Feider Machines FSP182A User manual

1

ORIGINAL INSTRUCTIONS

MINI CIRCULAR SAW CORDLESS

FSP182A

INSTRUCTION MANUAL

BUILDER SAS

32, rue Aristide Bergès -ZI 31270 Cugnaux –France

IMPORTANT: Please read the instruction manual before using.

2

ORIGINAL INSTRUCTIONS

Technical Data

Rated Voltage

20V d.c.

No-load Speed

4500/min ±10%

Max. Cutting

Capacity

@ 90o

42.8mm (1-11/16”)

@ 45o

28mm (1-1/8”)

Saw Blade Diameter

115mm (4-1/2”)

Sound power level

LWA: 97 dB(A) KWA:3 dB(A)

Sound pressure level

LpA:86 dB(A) KpA:3 dB(A)

Vibration

ahW=4,03 m/s² K = 1,5 m/s²

Information:

- That the declared vibration total value(s) and the declared noise emission

value(s) have been measured in accordance with a standard test method

and may be used for comparing one tool with another;

- That the declared vibration total value(s) and the declared noise emission

value(s) may also be used in a preliminary assessment of exposure.

Warning

- That the vibration and noise emissions during actual use of the power tool

can differ from the declared values depending on the ways in which the tool

is used especially what kind of workpiece is processed; and

3

ORIGINAL INSTRUCTIONS

-of the need to identify safety measures to protect the operator that are

based on an estimation of exposure in the actual conditions of use (taking

account of all parts of the operating cycle such as the times when the tool is

switched off and when it is running idle in addition to the trigger time).

General power tool safety warnings

WARNING Read all safety warnings, instructions, illustrations and

specifications provided with this power tool. Failure to follow all instructions

listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

4

ORIGINAL INSTRUCTIONS

a) Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

5

ORIGINAL INSTRUCTIONS

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as a dust mask, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or energising

power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and

clothing away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become

complacent and ignore tool safety principles. A careless action can cause

severe injury within a fraction of a second.

4) Power tool use and care

6

ORIGINAL INSTRUCTIONS

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must be

repaired.

c) Disconnect the plug from the power source and/or remove the battery pack,

if detachable, from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding

of moving parts, breakage of parts and any other condition that may affect

the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

7

ORIGINAL INSTRUCTIONS

h) Keep handles and grasping surfaces dry, clean and free from oil and

grease. Slippery handles and grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer.A charger

that is suitable for one type of battery pack may create a risk of fire when used with

another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any

other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like

paper clips, coins, keys, nails, screws or other small metal objects, that can

make a connection from one terminal to another.Shorting the battery terminals

together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts

eyes, additionally seek medical help.Liquid ejected from the battery may cause

irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified.Damaged or

modified batteries may exhibit unpredictable behaviour resulting in fire, explosion or

risk of injury.

f) Do not expose a battery pack or tool to fire or excessive temperature.

Exposure to fire or temperature above 130 °C may cause explosion.

NOTE the temperature „130 °C“can be replaced by the temperature „265 °F“.

8

ORIGINAL INSTRUCTIONS

g) Follow all charging instructions and do not charge the battery pack or tool

outside the temperature range specified in the instructions. Charging

improperly or at temperatures outside the specified range may damage the battery

and increase the risk of fire.

6) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

b) Never service damaged battery packs. Service of battery packs should only be

performed by the manufacturer or authorized service providers.

Safety instructions for all saws

Cutting procedures

a) DANGER: Keep hands away from cutting area and the blade. Keep your

second hand on auxiliary handle, or motor housing. If both hands are holding

the saw, they cannot be cut by the blade.

b) Do not reach underneath the workpiece. The guard cannot protect you from

the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece. Less than a full

tooth of the blade teeth should be visible below the workpiece.

d) Never hold the workpiece in your hands or across your leg while cutting.

Secure the workpiece to a stable platform. It is important to support the work

properly to minimise body exposure, blade binding, or loss of control.

9

ORIGINAL INSTRUCTIONS

e) Hold the power tool by insulated gripping surfaces, when performing an

operation where the cutting tool may contact hidden wiring or its own cord.

