apply

to

drawout

mounted

breakers

.

FIXED

MOUNTED

BREAKERS

H

-

2

and

HL

-

2

circuit

breakers

should

be

mounted

in

sheet

steel

enclosures

in

accordance

with

recommended

dimensions

.

The

mounting

support

should

be

a

rigid

structure

able

to

withstand

the

im

-

pact

caused

by

the

switching

operations

,

without

any

deflection

of

the

frame

which

may

cause

distor

-

tion

and

undue

vibration

of

the

mechanism

.

•

x

-

POWER

TERMINAL

CONNECTIONS

The

H

-

2

and

HL

-

2

terminals

are

silver

plated

for

maximum

joint

efficiency

and

cable

connectors

must

be

clean

and

free

from

dents

or

burrs

,

and

bolted

securely

to

the

terminals

.

Poor

joints

lead

to

over

-

heating

and

subsequent

contact

deterioration

,

and

an

eventual

failure

.

Cables

or

bus

connections

should

be

properly

supported

so

as

not

to

transfer

any

unnecessary

mechanical

or

short

circuit

stress

to

the

terminals

.

Any

strain

which

may

have

no

ap

-

parent

effect

initially

,

may

,

after

prolonged

periods

of

vibration

and

shock

from

normal

operation

,

cause

poor

contact

alignment

.

Meter

shunts

,

resistors

,

and

similar

devices

which

operate

at

relatively

high

temperature

should

be

mounted

away

from

the

circuit

breaker

so

they

do

not

contribute

to

the

heating

of

the

unit

.

Handling

and

Storage

Lift

the

breaker

by

the

steel

channels

at

the

front

and

back

.

Do

not

lift

by

the

connecting

terminals

or

the

asbestos

hoods

and

arc

chutes

,

or

by

the

operating

handle

.

Check

the

unit

thoroughly

to

see

that

no

parts

were

damaged

or

forced

out

of

alignment

dur

-

ing

shipment

.

If

replacement

parts

are

required

,

the

manufacturer

should

be

notified

promptly

.

The

breaker

should

be

installed

in

a

clean

dry

ventilated

area

,

which

is

free

from

atmospheric

contaminants

.

Each

circuit

breaker

should

be

stored

in

its

shipping

crate

in

an

upright

position

in

a

clean

dry

area

.

Should

the

unit

get

wet

,

it

must

be

thoroughly

dried

out

using

forced

warm

air

over

an

extended

period

until

“

infinite

"

readings

are

obtained

using

a

600

volt

megger

.

BREAKER

OPERATION

SECONDARY

CONTROL

CIRCUITS

Control

circuit

wiring

,

where

applicable

,

should

be

made

in

strict

accordance

with

detailed

wiring

diagrams

.

Wiring

connections

,

which

are

made

to

terminal

blocks

should

be

run

in

a

supported

and

protected

manner

,

so

control

wiring

cannot

come

into

contact

with

the

primary

connections

.

DRAWOUT

MOUNTED

BREAKERS

Switchgear

assemblies

for

drawout

mounted

breakers

are

provided

with

supporting

rails

,

main

power

contacts

and

secondary

contacts

to

mate

with

those

on

the

breakers

when

it

is

racked

into

position

.

Drawout

Racking

Mechanism

An

interlock

is

provided

which

will

ensure

that

the

unit

is

open

and

the

main

spring

is

discharged

when

it

is

either

engaging

or

disengaging

the

main

dis

-

connecting

contacts

.

A

block

is

provided

on

the

racking

mechanism

which

operates

in

conjunction

with

the

gate

interlock

lever

over

the

racking

open

-

ing

.

Before

withdrawing

electrically

operated

breakers

,

turn

off

the

motor

isolating

switch

on

the

faceplate

.

To

withdraw

the

unit

,

move

the

gate

over

the

crank

opening

down

so

as

to

expose

the

socket

end

of

the

drawout

racking

shaft

.

This

action

will

first

open

the

unit

if

it

is

closed

and

then

discharge

the

main

spring

if

it

is

charged

.

The

racking

handle

may

now

be

inserted

in

the

racking

shaft

socket

and

by

counter

-

clockwise

rotation

the

unit

will

move

out

-

ward

.

At

the

“

test

”

position

the

main

contacts

are

withdrawn

but

the

auxiliary

contacts

remain

engag

-

ed

in

the

test

position

.

Further

turns

of

the

racking

handle

will

move

the

unit

to

the

“

disconnected

”

position

and

it

is

then

free

to

be

pulled

manually

forward

to

the

end

of

the

tracks

.

Two

lifting

lugs

are

provided

on

each

side

of

the

unit

so

that

it

can

be

lifted

clear

of

the

tracks

.

PRE

-

SERVICE

INSPECTION

Read

this

instruction

manual

completely

and

inspect

and

check

the

unit

in

accordance

with

this

manual

.

The

following

items

should

be

specifically

checked

.

1

.

Make

a

visual

inspection

after

installation

to

en

-

sure

that

no

parts

have

been

damaged

or

forced

out

of

alignment

.

2

.

Check

the

door

interlock

lever

for

freedom

of

movement

,

when

supplied

.

(

Fig

.

25

)

.

3

.

Check

the

main

and

drawout

contacts

to

see

that

they

are

clean

and

free

from

foreign

material

.

4

.

Check

all

the

control

wiring

to

ensure

that

it

has

not

been

damaged

or

moved

during

the

installation

.

5

.

Check

the

single

phase

protection

(

when

supplied

)

by

manually

raising

each

tripping

plunger

in

turn

on

the

three

tripping

coils

,

Fig

.

24

.

If

the

unit

is

closed

,

it

should

trip

and

the

correct

indicator

should

show

on

the

faceplate

.

(

Fig

.

2

)

.

6

.

Close

and

open

the

unit

several

times

to

ensure

correct

operation

.

Interlocks

should

be

defeated

or

be

in

normal

release

position

.

If

an

under

voltage

trip

unit

is

attached

hold

it

up

manually

,

so

the

spring

Page

4

Courtesy of store.ips.us

closing

mechanism

will

pick

up

the

contacts

,

and

thus

avoid

discharging

the

mechanism

without

its

normal

contact

spring

load

.

7

.

Manually

activate

the

tripping

devices

to

es

-

tablish

that

they

are

operable

.

These

devices

include

manual

trip

Fig

.

2

,

shunt

trip

Figs

.

11

,

12

and

under

-

voltage

trip

Figs

.

11

,

13

.

8

.

Check

all

cable

connections

to

ensure

that

they

are

tight

.

9

.

The

electrical

operation

of

drawout

breakers

should

be

checked

in

the

‘

test

’

position

.

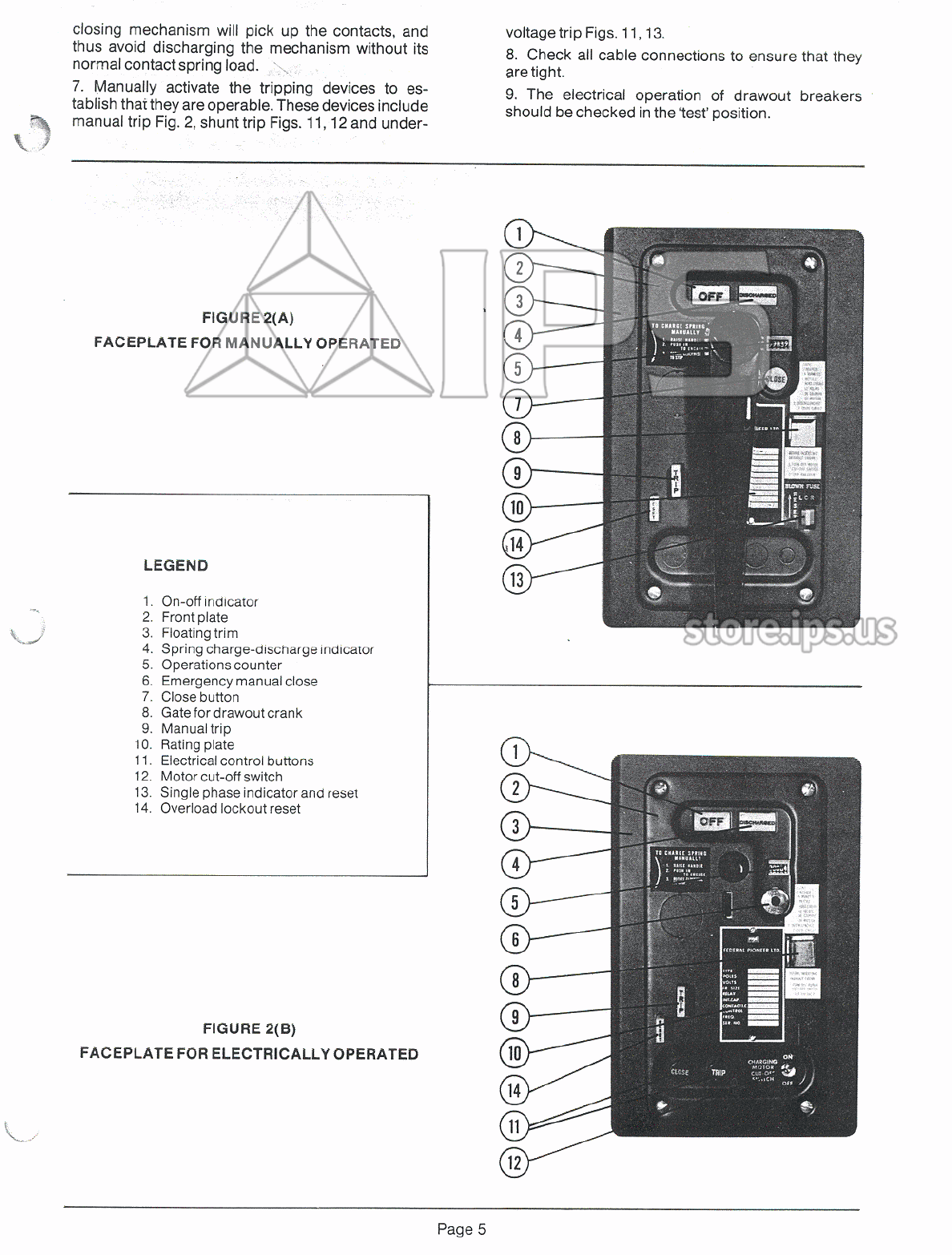

V

FIGURE

2

(

A

)

FACEPLATE

FOR

MANUALLY

OPERATED

©

10

14

LEGEND

13

1

.

