- 2 -

CONTENTS

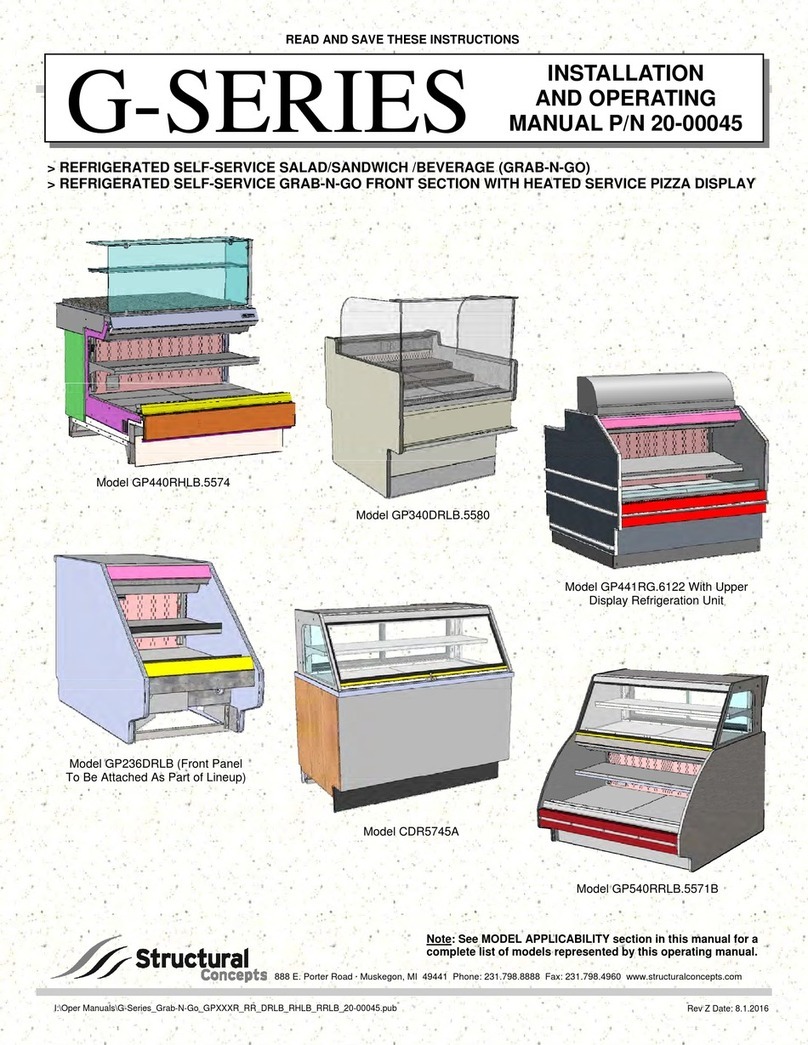

INTRODUCTION.......................................................................................................................................3

WARNING LABELS & SAFETY INSTRUCTIONS..............................................................................4

GENERAL ELECTRICAL & GROUNDING.........................................................................................5

Permanent Connected ......................................................................................................................5

Cord Connected (Option).................................................................................................................5

REFRIGERATION................................................................................................................................. 7-8