Contact with a "live" wire will also make exposed metal parts of the power tool "live"

and could give the operator an electric shock.

f) When ripping, always use a rip fence or straight edge guide. This improves

the accuracy of cut and reduces the chance of blade binding.

g) Always use blades with correct size and shape (diamond versus round) of

arbour holes. Blades that do not match the mounting hardware of the saw will run

off-centre, causing loss of control.

h) Never use damaged or incorrect blade washers or bolt. The blade washers

and bolt were specially designed for your saw, for optimum performance and safety

of operation.

Further safety instructions for all saws

Kickback causes and related warnings

-kickback is a sudden reaction to a pinched, jammed or misaligned saw blade,

causing an uncontrolled saw to lift up and out of the workpiece toward the

operator;

-when the blade is pinched or jammed tightly by the kerf closing down, the blade

stalls and the motor reaction drives the unit rapidly back toward the operator;

10

ORIGINAL INSTRUCTIONS

-If the blade becomes twisted or misaligned in the cut, the teeth at the back

edge of the blade can dig into the top surface of the wood causing the blade to

climb out of the kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below.

a) Maintain a firm grip with both hands on the saw and position your arms to

resist kickback forces. Position your body to either side of the blade, but not

in line with the blade. Kickback could cause the saw to jump backwards, but

kickback forces can be controlled by the operator, if proper precautions are taken.

b) When blade is binding, or when interrupting a cut for any reason, release

the trigger and hold the saw motionless in the material until the blade comes

to a complete stop. Never attempt to remove the saw from the work or pull the

saw backward while the blade is in motion or kickback may occur. Investigate

and take corrective actions to eliminate the cause of blade binding.

c) When restarting a saw in the workpiece, centre the saw blade in the kerf so

that the saw teeth are not engaged into the material. If a saw blade binds, it may

walk up or kickback from the workpiece as the saw is restarted.

d) Support large panels to minimise the risk of blade pinching and kickback.

Large panels tend to sag under their own weight. Supports must be placed under

the panel on both sides, near the line of cut and near the edge of the panel.

e) Do not use dull or damaged blades. Unsharpened or improperly set blades

produce narrow kerf causing excessive friction, blade binding and kickback.

11

ORIGINAL INSTRUCTIONS

f) Blade depth and bevel adjusting locking levers must be tight and secure

before making the cut. If blade adjustment shifts while cutting, it may cause

binding and kickback.

g) Use extra caution when sawing into existing walls or other blind areas. The

protruding blade may cut objects that can cause kickback.

Safety instructions for saws with pendulum guard and saws with tow guard

Lower guard function

a) Check the lower guard for proper closing before each use. Do not operate

the saw if the lower guard does not move freely and close instantly. Never

clamp or tie the lower guard into the open position. If the saw is accidentally

dropped, the lower guard may be bent. Raise the lower guard with the retracting

handle and make sure it moves freely and does not touch the blade or any other

part, in all angles and depths of cut.

b) Check the operation of the lower guard spring. If the guard and the spring

are not operating properly, they must be serviced before use. Lower guard

may operate sluggishly due to damaged parts, gummy deposits, or a build-up of

debris.

c) The lower guard may be retracted manually only for special cuts such as

"plunge cuts" and "compound cuts". Raise the lower guard by the retracting

handle and as soon as the blade enters the material, the lower guard must be

released. For all other sawing, the lower guard should operate automatically.

12

ORIGINAL INSTRUCTIONS

d) Always observe that the lower guard is covering the blade before placing

the saw down on bench or floor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its path. Be aware of the time it takes

for the blade to stop after switch is released.

-Never use the saw when transported to another location. The blade guard can

be opened and can cause serious injury.

-If the switch does not turn on or off the saw properly, stop using it immediately

and have the saw switch repaired.

-Always allow the saw to reach full speed before starting the cut.

-Never use the side of the blade to cut. When making horizontal cuts, make sure

that the weight of the tool does not force the side of the blade to be cut. This will

reduce the risk of rebound.

-Make sure there are no nails or foreign objects in the area of the

workpiece.