On

-

off

indicator

2

.

Front

plate

3

.

Floating

trim

4

.

Spring

charge

-

discharge

indicator

5

.

Operations

counter

6

.

Emergency

manual

close

7

.

Close

button

8

.

Gate

for

drawout

crank

9

.

Manual

trip

10

.

Rating

plate

11

.

Electrical

control

buttons

12

.

Motor

cut

-

off

switch

13

.

Single

phase

indicator

and

reset

14

.

Overload

lockout

reset

FIGURE

2

(

B

)

FACEPLATE

FOR

ELECTRICALLY

OPERATED

10

14

11

12

Page

5

Courtesy of store.ips.us

Manual

Closing

The

closing

mechanism

compresses

a

main

spring

which

is

held

compressed

until

released

.

The

handle

is

rotated

counter

-

clockwise

to

the

vertical

position

and

pushed

in

to

engage

the

clutch

.

Rotating

the

handle

180

°

clockwise

fully

charges

the

spring

and

as

the

internal

crank

passes

through

top

-

dead

-

centre

,

rotation

is

stopped

,

and

held

by

the

close

release

latch

.

Operation

of

this

latch

by

means

of

the

close

push

button

Fig

.

2

in

the

faceplate

releases

the

spring

energy

to

close

the

breaker

.

A

multi

-

tooth

ratchet

wheel

prevents

recoil

and

permits

the

spring

charging

to

be

performed

in

several

short

strokes

if

desired

.

On

frame

sizes

1600

amperes

and

above

,

the

handle

is

a

pull

-

out

extension

type

for

ease

of

operation

.

breakers

were

still

operational

.

In

service

it

is

possi

-

ble

to

encounter

dusk

,

corrosive

atmospheres

and

other

adverse

conditions

which

may

impair

proper

operation

.

Therefore

we

consider

it

prudent

to

lubricate

and

clean

breakers

periodically

.

ANSI

standards

recommend

lubrication

and

servicing

to

be

carried

out

at

the

following

periods

.

In

frame

sizes

up

to

and

including

2000

amps

,

this

interval

is

500

operations

,

and

in

sizes

3000

amps

and

above

,

250

operations

.

The

following

points

should

receive

attention

:

-

Electrical

Closing

On

all

electrically

operated

units

the

motor

charges

the

spring

unit

the

close

release

latch

engages

.

The

close

latch

is

operated

by

a

solenoid

energized

from

the

push

button

in

the

faceplate

,

Fig

.

2

or

by

a

remote

button

.

The

closing

stroke

then

follows

in

a

similar

manner

to

that

of

the

manual

type

described

above

.

A

removable

handle

is

provided

to

permit

manual

charging

of

the

spring

.

A

mechanical

close

button

similar

to

that

on

the

manually

operated

unit

is

not

included

.

Emergency

operation

of

the

close

release

latch

is

accomplished

by

insertion

of

a

pin

through

a

small

aperture

in

the

faceplate

,

Fig

.

2

.

A

suitable

pin

is

provided

in

the

upper

end

of

the

manual

charging

handle

.

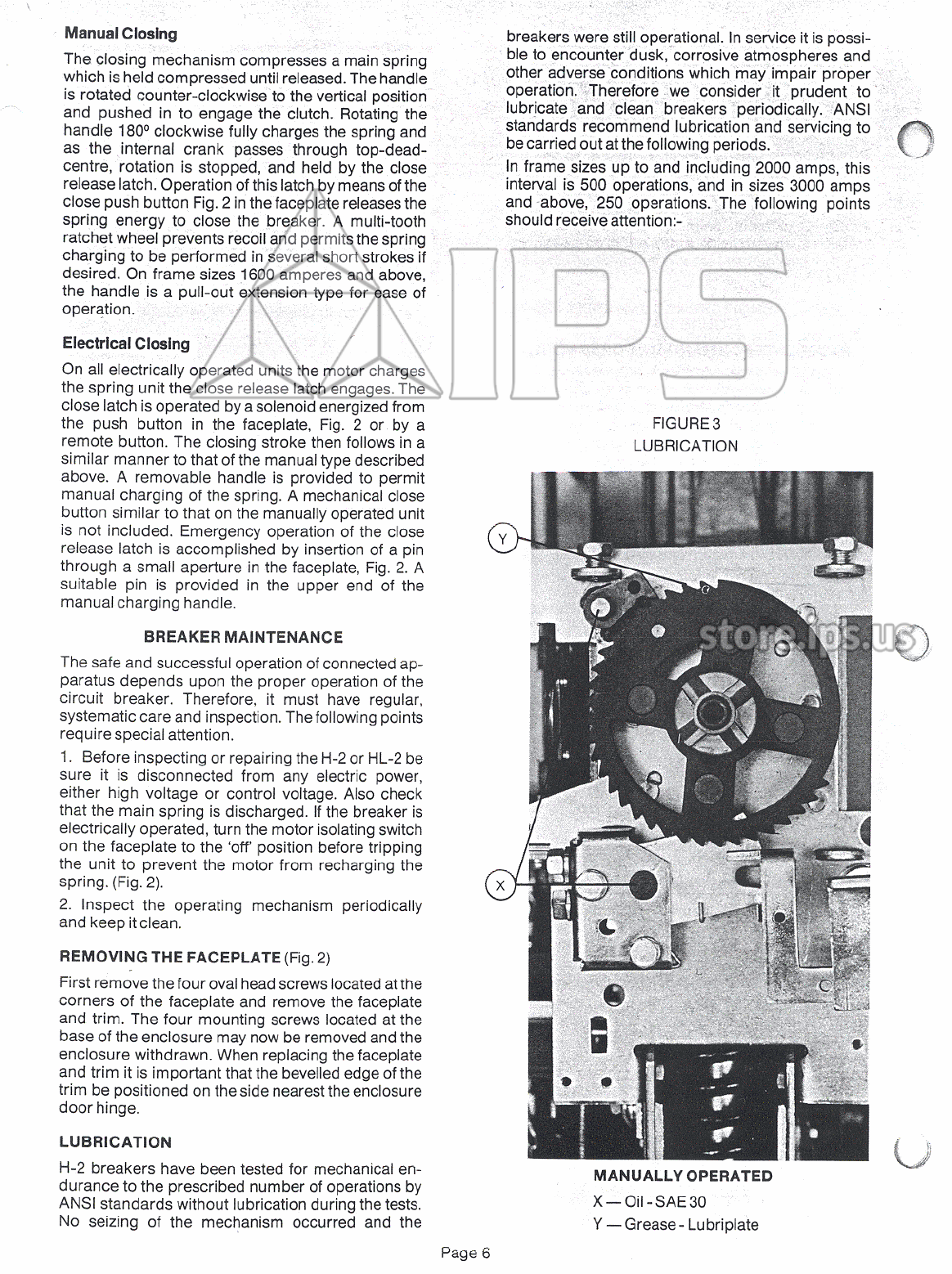

FIGURE

3

LUBRICATION

Y

BREAKER

MAINTENANCE

The

safe

and

successful

operation

of

connected

ap

-

paratus

depends

upon

the

proper

operation

of

the

circuit

breaker

.

Therefore

,

it

must

have

regular

,

systematic

care

and

inspection

.

The

following

points

require

special

attention

.

1

.

Before

inspecting

or

repairing

the

H

-

2

or

HL

-

2

be

sure

it

is

disconnected

from

any

electric

power

,

either

high

voltage

or

control

voltage

.

Also

check

that

the

main

spring

is

discharged

.

If

the

breaker

is

electrically

operated

,

turn

the

motor

isolating

switch

on

the

faceplate

to

the

‘

off

’

position

before

tripping

the

unit

to

prevent

the

motor

from

recharging

the

spring

.

(

Fig

.

2

)

.

2

.

Inspect

the

operating

mechanism

periodically

and

keep

it

clean

.

X

REMOVING

THE

FACEPLATE

(

Fig

.

2

)

First

remove

the

four

oval

head

screws

located

at

the

corners

of

the

faceplate

and

remove

the

faceplate

and

trim

.

The

four

mounting

screws

located

at

the

base

of

the

enclosure

may

now

be

removed

and

the

enclosure

withdrawn

.

When

replacing

the

faceplate

and

trim

it

is

important

that

the

bevelled

edge

of

the

trim

be

positioned

on

the

side

nearest

the

enclosure

door

hinge

.

LUBRICATION

H

-

2

breakers

have

been

tested

for

mechanical

en

-

durance

to

the

prescribed

number

of

operations

by

ANSI

standards

without

lubrication

during

the

tests

.