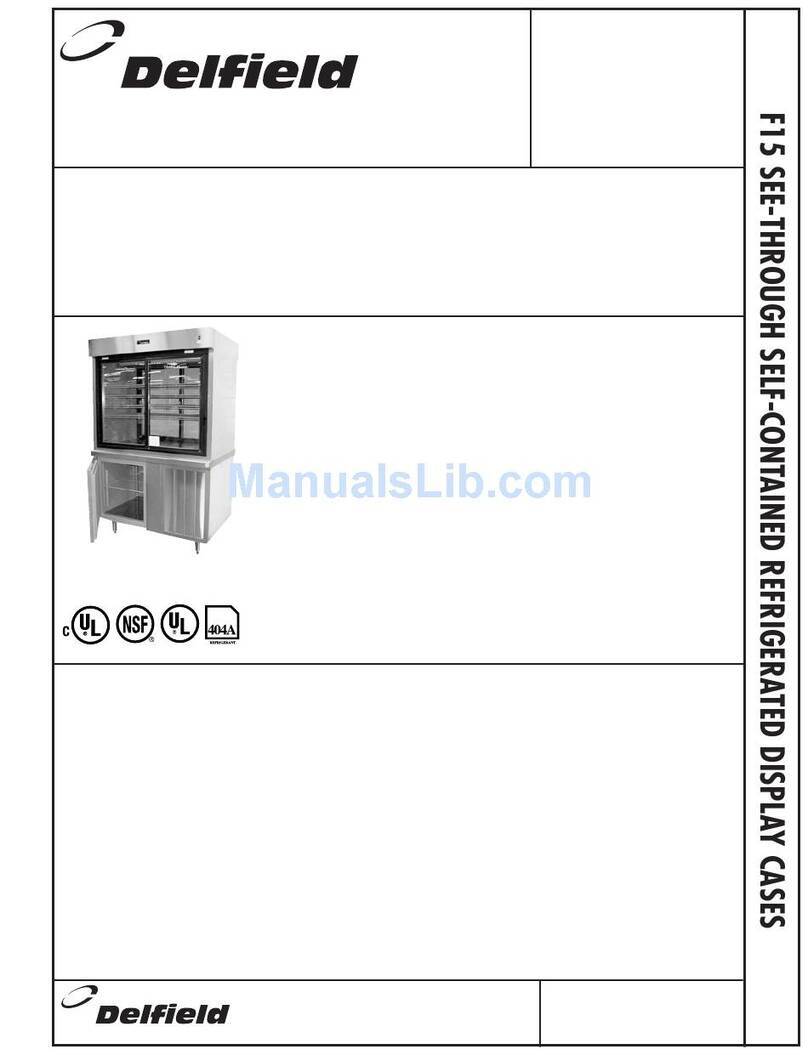

Self Contained Models.....................................................................................................................7

Self Contained Refrigeration Operation......................................................................................7

Remote Models ................................................................................................................................8

Remote Refrigeration Operation .................................................................................................8

Remote Refrigeration Instruction................................................................................................8

Condensate Evaporator pan and Pump.............................................................................................8

BASE COMPONENT LAYOUT...............................................................................................................6

Non-Refrigerated Models.................................................................................................................6

Refrigerated Self Contained Models................................................................................................6

Refrigerated Remote Models............................................................................................................6

INSTALLATION INSTRUCTIONS, FLOOR MODELS.......................................................................6

Inspection For Shipping Damage.....................................................................................................5

Locating The Display Case ..............................................................................................................6

Removing Case From Shipping Skid...............................................................................................6

Additional Parts................................................................................................................................6

Cleaning ...........................................................................................................................................6

INSTALLATION INSTRUCTIONS, COUNTER MODELS.................................................................6

Inspection For Shipping Damage.....................................................................................................5

Locating The Display Case ..............................................................................................................6

Removing Case From Shipping Skid...............................................................................................6

Additional Parts................................................................................................................................6

Cleaning ...........................................................................................................................................6

CABINET MOUNTING, COUNTER MODELS.....................................................................................6

ITD Non Refrigerated Models .........................................................................................................6

ITR Refrigerated Self Contained Models.........................................................................................6

ITR Refrigerated Remote Models....................................................................................................6

Additional Parts................................................................................................................................6

Cleaning ...........................................................................................................................................6

COMPARTMENT PANEL REMOVAL............................................................................................ 9-11

Floor Models.............................................................................................................................. 9-10

Counter Models..............................................................................................................................10

END PANEL INSTALLATION & REMOVAL................................................................................ 9-11

SHELVING INSTALLATION & REMOVAL.................................................................................. 9-11

Shelf Brackets & Supports......................................................................................................... 9-10

Glass Shelves .................................................................................................................................11

REAR DOORS REMOVAL............................................................................................................... 12-13

OPERATING INSTRUCTIONS ....................................................................................................... 16-17

Control Description........................................................................................................................16

Using Electronic Control................................................................................................................16

Initial Startup..................................................................................................................................16

Placing Product In Case .................................................................................................................20

MAINTENANCE ......................................................................................................................................21

Cleaning Condenser Coil................................................................................................................22

Top LED Strip Replacement..........................................................................................................21

Shelf LED Replacement.................................................................................................................21