-Never put the workpiece on hard surfaces such as concrete, stone, etc. A

protruding blade can blow the tool.

-DANGER: To prevent accidental starting, always remove the plug from the

power source before making any adjustments and before installing or removing

a saw blade.

-After changing a blade or making adjustments, make sure that the blade

clamping screw is tight because a loose blade can be thrown violently.

13

ORIGINAL INSTRUCTIONS

-Never touch the blade during or immediately after use. After use, the blade is

too hot to be touched with bare hands.

-Use only blade diameters in accordance with the markings. Installing an

incorrect blade can result in injury and poor cutting.

-Use the correct saw blade for the material to be cut;

-Use only saw blades that are marked with a speed equal or higher than the

speed marked on the tool.

-Check every time the function of all blades guards operations. To do this, check

to see if the protective cover covers the blade properly and can be opened

without any problem by using the lever.

-Work only wood, PVC, aluminum, ceramic tile and cement slabs by using the

appropriate disc.

-Do not use abrasive wheels.

-Avoid overheating the blade tips.

-Always use a dust collection system.

-Wear a dust mask.

-Use only saw blades recommended by the manufacturer, which conform to EN

847-1.

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT.

WARNING: Dust that is created by power sanding, sawing, grinding,

14

ORIGINAL INSTRUCTIONS

drilling, and other construction activities may contain chemicals that are

known to cause cancer, birth defects, or other genetic abnormalities.

These chemicals include:

-Lead from lead-based paint

-Crystalline silica from bricks, cement, and other masonry products

-Arsenic and chromium from chemically treated lumber

The level of risk from exposure to these chemicals varies, according to how often

this type of work is performed. In order to reduce exposure to these chemicals,

work in a well-ventilated area, and use approved safety equipment, such as a

dust mask that is specifically designed to filter out microscopic particles.

SAFETY INSTRUCTIONS FOR BATTERY

CHARGER

This charger can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

15

ORIGINAL INSTRUCTIONS

supervision or instruction concerning use of

the appliance in a safe way and understand

the hazards involved. Children shall not play

with the appliance. Cleaning and user

maintenance shall not be made by children

without supervision.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similarly qualified persons in order to

avoid a hazard.

CAUTION – Do not recharge non-rechargeable batteries

Symbols

Read instructions manual

16

ORIGINAL INSTRUCTIONS

Wear eyes protection

LASER RADIATION - DO NOT STARE

INTO BEAM - CLASS 2 LASER PRODUC

Function Description

The numbering of the products features refers to the illustration of the machine on the

graphics page.

1.

Lock-Off / Plunge Release

Button

9.

Cutting Depth Scale

2.

ON/OFF Trigger Switch

10.

Rip Guide

3.

Laser

11.

Rip Guide Locking Screw

4.

Retractable Lower

Blade Guard

12.

Spindle Lock

5.

Saw Blade

13.

Dust Extraction Nozzle

6.

Base Plate

14.

Battery

7.

Soft Grip

15.

Cutting Depth Clamp

8.

Cutting Angle Clamp

16.

Cutting Depth Scale

17

ORIGINAL INSTRUCTIONS

.