No

seizing

of

the

mechanism

occurred

and

the

MANUALLY

OPERATED

X

—

OM

-

SAE

30

Y

—

Grease

-

Lubriplate

Page

6

Courtesy of store.ips.us

MANUALLY

OPERATED

MECHANISM

(

Ref

.

Fig

.

3

)

.

Oil

-

SAE

30

1

.

All

linkage

pivots

within

the

mechanism

compart

-

ment

.

2

.

All

closing

shaft

bearings

.

3

.

Holding

pawl

pivot

(

located

within

the

faceplate

enclosure

-

upper

left

hand

corner

)

.

4

.

Close

latch

pivot

(

located

below

the

main

ratchet

wheel

)

.

Grease

-

Lubriplate

Lo

-

Temp

.

1

.

Spring

guide

pin

(

located

at

the

lower

end

of

the

closing

spring

)

.

2

.

Ratchet

wheel

teeth

.

closing

spring

)

.

2

.

Ratchet

wheel

teeth

.

3

.

Front

face

of

the

ratchet

wheel

.

4

.

Oscillating

lever

-

right

hand

end

(

at

the

motor

drive

cam

)

.

5

.

Driving

pawl

pivot

and

springs

(

located

on

left

hand

end

of

the

closing

spring

)

.

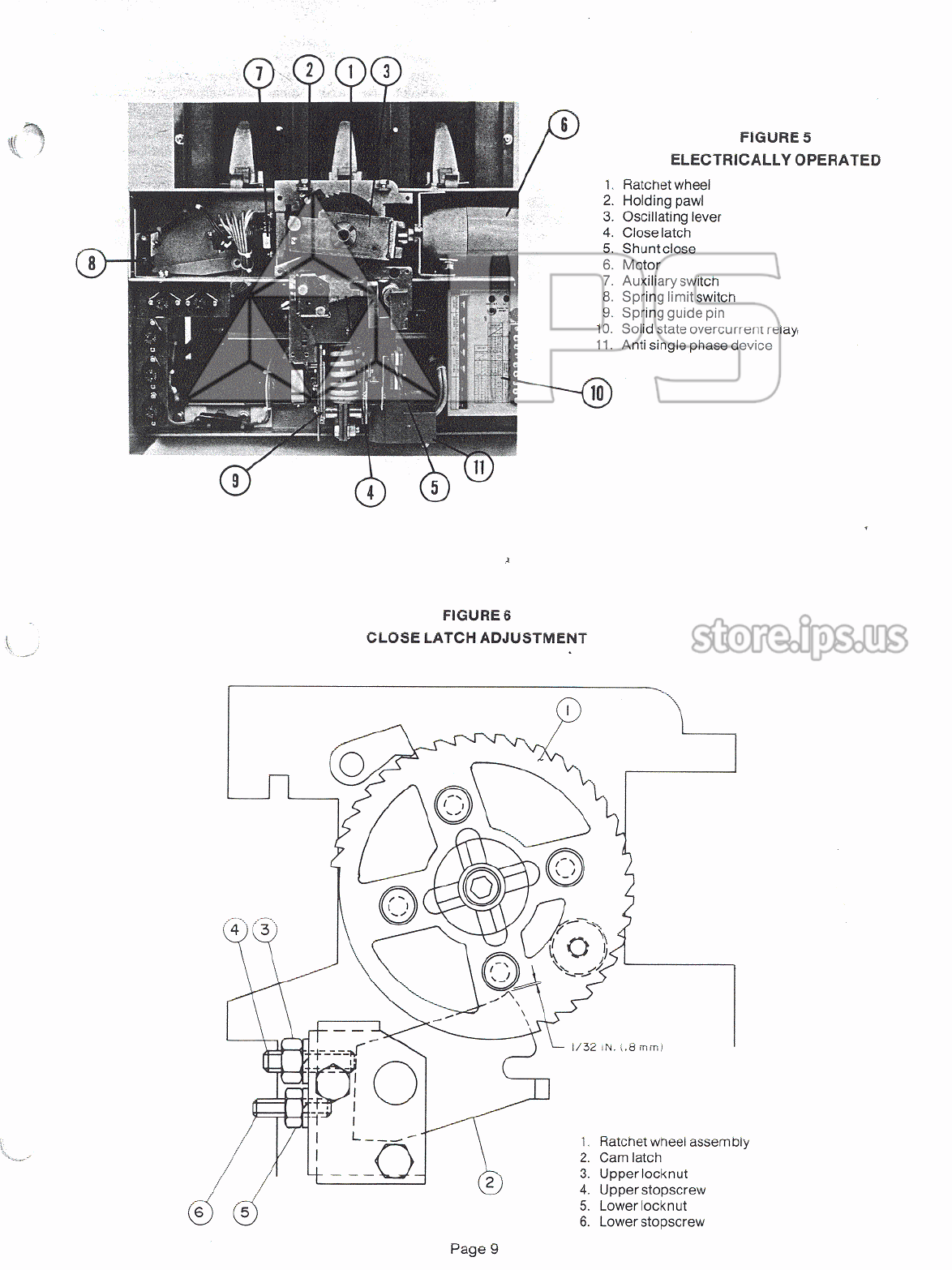

CLOSE

LATCH

ADJUSTMENT

(

Fig

.

6

)

The

function

of

the

close

latch

is

to

arrest

or

hold

the

ratchet

wheel

at

a

point

12

degrees

past

top

-

dead

-

centre

,

with

the

spring

fully

charged

in

readiness

to

close

.

The

closing

stroke

is

initiated

by

release

of

the

latch

,

either

manually

by

means

of

the

mechanical

push

button

in

the

faceplate

or

electrically

by

means

of

the

close

solenoid

.

Insufficient

engagement

of

the

latch

may

allow

the

closing

stroke

to

occur

at

com

-

pletion

of

the

charging

of

the

spring

.

Referring

to

Figure

6

,

the

adjustment

procedure

is

as

follows

.

The

ratchet

wheel

assembly

(

Item

1

)

is

made

up

of

two

plates

riveted

together

.

The

two

plates

are

held

apart

by

spacers

located

between

the

plates

on

the

four

rivets

.

Rotate

the

ratchet

wheel

until

one

of

the

spacers

on

a

rivet

is

directly

above

the

nose

of

the

cam

latch

(

Item

2

)

.

Loosen

locknut

(

Item

3

)

.

Turning

the

stop

screw

(

Item

4

)

counter

-

clockwise

adjusts

the

cam

latch

up

.

Adjust

the

cam

latch

height

until

there

is

approximately

1

/

32

inch

(

.

8

mm

)

clearance

between

the

spacer

and

the

nose

of

the

cam

latch

.

Tighten

the

locknut

securely

.

ELECTRICALLY

OPERATED

MECHANISM

(

Ref

.

Fig

.

3

)

.

Oil

-

SAE

30

1

.

All

linkage

pivots

within

the

mechanism

compart

-

ment

.

2

.

All

closing

shaft

bearings

.

3

.

Holding

pawl

pivot

(

located

within

the

faceplate

enclosure

-

upper

left

hand

corner

)

.

4

.

Motor

limit

switch

lever

pivot

(

located

within

the

front

channel

-

left

hand

corner

)

.

5

.

Close

latch

pivot

(

located

below

the

mam

ratchet

wheel

)

.

Grease

-

Lubriplate

Lo

-

Temp

.

1

.

Spring

guide

pin

(

located

at

the

lower

end

of

the

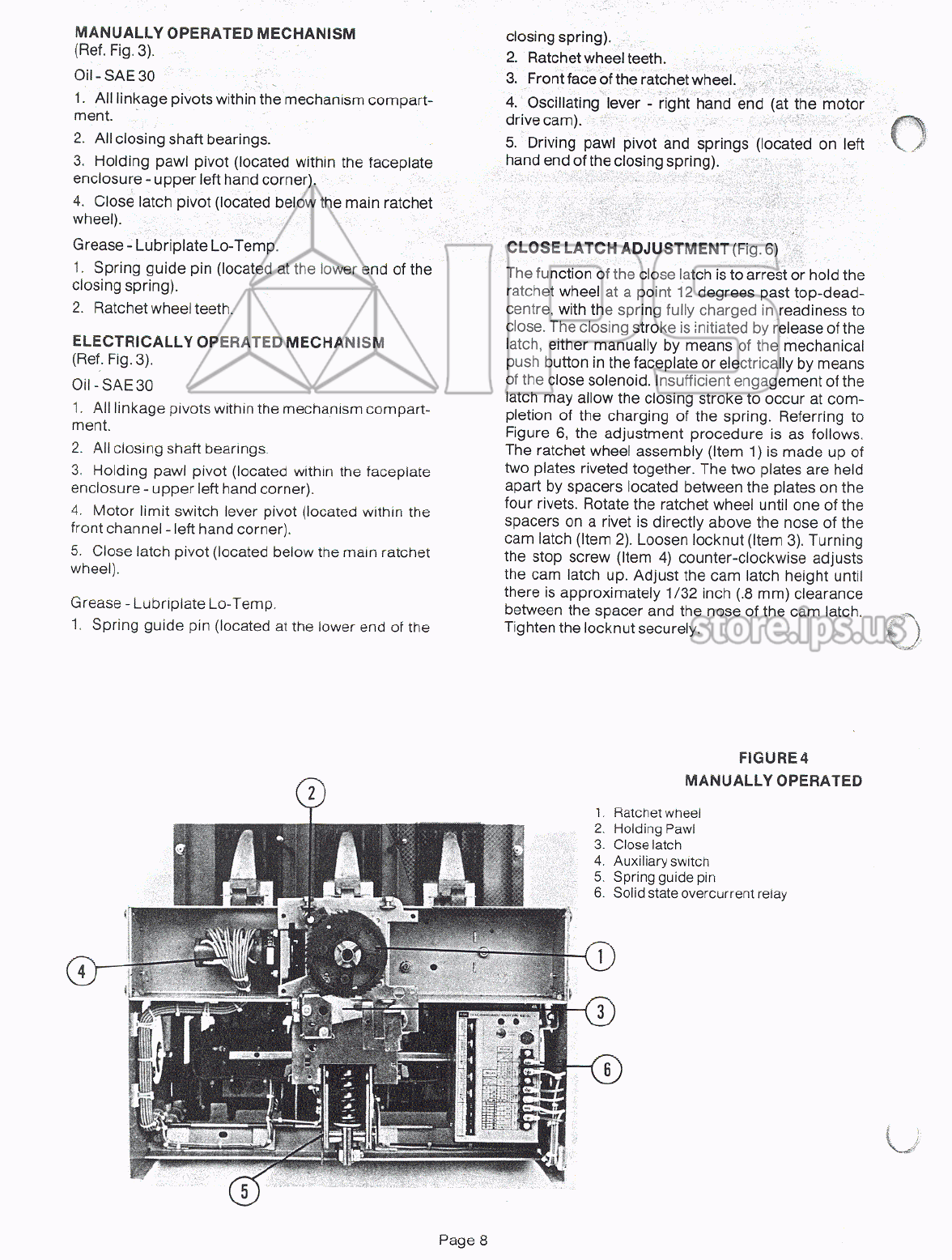

FIGURE

4

MANUALLY

OPERATED

2

1

.

Ratchet

wheel

2

.

Holding

Pawl

3

.

Close

latch

4

.

Auxiliary

switcn

5

.

Spring

guide

pin

6

.

Solid

state

overcurrent

relay

Courtesy of store.ips.us

FIGURES

ELECTRICALLY

OPERATED

1

.

Ratchet

wheel

2

.

Holding

pawl

3

.

Oscillating

lever

4

.

Close

latch

5

.

Shuntclose

6

.

Motor

7

.

Auxiliary

switch

8

.

Spring

limit

switch

9

.

Spring

guide

pin

10

.

Solid

state

overcurrent

relay

.

11

.

Anti

single

phase

device

10

FIGURE

6

CLOSE

LATCH

ADJUSTMENT

k

1

/

32

iN

.

l

,

8

mm

)

1

.

Ratchet

wheel

assembly

2

.

Cam

latch

3

.

Upper

locknut

4

.

Upper

stopscrew

5

.

Lower

locknut

6

.

Lower

stopscrew

£

Courtesy of store.ips.us

•

r

*

>

MECHANISM

LATCHING

AND

TRIP

SHAFT

ADJUSTMENT

Misadjustment

of

latching

results

in

failure

to

close

,

but

it

does

not

prevent

the

closing

spring

from

being

compressed

and

discharged

for

closure

.

There

are

3

possible

causes

of

improper

latching

:

A

)

On

units

equipped

with

an

overload

lockout

or

single

phase

device

,

failure

to

manually

reset

the

device

after

it

has

operated

,

will

prevent

latching

and

the

discharge

of

the

closing

spring

will

not

move

the

main

contacts

.

B

)

Misadjustment

of

the

main

linkage

(

which

governs

travel

of

the

latch

roller

)

will

prevent

latching

with

the

same

result

as

above

.

C

)

Insufficient

overlap

of

the

latch

roller

with

the

trip

cam

secured

to

the

trip

shaft

.

This

condition

will

cause

the

moving

contacts

to

pick

up

slightly

and

drop

back

to

fully

open

position

when

the

closing

spring

is

discharged

.

To

correct

A

-

push

manual

reset

lever

.

(

Fig

.

2

)

To

correct

B

-

Linkage

adjustment

must

be

made

(

Ref

.

Fig

.

7

)

.

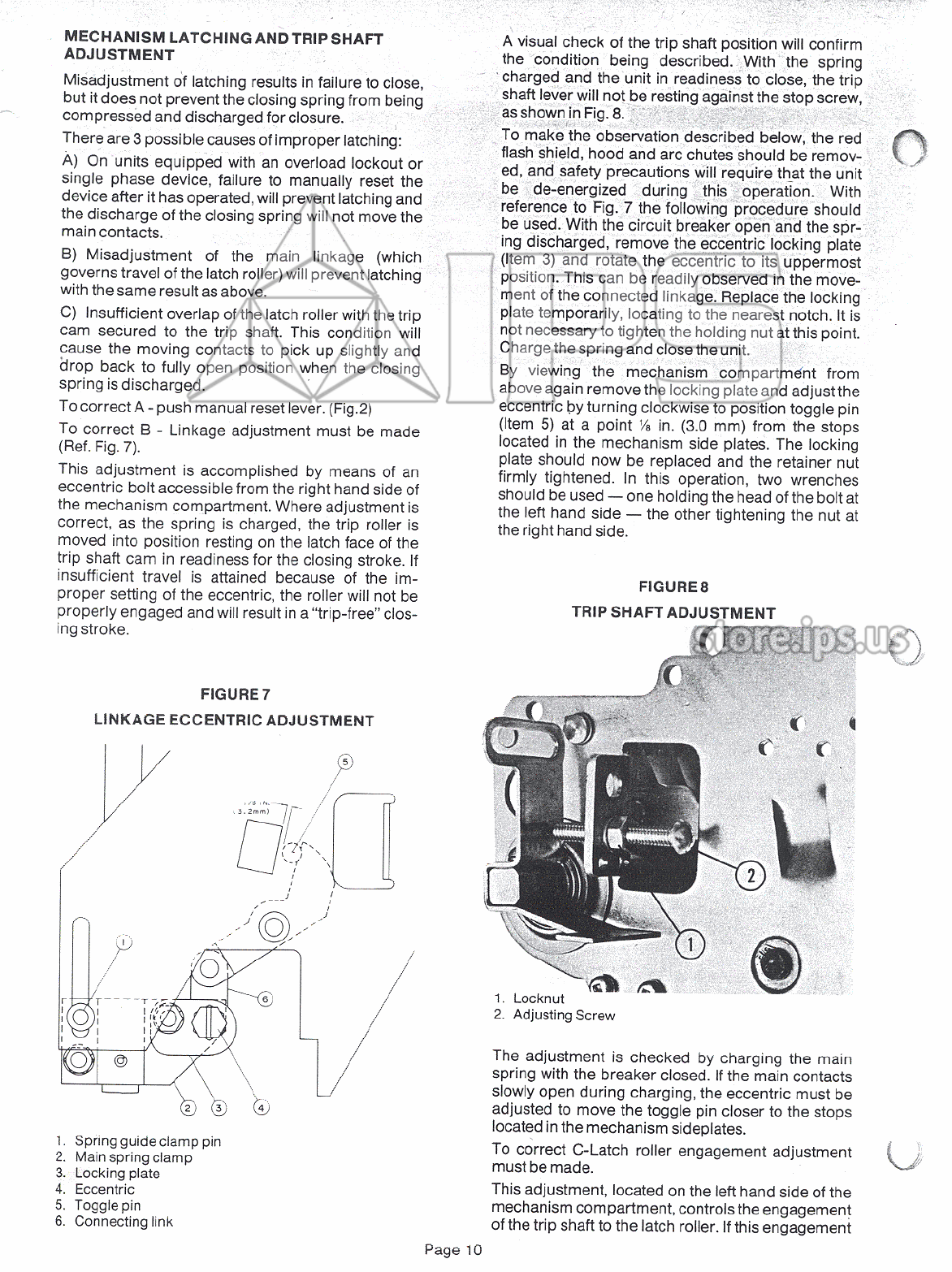

This

adjustment

is

accomplished

by

means

of

an

eccentric

bolt

accessible

from

the

right

hand

side

of

the

mechanism

compartment

.

Where

adjustment

is

correct

,

as

the

spring

is

charged

,

the

trip

roller

is

moved

into

position

resting

on

the

latch

face

of

the

trip

shaft

cam

in

readiness

for

the

closing

stroke

.

If

insufficient

travel

is

attained

because

of

the

im

-

proper

setting

of

the

eccentric

,

the

roller

will

not

be

properly

engaged

and

will

result

in

a

“

trip

-

free

"

clos

-

ing

stroke

.

A

visual

check

of

the

trip

shaft

position

will

confirm

the

condition

being

described

.

With

the

spring

charged

and

the

unit

in

readiness

to

close

,

the

trip

shaft

lever

will

not

be

resting

against

the

stop

screw

,

as

shown

in

Fig

.

8

.

To

make

the

observation

described

below

,

the

red

flash

shield

,

hood

and

arc

chutes

should

be

remov

-

ed

,

and

safety

precautions

will

require

that

the

unit

be

de

-

energized

during

this

operation

.

With

reference

to

Fig

.

7

the

following

procedure

should

be

used

.

With

the

circuit

breaker

open

and

the

spr

-

ing

discharged

,

remove

the

eccentric

locking

plate

(

Item

3

)

and

rotate

the

eccentric

to

its

uppermost

position

.

This

can

be

readily

observed

in

the

move

-

ment

of

the

connected

linkage

.

Replace

the

locking

plate

temporarily

,

locating

to

the

nearest

notch

.

It

is

not

necessary

to

tighten

the

holding

nut

at

this

point

.

Charge

the

spring

and

close

the

unit

.