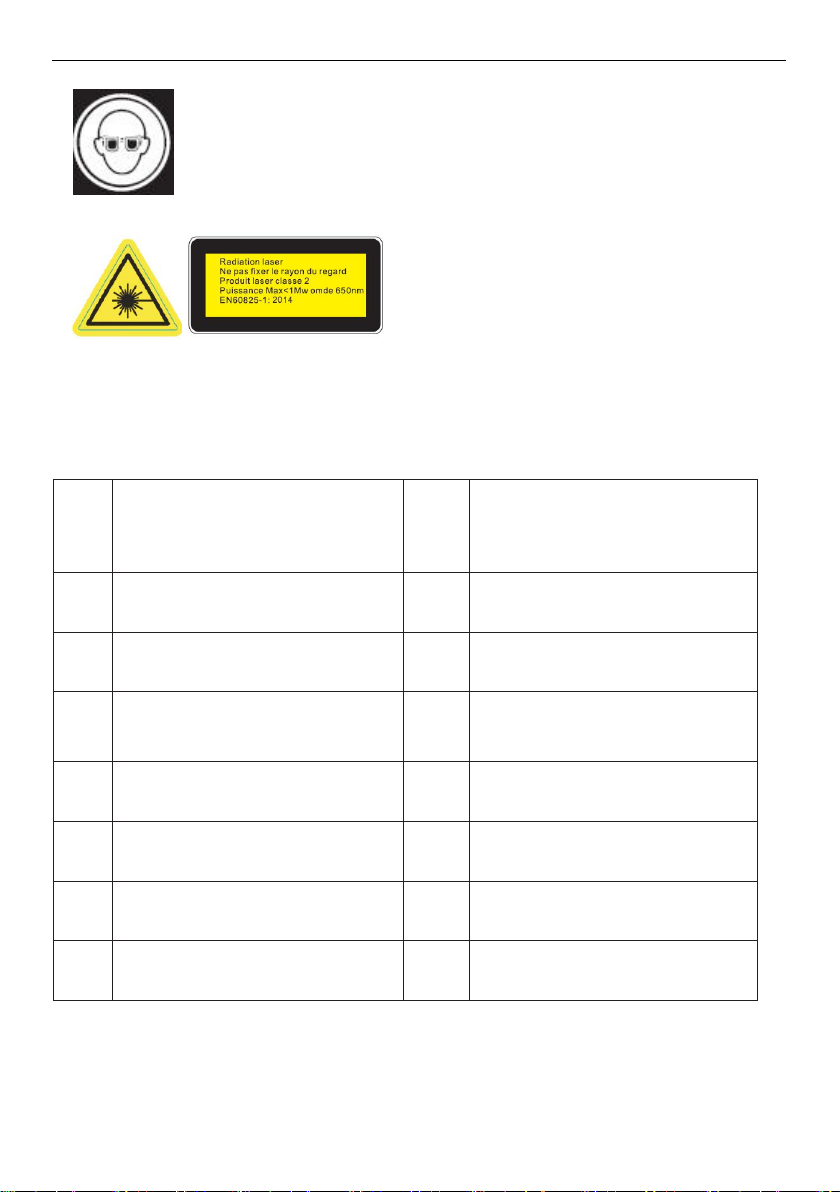

Inserting the battery

• Press the button of the charged battery.

• Push it completely into the base.

CAUTION

Use only original lithium ion batteries with the voltage listed on the nameplate of

18

ORIGINAL INSTRUCTIONS

your power tool. Using other batteries can lead to injuries and pose a fire hazard.

Removing the Battery

• The battery is equipped with two locking levels that should prevent the battery from

falling out when pushing the battery unlocking button unintentionally. As long as the

battery is inserted in the power tool, it is held in position by means of a spring.

• To remove the battery, press the battery unlocking button and pull the battery out of the

power tool toward the rear. Do not exert any force.

BATTERY ELECTRIC INDICATOR

The electric energy is divided into 3 grades, if you want to check the electric energy

of battery; you need to press down the electric indicator button.

•All LEDs on indicates the battery pack is fully charged.

19

ORIGINAL INSTRUCTIONS

Battery Charging

1. If fitted, remove any battery charger.

2. Insert the battery charger mains plug into a suitable mains socket.

•Only a steady RED Light indicates the charger has been plugged in.

•A steady RED Light and a Flashing GREEN light (with battery inserted) indicate the

battery is charging.

•A steady RED Light and A steady GREEN light (with battery inserted) indicate the

battery is completely charged.

20

ORIGINAL INSTRUCTIONS

•Only a Flashing RED Light (with battery inserted) indicates the battery pack is too hot.

You should let the battery pack cool down for approximately 30 minutes before attempting to

recharge.

•A RED and A GREEN light flashing alternatively (with battery inserted) indicate the

battery pack is defective and needs to be replaced. Please contact authorized service

personnel or dispose of the defective battery in the method explained in this manual.

WARING: Use this charger ONLY to charge the supplied battery or additional purchased

batteries that are specifically designed for this tool.

WARNING: Failure to follow the correct procedure when charging batteries will result in

permanent damage.

Note: Normal charging time is approximately 35minutes for a recently discharged 2.0Ah

capacity battery.