By

viewing

the

mechanism

compartment

from

above

again

remove

the

locking

plate

and

adjust

the

eccentric

by

turning

clockwise

to

position

toggle

pin

(

Item

5

)

at

a

point

Vi

in

.

(

3.0

mm

)

from

the

stops

located

in

the

mechanism

side

plates

.

The

locking

plate

should

now

be

replaced

and

the

retainer

nut

firmly

tightened

.

In

this

operation

,

two

wrenches

should

be

used

—

one

holding

the

head

of

the

bolt

at

the

left

hand

side

—

the

other

tightening

the

nut

at

the

right

hand

side

.

FIGURE

8

TRIP

SHAFT

ADJUSTMENT

FIGURE

7

LINKAGE

ECCENTRIC

ADJUSTMENT

5

.

r

'

tt

i

IV

—

^

5.2

mm

)

/

/

/

-

•

I

)

4

-

1

.

Locknut

2

.

Adjusting

Screw

r

i

Ik

i

i

!

;

„

r

.

T

.

The

adjustment

is

checked

by

charging

the

main

spring

with

the

breaker

closed

.

If

the

main

contacts

slowly

open

during

charging

,

the

eccentric

must

be

adjusted

to

move

the

toggle

pin

closer

to

the

stops

located

in

the

mechanism

sideplates

.

To

correct

C

-

Latch

roller

engagement

adjustment

must

be

made

.

This

adjustment

,

located

on

the

left

hand

side

of

the

mechanism

compartment

,

controls

the

engagement

of

the

trip

shaft

to

the

latch

roller

.

If

this

engagement

@

(

±

.

1

.

Spring

guide

clamp

pin

2

.

Main

spring

clamp

3

.

Locking

plate

4

.

Eccentric

5

.

Toggle

pin

6

.

Connecting

link

Page

10

Courtesy of store.ips.us

is

insufficient

,

the

roller

may

release

during

the

clos

-

ing

stroke

,

resulting

in

failure

to

close

.

The

main

con

-

tacts

will

appear

to

move

but

not

complete

the

travel

.

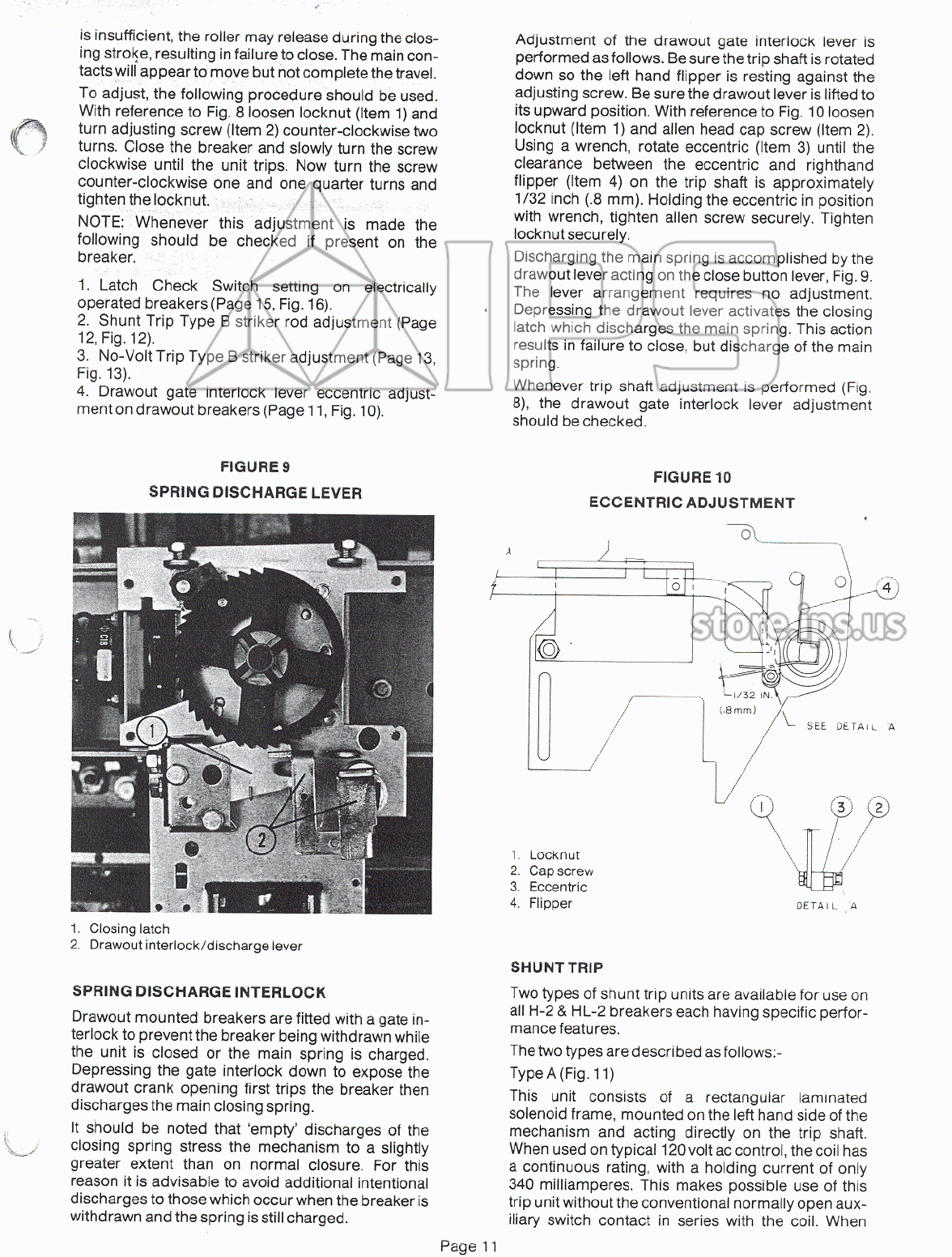

To

adjust

,

the

following

procedure

should

be

used

.

With

reference

to

Fig

.

8

loosen

locknut

(

Item

1

)

and

turn

adjusting

screw

(

Item

2

)

counter

-

clockwise

two

turns

.

Close

the

breaker

and

slowly

turn

the

screw

clockwise

until

the

unit

trips

.

Now

turn

the

screw

counter

-

clockwise

one

and

one

quarter

turns

and

tighten

the

locknut

.

NOTE

:

Whenever

this

adjustment

is

made

the

following

should

be

checked

if

present

on

the

breaker

.

1

.

Latch

Check

Switch

setting

on

electrically

operated

breakers

(

Page

15

,

Fig

.

16

)

.

2

.

Shunt

Trip

Type

B

striker

rod

adjustment

(

Page

12

,

Fig

.

12

)

.

3

.

No

-

Volt

Trip

Type

B

striker

adjustment

(

Page

13

,

Fig

.

13

)

.

4

.

Drawout

gate

interlock

lever

eccentric

adjust

-

ment

on

drawout

breakers

(

Page

11

,

Fig

.

10

)

.

Adjustment

of

the

drawout

gate

interlock

lever

is

performed

as

follows

.

Be

sure

the

trip

shaft

is

rotated

down

so

the

left

hand

flipper

is

resting

against

the

adjusting

screw

.

Be

sure

the

drawout

lever

is

lifted

to

its

upward

position

.

With

reference

to

Fig

.

10

loosen

locknut

(

Item

1

)

and

alien

head

cap

screw

(

Item

2

)

.

Using

a

wrench

,

rotate

eccentric

(

Item

3

)

until

the

clearance

between

the

eccentric

and

righthand

flipper

(

Item

4

)

on

the

trip

shaft

is

approximately

1

/

32

inch

(

.

8

mm

)

.

Holding

the

eccentric

in

position

with

wrench

,

tighten

alien

screw

securely

.

Tighten

locknut

securely

.

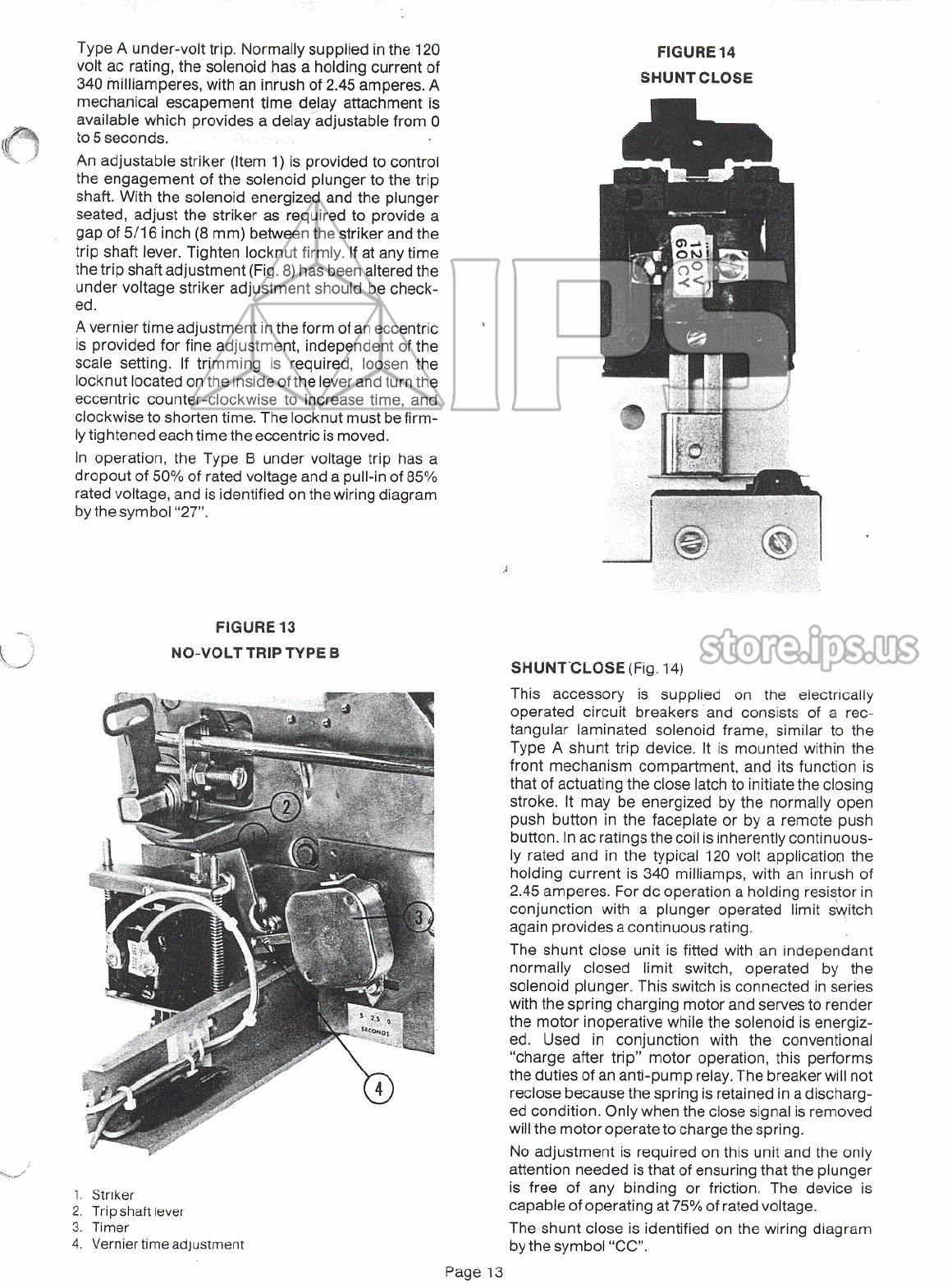

Discharging

the

main

spring

is

accomplished

by

the

drawout

lever

acting

on

the

close

button

lever

,

Fig

.

9

.

The

lever

arrangement

requires

no

adjustment

.

Depressing

the

drawout

lever

activates

the

closing

latch

which

discharges

the

main

spring

.

This

action

results

in

failure

to

close

,

but

discharge

of

the

main

spring

.

Whenever

trip

shaft

adjustment

is

performed

(

Fig

.

8

)

,

the

drawout

gate

interlock

lever

adjustment

should

be

checked

.

FIGURE

9

SPRING

DISCHARGE

LEVER

FIGURE

10

ECCENTRIC

ADJUSTMENT

~

"

sv

)

o

l

j

{

.

8

mm

)

SEE

DETAIL

A

/

/

/

1

.

Locknut

2

.

Capscrew

3

.

Eccentric

4

.

Flipper

DETAIL

A

1

.

Closing

latch

2

.

Drawout

interlock

/

discharge

lever

SHUNT

TRIP

Two

types

of

shunt

trip

units

are

available

for

use

on

all

H

-

2

&

HL

-

2

breakers

each

having

specific

perfor

-

mance

features

.

The

two

types

are

described

as

follows

:

-

Type

A

(

Fig

.

11

)

This

unit

consists

of

a

rectangular

laminated

solenoid

frame

,

mounted

on

the

left

hand

side

of

the

mechanism

and

acting

directly

on

the

trip

shaft

.

When

used

on

typical

120

volt

ac

control

,

the

coil

has

a

continuous

rating

,

with

a

holding

current

of

only

340

milliamperes

.

This

makes

possible

use

of

this

trip

unit

without

the

conventional

normally

open

aux

-

iliary

switch

contact

in

series

with

the

coil

.

When

SPRING

DISCHARGE

INTERLOCK

Drawout

mounted

breakers

are

fitted

with

a

gate

in

-

terlock

to

prevent

the

breaker

being

withdrawn

while

the

unit

is

closed

or

the

main

spring

is

charged

.

Depressing

the

gate

interlock

down

to

expose

the

drawout

crank

opening

first

trips

the

breaker

then

discharges

the

main

closing

spring

.

It

should

be

noted

that

‘

empty

’

discharges

of

the

closing

spring

stress

the

mechanism

to

a

slightly

greater

extent

than

on

normal

closure

.

For

this

reason

it

is

advisable

to

avoid

additional

intentional

discharges

to

those

which

occur

when

the

breaker

is

withdrawn

and

the

spring

is

still

charged

.

Page

11

Courtesy of store.ips.us

used

in

conjunction

with

a

typical

latching

-

type

ground

fault

relay

the

breaker

is

locked

out

and

will

be

totally

trip

-

free

until

the

relay

has

been

reset

.

Any

attempt

to

reclose

the

breaker

before

resetting

the

relay

will

preclude

a

restriking

of

the

ground

fault

.

No

adjustment

is

required

on

this

device

and

the

only

attention

needed

is

that

of

ensuring

that

the

plunger

is

free

of

any

binding

or

friction

.

This

unit

is

capable

of

tripping

at

50

%

of

the

rated

voltage

.

Type

B

(

Figure

12

)

This

is

a

cylindrical

solenoid

mounted

within

the

mechanism

comparment

at

the

lower

rear

and

ac

-

ting

directly

on

the

trip

shaft

.

Unlike

the

Type

A

unit

,

it

is

not

continuously

rated

and

for

any

application

a

normally

open

auxiliary

switch

contact

must

be

us

-

ed

.

In

the

120

volt

ac

application

the

Type

B

unit

is

equivalent

in

performance

to

the

Type

A

device

(

i

.

e

.

will

operate

at

50

%

of

rated

voltage

)

but

in

the

125

volt

dc

rating

,

tripping

can

be

performed

at

levels

as

low

as

25

%

of

nominal

rating

.

One

adjustment

is

provided

in

the

Type

B

trip

unit

to

control

the

extent

of

free

travel

between

the

plunger

and

the

trip

shaft

lever

.

By

lifting

the

plunger

until

the

striker

rod

is

lightly

touching

the

trip

shaft

lever

a

space

of

1

/

16

inch

(

1.6

mm

)

should

exist

between

the

end

of

the

plunger

and

the

stop

plate

as

shown

in

Figure

12

.

If

adjustment

is

required

,

loosen

the

8

-

32

socket

head

screw

located

at

the

bottom

end

of

the

plunger

,

and

turn

the

striker

rod

within

the

plunger

as

re

-

quired

.

Retighten

the

set

screw

.

If

trip

shaft

adjust

-

ment

(

Fig

.

8

)

is

altered

at

any

time

,

this

striker

rod

adjustment

should

be

checked

.

The

shunt

trip

is

identified

on

the

wiring

diagram

by

the

symbol

“

TC

”

.

Both

units

can

be

installed

on

one

breaker

.

With

regard

to

use

,

the

following

rules

are

usually

adhered

to

:

1

.

A

Type

B

is

used

where

only

a

separate

trip

coil

is

required

.

2

.

With

the

SD

relay

,

a

Type

B

is

used

between

the

mechanism

sideplates

to

operate

with

the

relay

,

and

possibly

a

Type

B

mounted

outside

the

left

hand

mechanism

sideplate

to

be

used

as

a

separate

trip

coil

.

3

.

A

Type

A

,

mounted

only

outside

the

left

hand

mechanism

sideplate

,

is

used

only

when

a

con

-

tinuous

rated

coil

for

a

separate

trip

source

is

re

-

quired

.

4

.

Type

A

and

Type

B

used

in

conjunction

with

the

SD

relay

can

both

be

used

on

the

same

unit

.

-

FIGURE

11

1

.

Shunt

trip

type

A

2

.

No

-

volt

trip

type

A

FIGURE

12

SHUNT

TRIPTYPEB

UNDER

VOLT

TRIP

-

TYPE

A

(

Fig

.

11

)

The

Type

A

Under

-

Volt

Trip

is

a

gravity

-

operated

device

mounted

on

the

left

hand

side

of

the

mechanism

compartment

and

acting

directly

on

the

trip

shaft

.

The

operating

solenoid

is

similar

to

the

Type

A

shunt

trip

,

and

is

normally

supplied

in

the

120

volt

ac

rating

,

with

a

holding

current

of

340

milliamperes

and

an

inrush

of

2.45

amperes

.

A

mechanical

escapement

time

delay

attachment

is

available

which

provides

a

delay

adjustable

from

0

to

5

seconds

.

In

operation

the

unit

has

a

dropout

of

50

%

of

rated

voltage

and

a

pull

in

of

85

%

of

rated

voltage

,

and

is

identified

on

the

wiring

diagram

by

the

symbol

“

27

”

UNDER

VOLT

TRIP

-

TYPE

B

(

Fig

.

13

)

Type

B

Under

Volt

Trip

is

a

spring

operated

unit

mounted

on

the

left

hand

side

of

the

main

mechanism

compartment

and

acting

directly

on

the

trip

shaft

.

In

operation

two

springs

are

held

in

com

-

pression

by

a

rectangular

solenoid

similar

to

the

u

1

.

Plunger

2

.