However, if the Battery has been left in a discharged state for some time, it may take

Additional time to charge.

Note: Make sure the Battery and Battery Charger are lined up correctly. If the Battery does

not slide on to the Battery Charger easily, don’t force it. Instead, remove the battery; check

the top of Battery and the Battery Charger slot are clean and undamaged and that the

contacts are not bent.

IMPORTANT: When a low charge level is indicated, the tool may stop operating while in use,

which is dangerous when operating a circular saw. Always ensure the battery pack has a

good charge level.

When the battery is full charged, the battery charger will stop charging (switch to stand by).

Table of contents

Other Feider Machines Saw manuals

Feider Machines

Feider Machines FSOR254S2L User manual

Feider Machines

Feider Machines FSC1485 User manual

Feider Machines

Feider Machines FSOR20255 User manual

Feider Machines

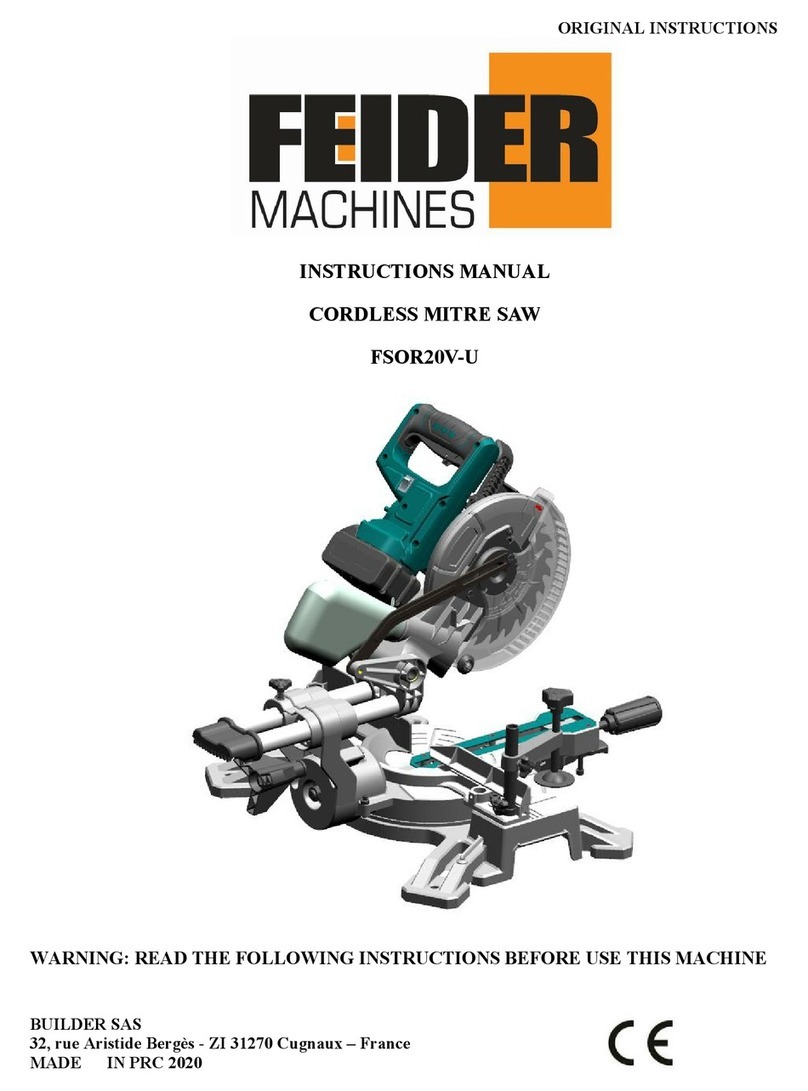

Feider Machines FSOR20V-U User manual

Feider Machines

Feider Machines FSO20254 User manual

Feider Machines

Feider Machines FSC1485-B User manual

Feider Machines

Feider Machines F405SC3F User manual

Feider Machines

Feider Machines FSC20235 User manual

Feider Machines

Feider Machines FDL125 User manual

Feider Machines

Feider Machines FSSAB20V-B User manual