Stop

plate

Page

12

Courtesy of store.ips.us

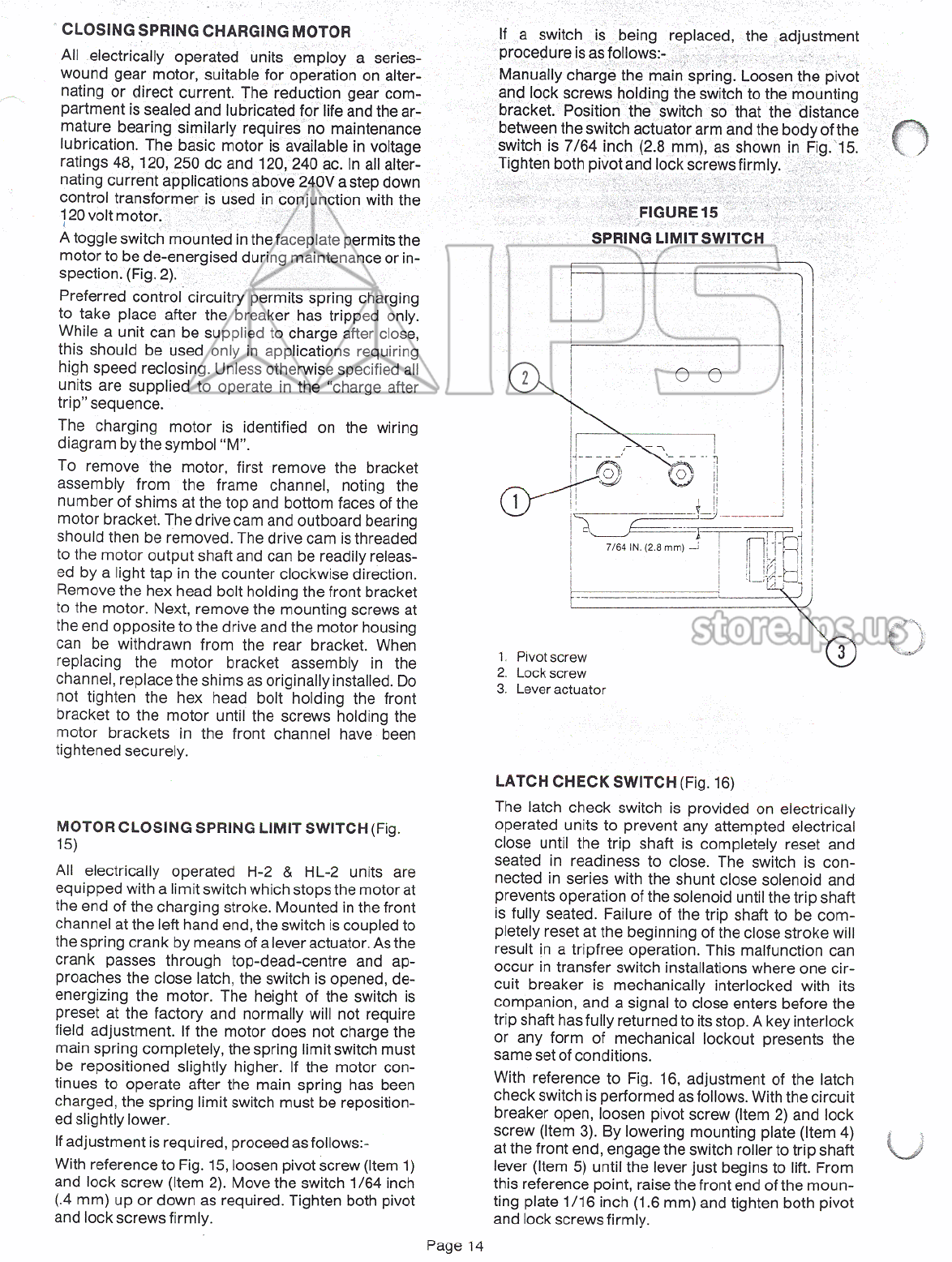

Type

A

under

-

volt

trip

.

Normally

supplied

in

the

120

volt

ac

rating

,

the

solenoid

has

a

holding

current

of

340

milliamperes

,

with

an

inrush

of

2.45

amperes

.

A

mechanical

escapement

time

delay

attachment

is

available

which

provides

a

delay

adjustable

from

0

to

5

seconds

.

An

adjustable

striker

(

Item

1

)

is

provided

to

control

the

engagement

of

the

solenoid

plunger

to

the

trip

shaft

.

With

the

solenoid

energized

and

the

plunger

seated

,

adjust

the

striker

as

required

to

provide

a

gap

of

5

/

16

inch

(

8

mm

)

between

the

striker

and

the

trip

shaft

lever

.

Tighten

locknut

firmly

.

If

at

any

time

the

trip

shaft

adjustment

(

Fig

.

8

)

has

been

altered

the

under

voltage

striker

adjustment

should

be

check

-

FIGURE

14

SHUNTCLOSE

CJ

:

ON

)

!

ed

.

A

vernier

time

adjustment

in

the

form

of

an

eccentric

is

provided

for

fine

adjustment

,

independent

of

the

scale

setting

.

If

trimming

is

required

,

loosen

the

locknut

located

on

the

inside

of

the

lever

and

turn

the

eccentric

counter

-

clockwise

to

increase

time

,

and

clockwise

to

shorten

time

.

The

locknut

must

be

firm

-

ly

tightened

each

time

the

eccentric

is

moved

.

In

operation

,

the

Type

B

under

voltage

trip

has

a

dropout

of

50

%

of

rated

voltage

and

a

pull

-

in

of

85

%

rated

voltage

,

and

is

identified

on

the

wiring

diagram

by

the

symbol

“

27

”

.

FIGURE

13

NO

-

VOLT

TRIP

TYPE

B

SHUNT

CLOSE

(

Fig

.

14

)

This

accessory

is

supplied

on

the

electrically

operated

circuit

breakers

and

consists

of

a

rec

-

tangular

laminated

solenoid

frame

,

similar

to

the

Type

A

shunt

trip

device

.

It

is

mounted

within

the

front

mechanism

compartment

,

and

its

function

is

that

of

actuating

the

close

latch

to

initiate

the

closing

stroke

.

It

may

be

energized

by

the

normally

open

push

button

in

the

faceplate

or

by

a

remote

push

button

.

In

ac

ratings

the

coil

is

inherently

continuous

-

ly

rated

and

in

the

typical

120

volt

application

the

holding

current

is

340

milliamps

,

with

an

inrush

of

2.45

amperes

.

For

dc

operation

a

holding

resistor

in

conjunction

with

a

plunger

operated

limit

switch

again

provides

a

continuous

rating

.

The

shunt

close

unit

is

fitted

with

an

independant

normally

closed

limit

switch

,

operated

by

the

solenoid

plunger

.

This

switch

is

connected

in

series

with

the

spring

charging

motor

and

serves

to

render

the

motor

inoperative

while

the

solenoid

is

energiz

-

ed

.

Used

in

conjunction

with

the

conventional

“

charge

after

trip

”

motor

operation

,

this

performs

the

duties

of

an

anti

-

pump

relay

.

The

breaker

will

not

reclose

because

the

spring

is

retained

in

a

discharg

-

ed

condition

.

Only

when

the

close

signal

is

removed

will

the

motor

operate

to

charge

the

spring

.

No

adjustment

is

required

on

this

unit

and

the

only

attention

needed

is

that

of

ensuring

that

the

plunger

is

free

of

any

binding

or

friction

.

The

device

is

capable

of

operating

at

75

%

of

rated

voltage

.

The

shunt

close

is

identified

on

the

wiring

diagram

by

the

symbol

“

CC

”

.

1

.

Striker

2

.

Trip

shaft

lever

3

.

Timer

4

.

Vernier

time

adjustment

Page

13

Courtesy of store.ips.us

CLOSING

SPRING

CHARGING

MOTOR

All

electrically

operated

units

employ

a

series

-

wound

gear

motor

,

suitable

for

operation

on

alter

-

nating

or

direct

current

.

The

reduction

gear

com

-

partment

is

sealed

and

lubricated

for

life

and

the

ar

-

mature

bearing

similarly

requires

no

maintenance

lubrication

.

The

basic

motor

is

available

in

voltage

ratings

48

,

120

,

250

dc

and

120

,

240

ac

.

In

all

alter

-

nating

current

applications

above

240

V

a

step

down

control

transformer

is

used

in

conjunction

with

the

120

volt

motor

.

A

toggle

switch

mounted

in

the

faceplate

permits

the

motor

to

be

de

-

energised

during

maintenance

or

in

-

spection

.

(

Fig

.

2

)

.

Preferred

control

circuitry

permits

spring

charging

to

take

place

after

the

breaker

has

tripped

only

.

While

a

unit

can

be

supplied

to

charge

after

close

,

this

should

be

used

only

in

applications

requiring

high

speed

reclosing

.

Unless

otherwise

specified

all

units

are

supplied

to

operate

in

the

“

charge

after

trip

"

sequence

.

The

charging

motor

is

identified

on

the

wiring

diagram

by

the

symbol

“

M

”

.

To

remove

the

motor

,

first

remove

the

bracket

assembly

from

the

frame

channel

,

noting

the

number

of

shims

at

the

top

and

bottom

faces

of

the

motor

bracket

.

The

drive

cam

and

outboard

bearing

should

then

be

removed

.

The

drive

cam

is

threaded

to

the

motor

output

shaft

and

can

be

readily

releas

-

ed

by

a

light

tap

in

the

counter

clockwise

direction

.

Remove

the

hex

head

bolt

holding

the

front

bracket

to

the

motor

.

Next

,

remove

the

mounting

screws

at

the

end

opposite

to

the

drive

and

the

motor

housing

can

be

withdrawn

from

the

rear

bracket

.

When

replacing

the

motor

bracket

assembly

in

the

channel

,

replace

the

shims

as

originally

installed

.

Do

not

tighten

the

hex

head

bolt

holding

the

front

bracket

to

the

motor

until

the

screws

holding

the

motor

brackets

in

the

front

channel

have

been

tightened

securely

.

If

a

switch

is

being

replaced

,

the

adjustment

procedure

is

as

foliows

:

-

Manually

charge

the

main

spring

.

Loosen

the

pivot

and

lock

screws

holding

the

switch

to

the

mounting

bracket

.

Position

the

switch

so

that

the

distance

between

the

switch

actuator

arm

and

the

body

of

the

switch

is

7

/

64

inch

(

2.8

mm

)

,

as

shown

in

Fig

.

15

.

Tighten

both

pivot

and

lock

screws

firmly

.

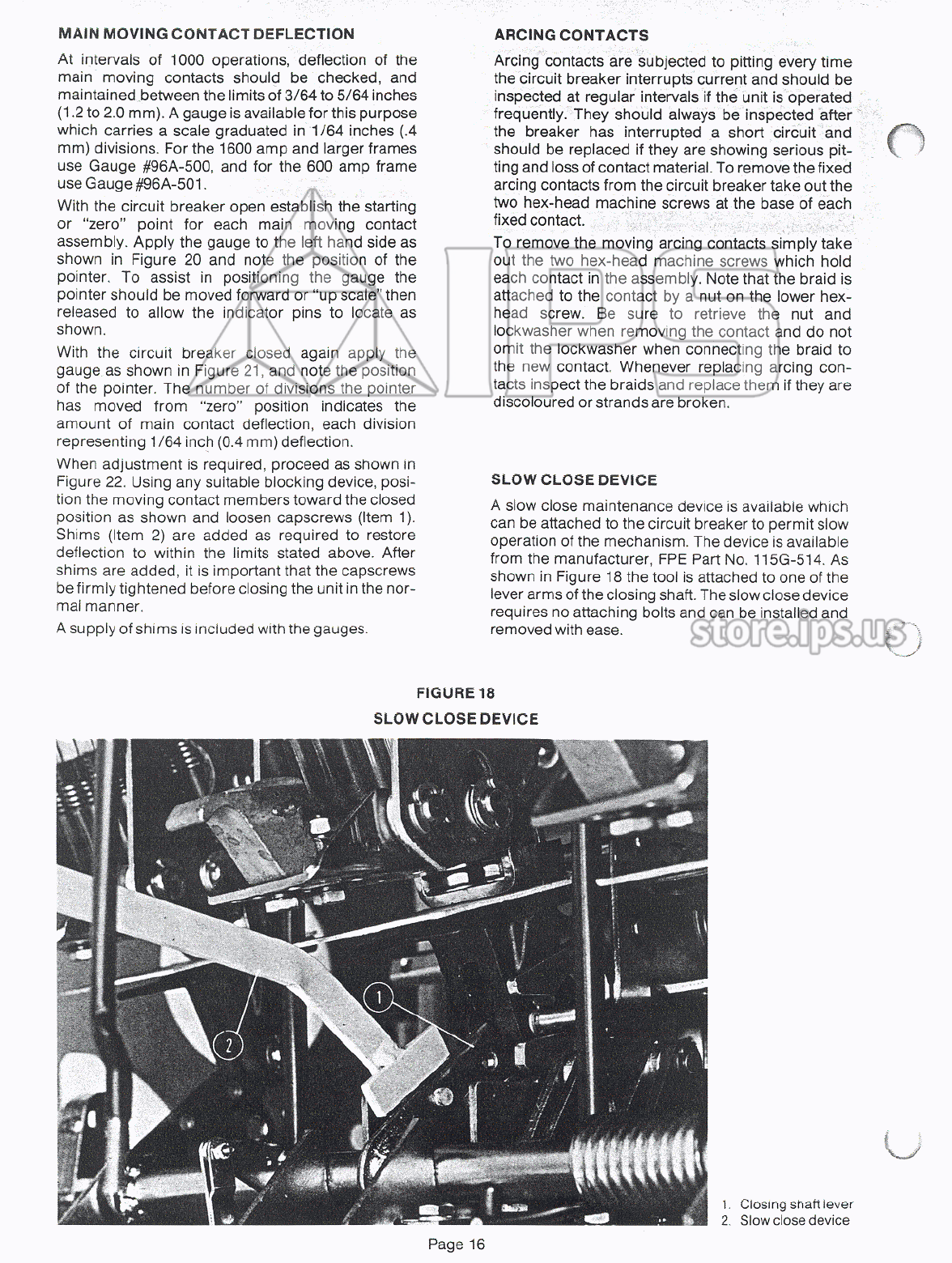

FIGURE

15

SPRING

LIMIT

SWITCH

oo

2

;

H

i

1

rs

II

FlfF

7

/

64

IN

.

(

2.8

mm

)

\

~

(

A

H

i

JM

-

’

s

'

S

U

3

1

.

Pivot

screw

2

.

Lockscrew

3

.

Lever

actuator

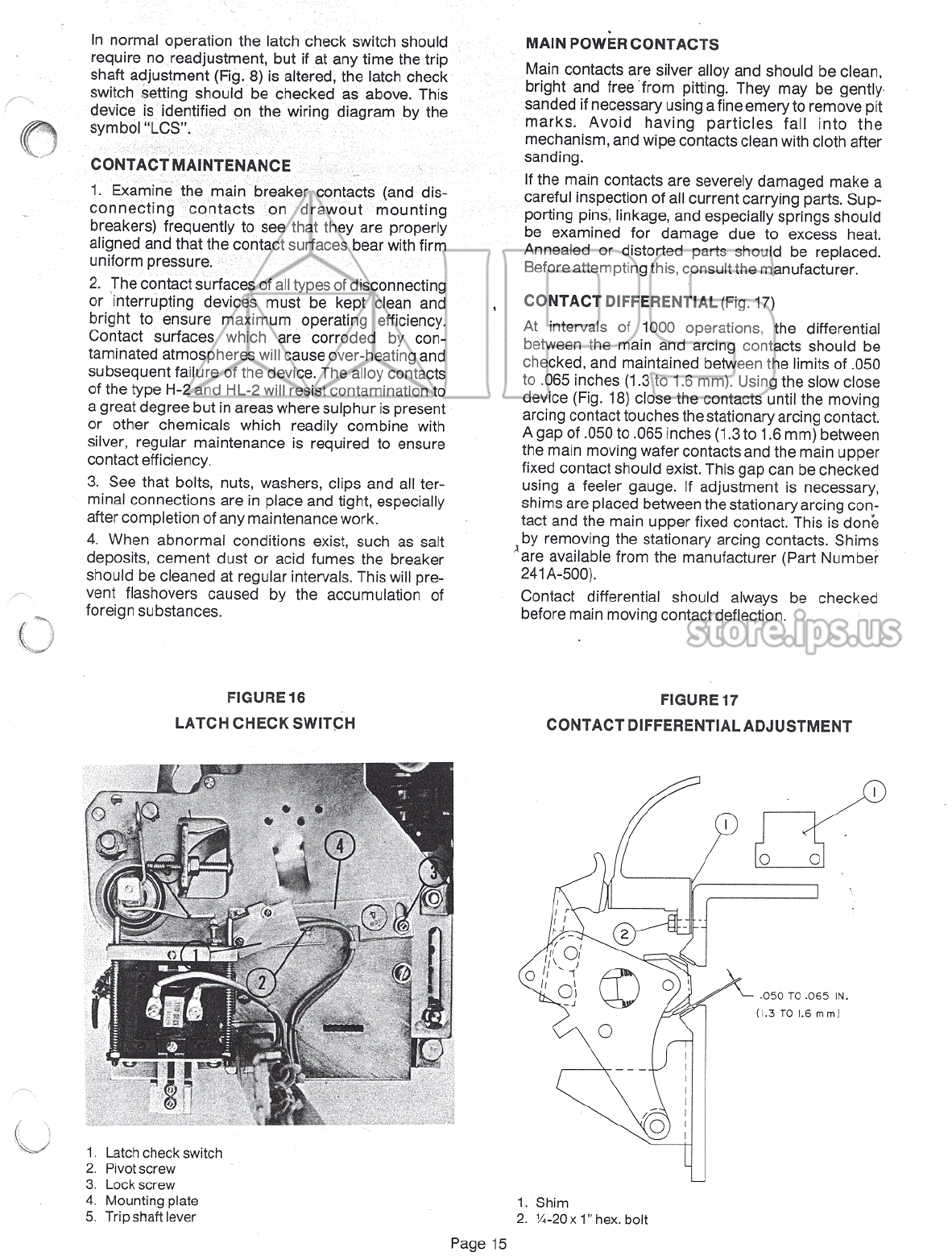

LATCH

CHECK

SWITCH

(

Fig

.

16

)

The

latch

check

switch

is

provided

on

electrically

operated

units

to

prevent

any

attempted

electrical

close

until

the

trip

shaft

is

completely

reset

and

seated

in

readiness

to

close

.

The

switch

is

con

-

nected

in

series

with

the

shunt

close

solenoid

and

prevents

operation

of

the

solenoid

until

the

trip

shaft

is

fully

seated

.

Failure

of

the

trip

shaft

to

be

com

-

pletely

reset

at

the

beginning

of

the

close

stroke

will

result

in

a

tripfree

operation

.

This

malfunction

can

occur

in

transfer

switch

installations

where

one

cir

-

cuit

breaker

is

mechanically

interlocked

with

its